Praseodymium-doped indium lead magnesium niobate-lead titanate luminescent piezoelectric ceramic as well as preparation method and application thereof

A technology of lead indium magnesium niobate and piezoelectric ceramics, applied in piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric devices or electrostrictive devices, circuits, etc., can solve the electrical properties Low problems, to achieve the effect of electro-optical regulation, high temperature sensing, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

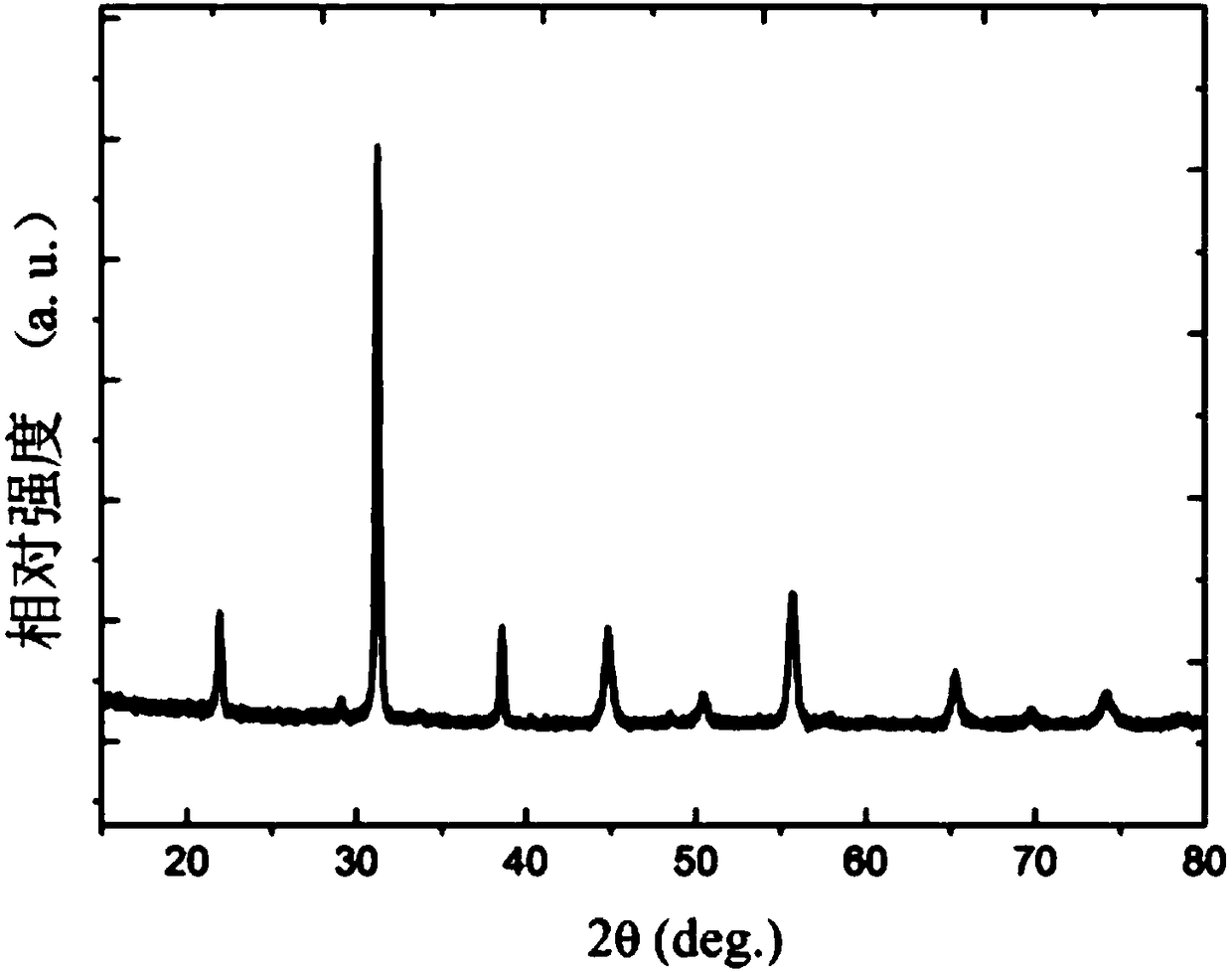

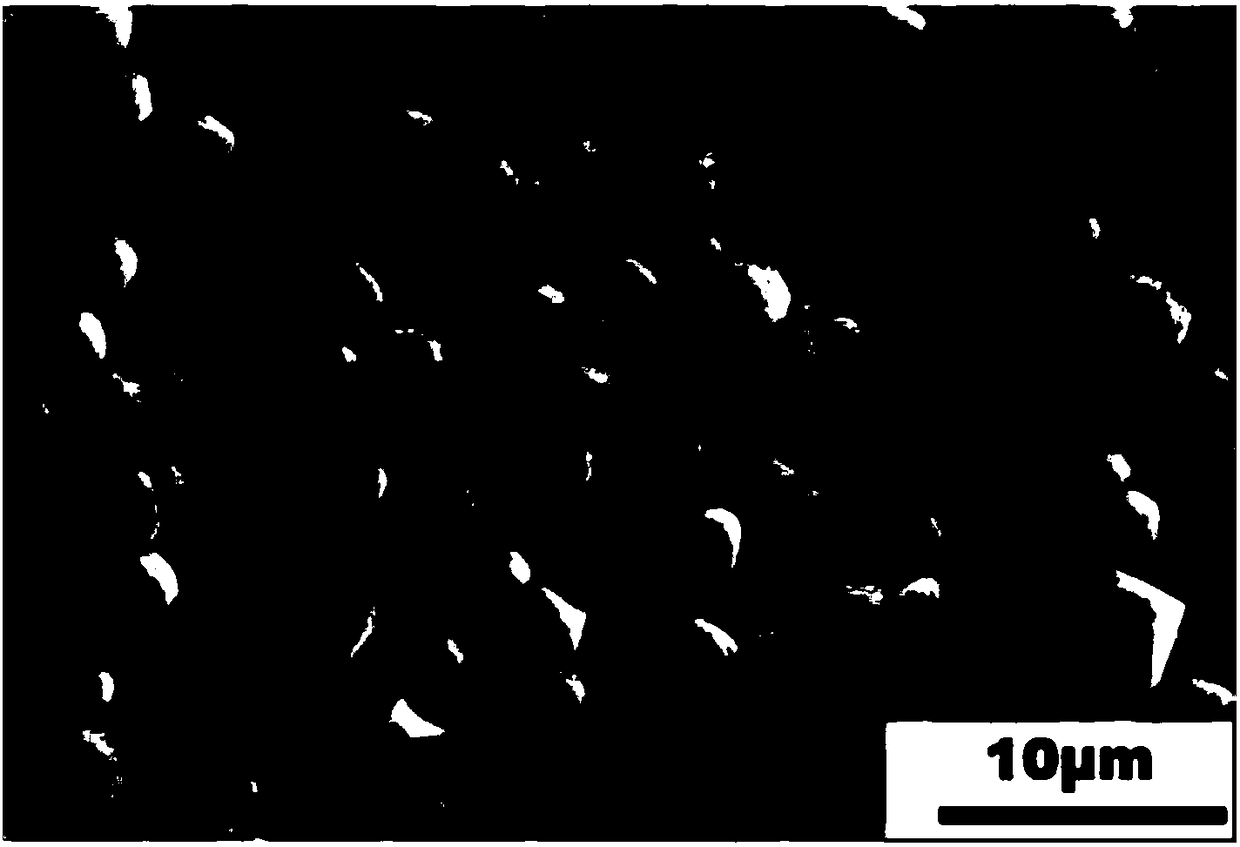

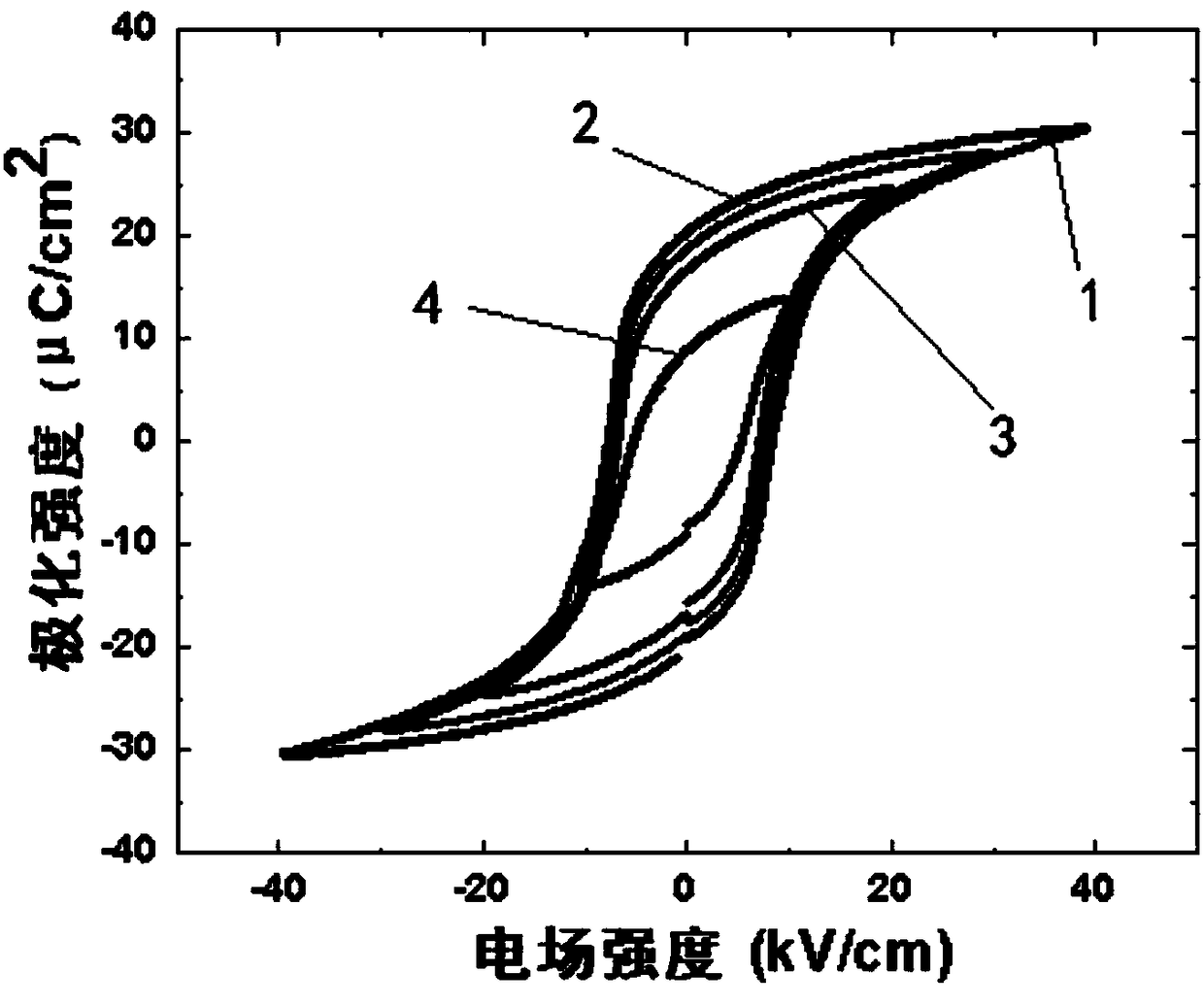

[0022] Embodiment 1: The general chemical formula of a praseodymium-doped lead indium magnesium niobium oxide-lead titanate luminescent piezoelectric ceramic in this embodiment is 0.24Pb (In 1 / 2 Nb 1 / 2 )O 3 -0.42Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.34PbTiO 3 :xPr 3+ , where x is the mole fraction, 0<x≤0.02.

specific Embodiment approach 2

[0023] Specific embodiment 2: The preparation method of a praseodymium-doped lead indium magnesium niobium oxide-lead titanate luminescent piezoelectric ceramic in this embodiment is completed according to the following steps:

[0024] 1. Synthesis of pure-phase InNbO by solid-phase reaction method 4 precursor powder;

[0025] 2. Synthesis of pure-phase MgNb by solid-phase reaction method 2 O 6 precursor powder;

[0026] Third, with PbO, TiO 2 , Pr 6 O 11 , pure phase InNbO 4 Precursor powder and pure phase MgNb 2 O 6 The precursor powder is used as the raw material, and the calcined powder with the calcinite structure is synthesized by the solid-phase reaction method;

[0027] 4. Put the calcined powder with calcite structure into a mortar for grinding, then transfer it to a ball mill, and use anhydrous ethanol as the ball milling medium for ball milling for 8 to 12 hours at a rotational speed of 120 to 200 r / min. The ball-milled wet material is obtained, and the ba...

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, a pure phase InNbO is synthesized by a solid phase reaction method 4 Precursor powder is specifically carried out according to the following steps:

[0032] Will In 2 o 3 and Nb 2 o 5 Weigh according to the molar ratio of 1:1, the weighed In 2 o 3 and Nb 2 o 5 Mix and place in a ball milling tank, use absolute ethanol as the ball milling medium at a speed of 200~260r / min for 40~50 hours to get the wet material after ball milling, and place the wet material after ball milling at a temperature of 80~ Dry in an electric blast drying oven at 120°C to obtain a dry block, press the dry block into a disc with a diameter of 30mm under a pressure of 20-30MPa, place the disc with a diameter of 30mm in a crucible, and use 2 Raise the temperature of the crucible from room temperature to 1000-1200°C at a heating rate of ~4°C / min, and sinter at a temperature of 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com