Textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material and preparation method thereof

A technology of rare earth modification and lead magnesium niobate, which is applied in the field of functional ceramic materials, can solve the problems of low electrical performance and achieve the effects of simple equipment, high production efficiency, improved cost performance and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

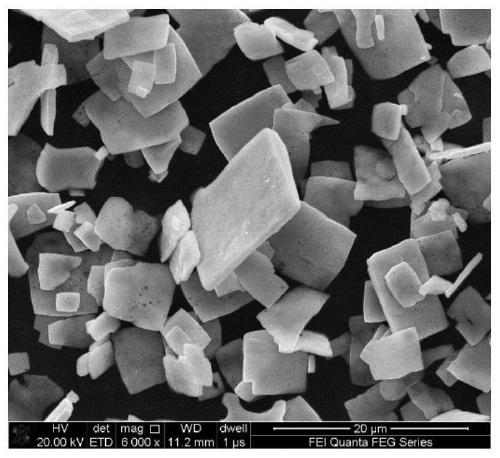

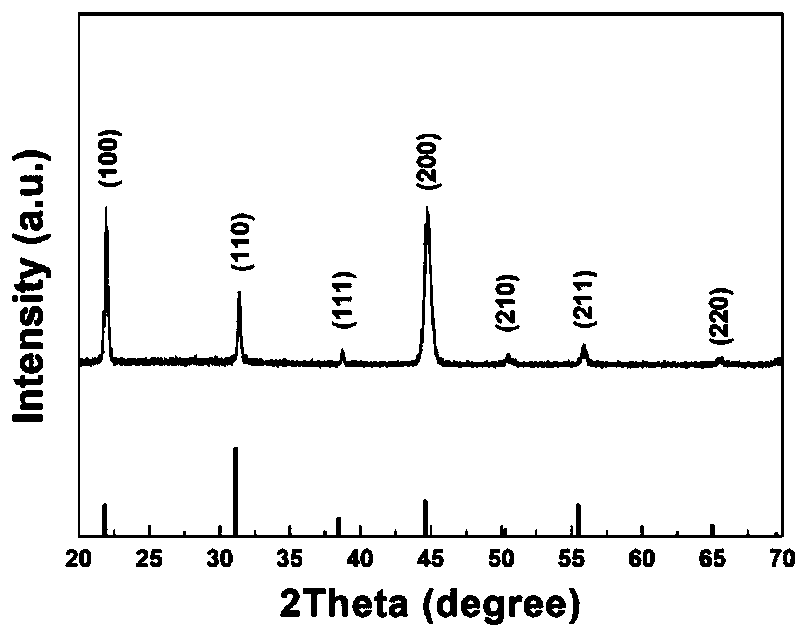

[0042] The preparation method of a textured rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic material specifically includes the following steps:

[0043] Step 1. Use CP or AR grade PbO, MgO, Nb 2 o 5 、TiO 2 and Sm 2 o 3 or Dy 2 o 3 As a raw material, a pure-phase rare earth modified lead magnesium niobate-lead titanate based piezoelectric ferroelectric ceramic matrix was prepared by a two-step solid-state reaction method;

[0044] Specifically, first use MgO and Nb 2 o 5 Synthesis of pure phase MgNb by reaction 2 o 6 precursor, and then the pure phase MgNb 2 o 6 Precursors, PbO, TiO 2 and Sm 2 o 3 or Dy 2 o 3 Mixing by ball milling, drying, and sintering to obtain a pure-phase rare earth modified lead magnesium niobate-lead titanate-based piezoelectric ferroelectric ceramic matrix;

[0045] Step 2. Using Bi 2 o 3 、TiO 2 and BaCO 3 As a raw material, BaTiO with a perovskite structure was prepared by local ch...

Embodiment 1

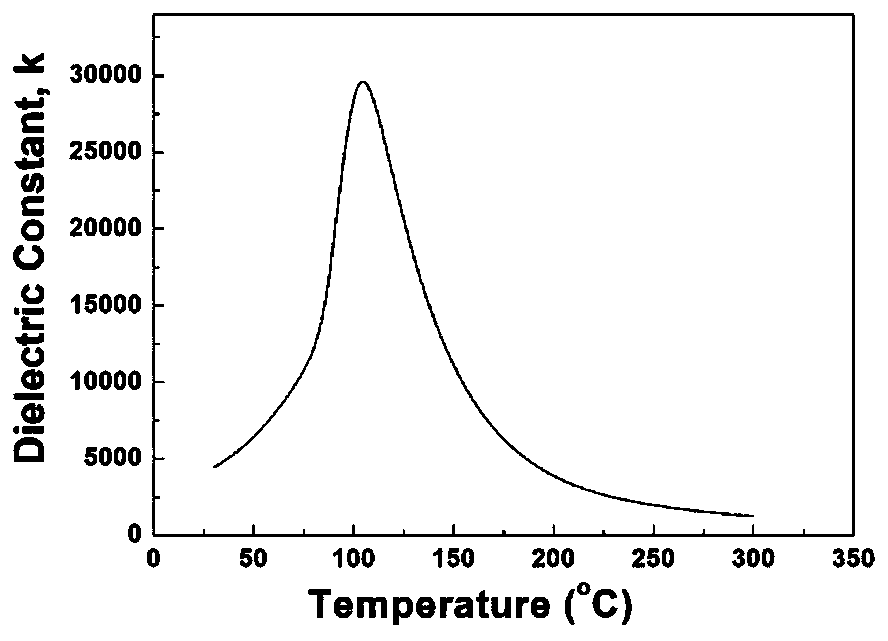

[0051] The composition of the textured rare earth modified lead magnesium niobate-lead titanate based piezoelectric ferroelectric ceramic material is:

[0052] [R x -Pb (1-1.5x) ][(Mg 1 / 3 Nb 2 / 3 )(1-y)Ti y ]O 3 –avol.%BaTiO 3 ;

[0053] Among them, R=Sm 3+ , x=0.01, y=0.29, a=0.05.

[0054] Step 1. Use CP or AR grade PbO, MgO, Nb 2 o 5 、TiO 2 and Sm 2 o 3 as raw material, fully dried and then used; using MgO and Nb 2 o 5 Synthesis of pure phase MgNb by reaction 2 o 6 precursor, and then the pure phase MgNb 2 o 6 Precursors and PbO, TiO 2 and Sm 2 o 3 Ball milling, drying, and sintering to obtain a pure-phase rare earth modified lead magnesium niobate-lead titanate ceramic matrix;

[0055] Step 2. Put Bi 2 o 3 、TiO 2 After uniform mixing with molten salt at 1100-1200°C, Bi 4 Ti 3 o 12 Powder, wherein, molten salt one is a mixture of NaCl molten salt and KCl molten salt with a molar ratio of 1:1; Bi 4 Ti 3 o 12 Powder, BaCO 3 、TiO 2 Mix and stir ...

Embodiment 2

[0064] The composition of the textured rare earth modified lead magnesium niobate-lead titanate based piezoelectric ferroelectric ceramic material is:

[0065] [Rx -Pb (1-1.5x) ][(Mg 1 / 3 Nb 2 / 3 )(1-y)Ti y ]O 3 –avol.%BaTiO 3 ;

[0066] Among them, R=Sm 3+ , x=0.025, y=0.29, a=0.05.

[0067] Step 1. Use CP or AR grade PbO, MgO, Nb 2 o 5 、TiO 2 and Sm 2 o 3 as raw material, fully dried and then used; using MgO and Nb 2 o 5 Synthesis of pure phase MgNb by reaction 2 o 6 precursor, and then the pure phase MgNb 2 o 6 Precursors and PbO, TiO 2 and Sm 2 o 3 Ball milling, drying, and sintering to obtain a pure-phase rare earth modified lead magnesium niobate-lead titanate ceramic matrix;

[0068] Step 2. Put Bi 2 o 3 、TiO 2 After uniform mixing with molten salt at 1100-1200°C, Bi 4 Ti 3 o 12 Powder, wherein, molten salt one is a mixture of NaCl molten salt and KCl molten salt with a molar ratio of 1:1; Bi 4 Ti 3 o 12 Powder, BaCO 3 、TiO 2 Mix and stir w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| T m | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| D33 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com