Ferroelectric piezoelectric single crystal lead holmium niobate-lead magnesium niobate-lead titanate as well as preparation and application thereof

A technology of lead holmium niobate and lead magnesium niobate, applied in the field of new ferroelectric single crystal, can solve the problems of difficult growth of ferroelectric single crystal and lack of high-power devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

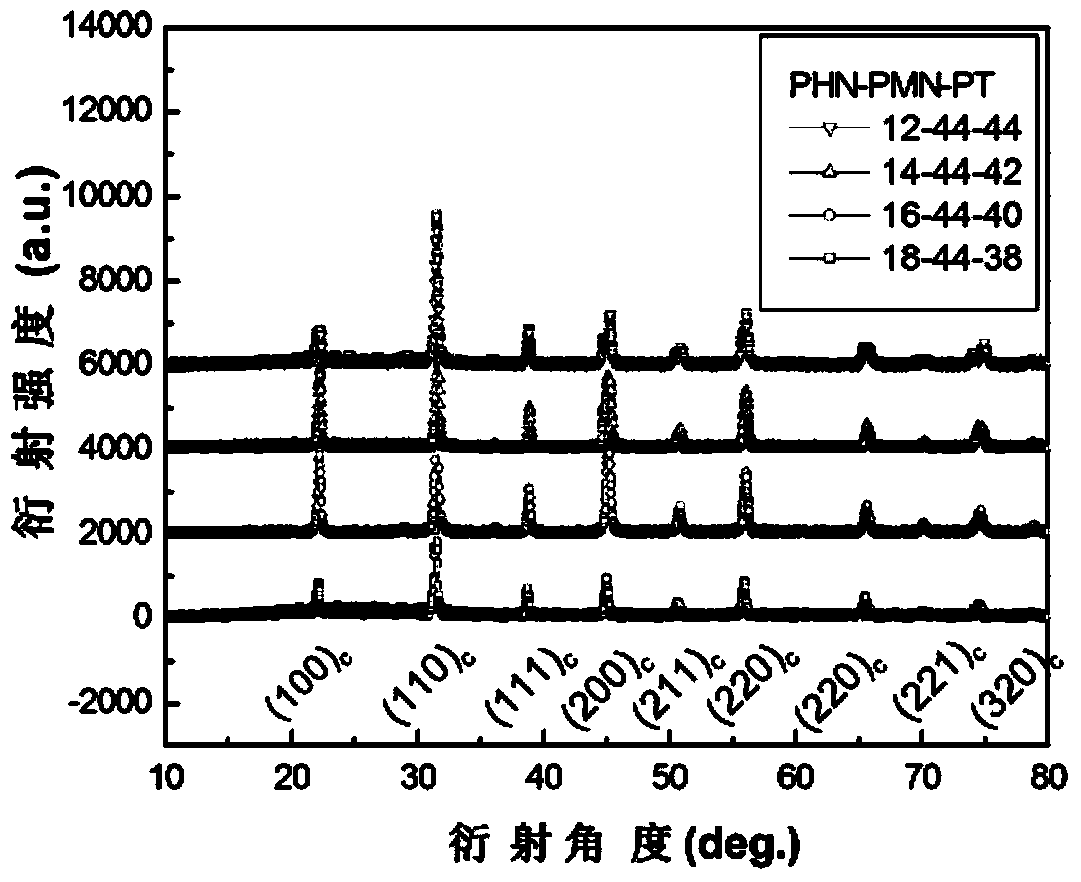

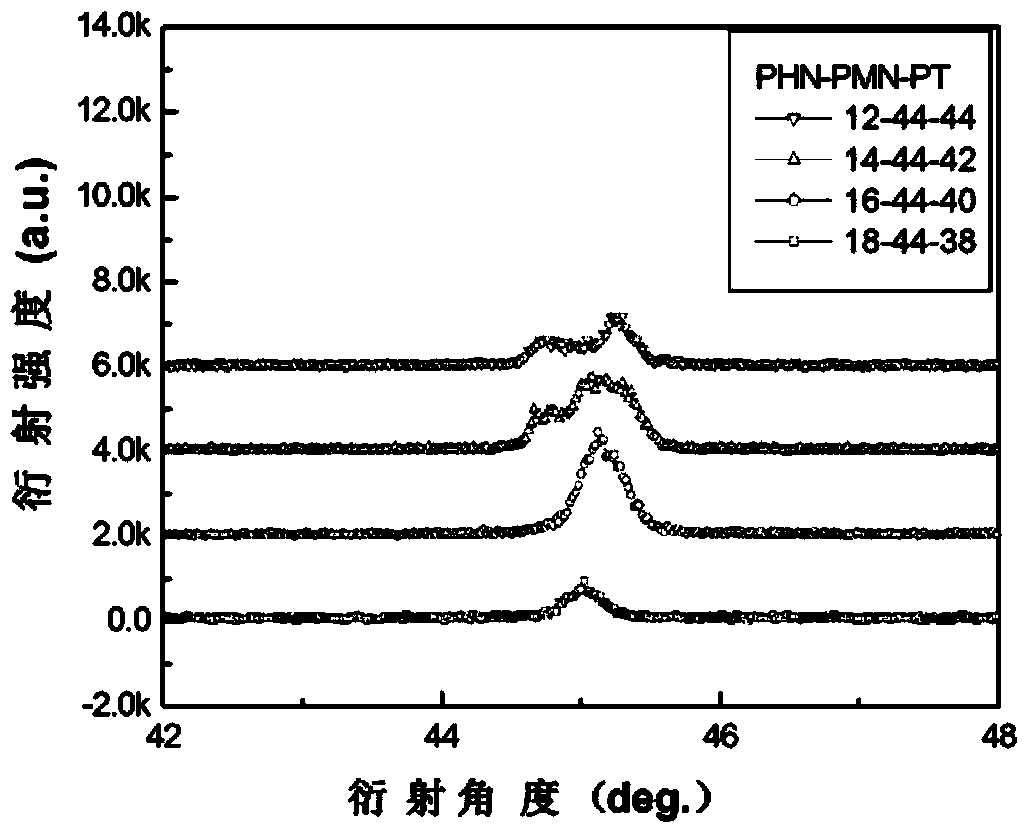

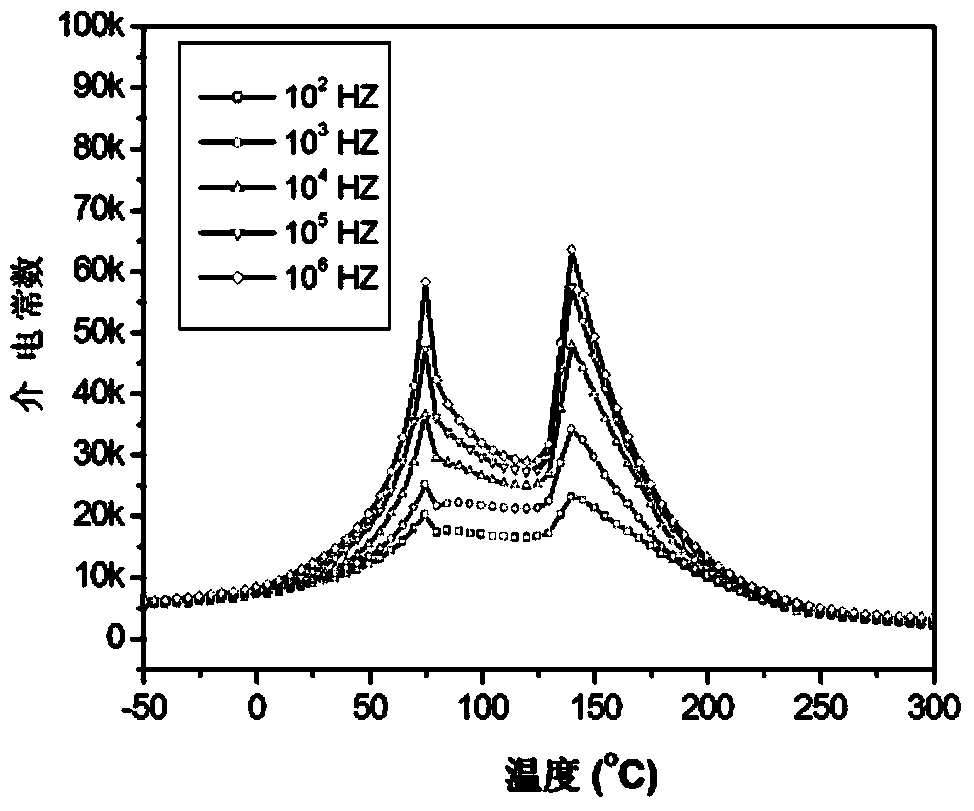

[0030] The PHN-PMN-PT ferroelectric single crystal material was grown by high temperature solution method.

[0031] The initial raw material PbO or Pb 3 o 4 、Ho 2 o 3 , MgO, TiO 2 , Nb 2 o 5 , co-solvent using PbO or Pb 3 o 4 and H 3 BO 3 or B 2 o 3 Composite co-solvent, weighed according to the ratio of 0.12PHN-0.44PMN-0.44T, stirred, mixed and ground. Put the uniformly mixed powder into a platinum crucible, and place the platinum crucible in a crystal growth furnace to form the material. Heat up the crystal growth furnace until the mixed powder is in a molten state, and keep the temperature constant for a certain period of time; cool down at an appropriate cooling rate, then use PMN-PT as the seed crystal to find the supersaturation temperature, and carry out crystal growth at the supersaturation temperature, and rotate the seed crystal during the growth process , the temperature is lowered at a rate of 1-20 ° C per day, and the cooling rate is adjusted accordin...

Embodiment 2

[0033] The PHN-PMN-PT ferroelectric single crystal material was grown by high temperature solution method.

[0034] The initial raw material PbO or Pb 3 o 4 、Ho 2 o 3 , MgO, TiO 2 , Nb 2 o 5 , co-solvent using PbO or Pb 3 o 4 and H 3 BO 3 or B 2 o 3 Composite co-solvent, weighed according to the ratio of 0.14PHN-0.44PMN-0.42T, stirred, mixed and ground. Put the uniformly mixed powder into a platinum crucible, and place the platinum crucible in a crystal growth furnace to form the material. Heat the prepared material above the supersaturation temperature, keep the temperature for a certain period of time, and use the seed crystal to find the growth point to grow; grow at about 1000-1100 °C, the crystal rotation rate is 5-30 rpm, and the cooling rate is 0.1-5 °C per day; After the growth is over, the crystal is lifted out of the liquid surface, and the temperature is lowered and annealed at 5-40°C / h. The grown single crystal is a square crystal with (001) natural g...

Embodiment 3

[0036] The PHN-PMN-PT ferroelectric single crystal material was grown by high temperature solution method.

[0037] The initial raw material PbO or Pb 3 o 4 、Ho 2 o 3 , MgO, TiO 2 , Nb 2 o 5 , co-solvent using PbO or Pb 3 o 4 and H 3 BO 3 or B 2 o 3 Composite co-solvent, weighed according to the ratio of 0.16PHN-0.44PMN-0.40T, stirred, mixed and ground. Put the uniformly mixed powder into a platinum crucible, and place the platinum crucible in a crystal growth furnace to form the material. Heat the prepared material above the supersaturation temperature, keep the temperature for a certain period of time, and use the seed crystal to find the growth point to grow; grow at about 1000-1100 °C, the crystal rotation rate is 5-30 rpm, and the cooling rate is 0.1-5 °C per day; After the growth is over, the crystal is lifted out of the liquid surface, and the temperature is lowered and annealed at 5-40°C / h. The grown single crystal is a square crystal with (001) natural g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Piezoelectric coefficient | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com