Focusing ultrasonic transducer and producing method thereof

An ultrasonic transducer, ultrasonic technology, applied in the direction of fluid using vibration, etc., can solve the problems of difficult application of new piezoelectric single crystals, easy brittle cracking, reduced performance of piezoelectric vibrators, etc., and achieves simple structure, low cost, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

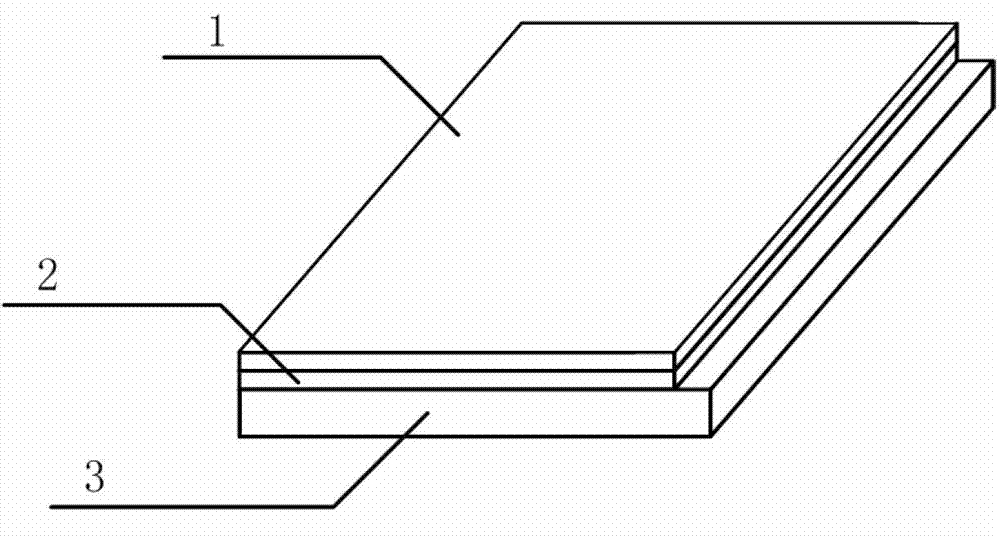

[0029] Such as figure 1 As shown, from top to bottom are the outer matching layer 1, the inner matching layer 2, and the piezoelectric vibrator layer 3. The outer matching layer 1 is directly cured by epoxy resin with low acoustic impedance. The inner matching layer 2 is made by mixing epoxy resin and fillers (such as tungsten powder, zirconia ceramic powder, etc.) according to certain acoustic impedance requirements. The piezoelectric vibrator layer 3 is made of a new piezoelectric single crystal / polymer 1-3 composite material, such as PMNT{(1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -xPbTiO 3}Single crystal material, grown by the improved Bridgman method, the orientation is , and the composition is 0.20≤x≤0.40; the new piezoelectric single crystal can also be PIMNT{xPb(In 1 / 2 Nb 1 / 2 )O 3 -yPb(Mg 1 / 3 Nb 2 / 3 )O 3 -(1-x-y)PbTiO 3}Single crystal material, the orientation is , the composition is 0.20≤x≤0.40 and 0.20≤y≤0.40. The piezoelectric single crystal / polymer 1-3 composite was pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com