MEMS (Micro-electromechanical Systems) wideband frequency vibration energy collector based on PMNT (Lead Magnesium Niobate-Lead Titanate) piezoelectric mono-crystal, and preparation method

A technology of vibration energy harvesting and piezoelectric single crystal, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. It can solve the problems of low output power and narrow operating frequency band, and achieve the effect of high output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

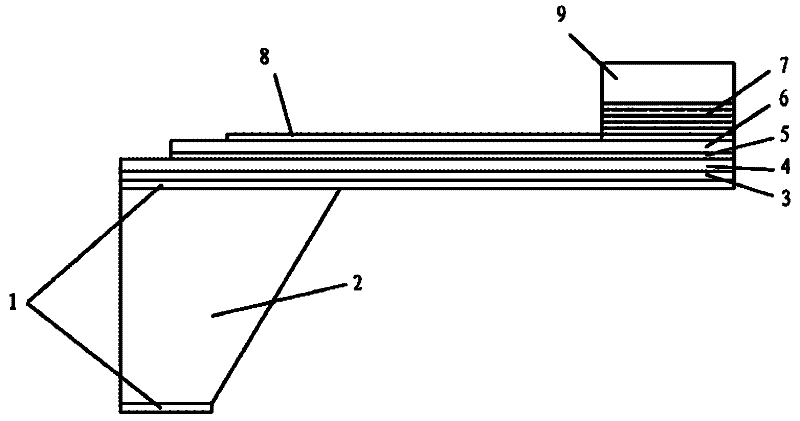

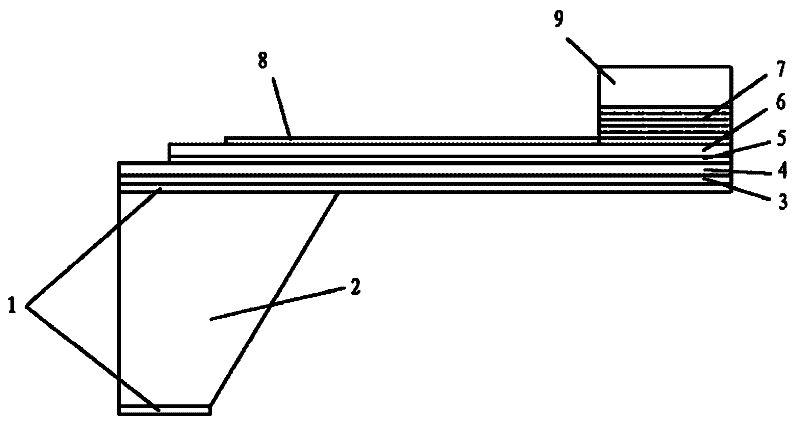

[0037] Embodiment one: if figure 1 As shown, the piezoelectric energy harvester of this embodiment includes a silicon fixed base, a support layer, a PMNT piezoelectric film layer and a quality block, wherein: 1-SiO 2 layer, 2-Si layer, 3-epoxy resin layer, 4-support layer, 5-conductive epoxy resin layer, 6-PMNT piezoelectric film layer, 7-liquid, 8-electrode layer, 9-container.

[0038] Described silicon fixing base is made of Si layer 2 and oxide SiO on it 2 Layer 1 composition;

[0039] The mass block is composed of a liquid layer 7 and a container 9;

[0040] The liquid layer 7 refers to liquid mercury;

[0041] The container 9 refers to a square container prepared by the SU8 glue process.

[0042] The support layer 4 refers to carbon fibers with a thickness of 15 μm;

[0043] The piezoelectric film 6 refers to a PMNT piezoelectric film layer with a thickness of 10 μm;

[0044] The electrode layer 8 is a Cr / Au alloy with a thickness of 0.20 μm.

[0045] The present e...

Embodiment 2

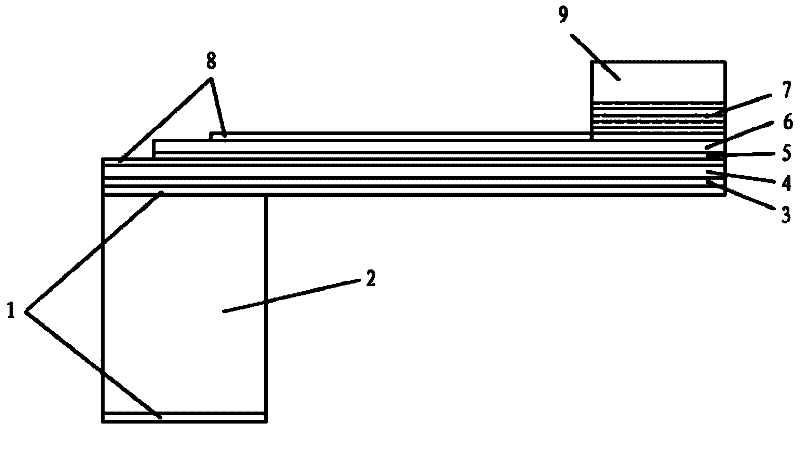

[0061] Embodiment two: if figure 2 As shown, the piezoelectric energy harvester of this embodiment includes a silicon fixed base, a support layer, a PMNT piezoelectric film layer and a quality block, wherein: 1-SiO 2 layer, 2-Si layer, 3-epoxy resin layer, 4-support layer, 5-conductive epoxy resin layer, 6-PMNT piezoelectric film layer, 7-liquid, 8-electrode layer, 9-container.

[0062] Described silicon fixing base is made of Si layer 2 and oxide SiO on it 2 Layer 1 composition;

[0063] The mass block is composed of a liquid layer 7 and a container 9;

[0064] The liquid layer 7 refers to liquid mercury;

[0065] The container 9 refers to a square container prepared by the SU8 glue process.

[0066] The support layer 4 refers to glass fibers with a thickness of 20 μm;

[0067] The piezoelectric film 6 refers to a PMNT piezoelectric film layer with a thickness of 15 μm;

[0068] The electrode layer 8 is a Ti / Pt alloy with a thickness of 0.15 μm.

[0069] The present e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com