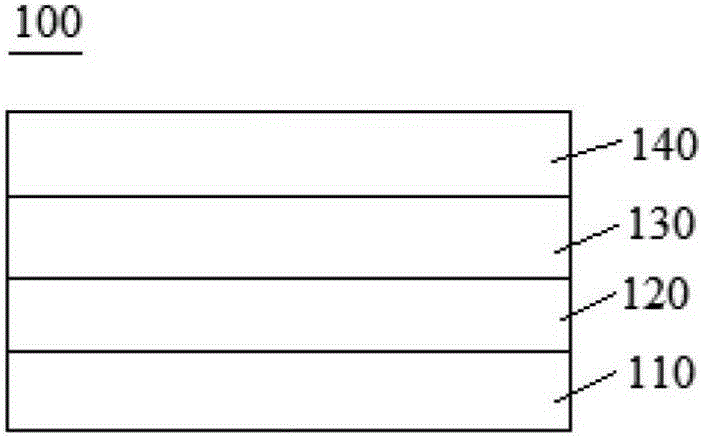

Composite single crystal thin film and method for manufacturing composite single crystal thin film

A single crystal thin film, legal technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve weak nonlinear optical effects, limited applications, electro-optical, acousto-optical, weak thermoelectric effects, etc. problems, to achieve the effect of good compatibility, effective industrial production, and broad industrial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

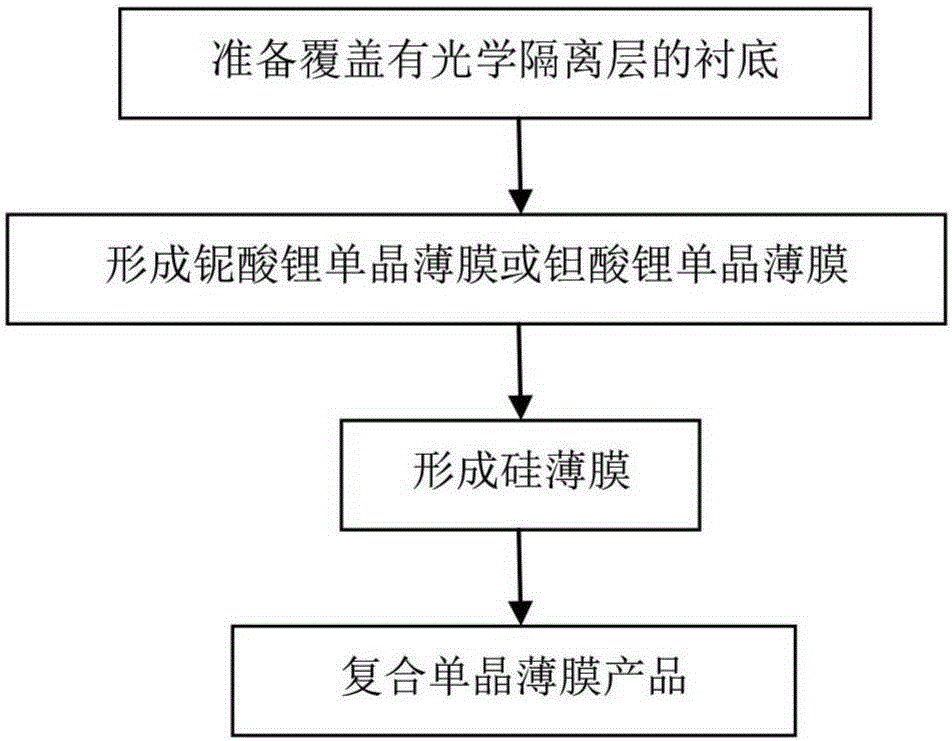

[0056] A single crystal silicon substrate covered with a silicon dioxide layer having a thickness of 2 μm and a single crystal silicon substrate having a thickness of 500 μm was prepared.

[0057] Provide lithium niobate wafer; adopt ion implantation method, helium ion (He 1+ and / or He 2+ ) into the lithium niobate wafer, the helium ion implantation energy is 250keV, and the dose is 4×10 16 ions / cm 2 .

[0058] Using the direct bonding method, the implanted surface of the lithium niobate wafer after the implantation is bonded with the silicon dioxide layer on the single crystal silicon substrate to form a bonded body; the bonded body is placed in an autoclave and filled with nitrogen ( N 2 ), the pressure was kept at 200bar, and then the temperature was raised to 350°C and kept for 10 hours. During this heating process, the lithium niobate wafer was separated at the position where the helium ions stayed; then it was lowered to room temperature, and the wafer was taken out ...

Embodiment 2

[0062] A single crystal silicon substrate covered with a silicon dioxide layer having a thickness of 2 μm and a single crystal silicon substrate having a thickness of 500 μm was prepared.

[0063] A lithium niobate wafer is provided; at room temperature, the lithium niobate wafer is bonded to a silicon dioxide layer on a single crystal silicon substrate by direct bonding; the lithium niobate wafer is ground to 5 μm and then polished to 4 μm, Thus, a three-layer structure having a 4 μm thick lithium niobate single crystal thin film was obtained.

[0064] Provide single crystal silicon wafers; use ion implantation method to implant hydrogen ions into single crystal silicon wafers, hydrogen ion implantation energy is 120keV, dose is 4×10 17 ions / cm 2 .

[0065] At room temperature, use the direct bonding method to bond the implanted surface of the implanted single crystal silicon wafer and the surface of the lithium niobate single crystal thin film together to obtain a bonded b...

Embodiment 3

[0067] A single crystal silicon substrate covered with a silicon dioxide layer having a thickness of 2 μm and a single crystal silicon substrate having a thickness of 500 μm was prepared.

[0068] Provide lithium niobate wafer; adopt ion implantation method, helium ion (He 1+ and / or He 2+ ) into the lithium niobate wafer, the helium ion implantation energy is 250keV, and the dose is 4×10 16 ions / cm 2 .

[0069]Using the direct bonding method, the implanted surface of the implanted lithium niobate wafer is bonded to the silicon dioxide layer on the single crystal silicon substrate to form a bonded body; the bonded body is heated to 250 ° C and kept for 10 hours, and then During this heating process, the lithium niobate wafer is separated at the position where the helium ions stay; then down to room temperature, the thickness of the lithium niobate single crystal film is about 0.83 μm; the lithium niobate single crystal film is heated, and the surrounding atmosphere is oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com