Patents

Literature

56results about How to "Stable industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel used at lower temperature and method for manufacturing same

ActiveCN101545077AIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsSheet steelChemical composition

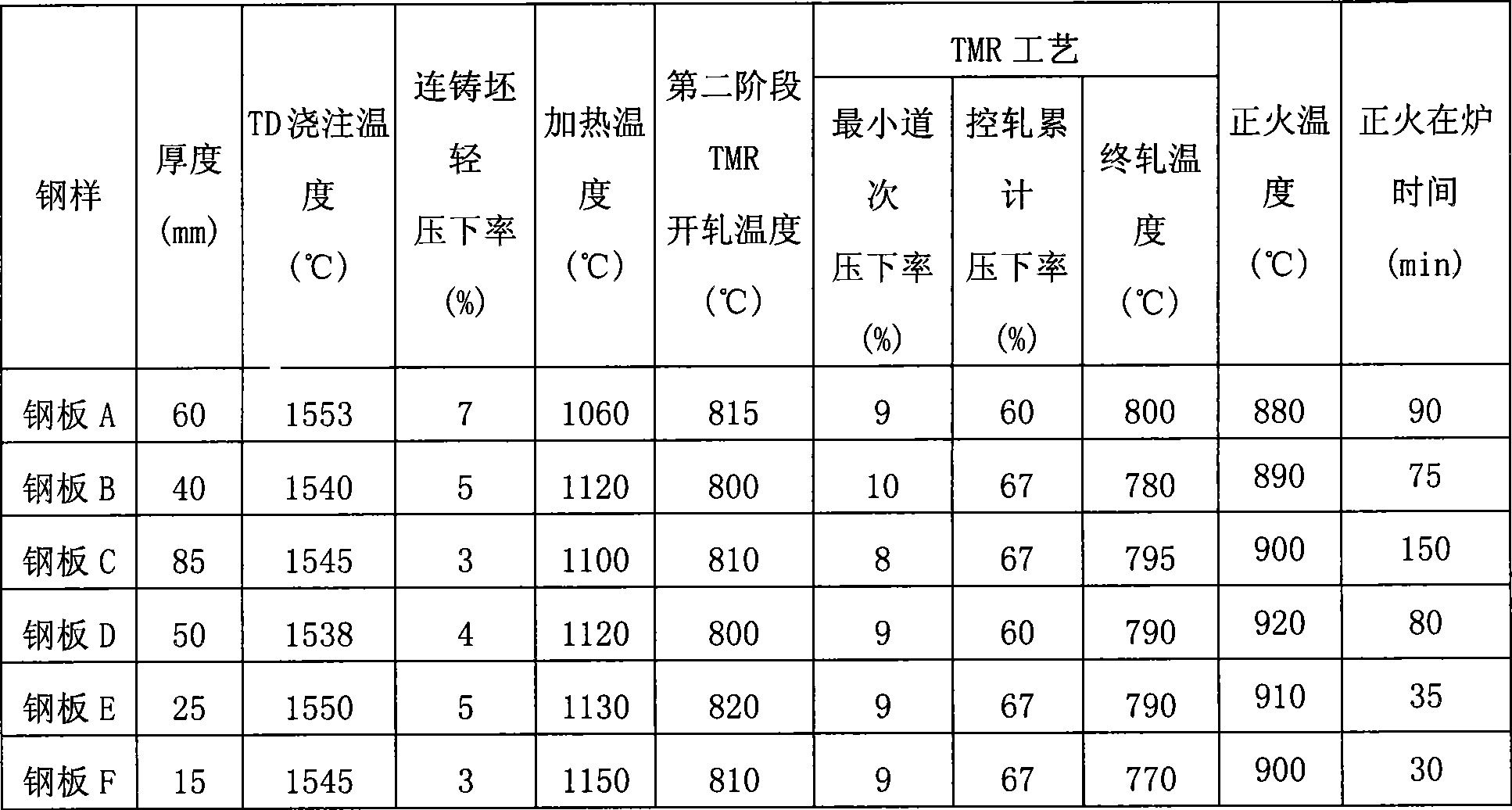

The invention discloses a steel used at a lower temperature and a method for manufacturing the same. The steel comprises the following chemical components by weight percentage: 0.060 to 0.090 percent of C, less than or equal to 0.20 percent of Si, 1.10 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.040 to 0.070 percent of Als, 0.05 to 0.45 percent of Cu, 0.05 to 0.35 percent of Ni, 0.05 to 0.30 percent of Cr, 0.007 to 0.011 percent of Ti, 0.007 to 0.020 percent of Nb, less than or equal to 0.0040 percent of N, 0.001 to 0.011 percent of Ca, and the balance of Fe and inevitable impurities. The manufacturing process comprises of the steps: making the steel plate obtain excellent low-temperature toughness and making the steel plate bear the big line energy welding. The steel and the method can be widely applied to petroleum natural gas pipelines, low-temperature gas tank bodies LPG, low temperature steel plates of LNG.

Owner:BAOSHAN IRON & STEEL CO LTD

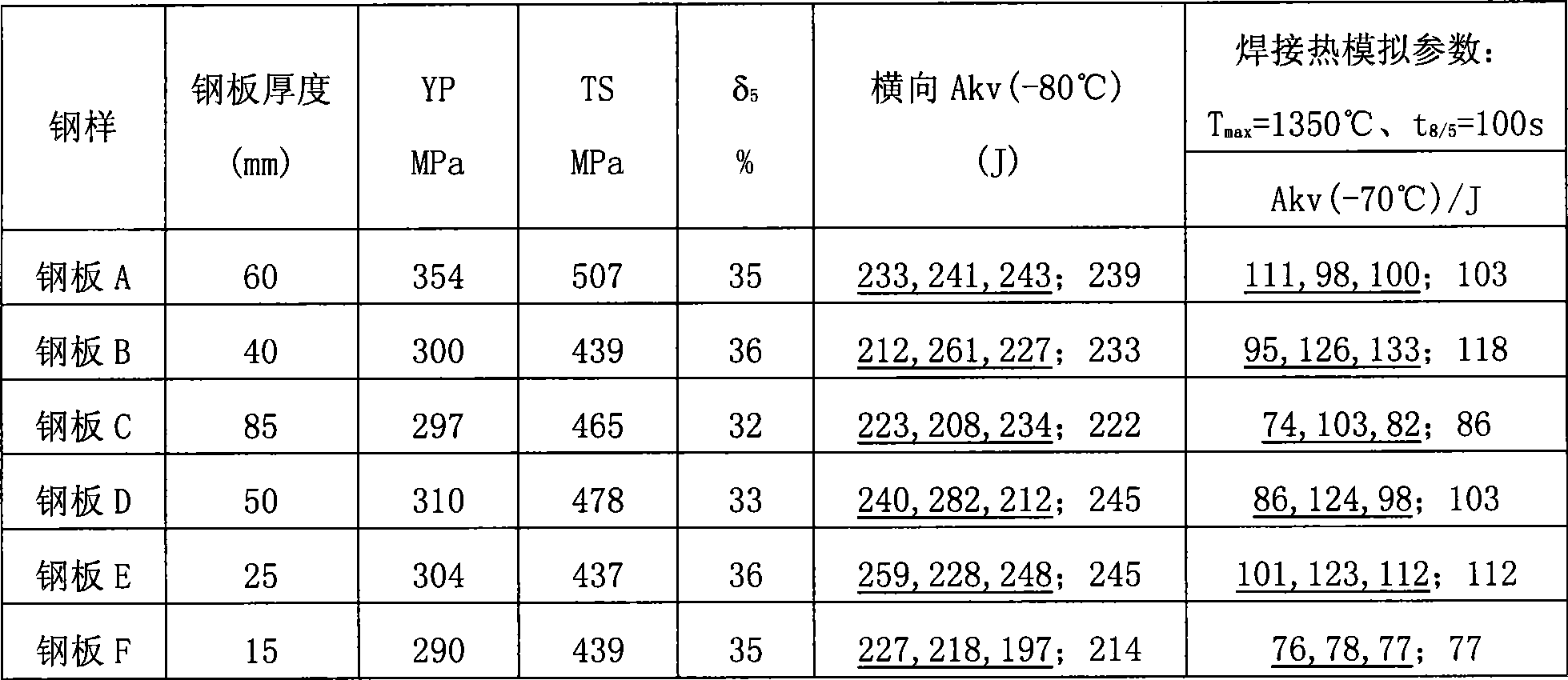

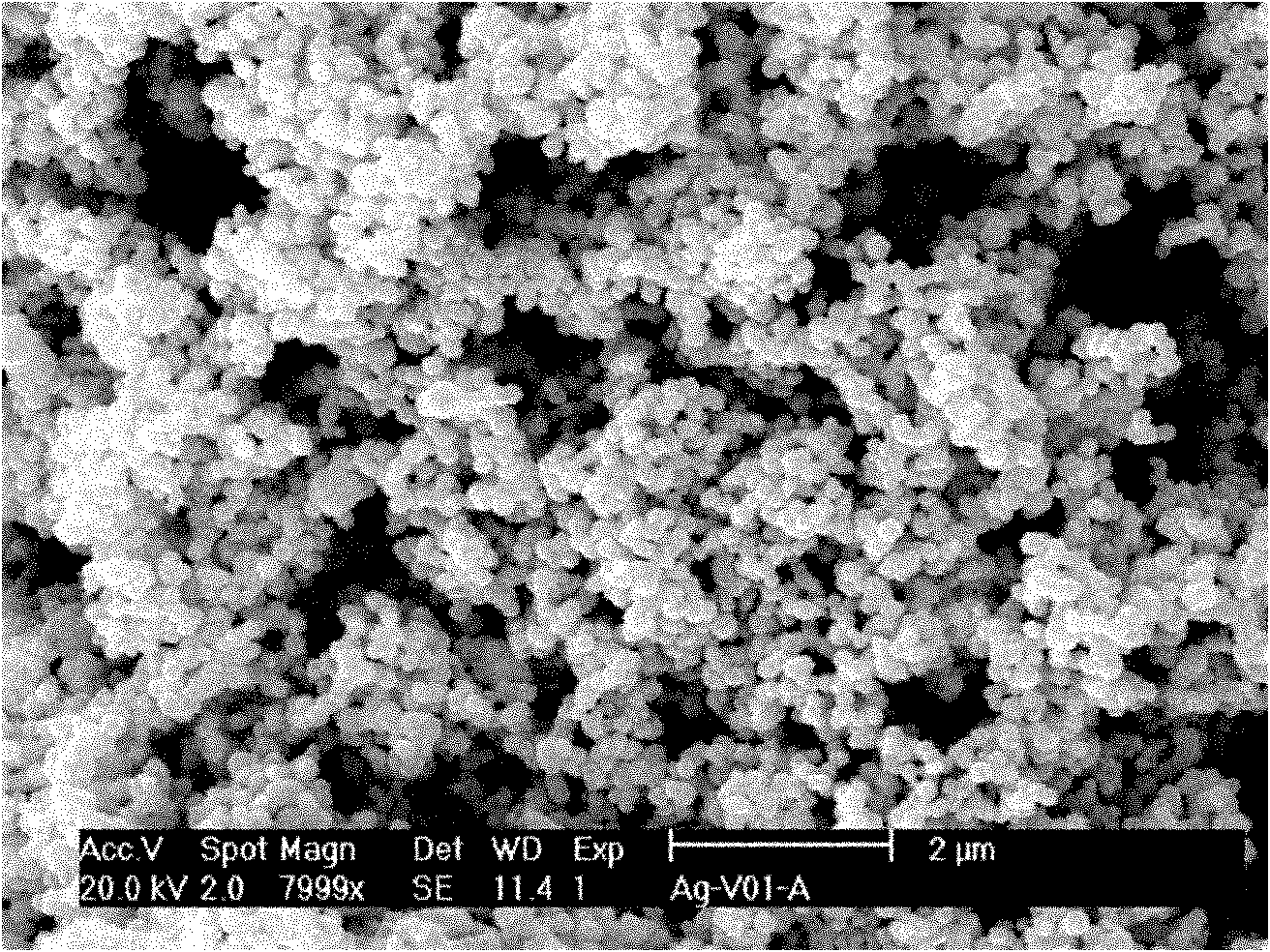

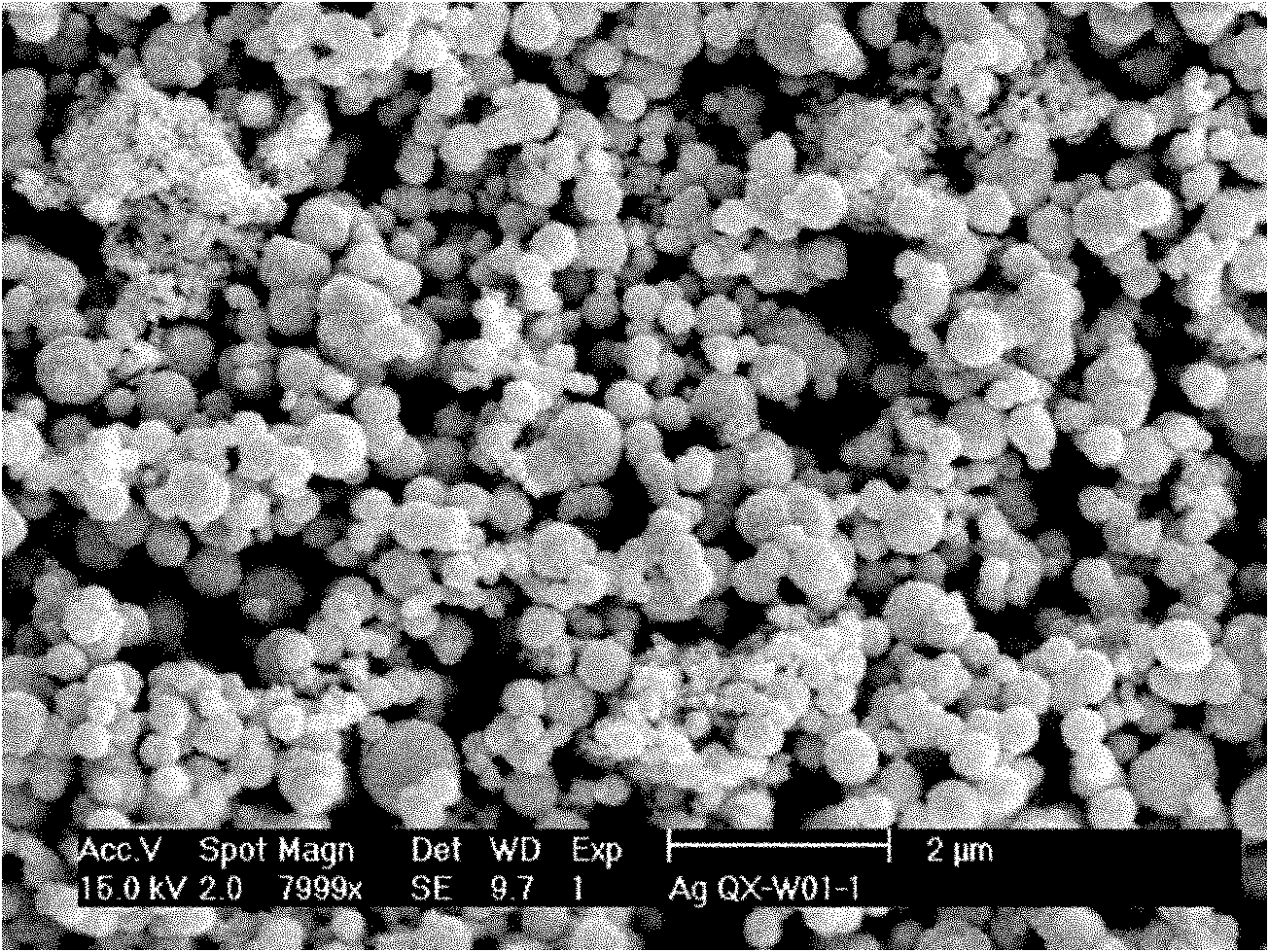

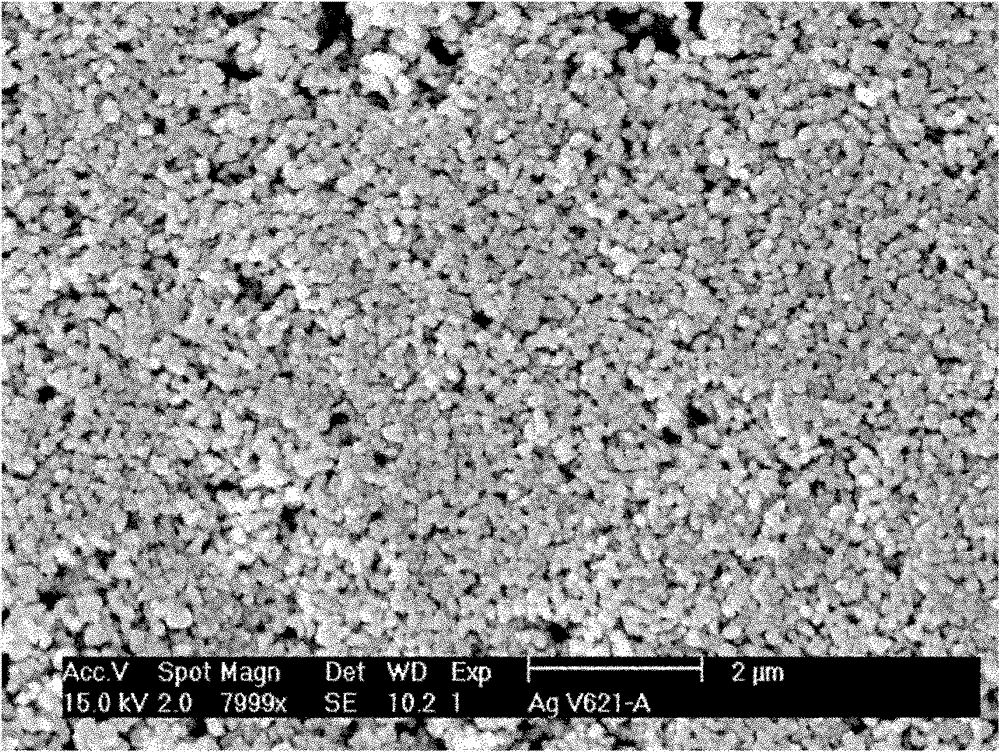

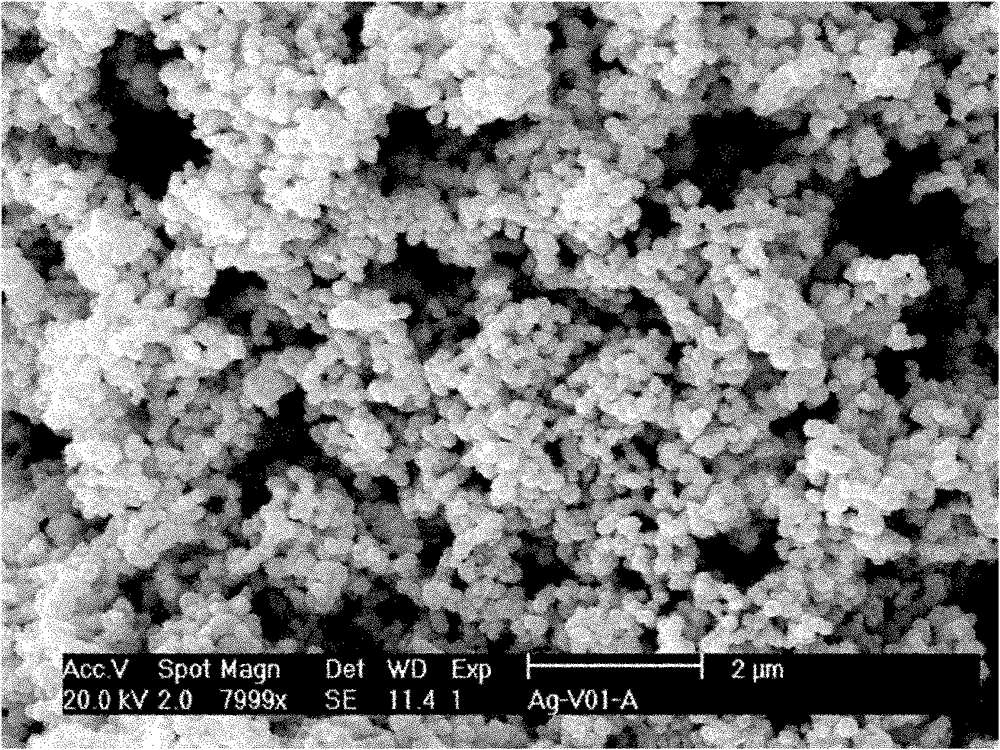

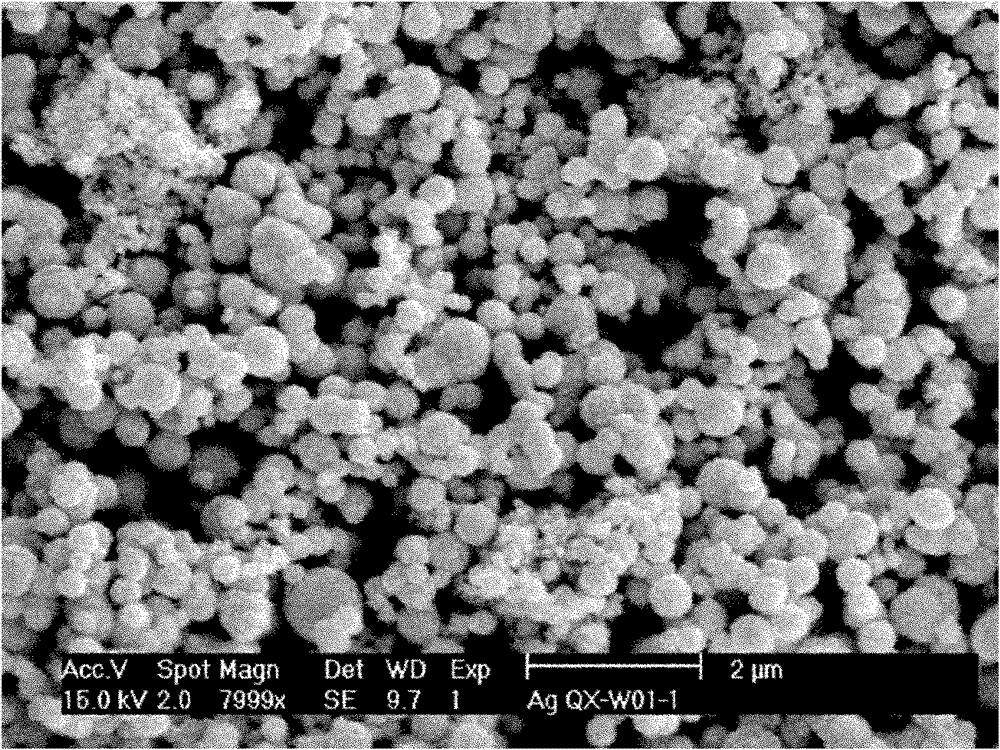

Method for preparing silver micro-powder for high-temperature sintering silver pastes

The invention discloses a method for preparing silver micro-powder for high-temperature sintering silver pastes, which comprises the following steps: preparing a colloidal liquid silver system, a colloidal reduction system and protection solution firstly; then mixing the three. In the invention, a sol gel process and a solution chemical reduction method are used to effectively control the reaction process, so that the industrialized production can be performed stably, and the uniform reaction under the condition of production enlarging still can be ensured, thereby greatly improving the uniformities of shapes and other superficial characteristics of silver particles generated by reaction, and eventually generating flocculating soft silver powder wodges which are easy to carry out post-processing such as collecting and washing, and the like.

Owner:广东羚光新材料股份有限公司

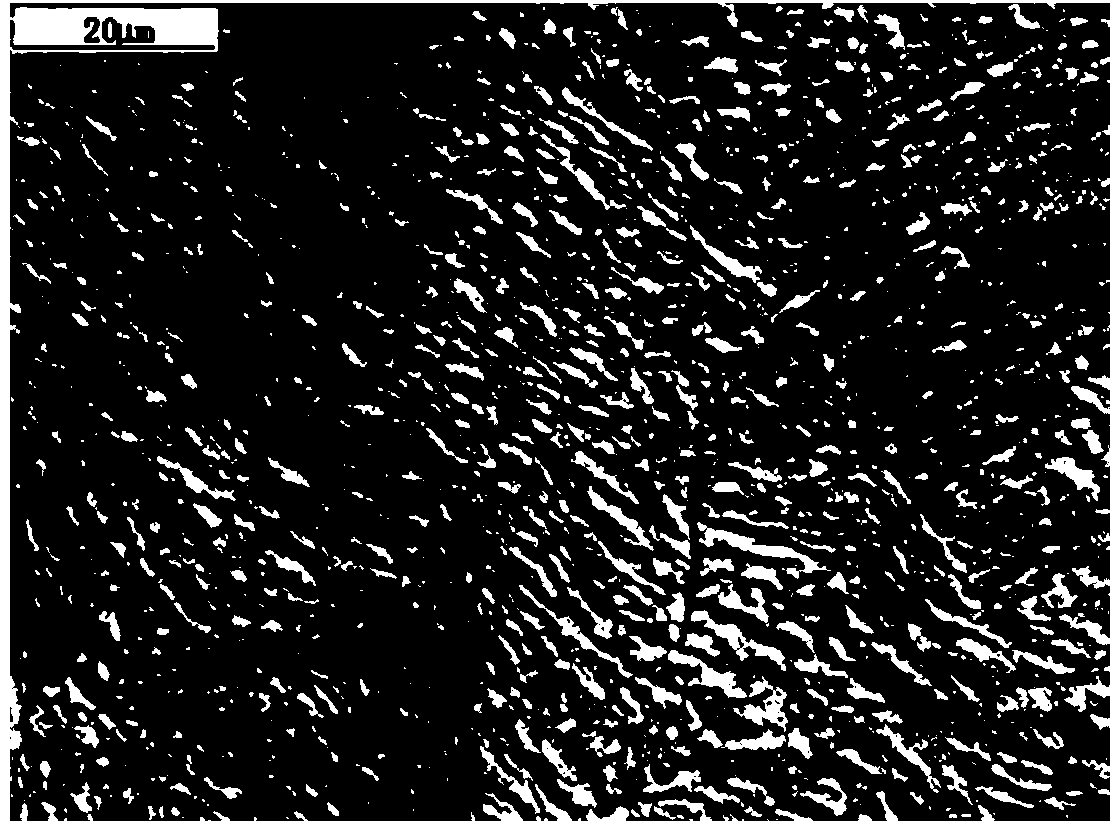

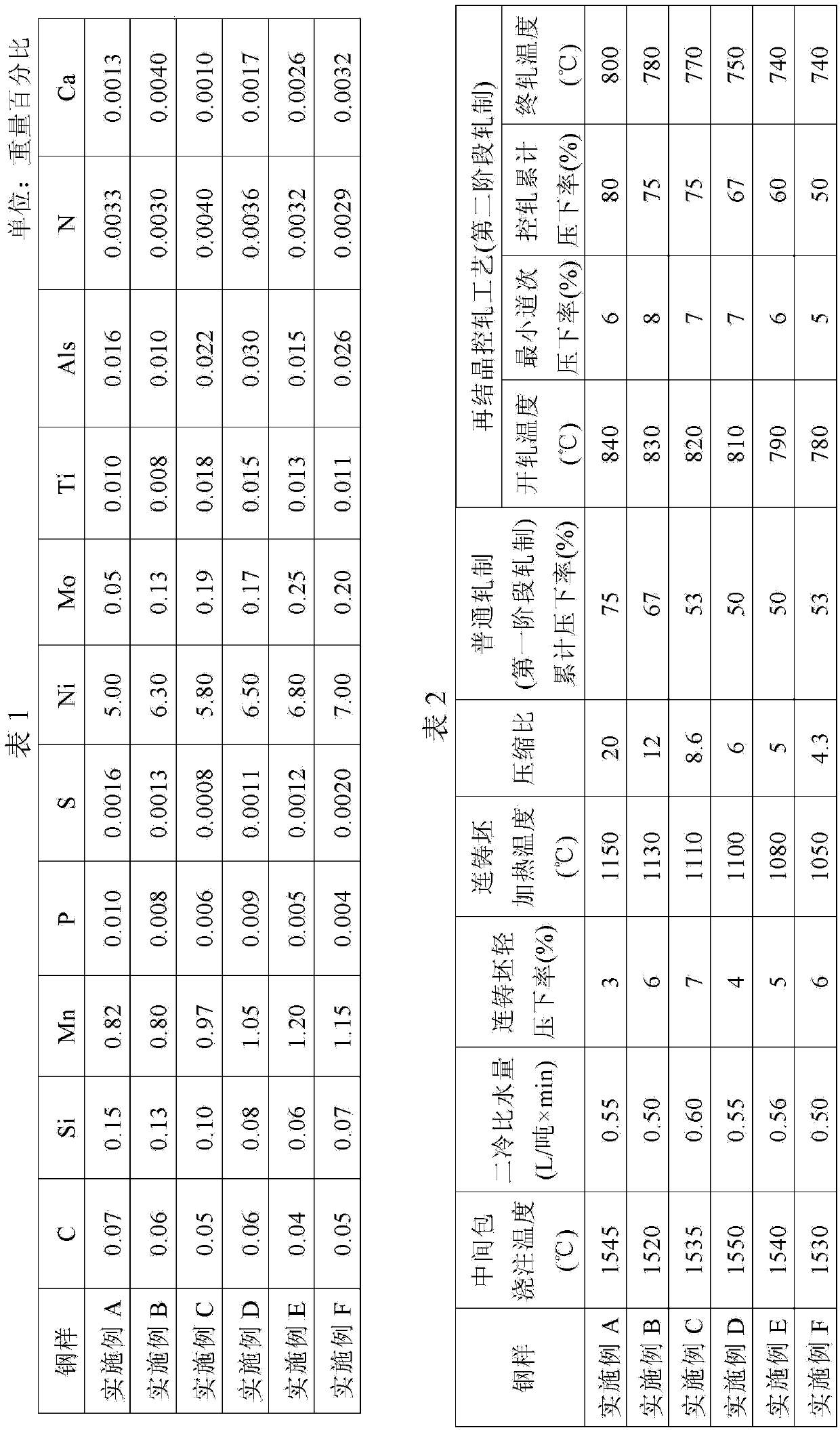

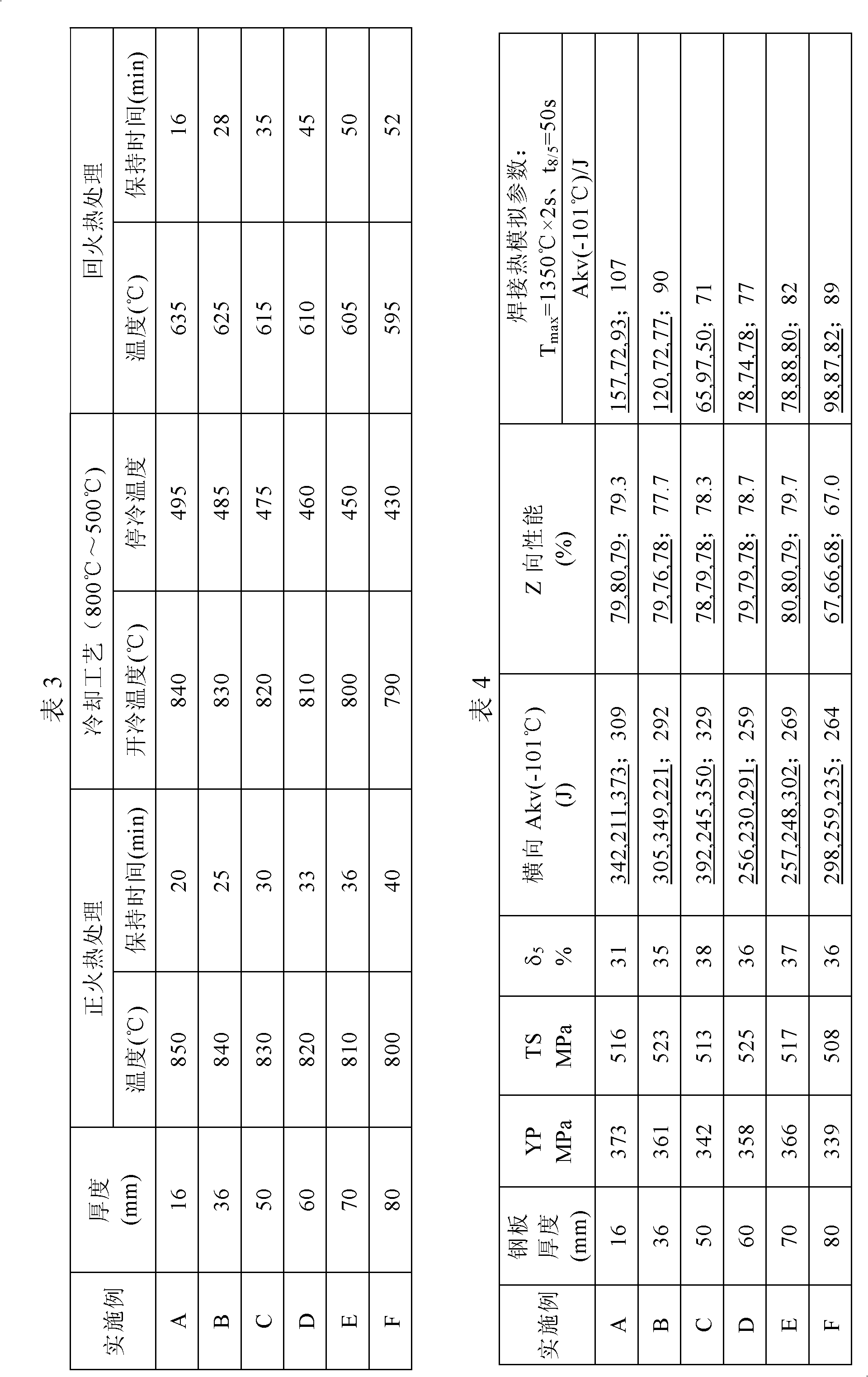

Ultralow temperature nickel steel with low cost and manufacturing method thereof

An ultralow temperature nickel steel with low cost and a manufacturing method thereof. The steel comprises the following components by weight: 0.04-0.070% of C, no more than 0.15% of Si, 0.80-1.20% of Mn, no more than 0.010% of P, 0.0020% of S, 5.00-7.00% of Ni, 0.05-0.25% of Mo, 0.010-0.030% of Als, 0.008-0.018% of Ti, no more than 0.0040% of N, 0.001-0.004% of Ca, and the balance of Fe and the inevitable inclusion. The invention uses a component system containing ultra low C, ultra low Si, middle Mn, low N and ultramicro Ti for treatment of low alloy steel, and controls the value of (%Mn)*[7.33 (%Si) + 5.16 (%Al)] at no more than 1.0, and the value of austenite stabilization index Au / intercritical quenching temperature T at no less than 0.007 and no more than 0.009; an optimized recrystallization controlled rolling and subsequent special heat treatment process endows the ultralow temperature nickel steel with ultrahigh ultralow temperature toughness, excellent weldability and bearing of high heat input welding, and the ultralow temperature nickel steel gains excellent anti-high tempering parameter SR embrittlement characteristics, and can be manufactured at a low cost.

Owner:BAOSHAN IRON & STEEL CO LTD

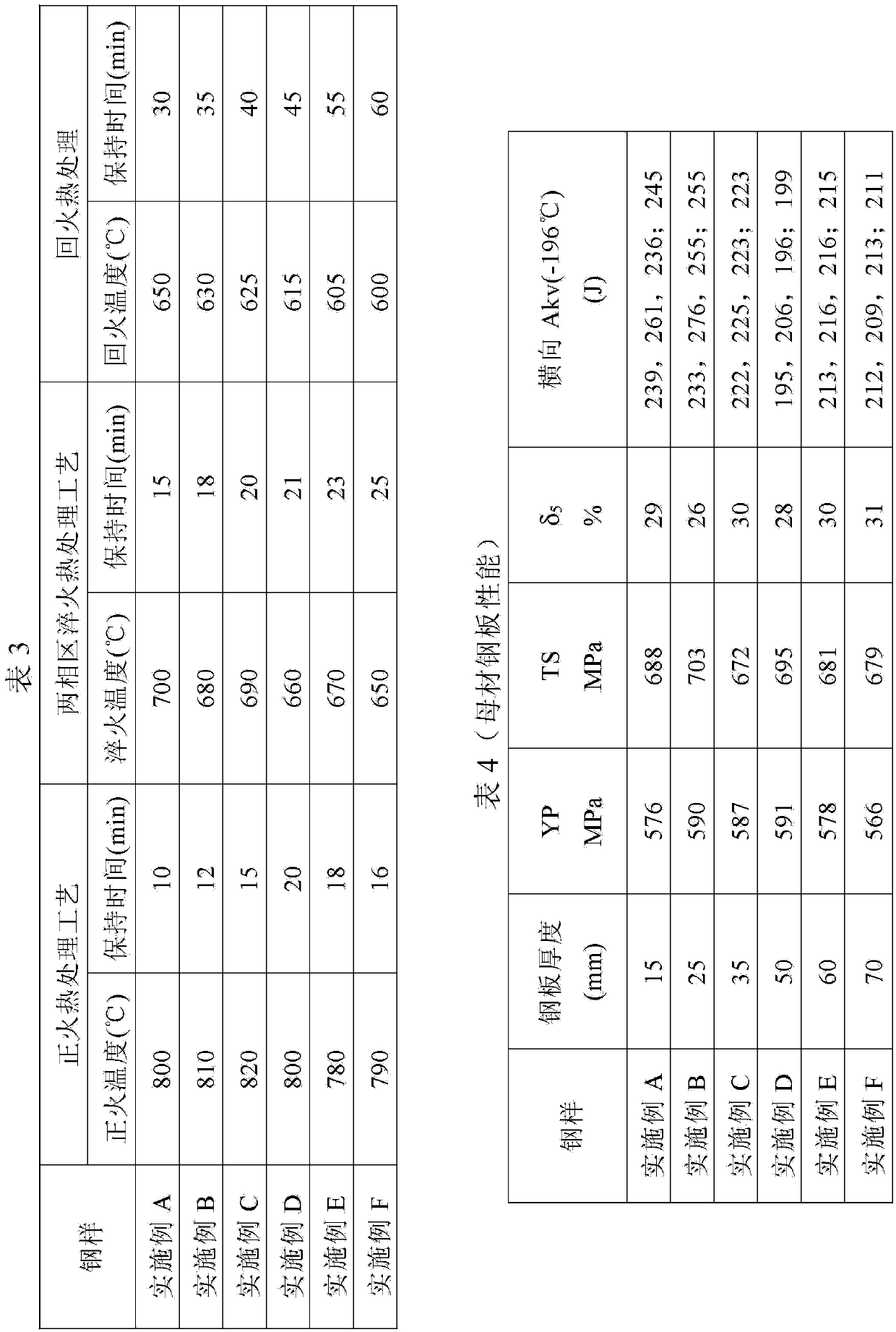

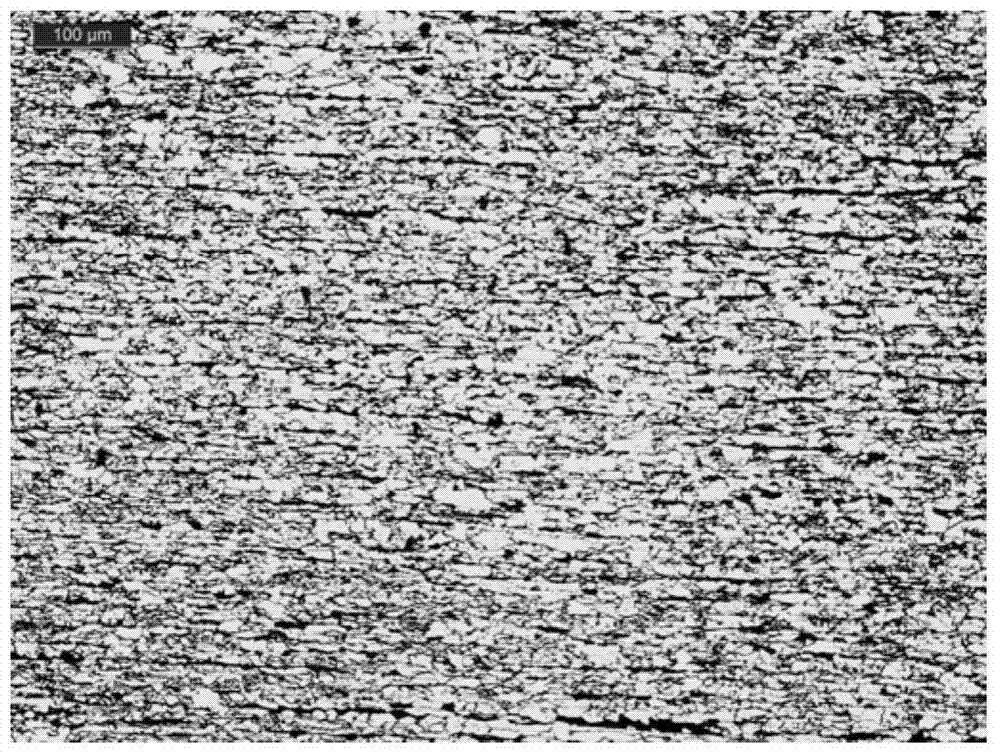

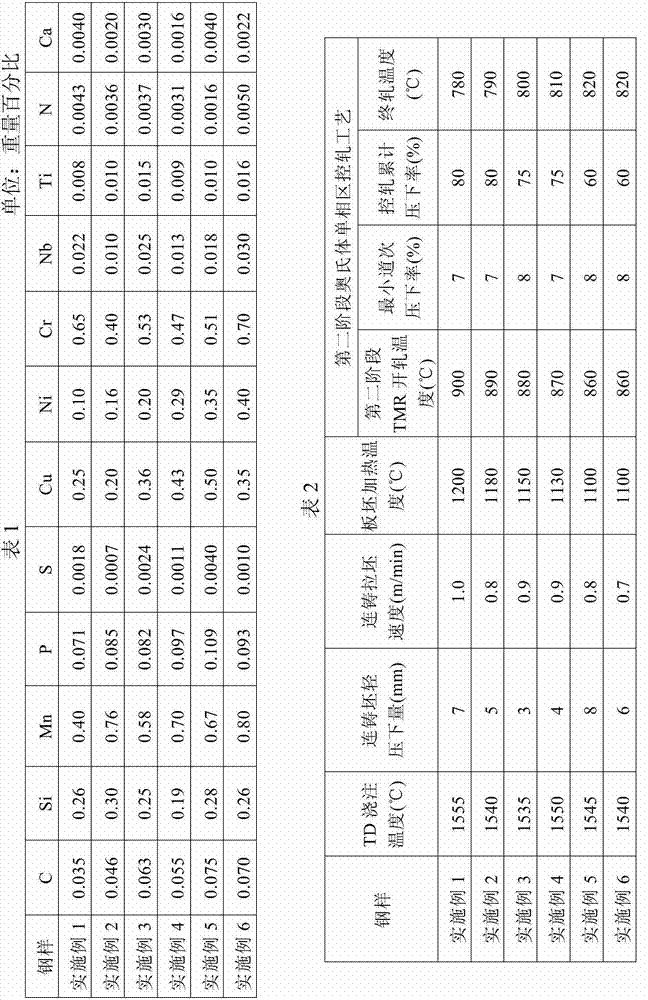

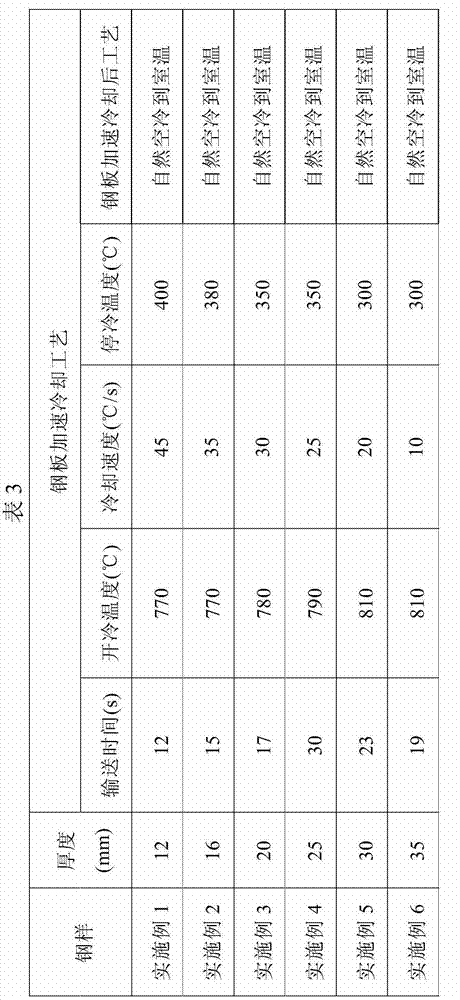

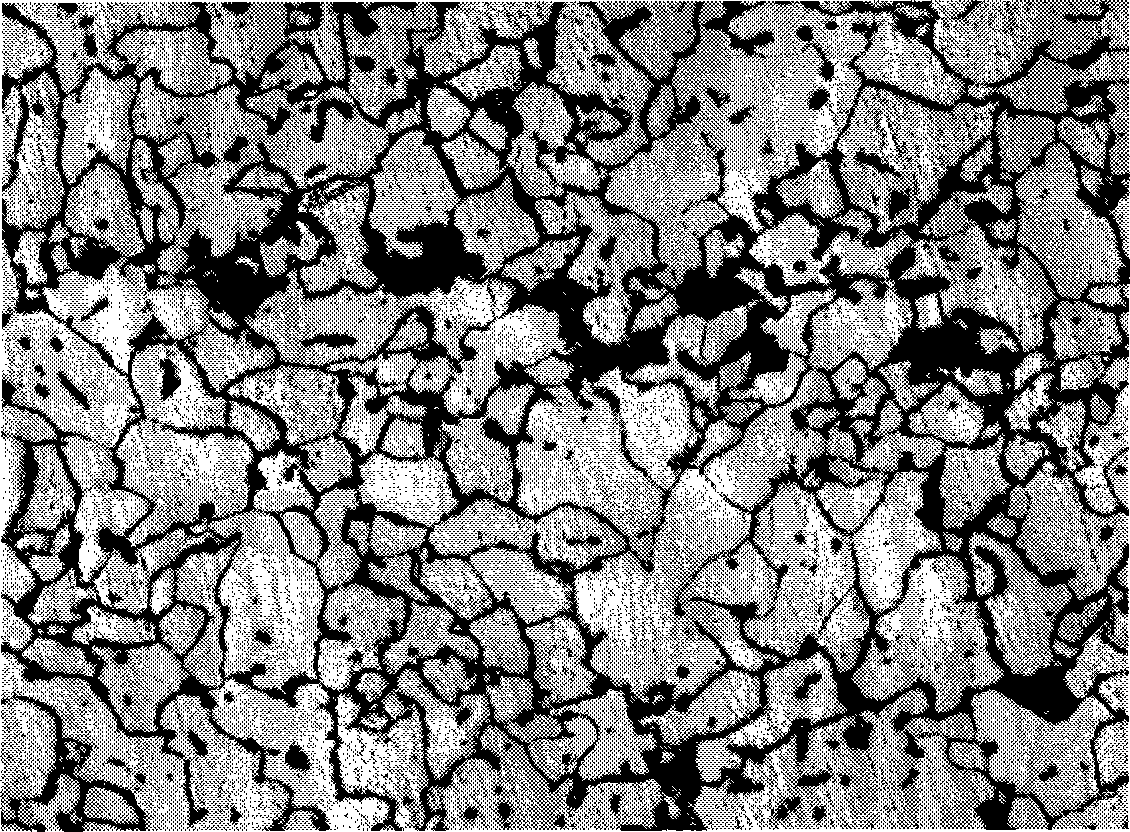

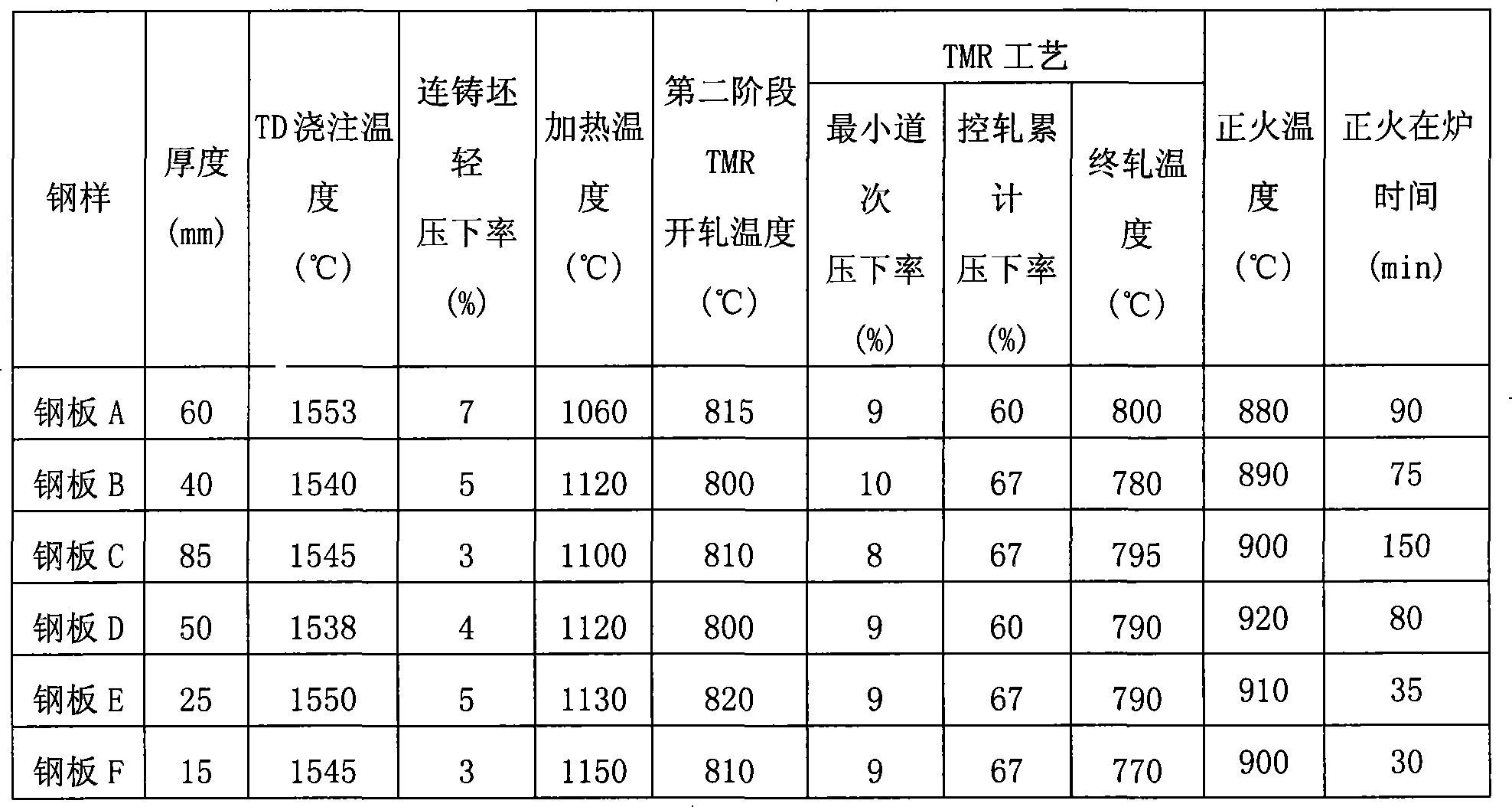

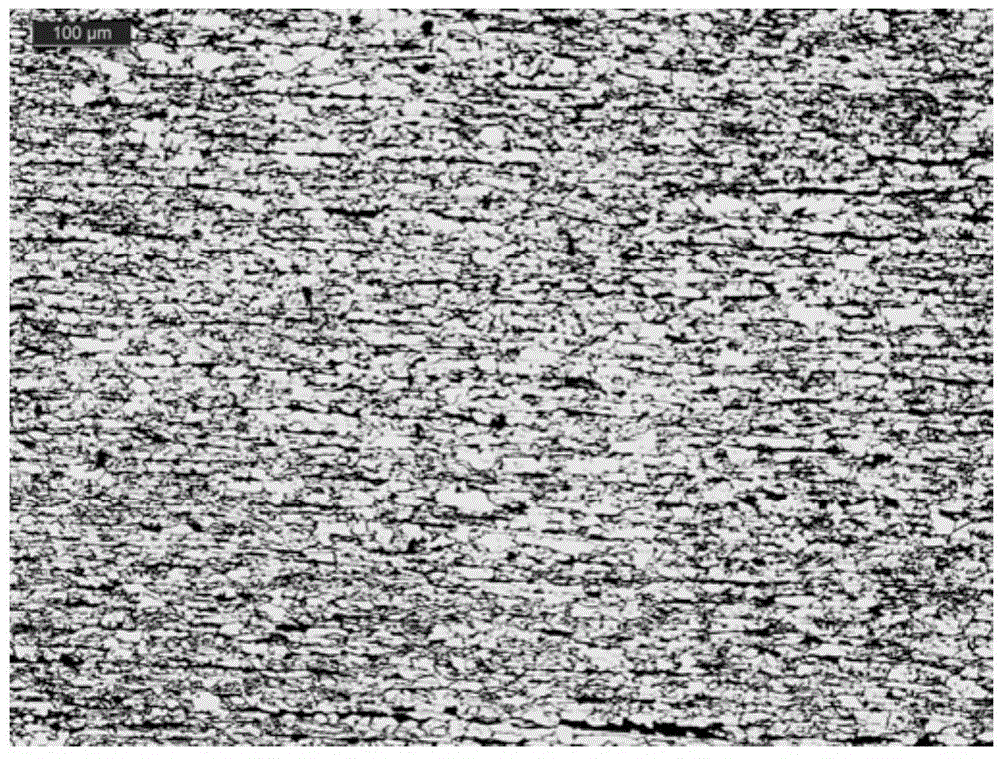

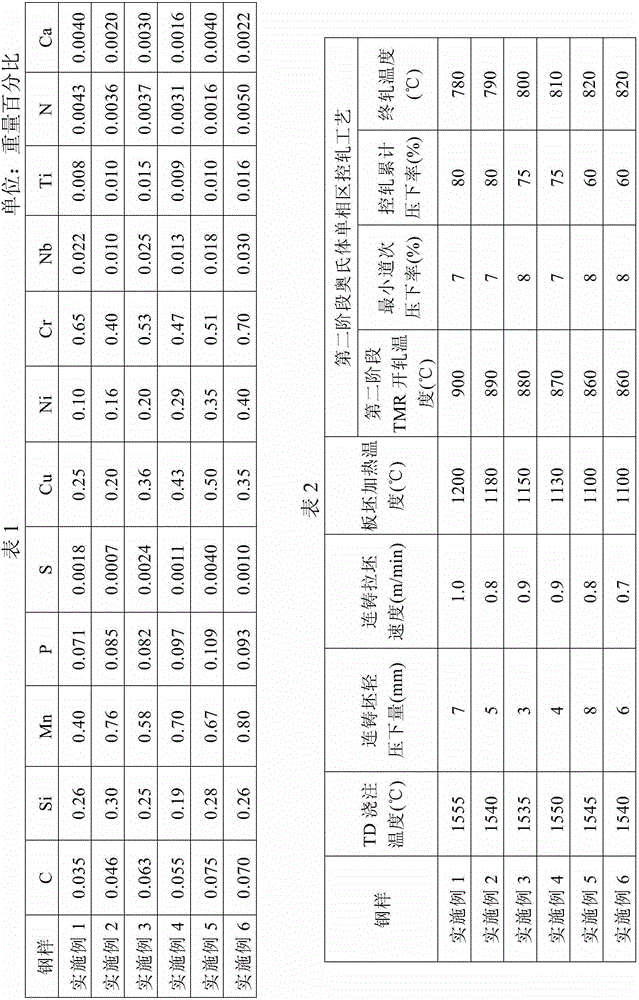

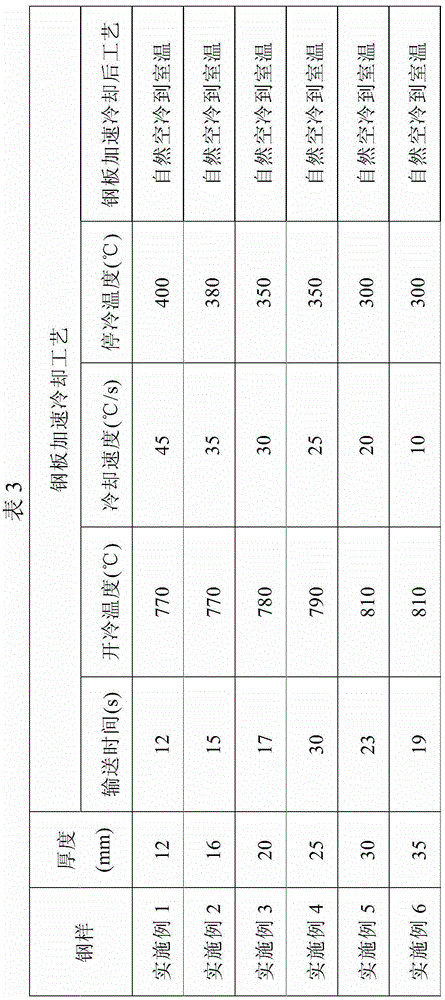

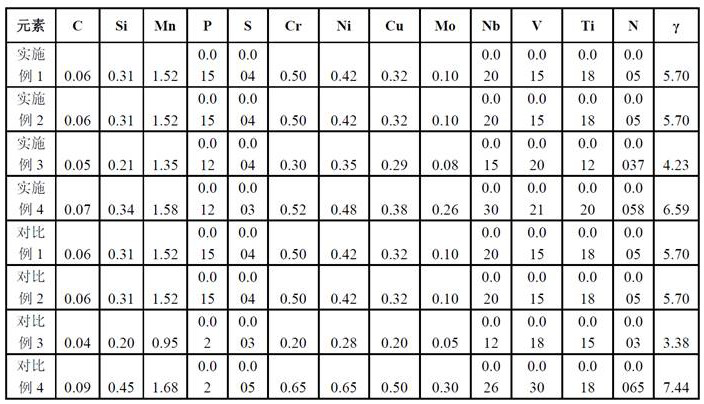

High-toughness and high-weather-resistance steel and manufacturing method thereof

The invention discloses high-toughness and high-weather-resistance steel and a manufacturing method thereof. The high-toughness and high-weather-resistance steel comprises the following components in percentage by weight: 0.035-0.075% of C, no more than 0.30% of Si, 0.40-0.80% of Mn, 0.07-0.11% of P, no more than 0.004% of S, 0.20-0.50% of Cu, 0.10-0.40% of Ni, 0.40-0.70% of Cr, 0.008-0.016% of Ti, 0.010-0.030% of Nb, no more than 0.0050% of N, 0.001%-0. 004% of Ca, and the balance of Fe and unavoidable impurities, wherein by taking a C-Mn-P component system with low C, low Mn and high P as a foundation and through the alloying of Cu, Ni and Cr, [%C] / [%P] is controlled to be not smaller than 0.49, [%Mn] / [%C] is controlled to be not smaller than 10, the weather resistance index DNH is controlled to be not smaller than 6.50%, [%C]*([%P]+2.5[%S]) is controlled to be not more than 0.0025, [%Ca] / [%S] is controlled to be equal to 1.0-3.0, ([%Cu]+0.36[%Ni]+0.27[%Cr])*[%P] is controlled to be not smaller than 0.030, [%Ca]*[%S]0.28 is controlled to be not more than 0.002, and a TMCP (ThermoMechanical Control Process) is adopted. Therefore, the high-toughness and high-weather-resistance steel has excellent low-temperature toughness, bending cold machining characteristic and high weather resistance, and is suitable to be used as a compartment body structure of a coating-free high-speed train.

Owner:BAOSHAN IRON & STEEL CO LTD

Acrylic fiber with excellent appearance and woven pile fabric

InactiveUS20030176563A1Stable Industrial ProductionGood lookingFilament/thread formingMonocomponent synthetic polymer artificial filamentPolymer scienceTransmittance

Acrylic fiber which can be produced industrially at a low cost and has excellent appearance properties that the individual fibers are clearly perceived visually is provided. The object is attained by using an acrylic fiber comprising an acrylic copolymer, which has a light transmittance of 15 to 65% in the fiber width direction and a maximum surface reflectance of 30 to 80% with respect to light incident thereon at an angle of 60 degrees in the fiber length direction, wherein the fiber contains 1.2 to 30 parts by weight of white pigment having a maximum particle size of at most 0.8 mum based on 100 parts by weight of the acrylic copolymer.

Owner:KANEKA CORP

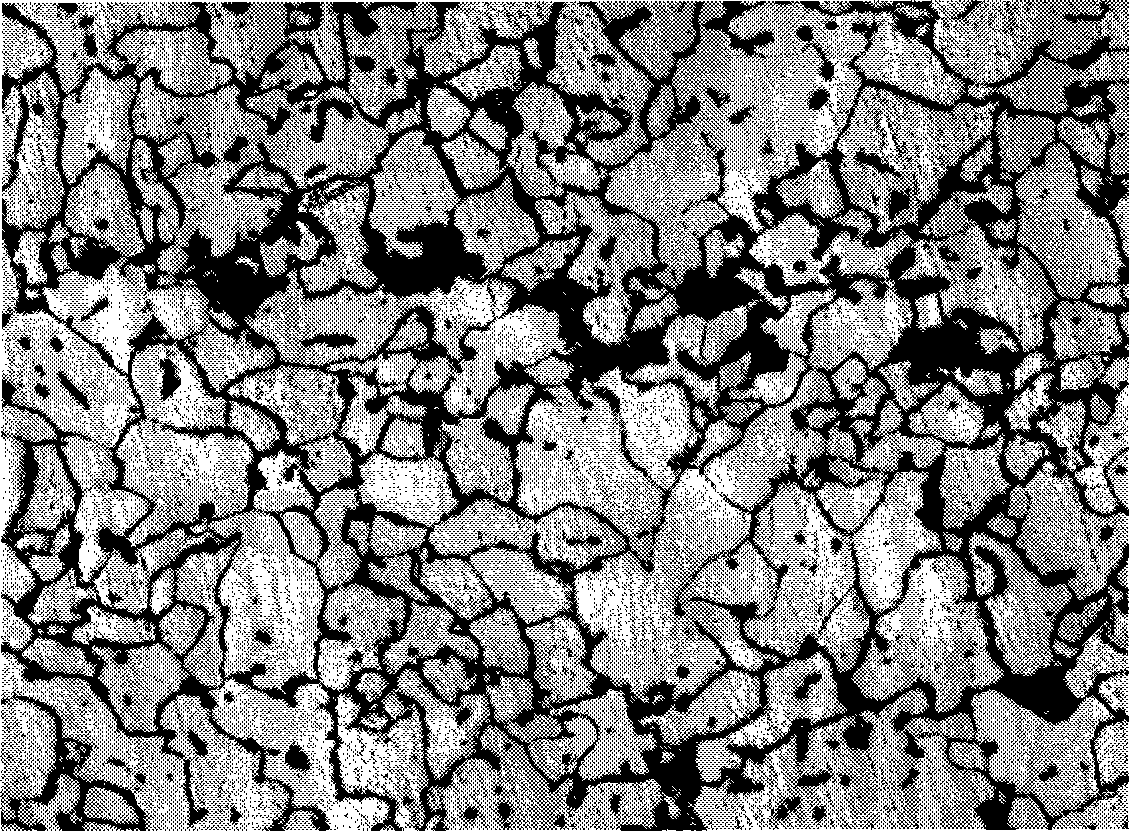

High tempering parameter SR embrittlement resistant cryogenic nickel steel and manufacture method thereof

ActiveCN102691006AExcellent resistance to high tempering parameter SR embrittlement characteristicsIncrease the content of acid-soluble AlsTemperature control deviceToughnessMaterials science

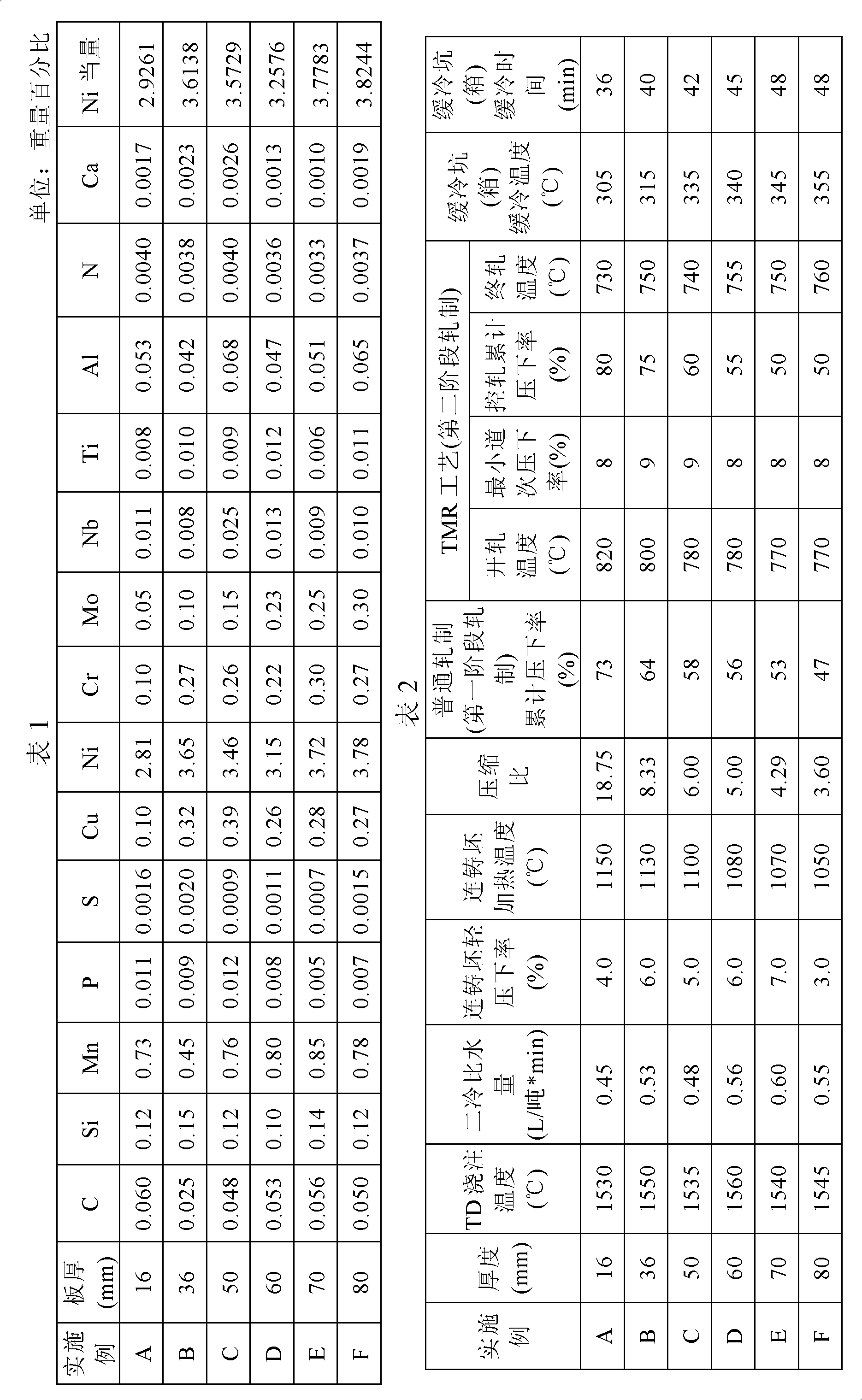

A high tempering parameter SR embrittlement resistant cryogenic nickel steel and a manufacture method thereof. The nickel steel comprises, by weight, 0.025%-0.060% of C, Si no more than 0.15%, 0.45%-0.85% of Mn, P no more than 0.012%, S no more than 0.0020%, 0.10%-0.40% of Cu, 2.80%-3.80% of Ni, 0.10%-0.30% of Cr, 0.05%-0.30% of Mo, 0.040%-0.070% of Als, 0.006%-0.012% of Ti, 0.008%-0.025% of Nb, N no more than 0.0040%, 0.001%-0.003% of Ca, residual iron and unavoidable inclusions. According to optimized controlled rolling and a normalizing plus tempering technology, the nickel steel gains extremely high ultralow temperature toughness, excellent HIC / SCC resistance, weldability and bearing capacity of high heat input welding; besides, the nickel steel has excellent high tempering parameter SR embrittlement resistance characteristic, and is especially suitable for manufacture of large-scale LPG low temperature storage tank, low temperature storage tank for ship and large-scale steel structure for ice ocean and polar region.

Owner:BAOSHAN IRON & STEEL CO LTD

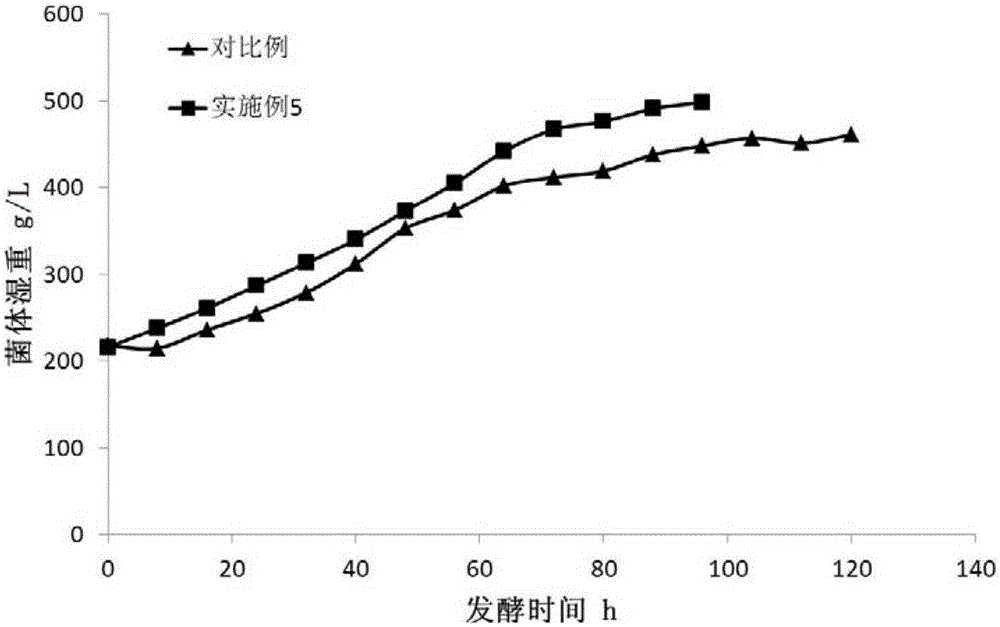

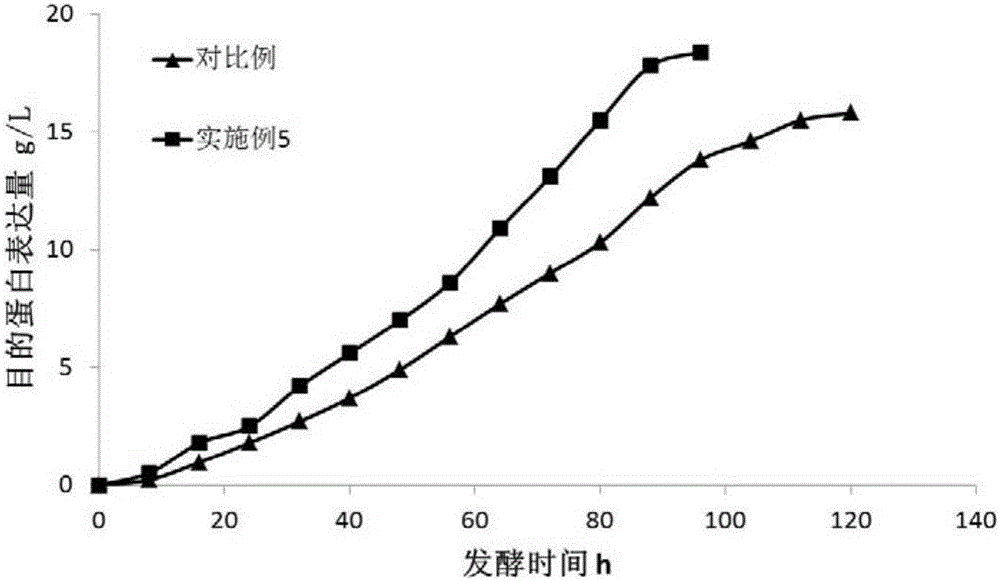

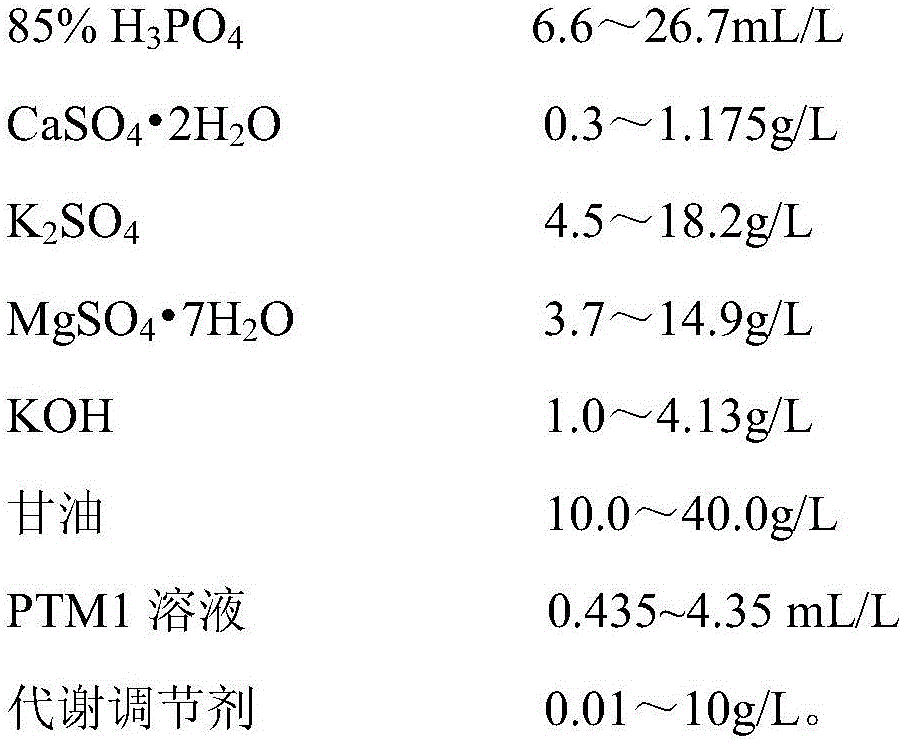

Pichia pastoris fermentation medium for large scale production of recombinant human collagen

ActiveCN106256911AHigh expressionShort induction periodMicroorganismsMicroorganism based processesPichia pastorisCollagen VI

The invention discloses a pichia pastoris fermentation medium for large scale production of recombinant human collagen. 0.01-10g / L of a metabolism conditioning agent is used in the medium so that pichia pastoris metabolism is adjusted, recombinant protein expression is accelerated, a fermentation period is shortened, energy consumption is reduced, an error risk is reduced and stable industrial production is guaranteed. The medium realizes large scale production of recombinant human collagen through 1000L of a fermentation cylinder, shortens a methanol induction period by 20% and improves a recombinant human collagen expression level by 16.5%. The pichia pastoris fermentation medium is especially suitable for a pichia pastoris methanol induction stage of recombinant human collagen industrial high density fermentation expression, effectively reduces a production cost, produces substantial economic benefits and has a very important meaning for industrial production of the recombinant human collagen.

Owner:浙江诸暨聚源生物技术有限公司

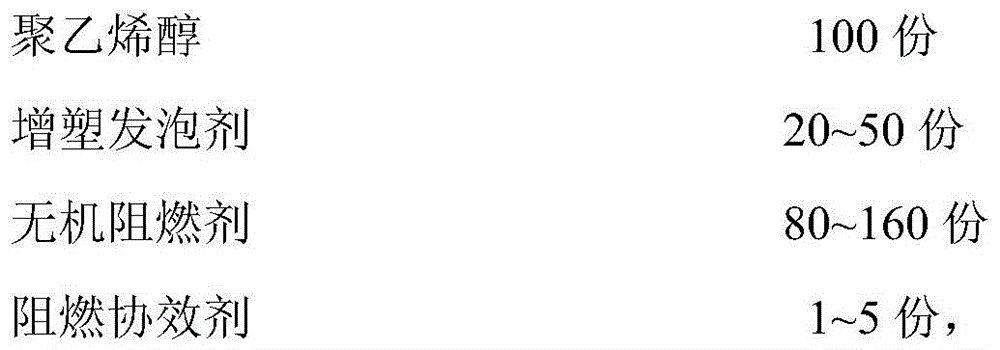

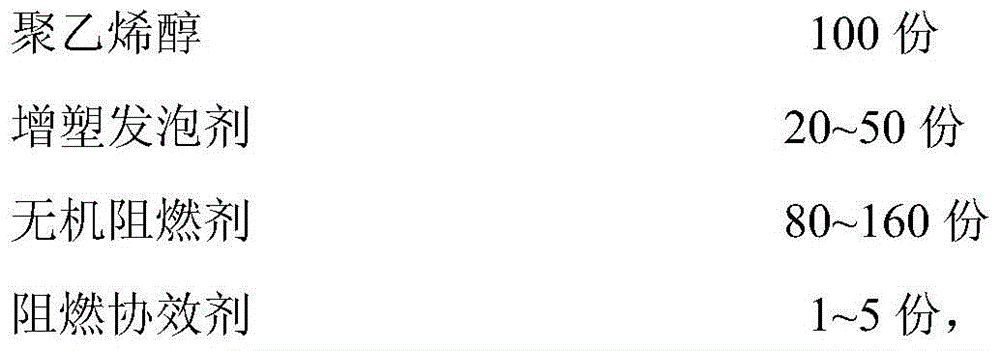

High-fill high-heat-resistance polyvinyl alcohol-based microcellular foam type flame retardant paper and thermoplastic processing method thereof

The invention discloses high-fill high-heat-resistance polyvinyl alcohol-based microcellular foam type flame retardant paper.The microcellular foam type flame retardant paper is prepared through the steps that polyvinyl alcohol and a plasticizing foaming agent are mixed and swelled and then mixed with an inorganic flame retardant and a flame retardant synergist to obtain composite powder; the composite powder is added into a screw extruder for microcellular foam extrusion, cooling traction, flattening and winding are conducted.The vertical burning class is V-0, the limit oxygen index is 35%-41%, the tensile strength is 1.0-4.5 MPa, the apparent density is 0.05-0.50 g / cm<3>, the average cell diameter is 70-200 micrometers, and the thickness is 0.1-2.0 mm.The flame retardant paper is excellent in thermal resistance, can meet the requirement of rapid laser printing, is excellent in comprehensive performance and low in cost and can be prepared by directly adopting a thermoplastic processing method, the technology is simple and easy to operate, and continuous industrialized production can be achieved.

Owner:SICHUAN UNIV

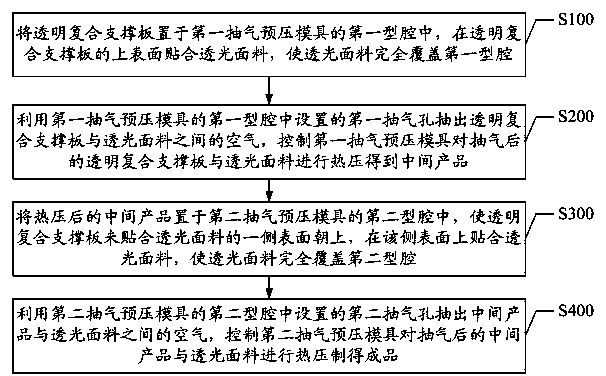

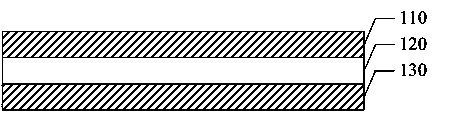

Leather sheath and production method thereof

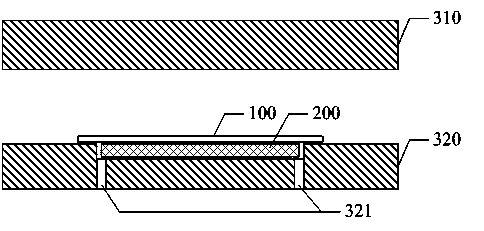

The invention discloses a leather sheath and a production method thereof. The method comprises the following steps: (A) a transparent compound support plate is positioned in a first cavity of a first air extracting prepressing mold; and the upper surface of the transparent compound support plate is bonded with a light transmitting fabric, so that the first cavity is totally covered by the light transmitting fabric; (B) air between the transparent compound support plate and the light transmitting fabric is extracted by using an air extracting hole in the first cavity; and an intermediate product is obtained through hot pressing; (C) the intermediate product, after the hot pressing, is positioned in a second cavity of a second air extracting prepressing mold; the surface of one side, not bonded with the light transmitting fabric, of the transparent compound support plate is upwards; the light transmitting fabric is bonded on the surface of the side; and the second cavity is totally covered; and (D) the air between the intermediate product and the light transmitting fabric is extracted by using an air extracting hole in the second cavity; and a finished product is obtained through hot pressing. The method adopts the special molds to realize an air extracting hot pressing process in the hot pressing process of the leather sheath, so that the problems of difficult air exhaust among layers of the leather sheath and easy generation of bubbles on the fabric in the hot pressing are solved. The method realizes stable industrial production of the leather sheath.

Owner:山东德浦泰管业科技有限公司

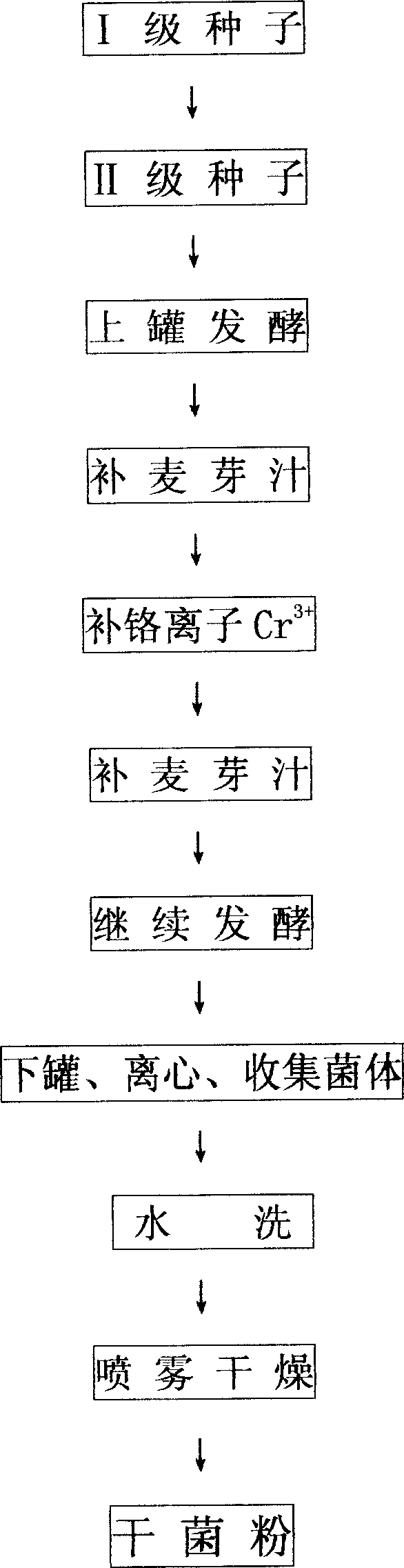

Process for preparing chromium-enriched beer yeast

The preparation process of chromium-rich beer yeast includes two-stage seed culture of the selected beer yeast monocolony; fermenting in a fermentor at pH 5.6-6.0 and 27-29 deg.c for 9-11 hr to OD600 not lower than 9.0; regulating pH to 5.5-5.6, adding trivalent Cr to 0.10-0.15 g / L and adding malt wort in the amount of 30-50 vol% of initial fermented liquid; fermentation until reaching the total fermentation time of 40-50 hr; centrifugally collecting thallus, washing with super-pure water, spray drying to obtain the dry beer yeast powder with bioactive chromium content of 222-318 microgram / g. The said preparation process has high beer yeast GTF content and is simple and practical.

Owner:HUNAN WEIHENG BIOTECH

Steel used at lower temperature and method for manufacturing same

ActiveCN101545077BIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsCompound (substance)Toughness

Owner:BAOSHAN IRON & STEEL CO LTD

Porous micro-fine denier nylon 6 POY filament yarns and preparation method thereof

InactiveCN104562275AFiber performance is stableImprove performanceSpinnerette packsFilament forming substance formingBreaking strengthPolymer science

The invention relates to the technical field of synthetic fibers, provides porous micro-fine denier nylon 6 POY filament yarns and a preparation method thereof, and aims at solving the problems that an existing differential micro-fine denier nylon 6 fiber production process is complicated, the cost is high and the fibers are not easy to stretch and deform. The porous micro-fine denier nylon 6 POY filament yarns have the characteristics that the filament number is 0.11dtex-0.55dtex, the elongation at break is 60%-90%, the breaking strength is 3.3cN / dtex-4.4cN / dtex, the oil content is 0.7%-1.2% and the full coiling rate of the fibers is 90.0%-98%. The production of the micro-fine denier nylon 6 POY filament yarns can be easily realized by conventional high-speed spinning equipment and the spun porous micro-fine denier nylon 6 POY filament yarns have stable performances and the relatively high strength and elongation; the texturing requirements can be met and the fibers are easy to dye; and the production cost is greatly reduced and the wide popularization and application are facilitated.

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of high toughness, high weather resistance steel and its manufacturing method

The invention discloses high-toughness and high-weather-resistance steel and a manufacturing method thereof. The high-toughness and high-weather-resistance steel comprises the following components in percentage by weight: 0.035-0.075% of C, no more than 0.30% of Si, 0.40-0.80% of Mn, 0.07-0.11% of P, no more than 0.004% of S, 0.20-0.50% of Cu, 0.10-0.40% of Ni, 0.40-0.70% of Cr, 0.008-0.016% of Ti, 0.010-0.030% of Nb, no more than 0.0050% of N, 0.001%-0. 004% of Ca, and the balance of Fe and unavoidable impurities, wherein by taking a C-Mn-P component system with low C, low Mn and high P as a foundation and through the alloying of Cu, Ni and Cr, [%C] / [%P] is controlled to be not smaller than 0.49, [%Mn] / [%C] is controlled to be not smaller than 10, the weather resistance index DNH is controlled to be not smaller than 6.50%, [%C]*([%P]+2.5[%S]) is controlled to be not more than 0.0025, [%Ca] / [%S] is controlled to be equal to 1.0-3.0, ([%Cu]+0.36[%Ni]+0.27[%Cr])*[%P] is controlled to be not smaller than 0.030, [%Ca]*[%S]0.28 is controlled to be not more than 0.002, and a TMCP (ThermoMechanical Control Process) is adopted. Therefore, the high-toughness and high-weather-resistance steel has excellent low-temperature toughness, bending cold machining characteristic and high weather resistance, and is suitable to be used as a compartment body structure of a coating-free high-speed train.

Owner:BAOSHAN IRON & STEEL CO LTD

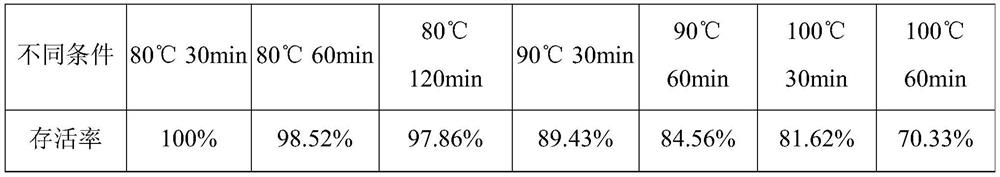

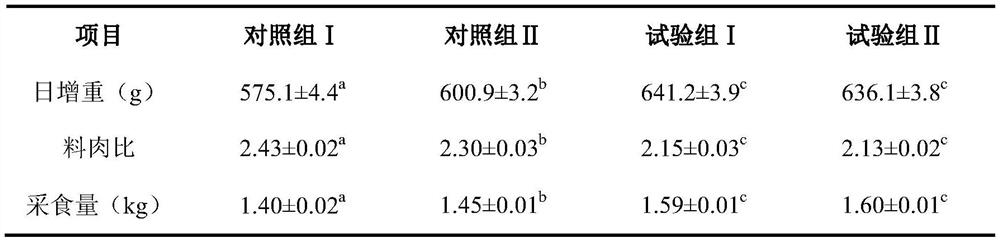

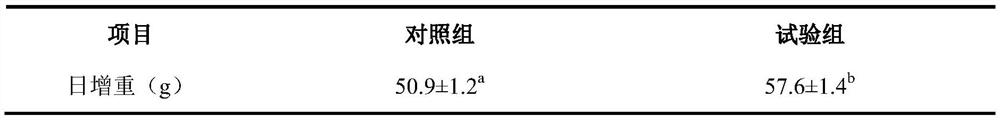

Bacillus coagulans and application thereof

ActiveCN113549574AGrowth inhibitionExcellent high temperature resistanceBacteriaFood processingAquaculture industryMicroorganism

The invention discloses bacillus coagulans and application thereof, and belongs to the technical field of microorganisms. The strain has various excellent characteristics of high temperature resistance, cholate resistance, acid resistance, good storage stability, rich lactic acid production and enzyme production, capability of degrading nitrite, inhibiting growth of pathogenic bacteria, capability of degrading various mycotoxins and the like. The Bacillus coagulans CGMCC No.21621 is wide in application range, and can be applied to the industries of animal husbandry, aquaculture industry, food, medicine, feed and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

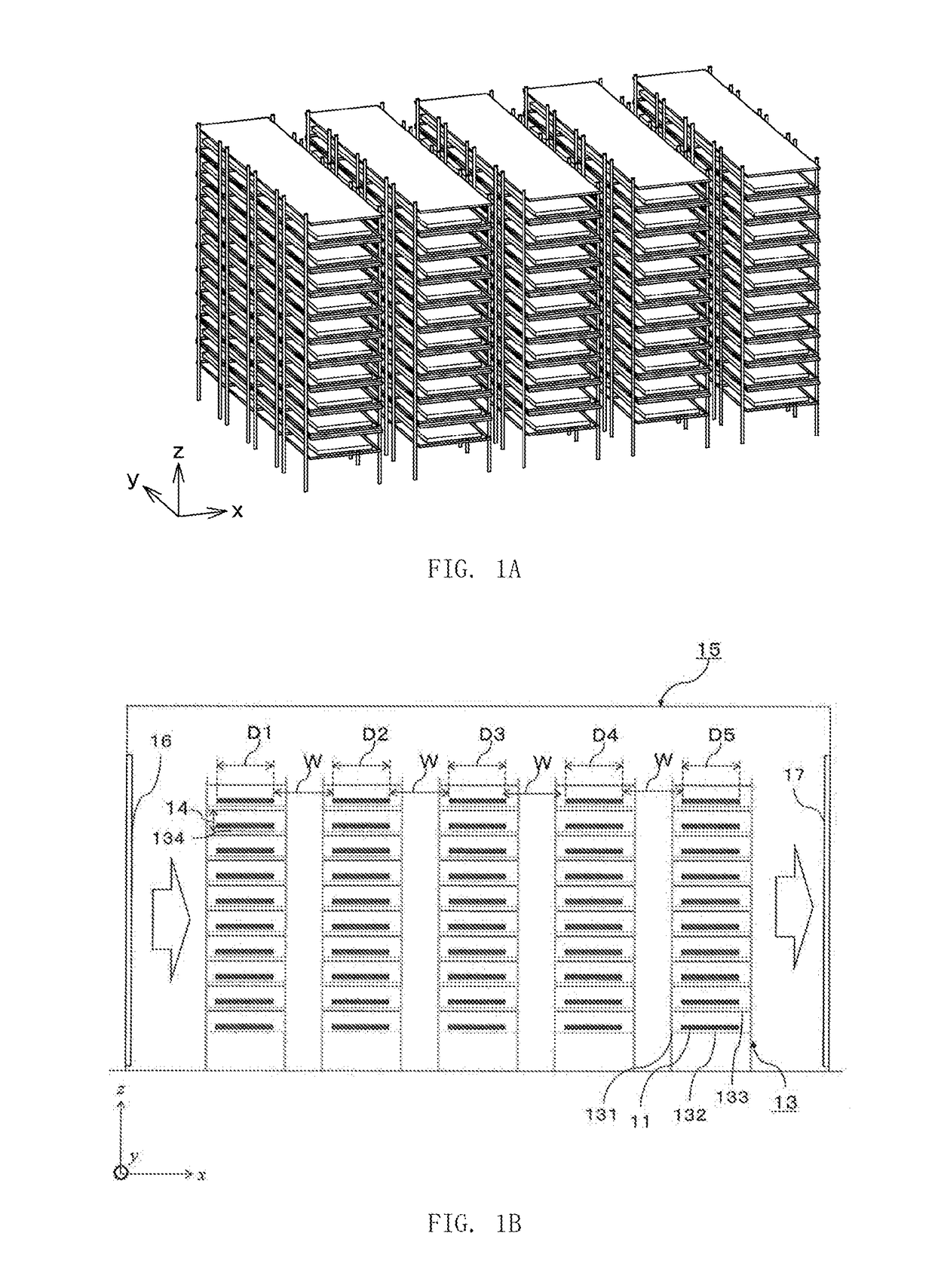

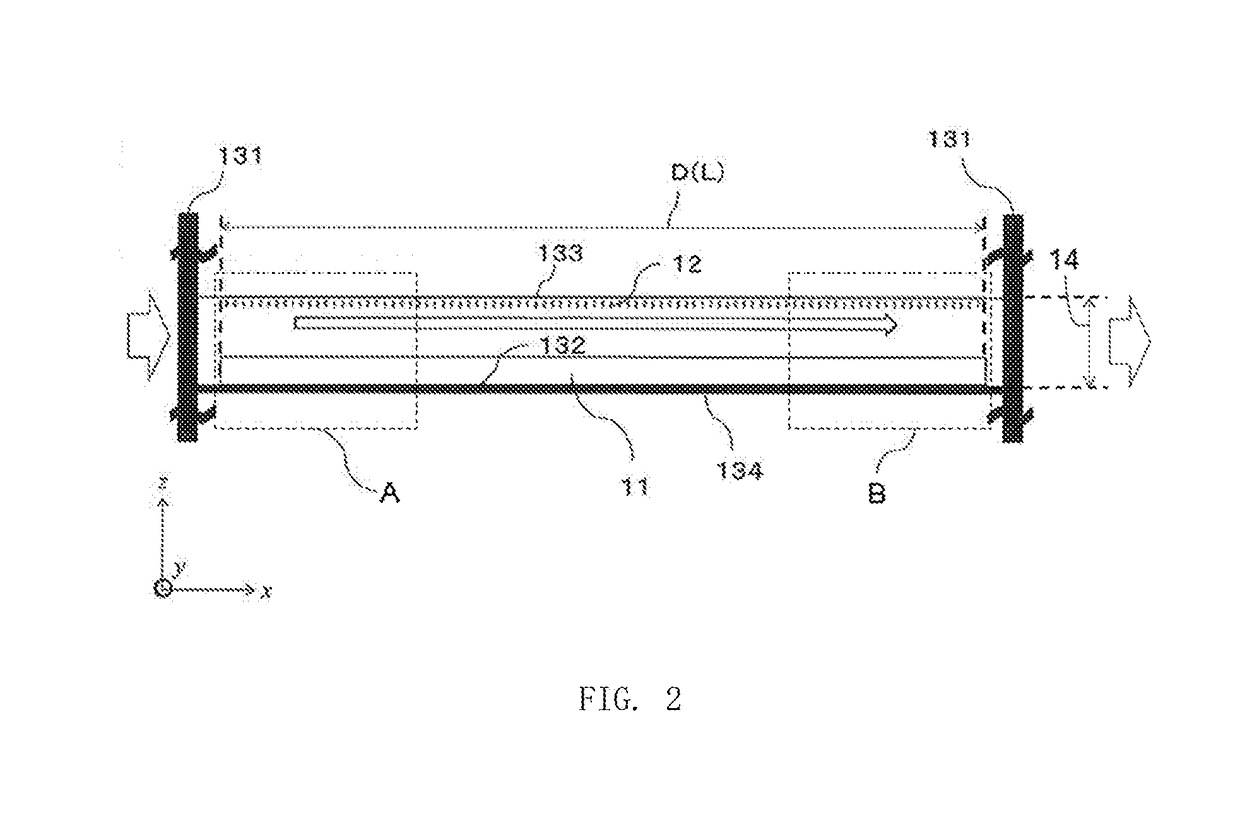

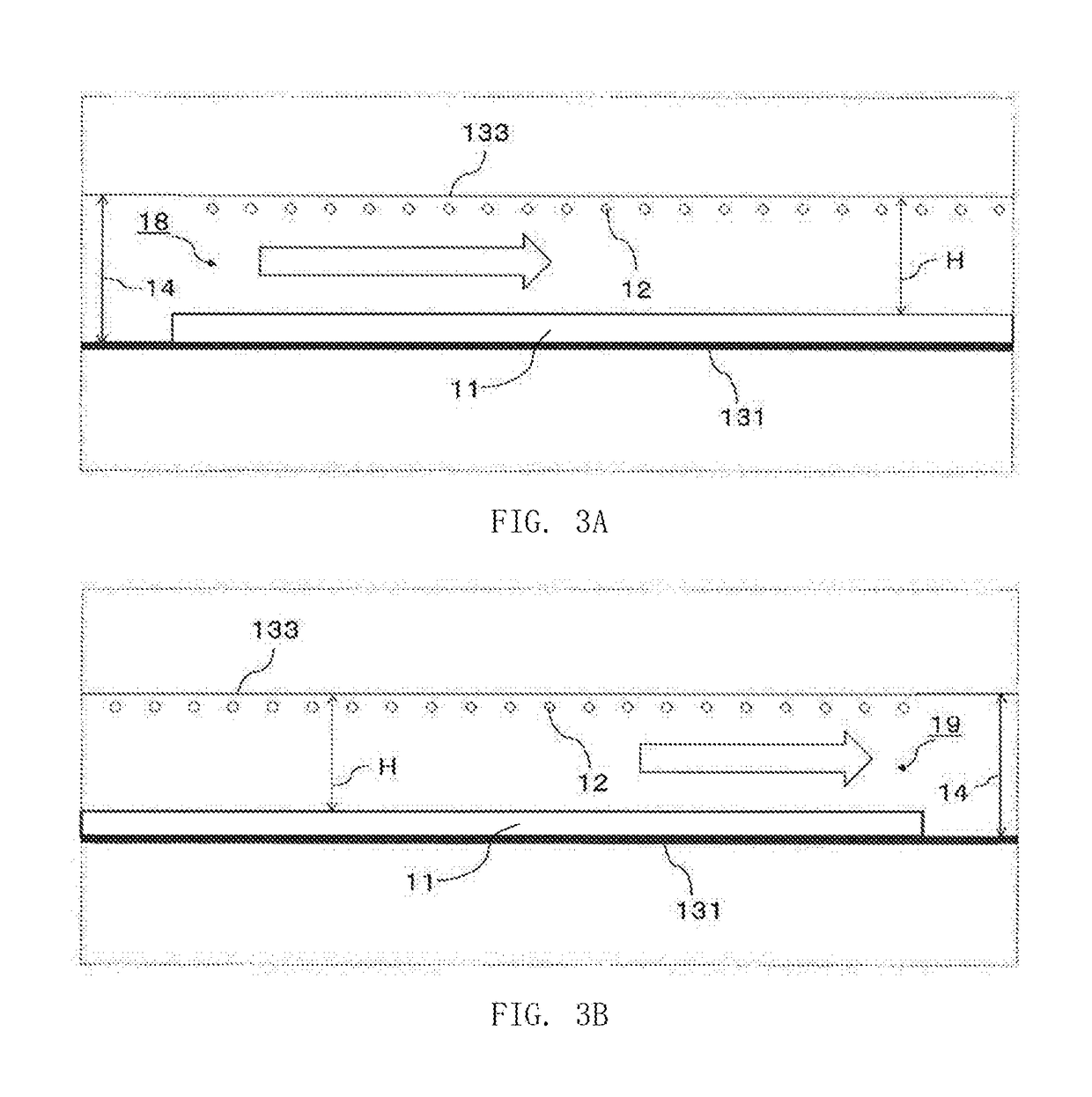

Cultivation shelf and plant cultivation facility

InactiveUS20190029189A1Stable industrial productionQuality improvementClimate change adaptationAgriculture gas emission reductionPlant cultivationMechanical engineering

Provided is a plant cultivation facility capable of keeping the temperature around plants in the optimum cultivation range. Provided is a plant cultivation facility comprising a cultivation shelf and an air conditioner in a chamber having a floor, side walls, and a ceiling, wherein an air blow part of the air conditioner is disposed on a side wall of the chamber, and wherein a suction part is disposed on a side wall surface opposed to said side wall surface; the plant cultivation shelf including: a holding container, a lighting device, and a support structure including a plurality of stages which are arranged in heightwise direction and each include, a supporting surface and a ceiling surface; wherein ΔT, obtained according to a particular mathematical equation (1) using an effective shelf-to-shelf height (H) and an effective shelf width (D), is 10° C. or less.

Owner:MITSUBISHI CHEM CORP

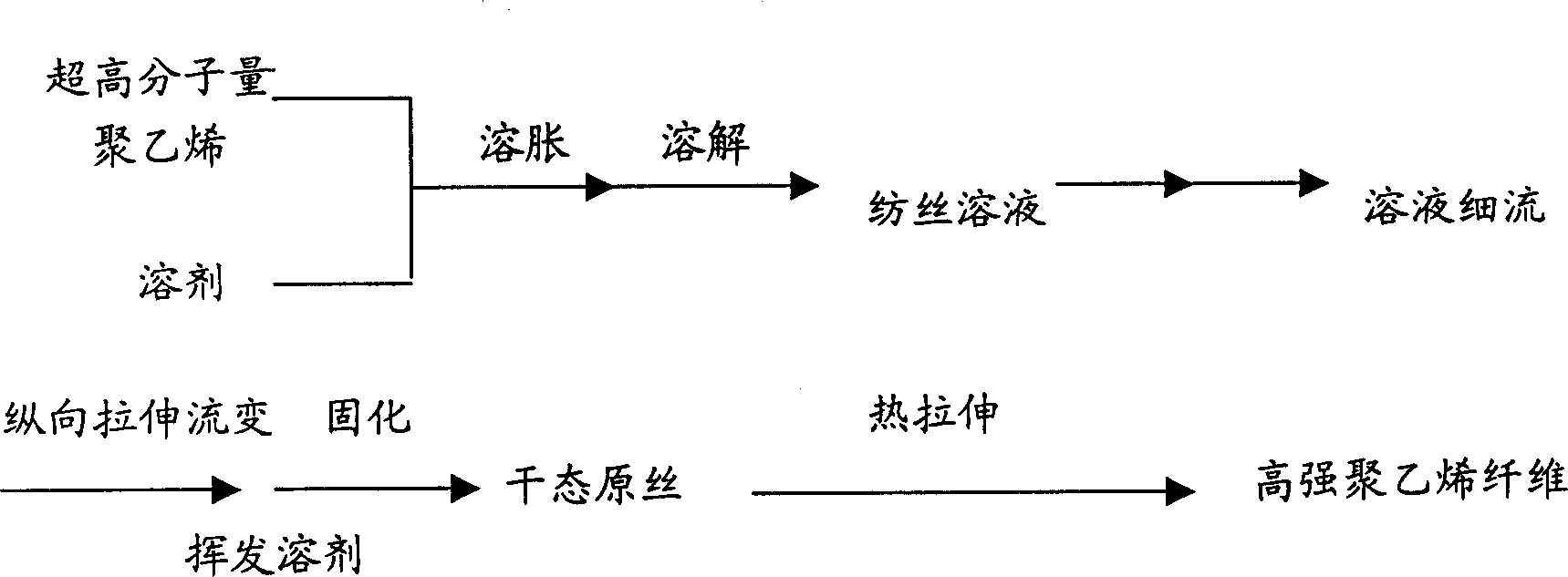

Manufacturing method of high strength polyethylene fiber

InactiveCN1300395CImprove mechanical propertiesShort processDry spinning methodsMonocomponent polyolefin artificial filamentFiberBreaking strength

A high-strength polyethene fibre with high breaking strength (15-45 g / d) and modulus (500-1500 g / d) is prepared from ultrahigh-molecular polyethene solution through dry spinning by spinneret, longitudinally drafting and solidifying.

Owner:CHINA PETROLEUM & CHEM CORP +1

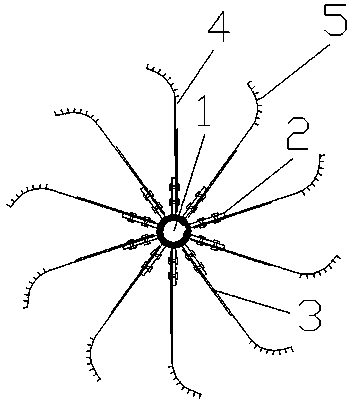

Label removing knife for polyester bottle label removing machine

ActiveCN103586239AWon't hurtSolve the problem of high wear and noiseHollow article cleaningPolyesterMechanical stability

The invention provides a label removing knife for a polyester bottle label removing machine, belongs to the technical field of polyester bottle label removing, and particularly relates to a knife structure for removing polyester bottle labels. The label removing knife comprises a rotating shaft, an extension part and a blade body. The direction of the extension part is consistent with the radius direction of the rotating shaft and the extension part extends outwards, and the blade body is connected with the extension part and composed of a rigid part and an elastic part. The rigid part is connected with the extension part, the elastic part is of a curved shape in the rotating plane of the rotating shaft, and a knife edge part is distributed on the elastic part. The label removing knife is applied to the polyester bottle label removing machine, a traditional chain mode is completely eradicated, the problems that a chain is large in abrasion and high in noise are solved, the label removing knife is suitable for high speed rotation, the label removing effect is improved, and mechanical stability of whole equipment is improved.

Owner:HUNAN CHANGZHONG MACHINERY

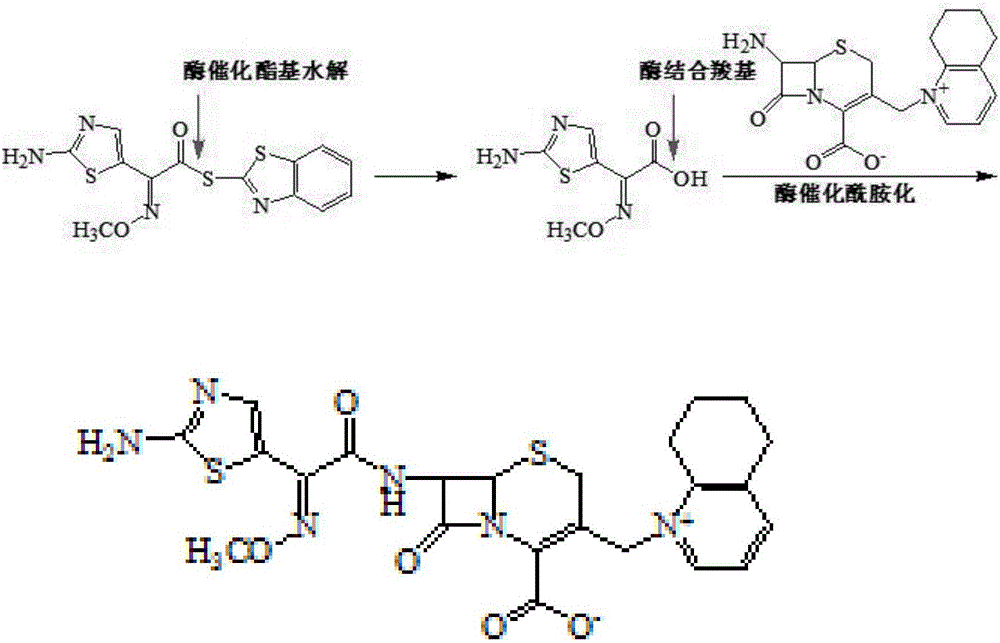

Enzymatic technology for compounding cefquinome sulfate

InactiveCN106350566ALess side effectsReduce red tapeOrganic chemistryOn/in organic carrierSolventChemistry

The invention relates to an enzymatic technology for compounding an antibiotic bulk drug-cefquinome sulfate special for animals. The enzymatic technology comprises the following steps: enabling an AE (Active Ester) to react with 7-amino cefquinome under a catalytic action of enzyme, thus generating cefquinome; filtering and separating a mother solution containing the cefquinome by using a screen; salifying and crystallizing, thus obtaining the cefquinome sulfate. The enzymatic technology disclosed by the invention adopts an enzymatic method to compound the cefquinome sulfate. Compared with an existing chemical technology, firstly, in aspect of catalytic synthesis, the selectivity of the enzyme is higher, side effects are less, generated impurities are relatively less, and the product quality is high; secondly, the enzymatic technology uses water as a reaction solvent, low-toxicity reagents are used in a technological process, the generation of waste is particularly reduced, and the enzymatic technology has obvious advantages in environment protection and is beneficial for environment protection; in addition, the enzymatic technology has the characteristics of strong parameter controllability, moderate reaction conditions, stable product quality and the like; since the enzyme can be recycled, the cost of the enzymatic technology is obviously lower than that of the chemical method, and the enzymatic technology is suitable for promotion and industrial production.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

Aluminium-vanadium-carbon interalloy and preparation method thereof

InactiveCN101570834ALittle impact on preparationNo defects such as inclusionsSmelting processTitanium

The invention relates to an aluminium-vanadium-carbon interalloy and a preparation method thereof. On the basis of producing an aluminium-vanadium interalloy in the prior aluminothermic method of reducing, the prior equipment and smelting process are utilized, and the good-quality aluminium-vanadium-carbon interalloy can be produced by only adding a certain amount of carbon powder. Through detection, the interalloy has uniform compositions without defects such as inclusions and the like, is added into a titanium ingot to make carbon element added in a carbon-containing interalloy mode, eliminates the quality hidden troubles of pollution and inclusions caused by directly using the carbon powder in a titanium ingot primary smelting process, can effectively improve the uniformity and accurate control of the carbon element in a titanium material, and solves the problems of addition and uniformity of the carbon element; and the produced titanium ingot has even distribution of the carbon element, has no metallurgical defects such as the inclusions and the like, and can meet the quality requirement on a high-quality titanium material in the fields such as aerospace and the like. The preparation method has the obvious advantages of simple process, simple and convenient operation, low cost, accurate composition control, stability and the like, and is suitable for industrial production.

Owner:BAOJI TITANIUM IND CO LTD

High-flux thick polytetrafluoroethylene film and preparation method thereof

ActiveCN105983352ASoften the bond fullyStable industrial productionSemi-permeable membranesPorosityComposite film

The invention discloses a high-flux thick polytetrafluoroethylene film and a preparation method thereof. The method comprises the following steps that 1, a plurality of single-layer polytetrafluoroethylene films are aligned and overlapped to form an overlapped multilayer film; 2, the overlapped multilayer film is fed into a hot air bonding device through a feeding roll, and I-time bonding treatment is carried out through hot airflow I so that the upper surface of the overlapped multilayer film can absorb heat to be softened and be bonded with the polytetrafluoroethylene film on the lower layer; 3, tension is adjusted; 4, II-time hot air bonding treatment is carried out through hot airflow II so that the lower surface of the multilayer composite film can absorb heat to be softened and be bonded with the adjacently-bonded polytetrafluoroethylene film; 5, the tension is adjusted; 6, winding output is carried out. The high-flux thick polytetrafluoroethylene film is high in porosity and good in gas permeability and covers non-woven filter felt to be manufactured into a filter material, the filter efficiency on fine particles in high-temperature flue gas is high, and the service life of a high-temperature filter material can be prolonged.

Owner:上海灵氟隆新材料科技有限公司 +1

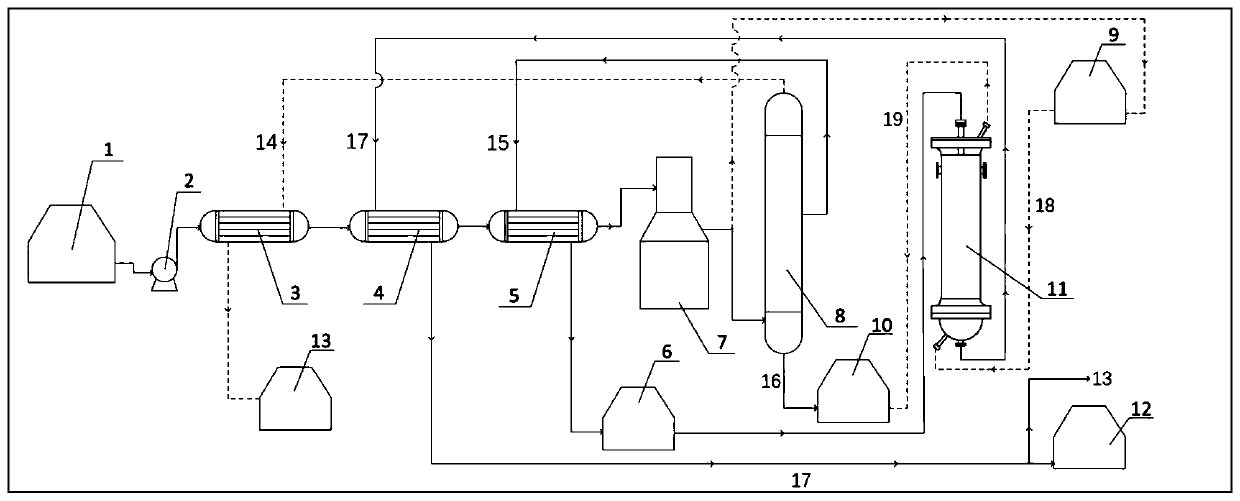

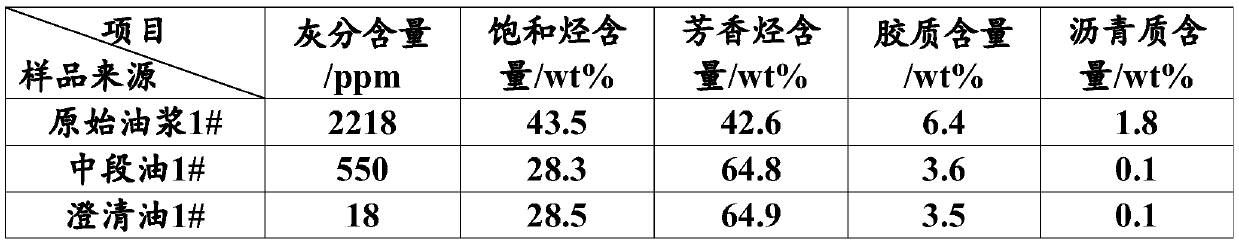

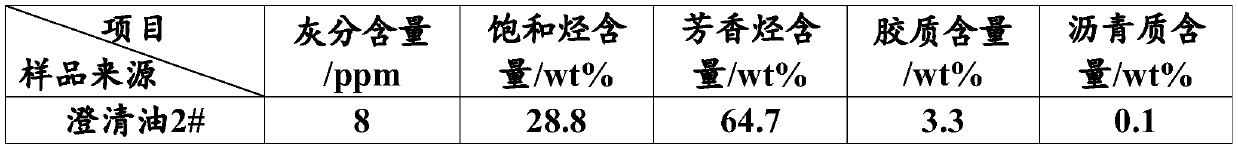

Method and system for producing needle coke raw material oil by performing reduced pressure distillation on catalytic slurry oil to remove aromatic hydrocarbon oil solids

InactiveCN111303939AImprove qualityHigh desolidification efficiencyTreatment with plural serial refining stagesProcess engineeringSlurry

The invention provides a method and a system for producing needle coke raw material oil by performing reduced pressure distillation on catalytic slurry oil to remove solid from aromatic hydrocarbon oil. According to the invention, aromatic hydrocarbon-rich oil with high economic value is obtained by comprehensively utilizing catalytic slurry oil, and the problem that the solid ash content of needle coke raw material oil prepared from the slurry oil is limited to be too high is solved by an efficient solid removal means; the traditional oil slurry comprehensive utilization method is difficult to achieve stable industrial production and low in solid removal efficiency, the ash content of the treated oil slurry can only be reduced to 300 ppm to 500 ppm, and the requirement for high-added-value application of the oil slurry cannot be met; the method of the invention is different from the traditional oil slurry comprehensive utilization method, adopts an efficient oil slurry solid removal technical means, and substantially improves the quality of the aromatic hydrocarbon-rich oil serving as the needle coke raw material oil; and the ash content of the oil slurry treated by the method disclosed by the invention can be reduced to be below 100 ppm, even below 10 ppm, which is far higher than that of the traditional comprehensive utilization method of the oil slurry, so that the processof converting the catalytic oil slurry which is difficult to treat and low in economic additional value into needle coke raw material oil with high additional value is realized.

Owner:武汉兰兆科技有限公司

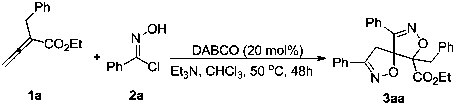

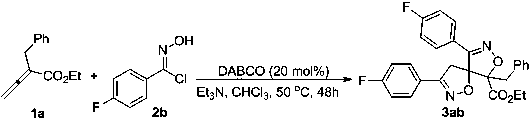

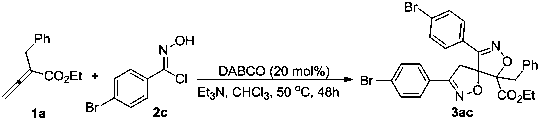

Synthetic method for spiro-cycle isoxazoline compound

InactiveCN107778320AWide variety of sourcesImprove performanceOrganic chemistryNatural productSolvent

The invention discloses a synthetic method for a spiro-cycle isoxazoline compound. The method comprises the following steps: in a reaction solvent, using allenoate and chlorinated aldehyde oxime as reaction raw materials, using Lewis base as a catalyst, and reacting to obtain the spiro-cycle isoxazoline compound. The method has the characteristics of mild reaction condition, easy acquirement and favorable prices of the raw materials, simple reaction operation and higher productive rate, is capable of providing a key skeleton structure for the synthesis of a number of natural products and medicines, and can be extensively applied to the industrial-scale production.

Owner:QINGDAO UNIV

Large-scale vegetative propagation production method of epipremnum pinnata seedling

ActiveCN103749294AStable genetic traitsIncrease acquisition ratePlant tissue cultureHorticulture methodsInsect pestBud

The invention discloses a large-scale vegetative propagation production method of an epipremnum pinnata seedling. The method is achieved by five steps: cultivation of a mother plant, pretreatment and explant collection, sterile material obtaining, domestication and subculture propagation of the sterile material, strong seedling root cultivation, and greenhouse planting. The perennial epipremnum pinnata which is excellent, healthy, and free of plant diseases and insect pests and has female characters is taken as a breeder's seed; the mother plant is cultivated by a cutting seedling obtained from the breeder's seed in a planting manner; a culture medium subjected to inducing, propagation expanding, cultivation and rooting is optimized and improved; rough buds of which the bud roughness is greater than 2.5mm are cut according to 2-4 buds in a cluster when transgenerational clumps are cut; small buds of which the bud roughness is smaller than or equal to 2.5mm are cut by the clumps of 8-10mm; the culture conditions of tissue culture seedlings at each stage are optimized; stable growth in cultivation can be ensured. By adopting the method disclosed by the invention, a great quantity of high-quality nursery-grown plants can be obtained within a short period of time.

Owner:SUNSHINE HORTICULTURE

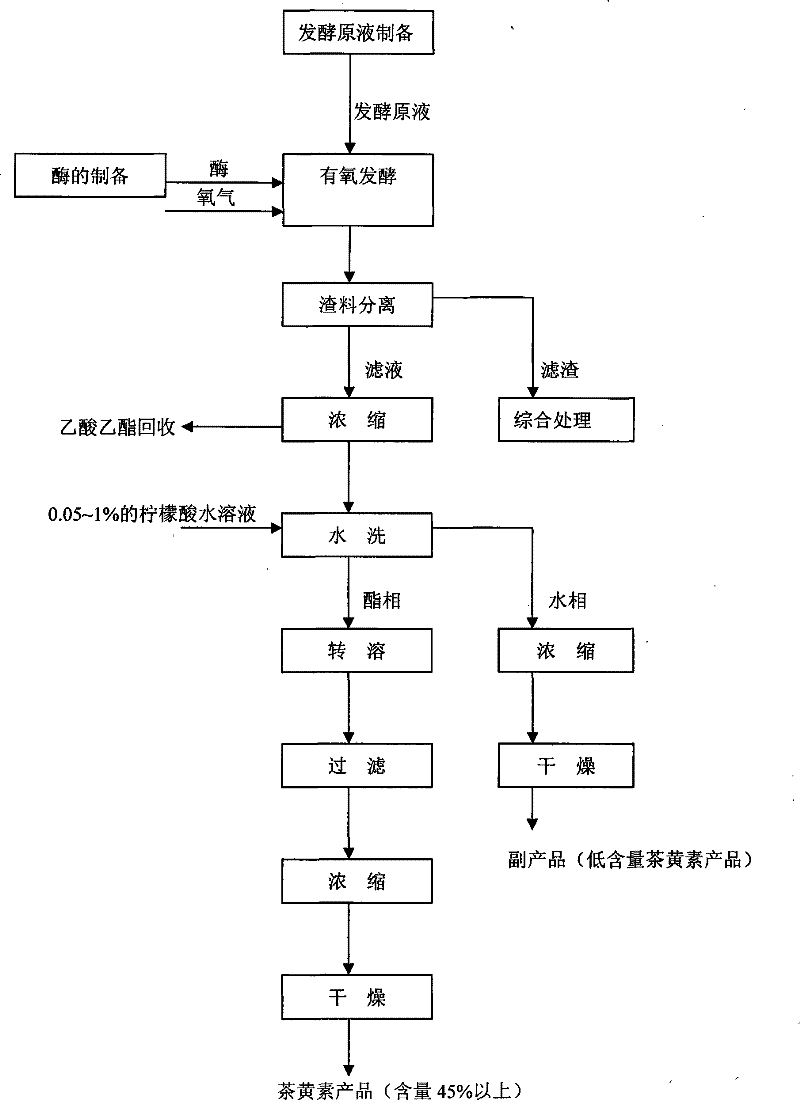

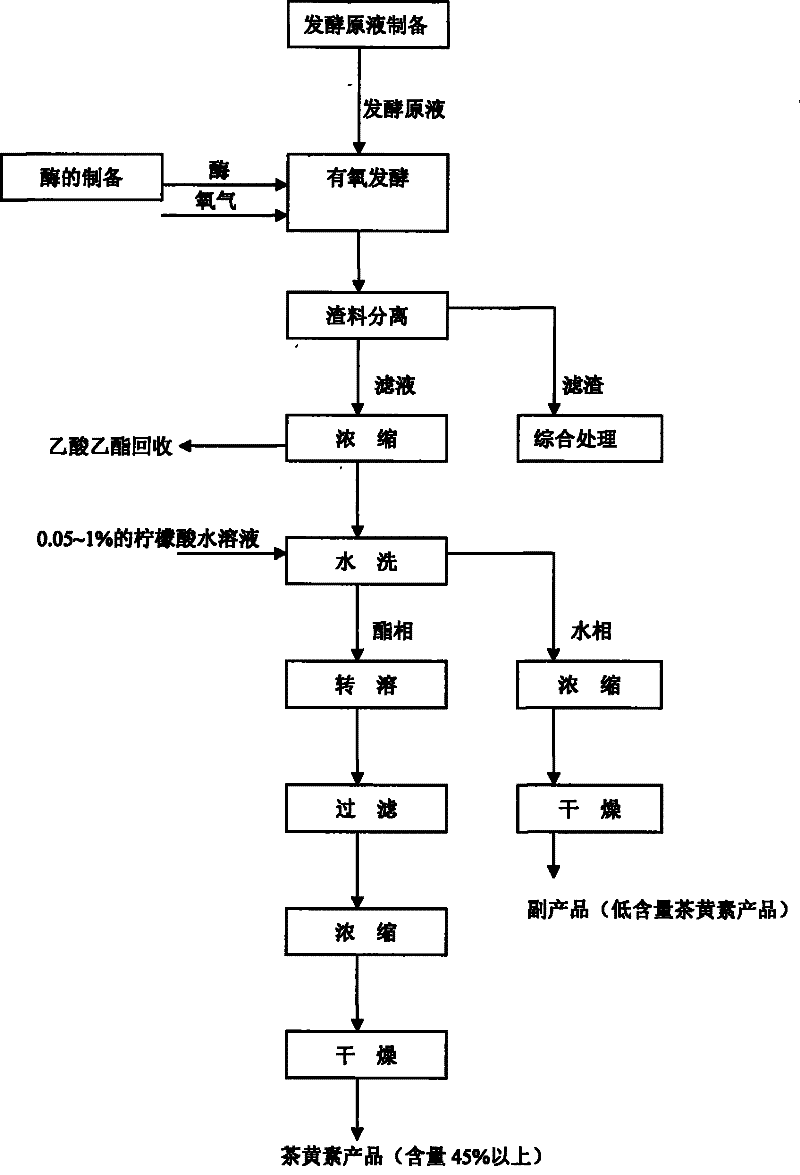

New process for preparing theaflavine

The invention provides a new process for using the enzyme owned by tea to converting tea polyphenol in the tea into theaflavin through biotransformation. The preparation process is as follows: adding fermenting enzyme made from fresh tea into green tea extracted by ethyl acetate, carrying out stirring and fermentation under the condition of pure oxygen, then going through separation, concentration, washing, conversion dissolving and filtration, and at last carrying out vacuum freeze drying, crushing and screening to obtain qualified theaflavin product. The theaflavin product made through the process has a stable quality, high theaflavin content, high yield and low cost. In addition, the method adopts pure ester phase oxidative fermentation, thereby solving the problem that the three phases are incapable of being separated after the traditional ester, water and refuse mixed-phase fermentation, and consequently carrying out stable and controllable industrialized production.

Owner:JIANGSU DEHE BIOTECH

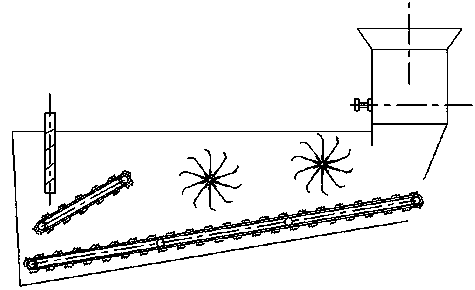

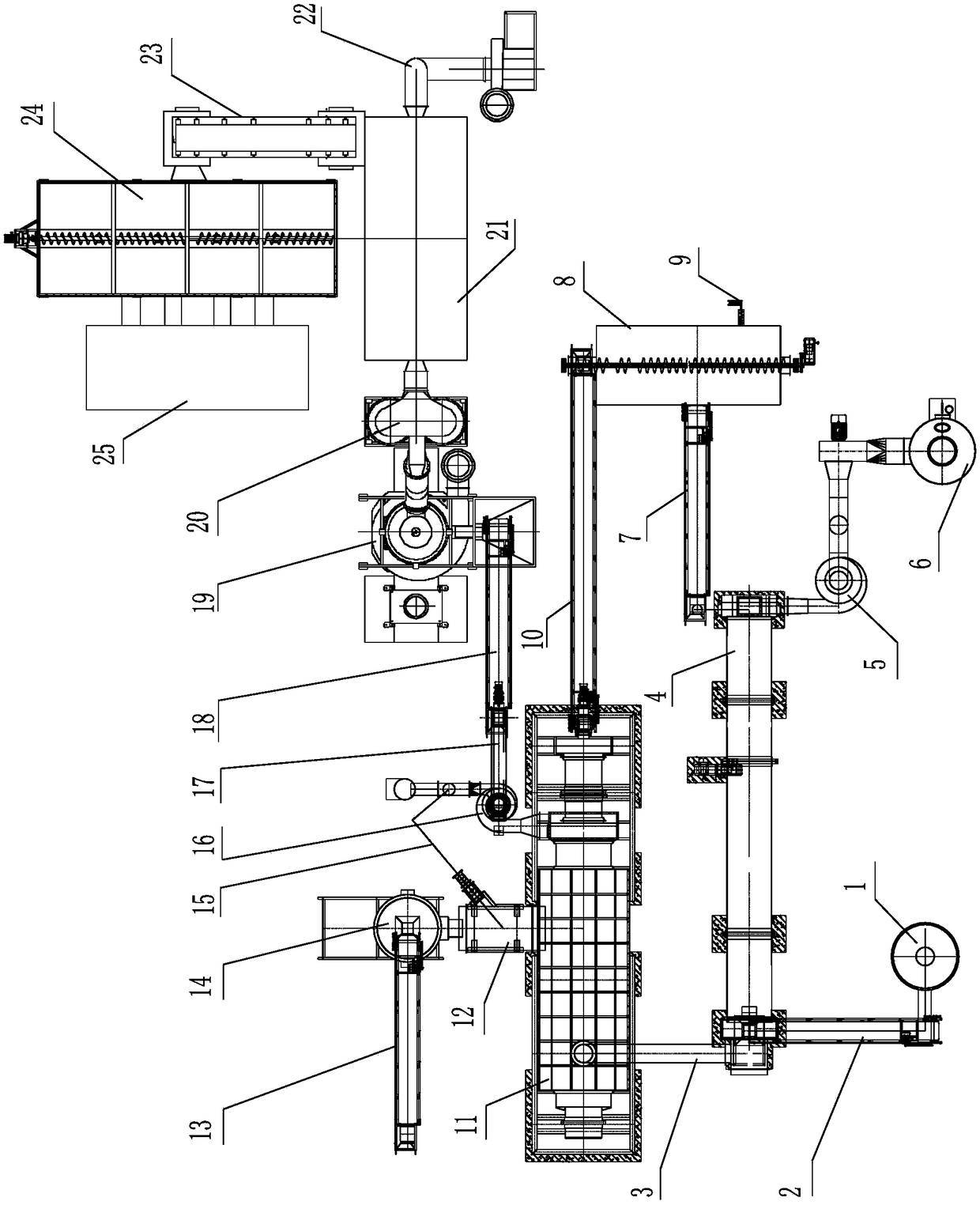

Biomass solid gas preparation system

PendingCN109266372ANot easy to cokeStable productionCombination devicesBiofuelsScrew conveyorBiomass

The invention relates to a biomass solid gas preparation system. The biomass solid gas preparation system is characterized by comprising a drying furnace, a first screw conveyor, a mixing device, a second screw conveyor, a biomass solid gas carbonization system, a conveying device and a mill. A discharging port of the drying furnace is connected with a feeding port of the mixing device through thefirst screw conveyor, and an air outlet of the drying furnace is communicated with an inlet of a first dedusting system; the mixing device is provided with an additive adding port, and a dischargingport of the mixing device is connected with a feeding port of a pyrolysis device of the biomass solid gas carbonization system through the second screw conveyor. The biomass solid gas carbonization system includes the pyrolysis device, a burner, a cracking gas pipe, a liquid gas separator, a waste heat pipe, and a cracking gas collection hood. A discharging port of the pyrolysis device is connected with a feeding port of the mill through the conveying device. The system has the advantages of low energy consumption and low emissions.

Owner:阔阳(湖北)环保节能科技有限公司

Ultra-low cost and SR brittle resisting low-temperature nickel steel plate and manufacturing method thereof

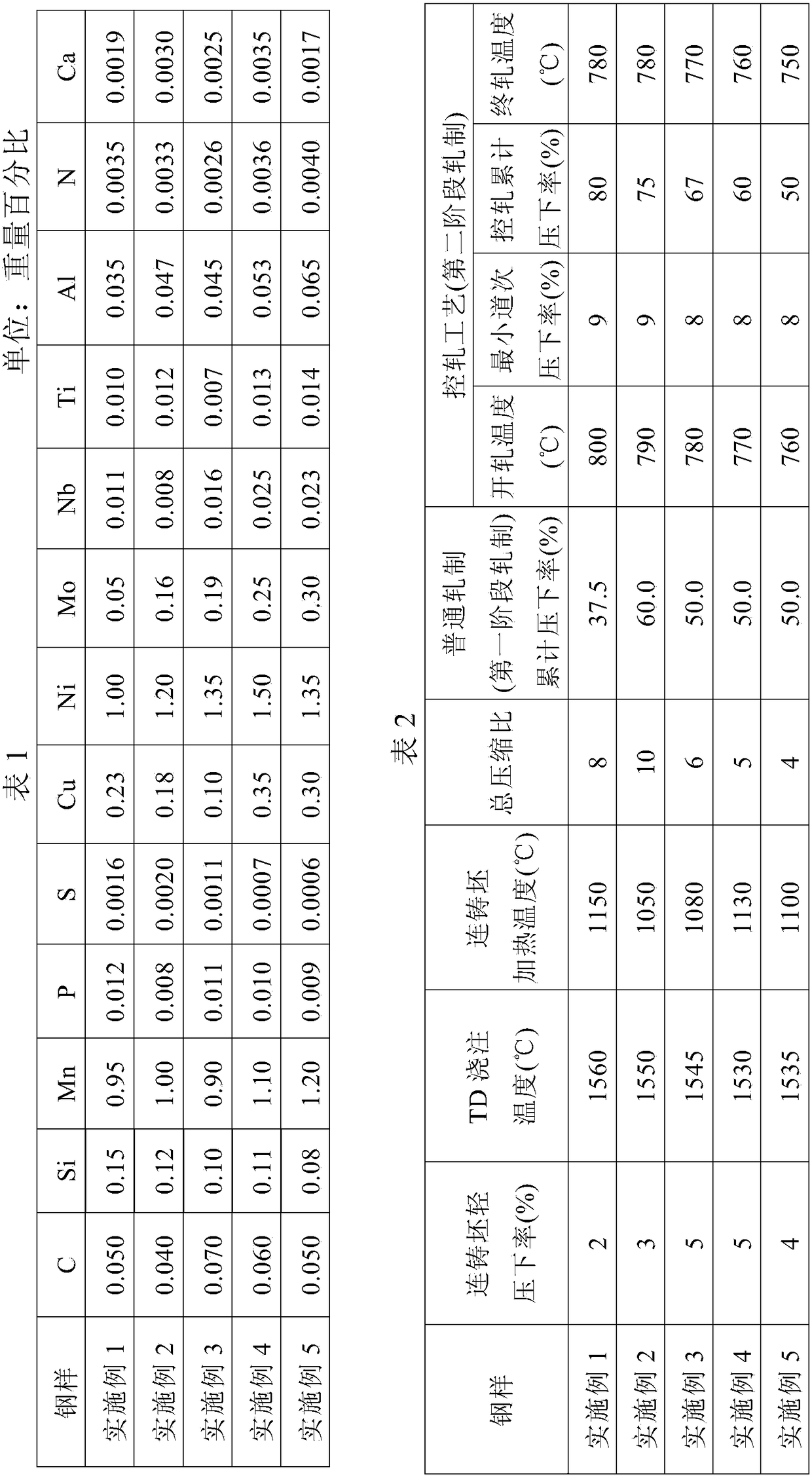

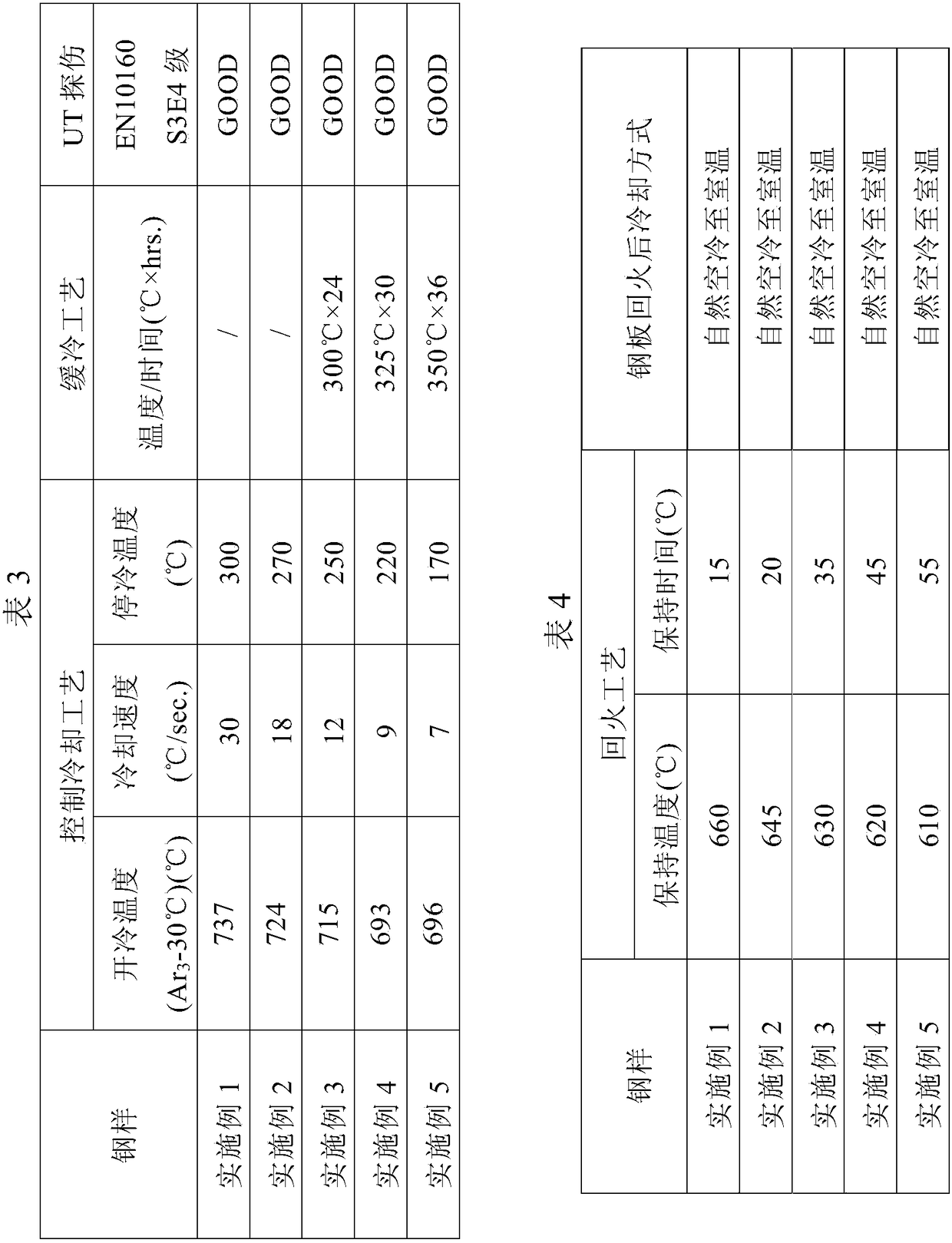

The invention discloses an ultra-low cost and SR brittle resisting low-temperature nickel steel plate and a manufacturing method thereof. The ultra-low cost and SR brittle resisting low-temperature nickel steel plate is prepared from the following components in percentage by weight: 0.040-0.070% of C, no more than 0.15% of Si, 0.90-1.20% of Mn, no more than 0.012% of P, no more than 0.0020% of S,0.10-0.35% of Cu, 1.00-1.50% of Ni, 0.05-0.30% of Mo, 0.040-0.070% of Als, 0.007-0.014% of Ti, 0.008-0.025% of Nb, no more than 0.0040% of N, 0.0010-0.0035% of Ca, and the balance of Fe and unavoidable impurities. Under the condition of postwelding heat treatment, the yield strength of the steel plate is greater than or equal to 420 MPa, the tensile strength of the steel plate is greater than or equal to 530 Mpa, the minus 110 DEG C low-temperature impact work single value Akv of the steel plate is greater than or equal to 47 J, the Z-direction property of the steel plate is greater than or equal to 35%, and large heat input welding can be achieved; and the ultra-low cost and SR brittle resisting low-temperature nickel steel plate is particularly suitable for manufacturing large LPG low-temperature storage tanks, marine LPG low-temperature storage tanks, and large steel structures in ice sea and polar regions, and ultra-low cost and stable batch industrial production can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

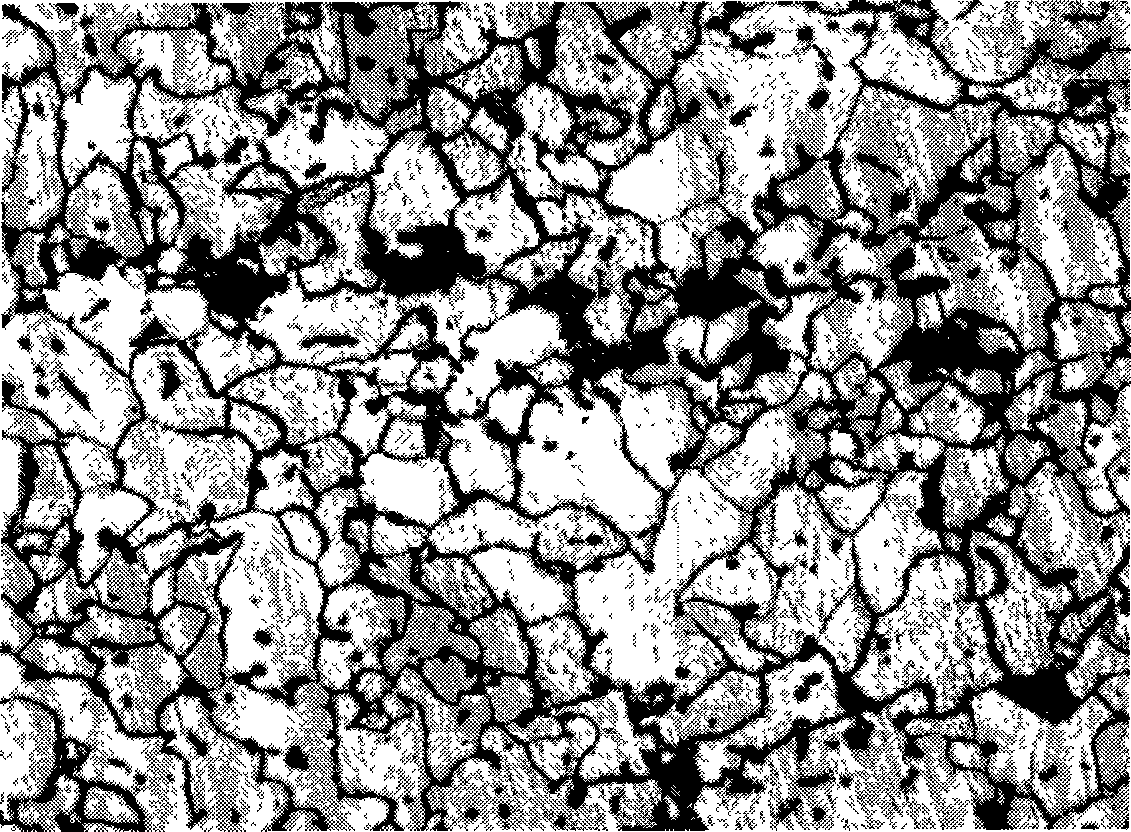

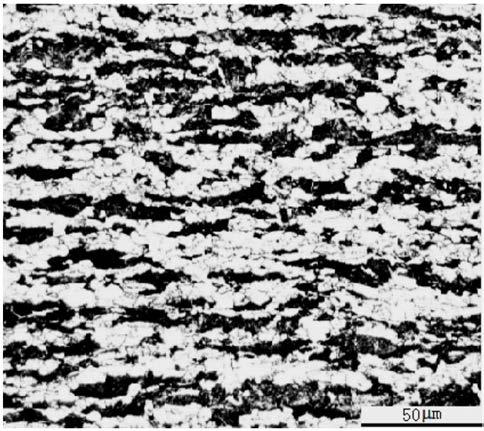

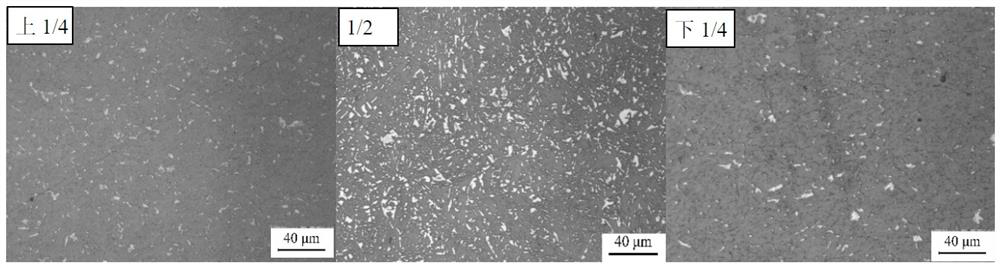

Rolling process for refining M-A components in low-carbon bainite steel

ActiveCN113814269AMeet construction needsEasy to implementTemperature control deviceHeat treatment process controlTowerUltimate tensile strength

The invention discloses a rolling process for refining M-A components in low-carbon bainite steel and belongs to the technical field of steel production. The rolling process comprises three steps of heating, rolling and cooling. The rolling process has the following beneficial technical effects: (1), the average size of the M-A components in the low-carbon bainite steel is not greater than 1.5 microns; (2), the average value of KV2 impact energy at 40 DEG C below zero of typical positions (1 / 4 position and 1 / 2 position) in a thickness direction of a low-carbon bainite steel plate with high thickness of more than 50mm is not less than 200J, and the difference value between single values is not greater than 20J; (3), the yield strength of typical positions (1 / 4 position and 1 / 2 position) in the thickness direction of the low-carbon bainite steel plate with high thickness of more than 50mm is 521-595MPa, the tensile strength is 652-710MPa, the yield ratio is 0.79-0.85, and the elongation rate is 19-23%; and (4), the preparation scheme of the low-carbon bainite steel is easy to implement, the production process is easy to control, low-cost stable batch industrial production can be realized, and the construction requirements of main bearing structures such as bridges, buildings, maritime work, pipelines, wind power towers and the like on high-thickness and high-strength steel can be met.

Owner:YANSHAN UNIV

Highly filled and highly heat-resistant polyvinyl alcohol-based micro-foaming flame-retardant paper and its thermoplastic processing method

The invention discloses high-fill high-heat-resistance polyvinyl alcohol-based microcellular foam type flame retardant paper.The microcellular foam type flame retardant paper is prepared through the steps that polyvinyl alcohol and a plasticizing foaming agent are mixed and swelled and then mixed with an inorganic flame retardant and a flame retardant synergist to obtain composite powder; the composite powder is added into a screw extruder for microcellular foam extrusion, cooling traction, flattening and winding are conducted.The vertical burning class is V-0, the limit oxygen index is 35%-41%, the tensile strength is 1.0-4.5 MPa, the apparent density is 0.05-0.50 g / cm<3>, the average cell diameter is 70-200 micrometers, and the thickness is 0.1-2.0 mm.The flame retardant paper is excellent in thermal resistance, can meet the requirement of rapid laser printing, is excellent in comprehensive performance and low in cost and can be prepared by directly adopting a thermoplastic processing method, the technology is simple and easy to operate, and continuous industrialized production can be achieved.

Owner:SICHUAN UNIV

A kind of preparation method of polyparaphenylene terephthalamide polymer

ActiveCN109293914BAvoid concentrated large amounts of heatResponse is safe and controllablePolymer scienceEnd-group

The invention relates to a preparation method of a poly (p-phenylene terephthalamide) polymer, which comprises the following steps: adjusting the molar ratio of p-phenylenediamine PPDA to terephthaloyl chloride TPC reaction monomer to determine the critical non-gel point of the polymerization reaction; preparing two kinds of low molecular weight poly (p-phenylene terephthalamide) polymer systems with amino group and acyl chloride group as terminal groups at critical non-gel point; subjecting the two kinds of polymer systems to second copolymerization to obtain the poly (p-phenylene terephthalamide) polymer with high molecular weight. The invention prepares two kinds of low molecular weight poly (p-phenylene terephthalamide) pre-polymer systems with different terminal groups, and the systems can stably exist for certain time, and the PPTA with high molecular weight and good solubility in concentrated sulfuric acid can be obtained by copolymerization. The reaction process is stable and easy to control, which is conducive to the industrial production of poly (p-phenylene terephthalamide) fiber.

Owner:DONGHUA UNIV

Method for preparing silver micro-powder for high-temperature sintering silver pastes

The invention discloses a method for preparing silver micro-powder for high-temperature sintering silver pastes, which comprises the following steps: preparing a colloidal liquid silver system, a colloidal reduction system and protection solution firstly; then mixing the three. In the invention, a sol gel process and a solution chemical reduction method are used to effectively control the reaction process, so that the industrialized production can be performed stably, and the uniform reaction under the condition of production enlarging still can be ensured, thereby greatly improving the uniformities of shapes and other superficial characteristics of silver particles generated by reaction, and eventually generating flocculating soft silver powder wodges which are easy to carry out post-processing such as collecting and washing, and the like.

Owner:广东羚光新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com