Leather sheath and production method thereof

A production method and holster technology, which are applied in the field of peripheral parts processing of smart terminal products, can solve the problems that the protective holster cannot take into account the transparency and air permeability of the material, and cannot eliminate air bubbles on the surface of the fabric, etc., and achieve the effect of stable industrial production and realization of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a leather case and a production method thereof. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

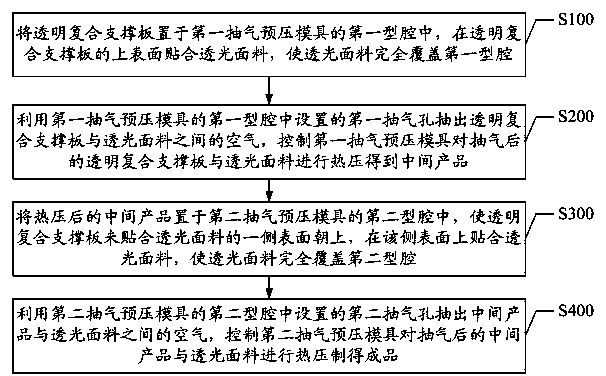

[0028] Such as figure 1 The production method of a kind of holster shown, wherein, described method comprises the following steps:

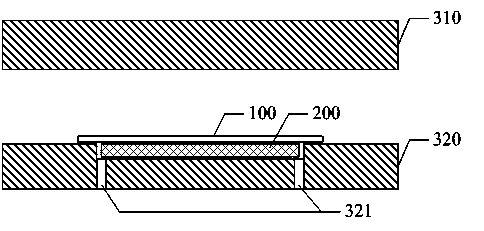

[0029] S100. Place the transparent composite support plate in the first cavity of the first air extraction pre-compression mold, and attach a light-transmitting fabric to the upper surface of the transparent composite support plate, so that the light-transmitting fabric completely covers the first cavity.

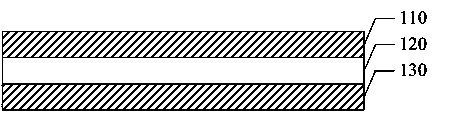

[0030] Wherein, the transparent composite supporting board is formed by laminating two layers of transparent supporting boards, specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com