LED (Light Emitting Diode) drive power source with high efficiency, low power consumption and low cost

A technology of LED driving and low power consumption, applied in the field of high-efficiency, low-power, low-cost LED driving power supply, can solve the problems of complex assembly process, low power supply efficiency, high power consumption, etc., achieve low standby power consumption, reduce components cost and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

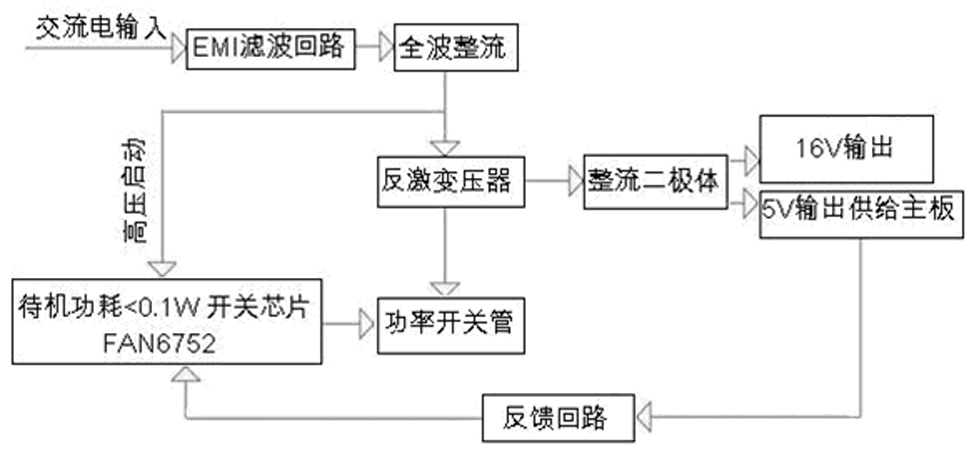

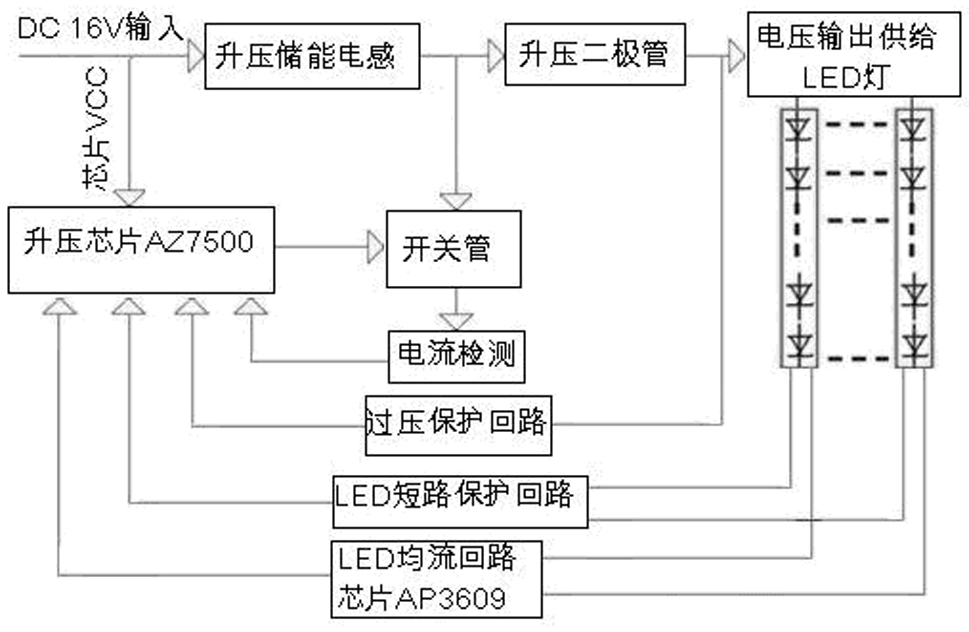

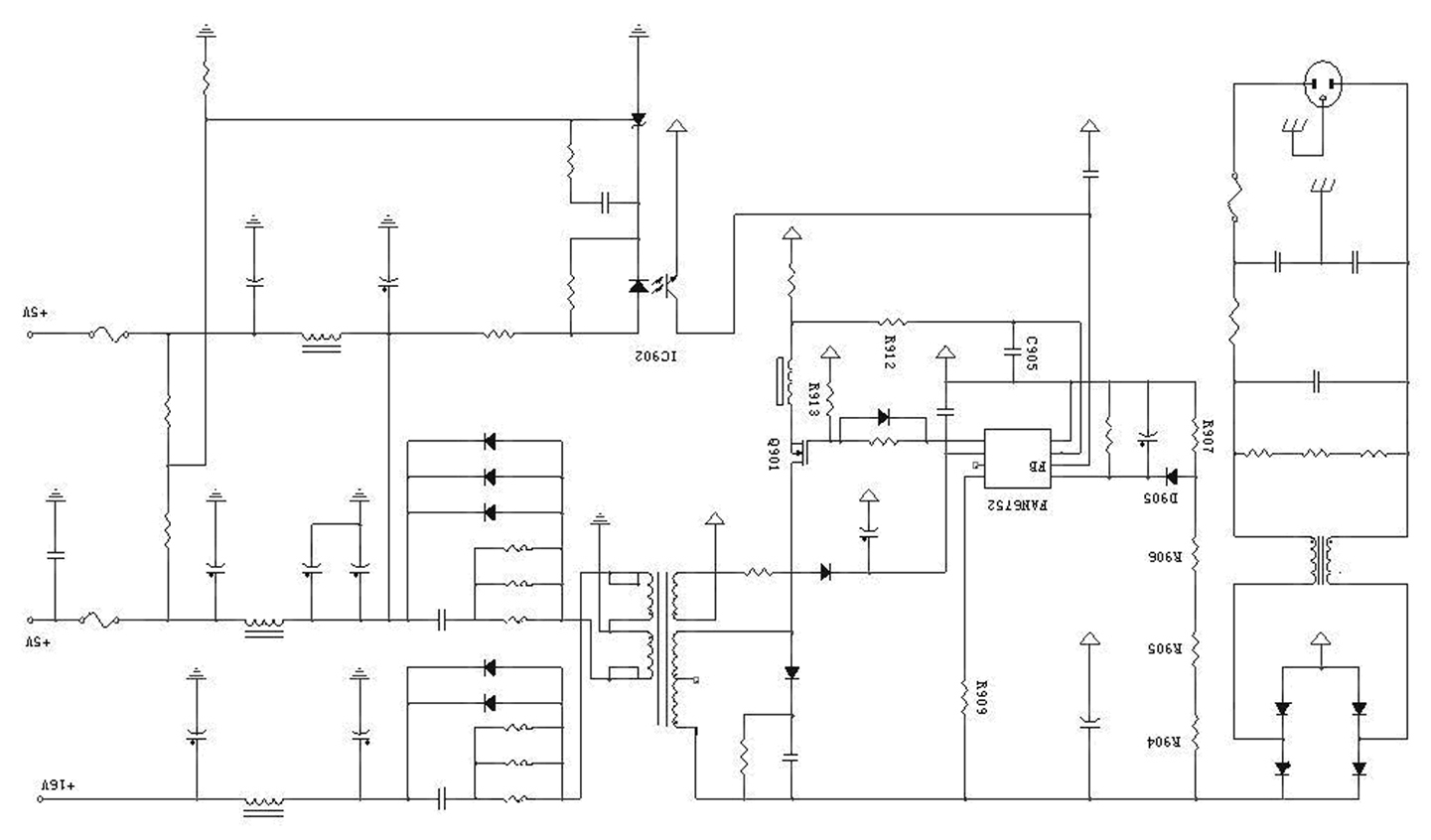

[0024] Such as figure 1 and figure 2 As shown, the present invention provides a high-efficiency, low-power, and low-cost LED drive power supply, which is characterized in that: it includes an AC-DC circuit and a DC-DC circuit electrically connected in sequence, and the DC-DC circuit combines the described The 16V voltage output by the AC-DC circuit generates a DC 36V voltage to supply power to the LED driver module through the Boost boost loop composed of the boost energy storage inductor, switch tube, Boost boost loop driver chip AZ7500, and boost diode. The loop drive chip AZ7500 has the function of setting the working frequency, soft start function, output OVP detection, and switching tube current OCP detection; The current equalizing loop chip AP3609 of the feedback interface realizes the current equalizing setting of the LED lamp, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com