Process for preparing chromium-enriched beer yeast

A brewer's yeast and preparation process technology, which is applied in the field of fermentation technology of chromium-rich brewer's yeast, can solve the problems of long process flow, large consumption of reagents and high concentration, and achieves the advantages of improving metabolism-dependent adsorption, increasing GTF content and simplifying the operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

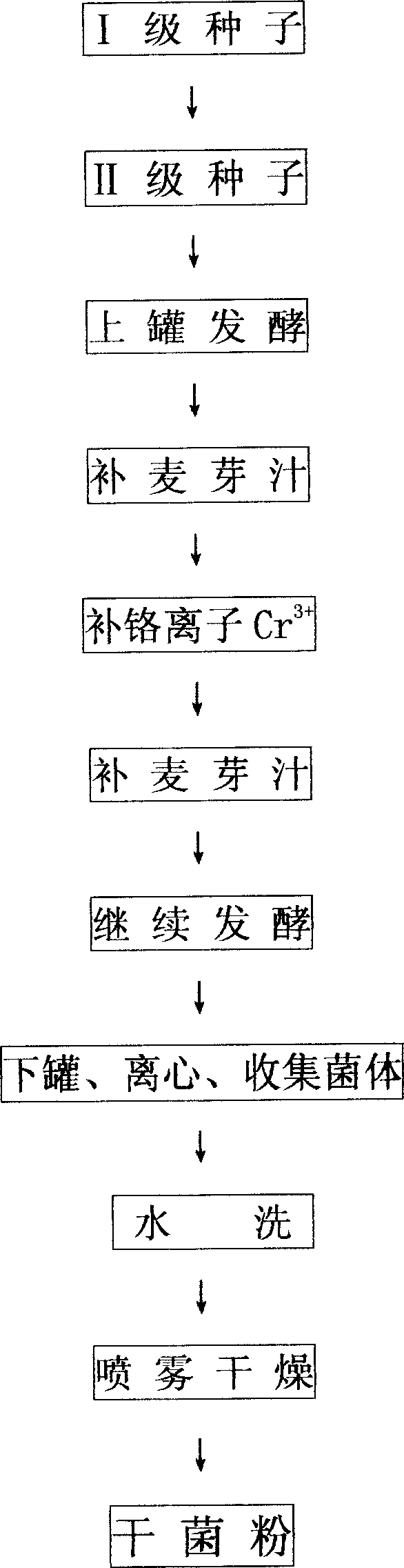

Image

Examples

Embodiment 1

[0023] Embodiment 1. Pick a Brewer yeast (saccharomyces cervisiae) single colony and carry out two-stage strain cultivation in the wort culture medium, seed culture condition: prepare 50% wort by wort: ultrapure water=1: 1, pH The value is 4.5-5.5, the temperature is 27°C-29°C, the shaking culture time of 200rpm is 20-24 hours for the first and second level, and the first level is cultivated to OD 600 ≥2.0, secondary culture to OD 600 ≥4.0, the inoculum size of secondary culture is 10%. Fermentation conditions in the tank: the initial volume of the fermented liquid is 18 liters, 100% wort medium, the secondary seeds are transferred to the medium by 10% of the amount of planting, and the pH value is adjusted to 6.0 with a concentration of 28% ammonia water; Gradient feeding of Cr after 10 hours 3+ ', that is, in the growth stage, after inoculation, adjust the rotational speed and ventilation rate, so that the dissolved oxygen DO≥20%, adjust the pH value to 5.6-6.0, and the te...

Embodiment 2

[0034] Example 2. The difference between this example and Example 1 is that the PH value is adjusted to 5.5 to 5.6 with 0.1N HCl during the chromium enrichment culture stage of fermentation, and after the yeast grows and cultures for 9 hours, it is cultivated for 8 hours, and then the wort is added Continue to culture for 1 hour to OD 600 After ≥9.0, the gradient addition method is used to add chromium salt solution until Cr 3+ The concentration is 0.05, 0.10, 0.15, 0.20g / l fermentation broth, stop adding Cr 3+ ', all the other conditions are identical with embodiment 1. The enrichment effect of chromium in brewer's yeast is listed in Table 2.

[0035] Table 2 Different Cr 3+ Chromium enrichment and OD in brewer's yeast at different concentrations 600 value

[0036] Cr 3+ Concentration g / L 0.05 0.10 0.15 0.20

[0037] OD 600 15.76 16.82 12.91 6.17

[0038] total intracellular chromium

[0039] 276.0 539.4 673.4 689.2

[0040] µg / g dry ye...

Embodiment 3

[0045] Embodiment 3. The difference between this embodiment and Example 2 is that after the yeast was grown and cultivated for 11 hours, it was cultivated for 8 hours, and then the wort was added to continue to cultivate for 3 hours to OD 600 ≥9.0, then use the gradient addition method to add chromium salt solution until Cr 3+ Concentration is 0.15g / l fermented liquid, total fermentation time is 30, 35, 40, 45, 50, 55 hours, all the other conditions are identical with embodiment 2. The enrichment effect of chromium in brewer's yeast is listed in Table 3.

[0046] Table 3 Chromium enrichment and wet cell production in beer yeast at different fermentation times

[0047] Time Total intracellular chromium Bioactive chromium Cell wet weight

[0048] hours µg / g dry yeast µg / g dry yeast g / L

[0049] 30 508.7 211.7 32.7

[0050] 35 601.3 287.6 35.2

[0051] 40 689.2 305.7 45.6

[0052] 45 676.3 318.2 47.8

[0053] 50 670.1 298.6 43.9

[0054] 55 506.3 262.4 35.1

[0055] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com