Enzymatic technology for compounding cefquinome sulfate

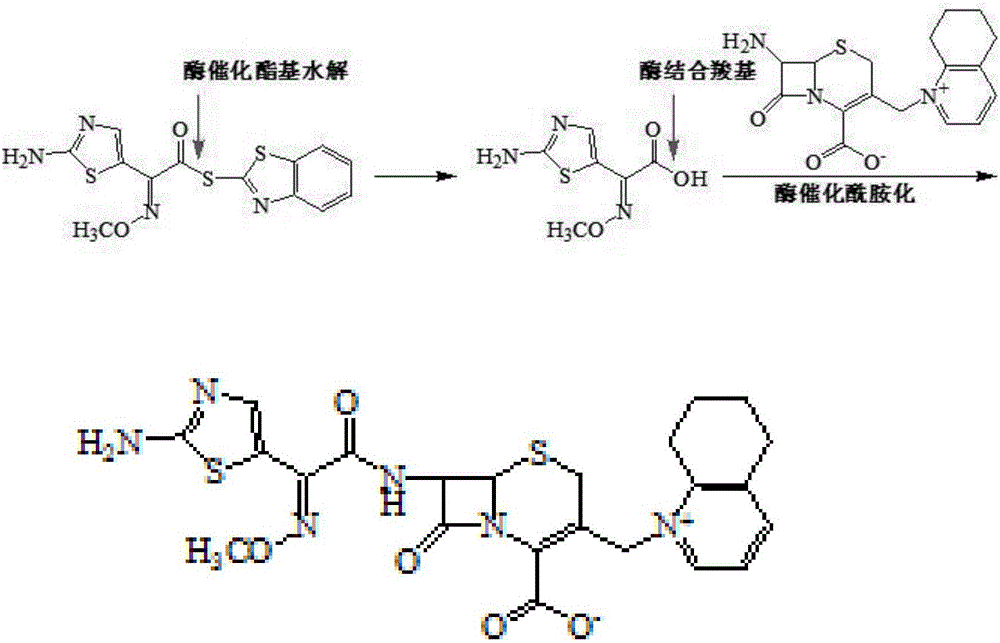

A technology of cefquinome sulfate and cefquinome sulfate, which is applied in the field of enzymatic process of cefquinome sulfate raw material drug for animals, can solve the problems of many reaction steps, harsh reaction conditions and low reaction temperature, and achieve mild reaction conditions , Product quality is stable, and the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the enzyme reactor, add 20000 u of immobilized enzyme and 1 L of deionized water, and start stirring. Add 0.5 mol of 7-aminocefotaxime and 0.65 mol of AE active ester. Add 1 mol / L hydrochloric acid solution dropwise to adjust the pH value to 5.5. The reaction temperature was controlled to be 20°C. The reaction was carried out for 3 hours until 0.05% of 7-aminocefotaxime remained as detected by HPLC. The reaction liquid is separated through a screen to obtain the cefquinome mother liquid, and the immobilized enzyme is collected and recycled. Extract the obtained cefquinome mother liquor with 500 ml of ethyl acetate, adjust the pH to 1.5 with 1 mol / L sulfuric acid solution in the water phase, add 1 L of acetone, stir until crystals are precipitated, grow crystals at 0-5°C for 1 hour, and then filter with suction. After washing with acetone and vacuum drying at 55° C., 289 g of cefquinoxime sulfate was obtained with a yield of 89.6% (the maximum single impurity detec...

Embodiment 2

[0027] In the enzyme reactor, add 30000 u of immobilized enzyme and 1 L of deionized water, and start stirring. Add 0.5 mol of 7-aminocefotaxime and 0.6 mol of AE active ester. Add dropwise 1mol / L hydrochloric acid solution to adjust the pH value to 6. The reaction temperature was controlled to be 25°C. The reaction was carried out for 3 h until 0.09% of 7-aminocefotaxime remained as detected by HPLC. Separating the reaction solution through a sieve to obtain the cefquinome mother liquor, extracting the obtained cefquinome mother liquor with 500ml ethyl acetate, adjusting the pH to 1.1 with 1mol / L sulfuric acid solution in the water phase, adding 1L of acetone, and stirring until crystals are precipitated , after crystal growth at 0-5° C. for 1 h, suction filtration, washing with acetone, and vacuum drying at 55° C., 291 g of cefquinome sulfate was obtained with a yield of 90.3% (the maximum single impurity detected by HPLC was 0.08%, and the total impurity was 0.39%).

Embodiment 3

[0029] In the enzyme reactor, add 10000 u of immobilized enzyme and 1 L of deionized water, and start stirring. Add 0.5 mol of 7-aminocefotaxime and 0.55 mol of AE active ester. Add dropwise 1mol / L hydrochloric acid solution to adjust the pH value to 5. The reaction temperature was controlled to be 15°C. React for 3 hours until the residual 7-aminocefotaxime detected by HPLC is less than 0.1%. Separating the reaction solution through a sieve to obtain cefquinome mother liquor, extracting the obtained cefquinome mother liquor with 500ml ethyl acetate, adjusting the pH to 1.3 with 1mol / L sulfuric acid solution in the water phase, adding 1L acetone, and stirring until crystals precipitated , after crystal growth at 0-5° C. for 1 h, suction filtration, washing with acetone, and vacuum drying at 55° C. to obtain 297 g of cefquinoxime sulfate with a yield of 92.1% (maximum single impurity 0.09% detected by HPLC, total impurity 0.51%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com