Ultra-low cost and SR brittle resisting low-temperature nickel steel plate and manufacturing method thereof

A manufacturing method and low-cost technology, applied in the low-temperature nickel steel plate and its manufacturing field, can solve the problems of high manufacturing cost, long manufacturing cycle, poor ability of steel plate to withstand large heat input welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

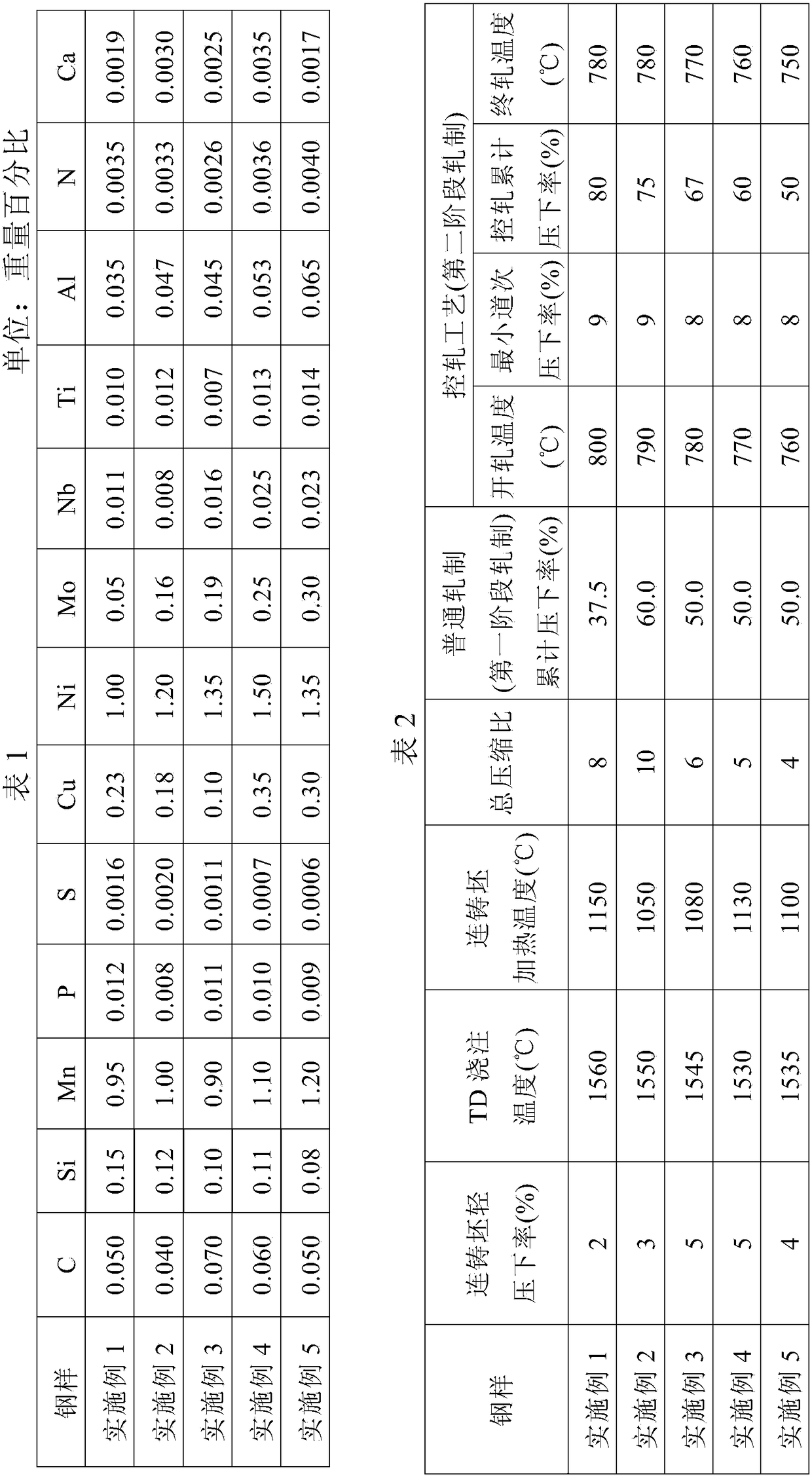

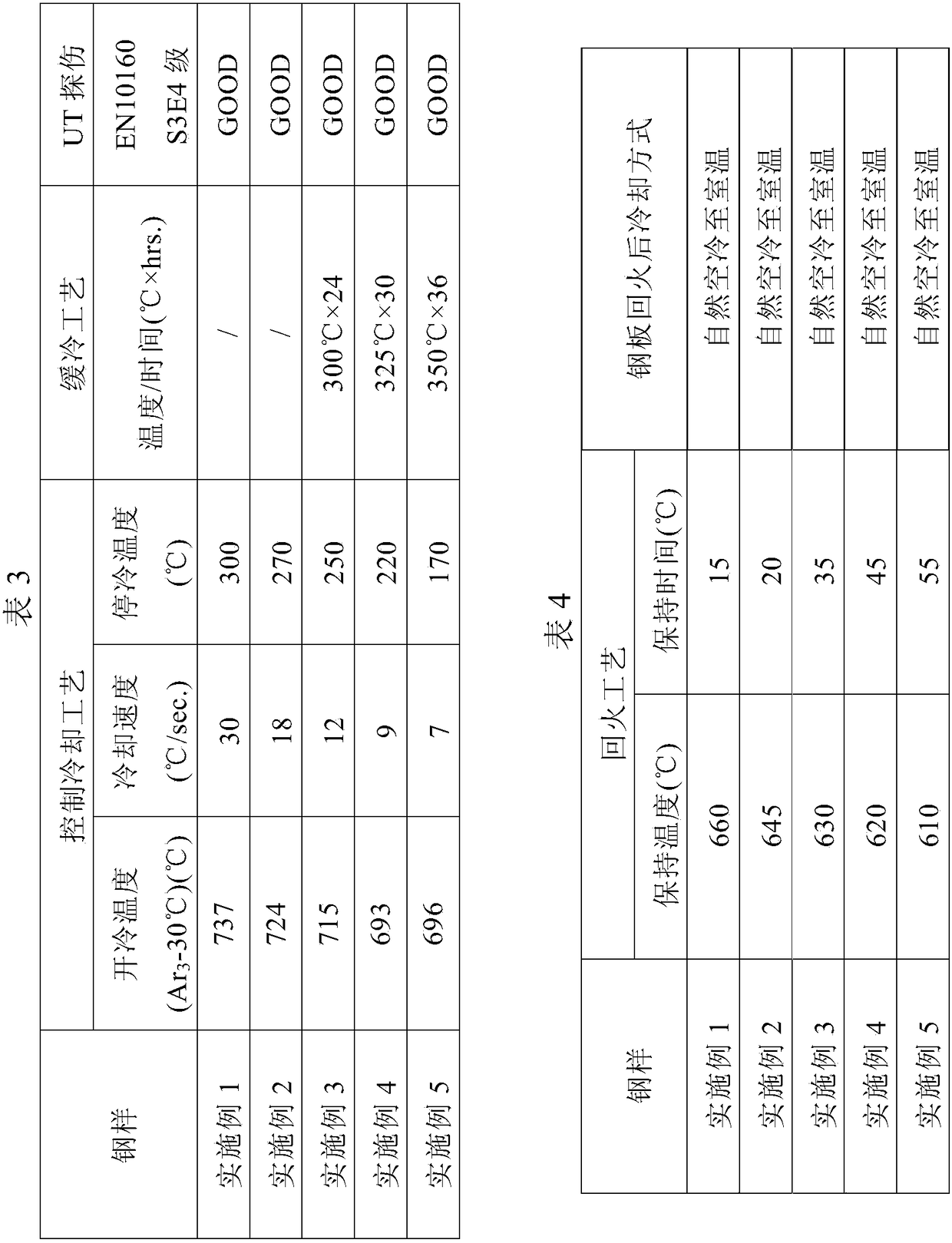

[0073] Refer to Table 1 for the steel composition of the embodiment of the present invention, Table 2 to Table 4 are the steel manufacturing process of the embodiment of the present invention, Table 5 is the performance of the base metal steel plate of the embodiment of the present invention, and Table 6 is the SR process of the steel plate of the embodiment of the present invention (i.e. simulated welding post heat treatment process) properties of the base metal steel plate.

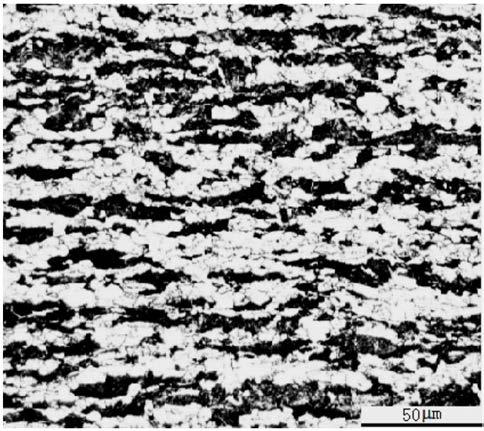

[0074] According to the technical characteristics of the steel plate of the present invention, the steel plate of the embodiment of the present invention is combined with DL (controlled rolling + delayed direct quenching in the two-phase zone of ferrite / austenite) and subsequent tempering process through a reasonable combination design of alloy elements, namely It can stably prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com