Rolling process for refining M-A components in low-carbon bainite steel

A carbon bainite steel and low carbon bainite technology is applied in the field of rolling technology for refining M-A components in low carbon bainite steel, and can solve the problem of strength, toughness, performance stability and thickness direction of thick steel plates. Lack of performance uniformity regulation, high yield-to-strength ratio, and strength that does not meet service requirements, etc., to achieve the effect of easy implementation of the preparation plan, easy control of the production process, low cost and stable batch industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

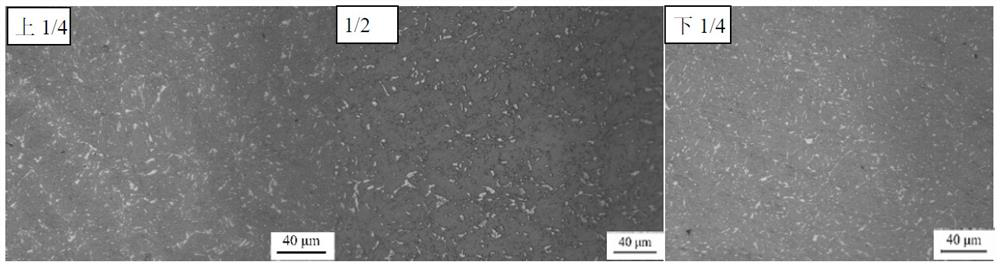

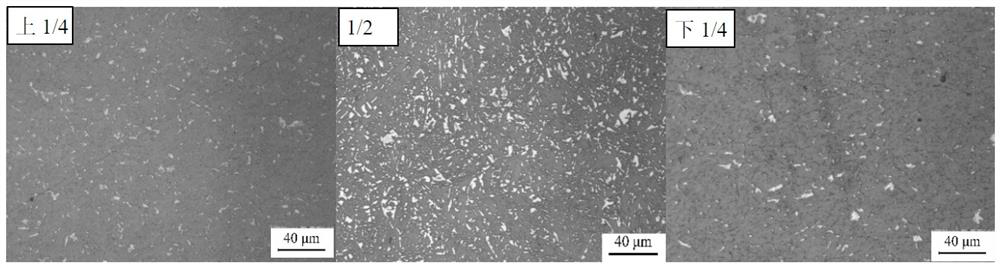

Image

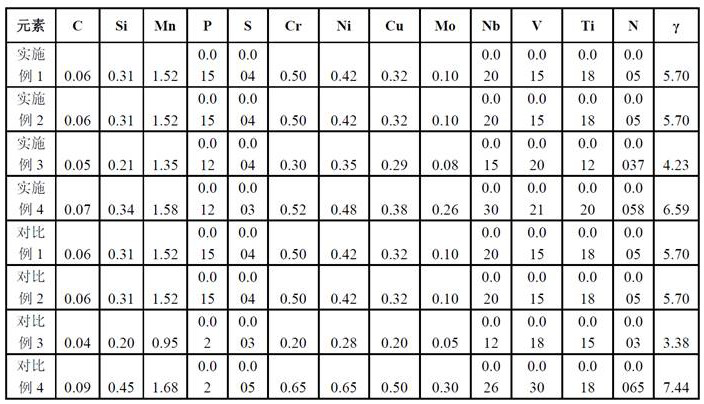

Examples

Embodiment Construction

[0026] The invention provides a rolling process for refining the M-A component in the structure of low-carbon bainite steel, which includes the following steps.

[0027] (1) Heating stage: the slab is heated at T 1 Heating to 1100~1200℃ within 1 minute, keep warm T 2 minutes, and 280≤T≤352, where T=T 1 +T 2 ,T 1 =(0.80~1.10)H,T 2 =(0.14~0.22)H, H is the thickness of the slab (mm).

[0028] (2) Rolling stage, including rough rolling stage and finish rolling stage.

[0029] In the rough rolling stage, the starting rolling temperature is 1020-1080°C, the final rolling temperature is 980-1060°C, and the intermediate billet is formed in 3-5 rolling passes. The reduction rate of a single pass is ≥12%, and the total reduction rate is not less than 55. %.

[0030] Intermediate billet thickness h=(1.8~2.2)t, t is the final target thickness of the steel plate (mm). The water spray device next to the intermediate billet to be warmed will spray water to accelerate the cooling of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com