Label removing knife for polyester bottle label removing machine

A technology for stripping machine and polyester bottle, which is applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of high noise and large chain wear, and achieves increased mechanical stability and improved stripping. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

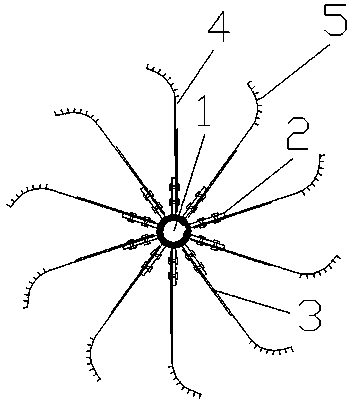

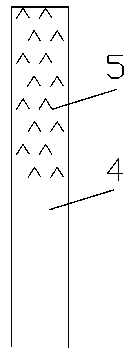

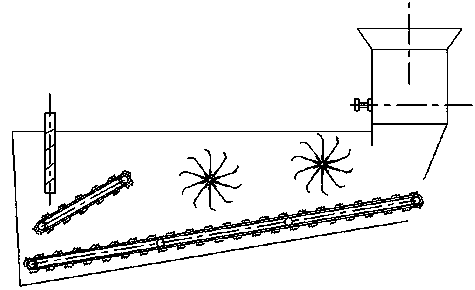

[0026] The polyester bottle labeling machine of the present embodiment uses the labeling cutter, and its structure is as follows figure 1 shown. The stripping knife includes a rotating shaft (1), an outwardly protruding extension part (2) consistent with the radial direction of the rotating shaft (1), and a blade body connected to the extension part (2). The blade body is divided into The rigid part (3) and the elastic part (4), the rigid part (3) is connected with the protruding part (2), the elastic part (4) is curved in the rotation plane of the shaft, and the elastic part (4) is distributed with blades (5).

[0027] The rigid part (3) and the protruding part (2) are connected by bolts. In this connection, when the blade (5) is not sharp, it is only necessary to replace the blade body instead of the entire stripping knife , reducing the cost of using the off-label knife.

[0028] The bending angle of the elastic part 4 is 60°.

specific Embodiment 2

[0029] The labeling knife for the polyester bottle labeling machine of this embodiment includes a rotating shaft (1), an outwardly protruding protruding part (2) consistent with the radial direction of the rotating shaft (1), connected with the protruding part (2) The blade body, the blade body is divided into a rigid part (3) and an elastic part (4), the rigid part (3) is connected with the protruding part (2), and the elastic part (4) is curved in the rotation plane of the shaft , blades (5) are distributed on the elastic part (4).

[0030] The rigid part (3) and the protruding part (2) are adhesively connected. This connection method is beneficial to reduce the weight of the label removal knife and reduce the burden on the transmission mechanism of the polyester bottle label removal machine.

[0031] The bending angle of the elastic part 4 is 60°.

[0032] In specific embodiment 1 and specific embodiment 2, the blade portion (5) is composed of triangular steel sheets arran...

specific Embodiment 3

[0034] The difference between the label-removing knife for polyester bottle label-removing machine in this embodiment and the specific embodiment 1 or 2 is that the bending angle of the elastic part (4) is 90°. This choice can make the elastic part (4) contact with the polyester bottle in parallel, so that the blade part (5) can reach the best working condition together, and increase the label-off effect of the polyester bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com