Biomass solid gas preparation system

A preparation system and biomass technology, applied in the field of biomass solid gas preparation system, can solve the problems of low cost performance, polluted air, high use cost, and achieve the effects of not easy coking, low energy consumption, and long-term stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples, and the content of the present invention covers but is not limited to the following examples.

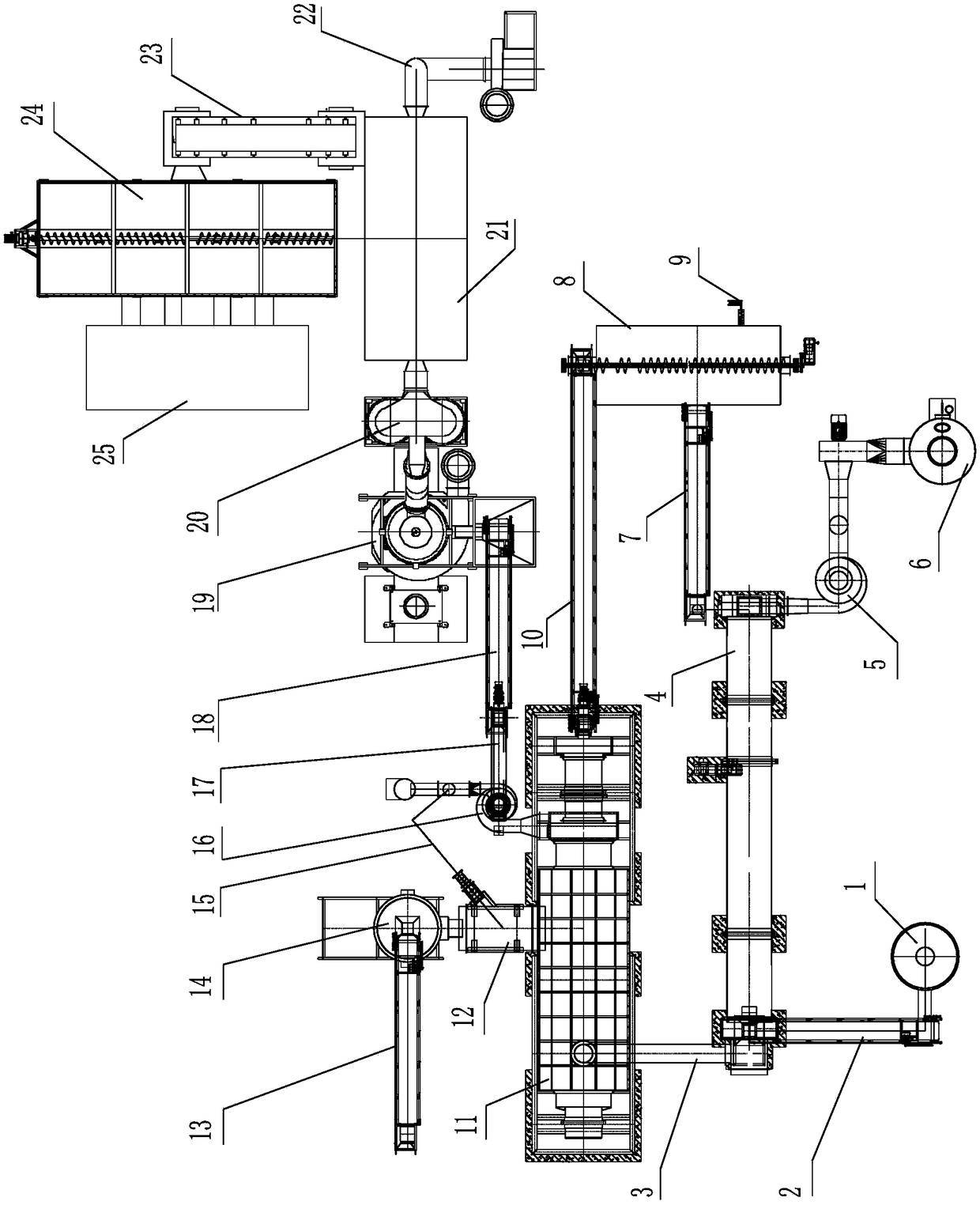

[0017] Such as figure 1 As shown, the biomass solid gas preparation system includes a drying furnace 4, a first dust removal system {cyclone dust collector 5, a spray tower (or tail gas treatment tower) 6}, a first screw conveyor 7, a mixing device 8, Second screw conveyor 10, biomass solid gas carbonization system, conveying device, mill 19, second dust removal system {cyclone vacuum cleaner (or cyclone vacuum cleaner) 20, pulse bag filter (or pulse bag dust collector) 21}; the discharge port of drying furnace 4 is connected by the feed port of mixing device 8 by the first screw conveyor 7 (the feed port of the first screw conveyor 7 is positioned at below the discharge port of drying furnace 4, or connected; the discharge port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com