Operation-controllable roof-cutting pressure-relief gob-side entry retaining method

A technology of roof cutting pressure relief and empty entry retaining, which is applied in earth-moving drilling, discharging machinery, ground mining, etc. Cantilever length, stress concentration relief, small dynamic disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

[0026] like Figure 1 to Figure 4 As shown, a controllable method of roof cutting, pressure relief and gob-side entry retention includes the following steps:

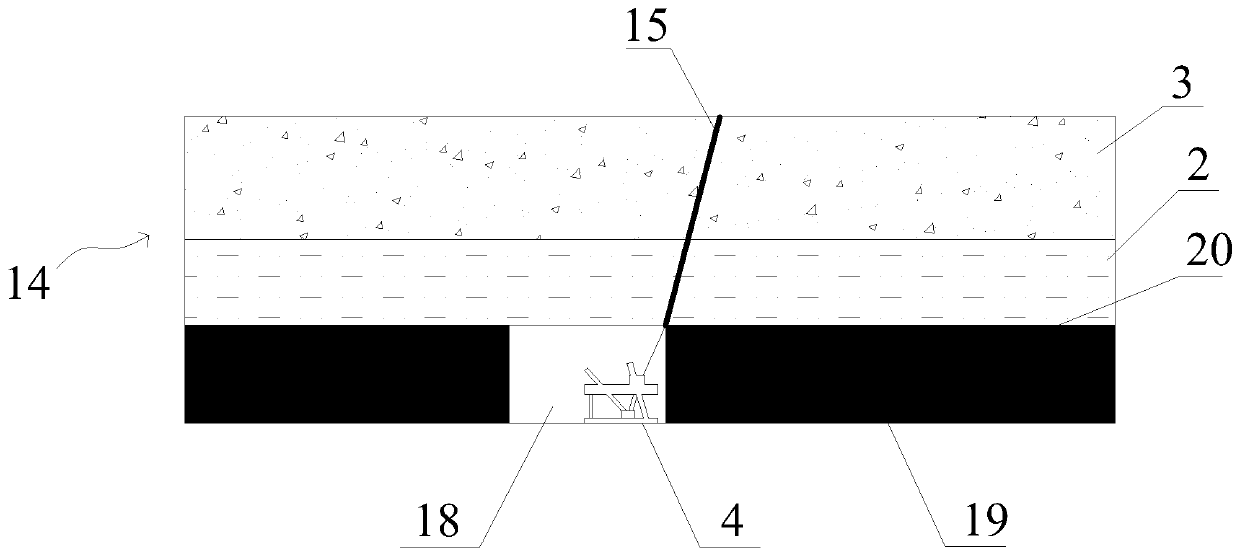

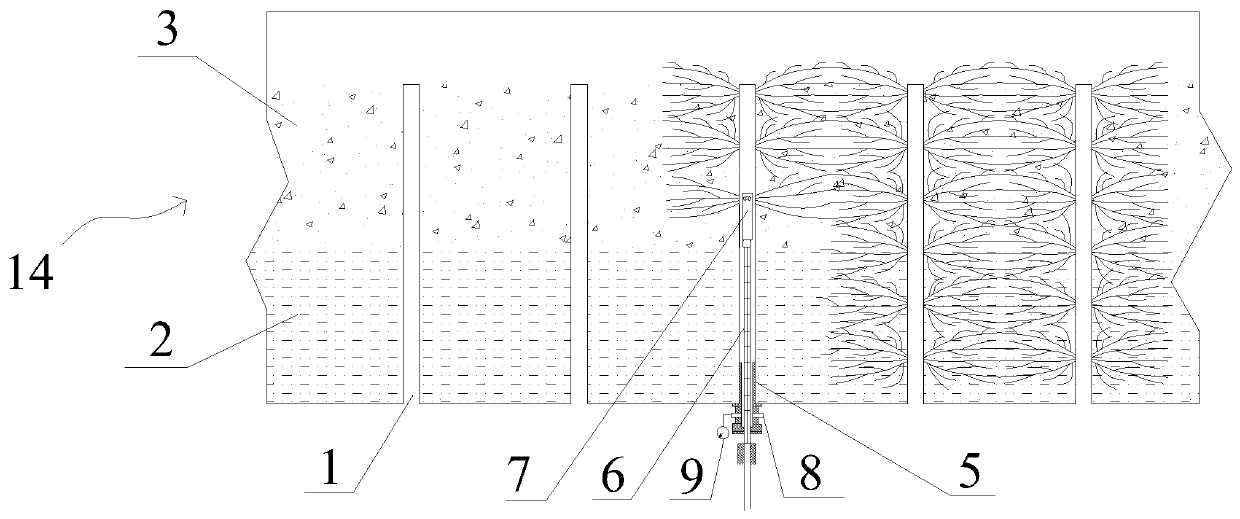

[0027] (1) Based on the original supporting foundation of the gob-side roadway 18, before the recovery of the mining face 19, the advanced working face is set up with a plurality of boreholes 1 at equal intervals in the rock formation 14 along the extension direction of the roadway 18, and the boreholes 1 start from The direct roof 2 extends obliquely to the interior of the basic roof 3 at its upper end;

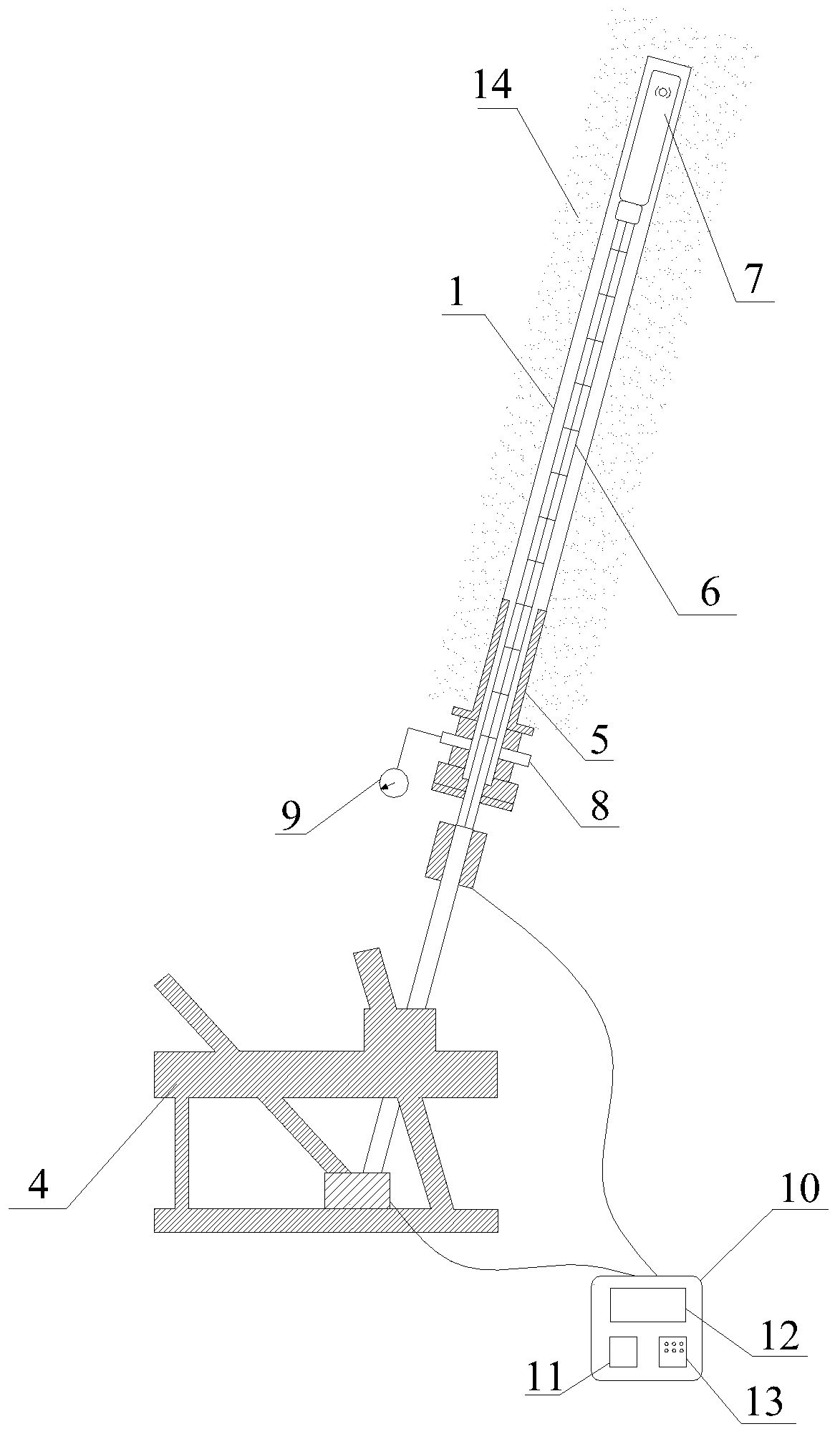

[0028] (2) Shock wave device 4 is installed below the first borehole 1. Shock wave device 4 includes hole sealer 5, push rod 6 and shock wave generator 7. Shock wave generator 7 is arranged on the upper end of push rod 6. Shock wave generator 7 and the outer diameter of the push rod 6 are smaller than the diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com