Device for purifying paper-making waste gas and operation method of device

An exhaust gas purification device and exhaust gas purification technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as complicated operation, poor spray effect, and high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

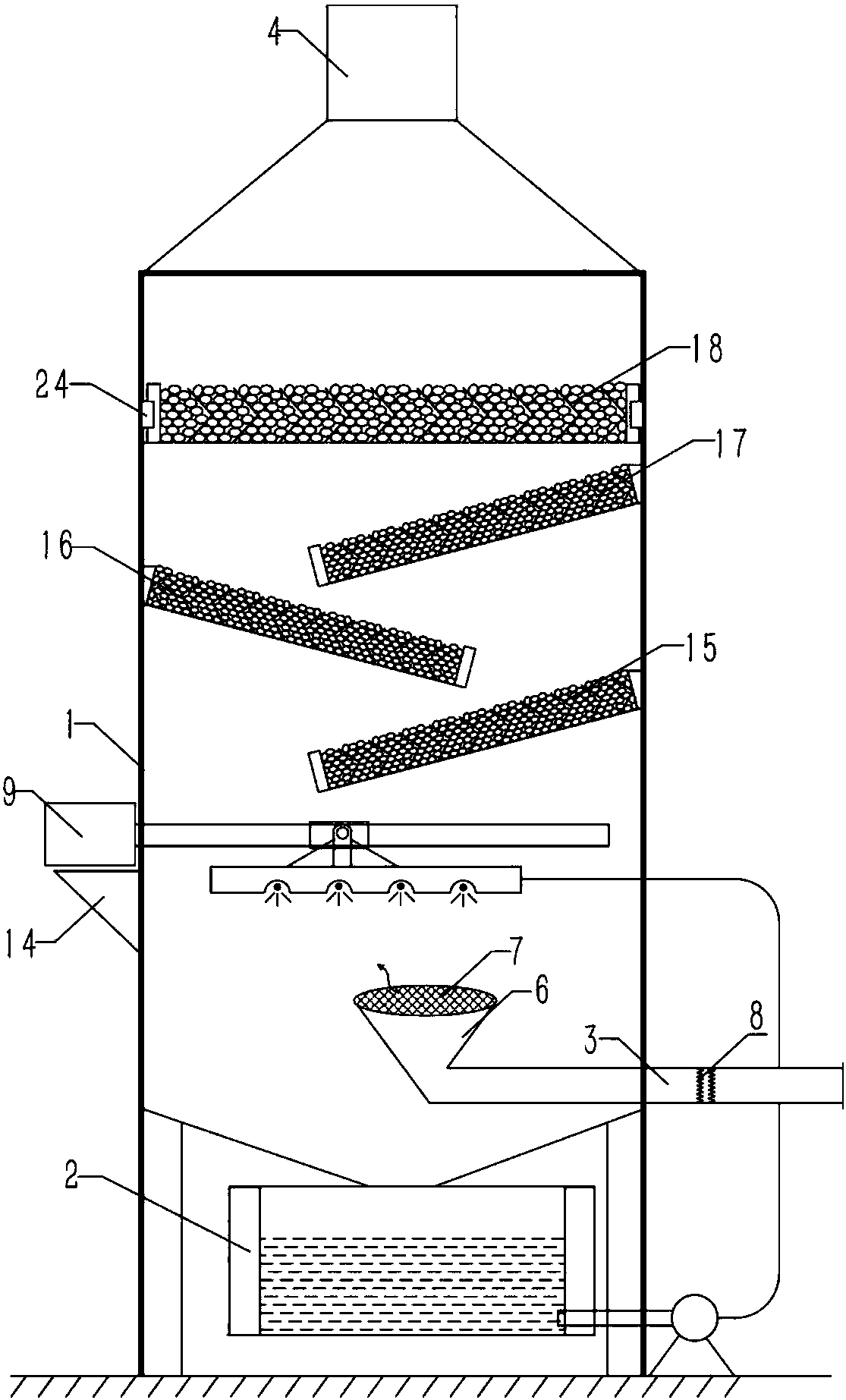

Embodiment 1

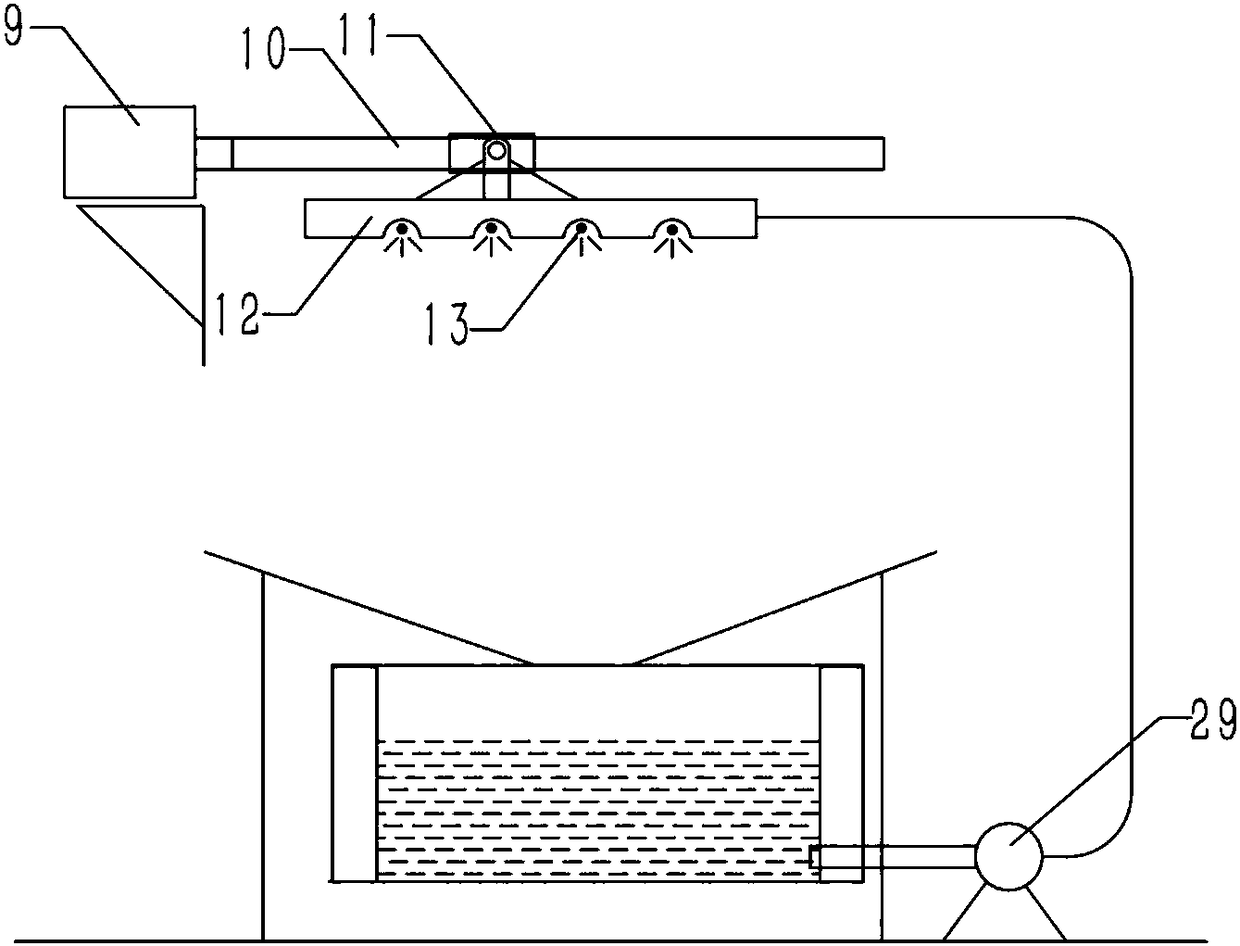

[0044]The operation process of Embodiment 1 is as follows: first, the infusion pump 29 extracts the spray liquid in the waste gas purification spray storage tank 2 and lifts it to the connection spray rack 12, and sprays it in real time by the spray head 13; at the same time, start The motor 9 fixed on the outside of the device housing 1 performs forward and reverse work alternately. The motor 9 drives the helical rotating rod 10 to rotate through the rotating end, thereby driving the moving sleeve 11 to move back and forth on the helical rotating rod 10, thereby realizing the spray rack 12 and a plurality of shower heads 13 that drive the lower end to move at a constant speed inside the device housing 1 .

[0045] The exhaust gas is transported into the device housing 1 successively from the exhaust gas inlet pipe 3, and at the same time, the electric heating wire 8 set in the exhaust gas inlet pipe 3 burns and heats the exhaust gas, so that the heat-sensitive substances in th...

Embodiment 2

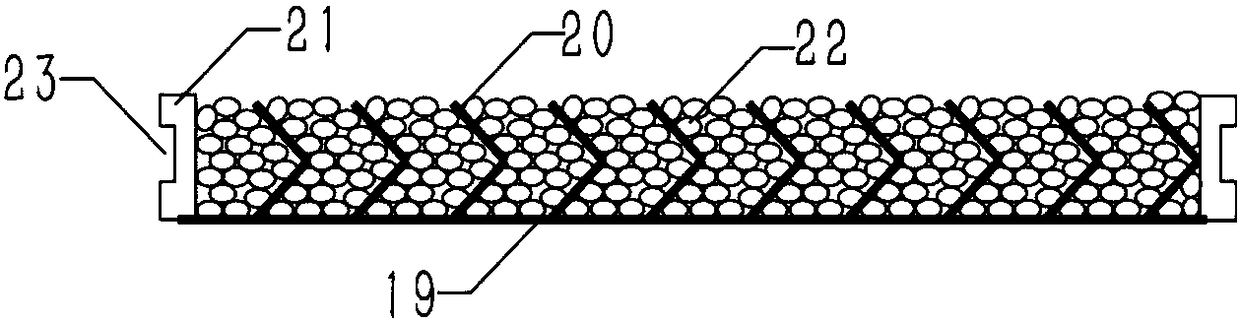

[0048] Such as Figure 4 Shown, embodiment 2: a kind of papermaking exhaust gas purification device, with figure 1 Compared with the illustrated embodiment 1, the difference is that the embodiment 2 is also provided with a return air pipeline 25 on the upper end of the device housing 1 and below the air outlet 4, and the return air pipeline 25 is provided with a return air blower 26. The outlet 27 of the air pipeline 25 corresponds to the bottom of the fourth activated carbon filter adsorption unit 18 .

[0049] Wherein, it is better that the outlet 27 is inclined downward during implementation.

[0050] The operation process of embodiment 2 is as follows: first, the spray liquid in the exhaust gas purification spray storage tank 2 is extracted and lifted to the connection spray rack 12 by the infusion pump 29, and sprayed in real time by the spray head 13; at the same time, start The motor 9 fixed on the outside of the device housing 1 performs forward and reverse work alt...

Embodiment 3

[0054] Such as Figure 5 Shown, embodiment 3: a kind of papermaking exhaust gas purification device, with Figure 4 Compared with the shown embodiment 2, the difference lies in that the return air pipeline 25 also has a second outlet 28 , and the second outlet 28 corresponds horizontally between the first activated carbon filter adsorption unit 15 and the second activated carbon filter adsorption unit 16 .

[0055] The first stage of the operation process of embodiment 3 is the same as that of embodiment 2; when the gas is adsorbed by the fourth activated carbon filter adsorption unit 18, part of the gas will be pumped through the outlet 27 under the action of the return air fan 26 Returning to the bottom of the fourth activated carbon filter adsorption unit 18, part of the gas will be horizontally drawn back to the cavity between the first activated carbon filter adsorption unit 15 and the second activated carbon filter adsorption unit 16 through the second outlet 28 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com