Satellite propulsion service cabin structure

A service cabin, star and arrow technology, which is applied to the propulsion system devices of space navigation vehicles, space navigation equipment, space navigation vehicles, etc., can solve the problems of less connection points and less layout space, and achieves reduction of structural mass and satellite center of mass. , The effect of reducing the load of the star-arrow connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The cabin structure according to the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0025] In order to realize a satellite structure that meets the requirements of large load capacity and multi-load adaptability, the propulsion service module structure of the present invention is proposed, and the specific implementation method is as follows.

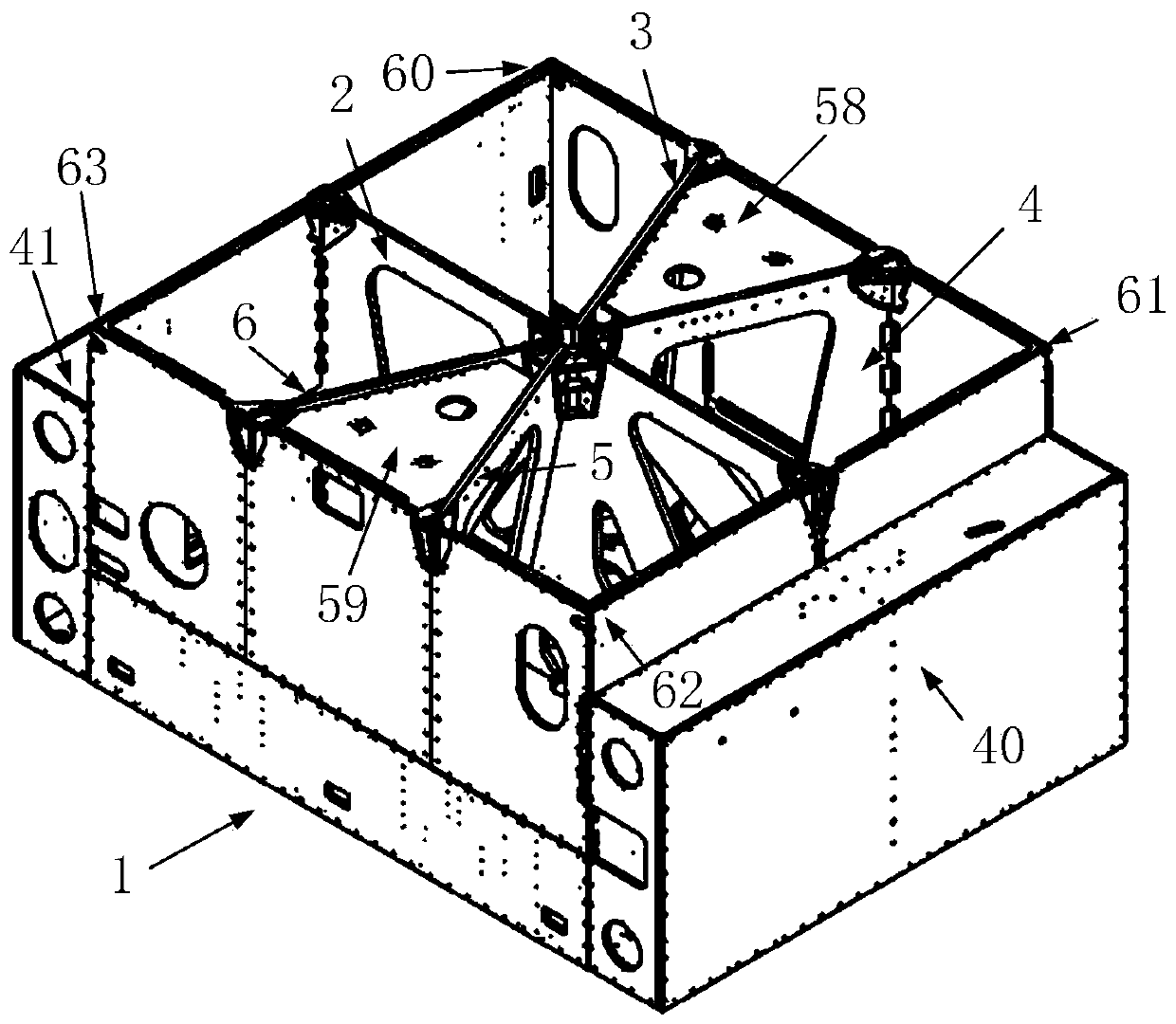

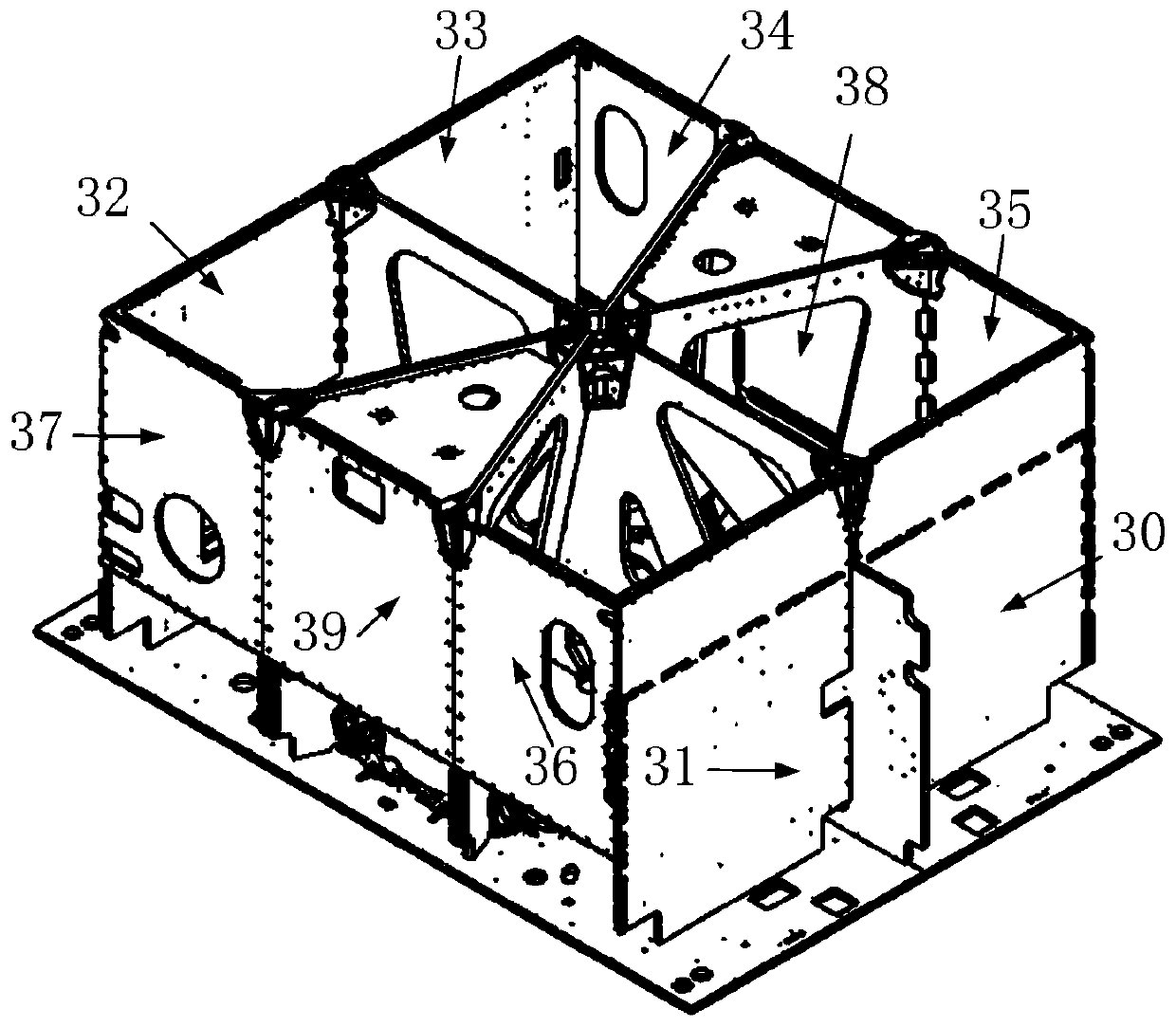

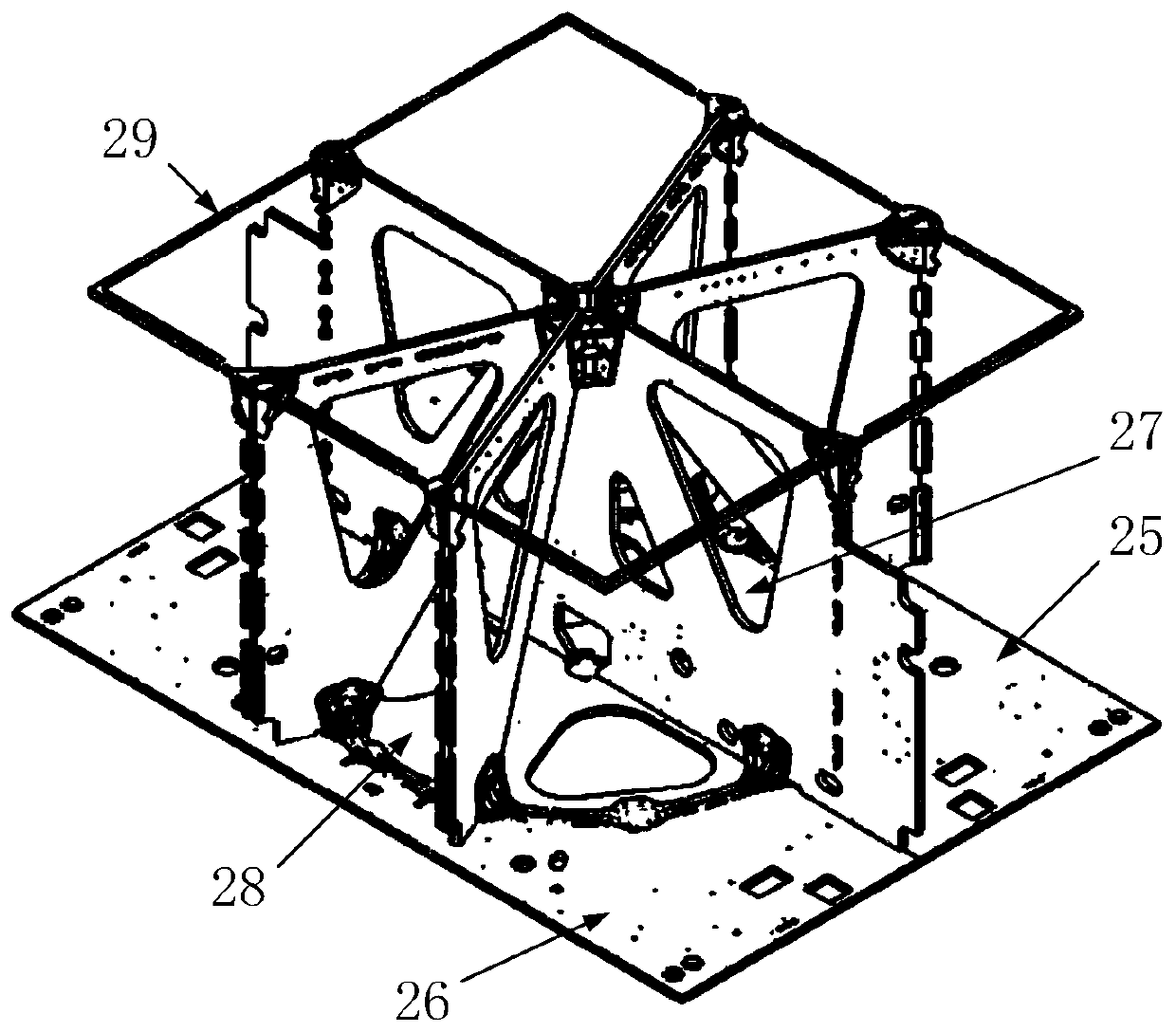

[0026] According to the structure of the propulsion service cabin of the present invention, its main load-bearing structure is composed of a point-connected star-arrow docking ring 1, a main partition 2 and inclined partitions 3-6. Among them, the first inner rod 201, the second inner rod 202, the first outer rod 203, the second outer rod 204, the first upper rod 205, and the second upper rod 206 are embedded in the main partition 2, forming two sets of triangular planar truss units , the two groups of units are arranged symmetrically about the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com