Guide support for a follower plate pump and follower plate pump

A technology of plate pumps and guides, which is applied to components of pumping devices for elastic fluids, pump elements, variable displacement pump components, etc., can solve problems such as difficult operation of pumps, and achieve reliable operation, compact structure, and simplicity The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

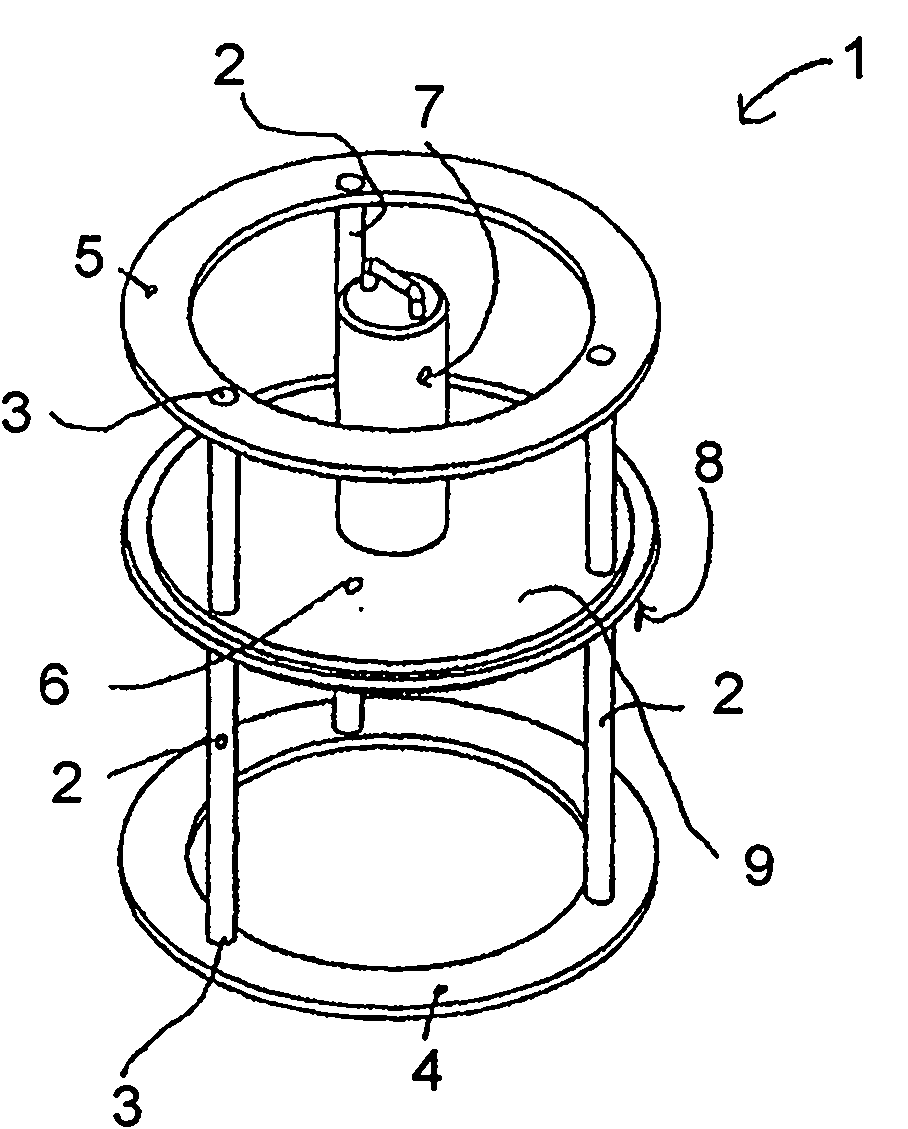

[0028] figure 1 The guide bracket 1 shown schematically in , has three rods 2 which are designed as guides and which are each connected at their ends 3 to an annular foot 4 and an annular cover 5 respectively. The connection is a screw connection (not shown in detail). A trailing plate 6 is guided on the rod 2 and carries a trailing plate pump 7 . The suction opening (not shown) of the trailing plate pump is located on the underside 8 of the trailing plate 6 . The follower plate 6 is guided on the rod 2 in such a way that a self-locking connection is formed. This means that the follower plate 6 with the follower plate pump 7 attached to it does not automatically settle downwards due to gravity, but the self-locking is arranged in such a way that the follower plate 6 can pass under the follower plate 6 The resulting low pressure is moved downwards either by air pressure acting on the upper side 9 of the follower plate 6 .

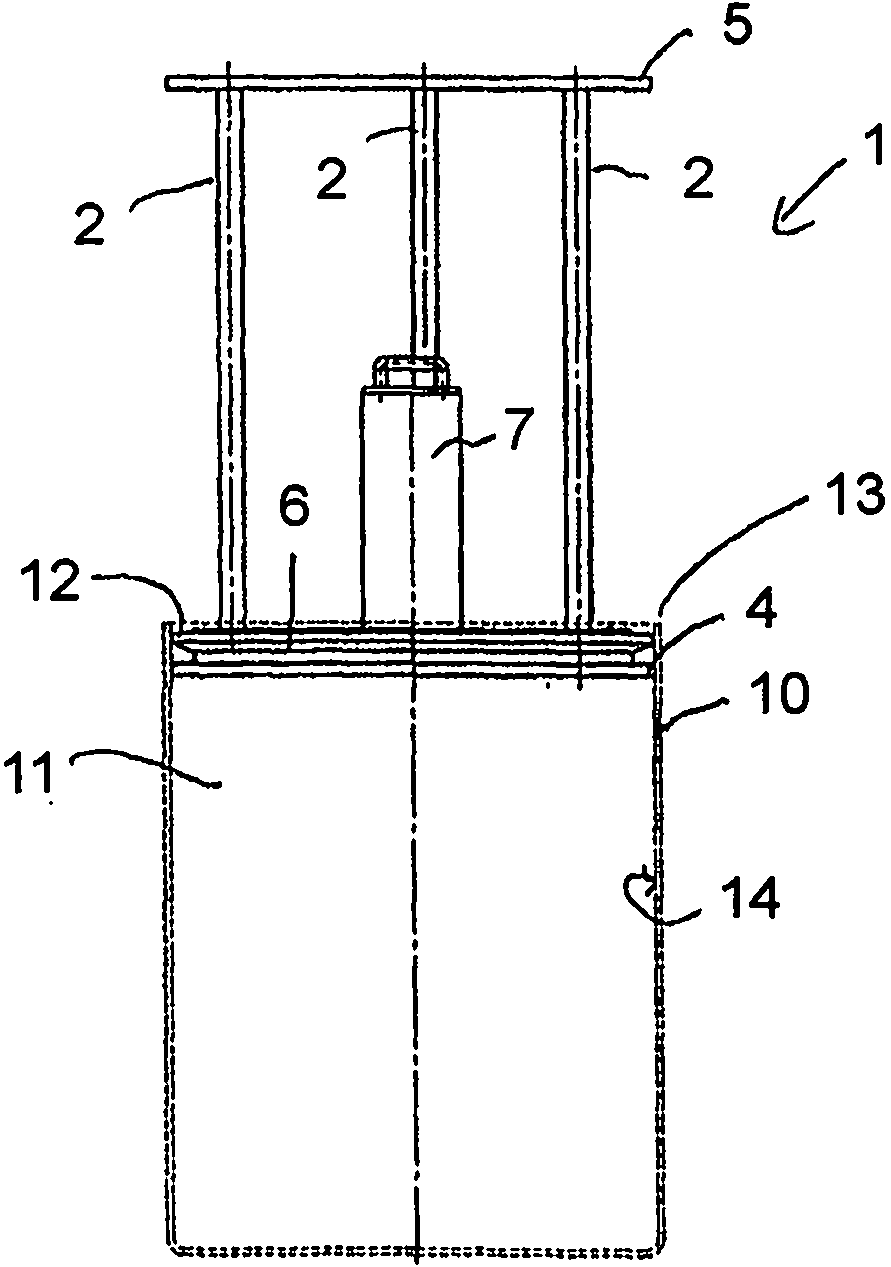

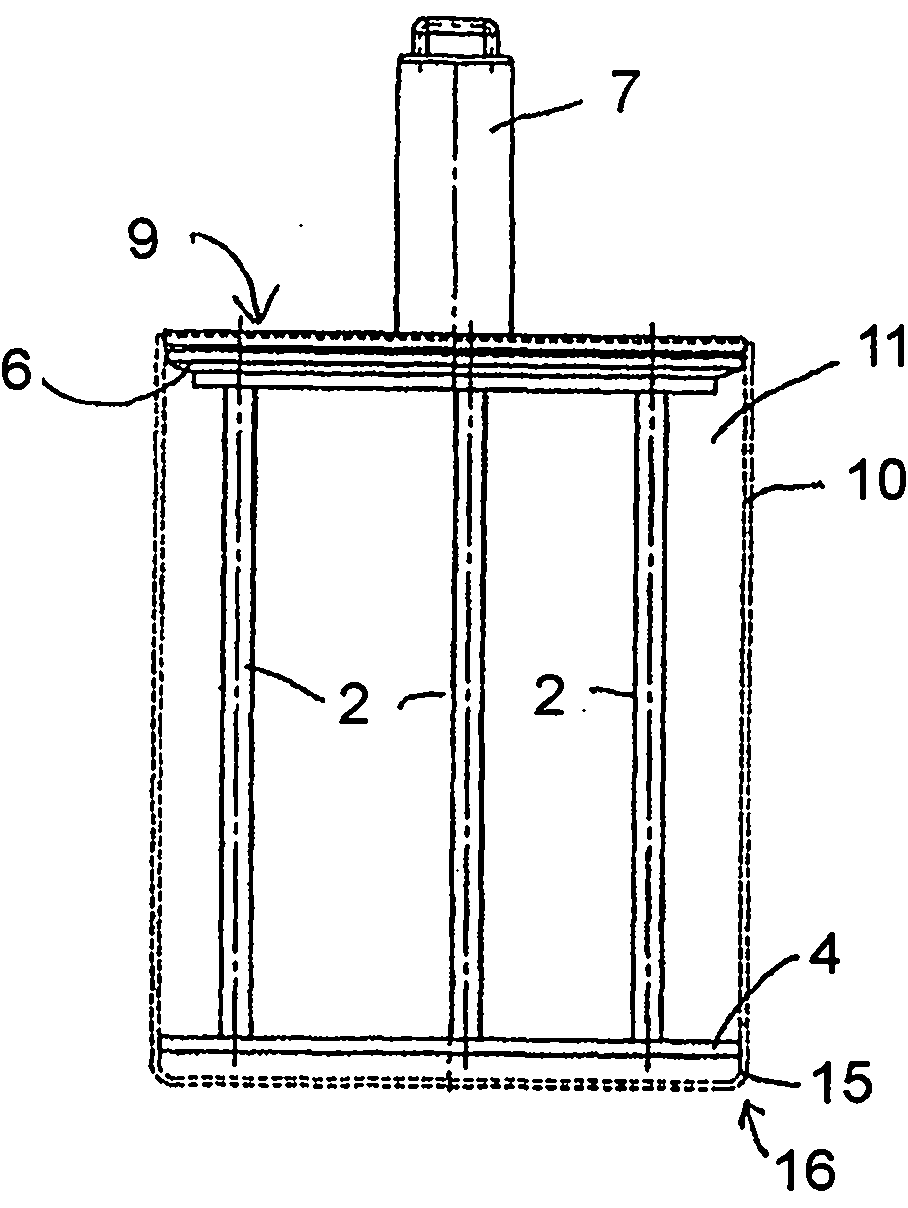

[0029] figure 2 The guide bracket 1 shown in is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com