Carbon fiber reinforced composite vehicle door anti-collision beam

A technology of reinforced composite materials and anti-collision beams, which is applied in the field of vehicle engineering, can solve the problems of limited arrangement of door anti-collision beams, high mold cost, and heavy weight, and achieves convenient layup design and process molding, and low mold cost , the effect of reducing the quality of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

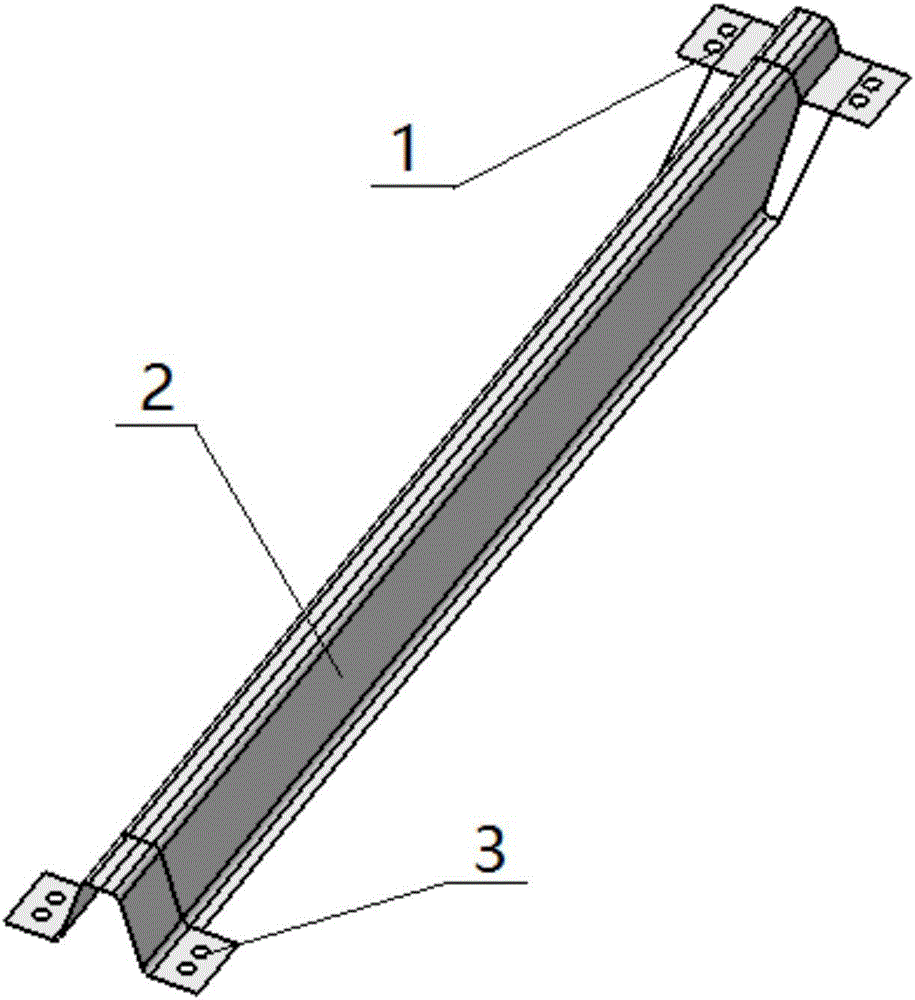

[0013] Specific implementation mode 1. Combination figure 1 and figure 2 In this embodiment, a car door anti-collision beam made of carbon fiber reinforced composite material includes an anti-collision beam 2 , a front fixing bracket 1 connected to the front end of the anti-collision beam and a rear fixing bracket 3 connected to the rear end of the anti-collision beam. The anti-collision beam 2 is made of carbon fiber reinforced composite material, and the front and rear fixing brackets are made of aluminum alloy extrusion or steel plate stamping, so that the material is the same as the inner panel of the car door. The front and rear fixing brackets are connected with the anti-collision beam 2 of the car door by gluing, and the front and rear fixing brackets are connected with the inner panel of the car door by bolts.

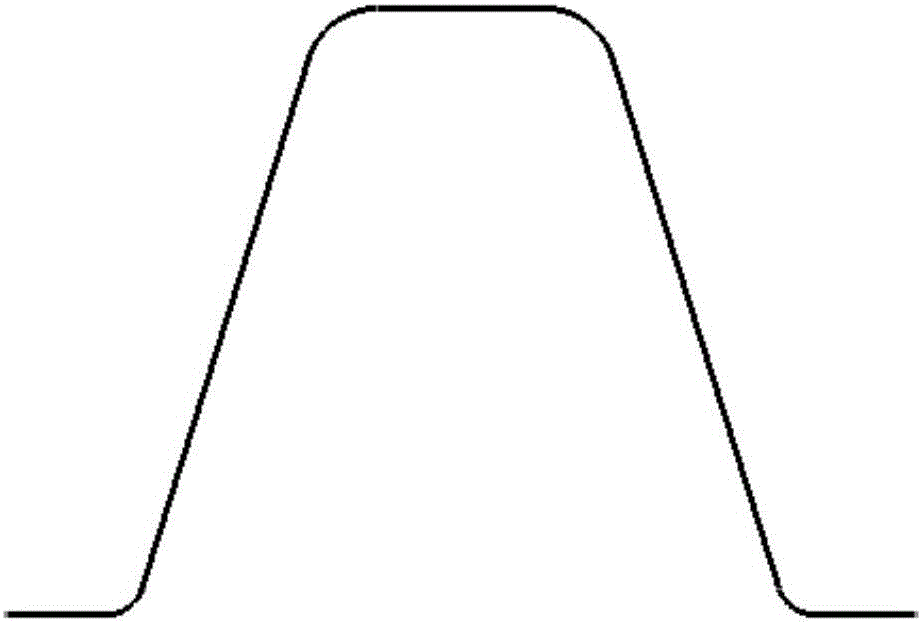

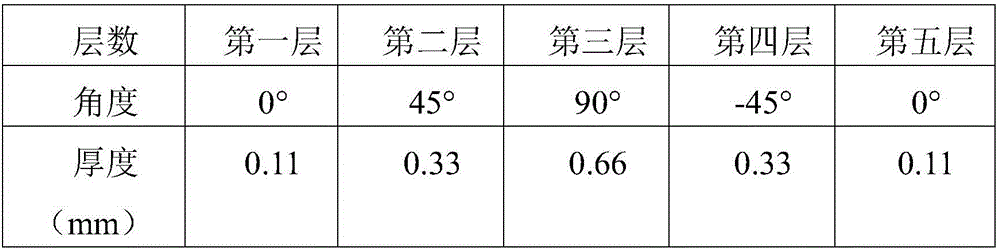

[0014] Wherein, the cross section of the anti-collision beam 2 is a trapezoidal structure, and the opening faces the inner panel of the car door, and the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com