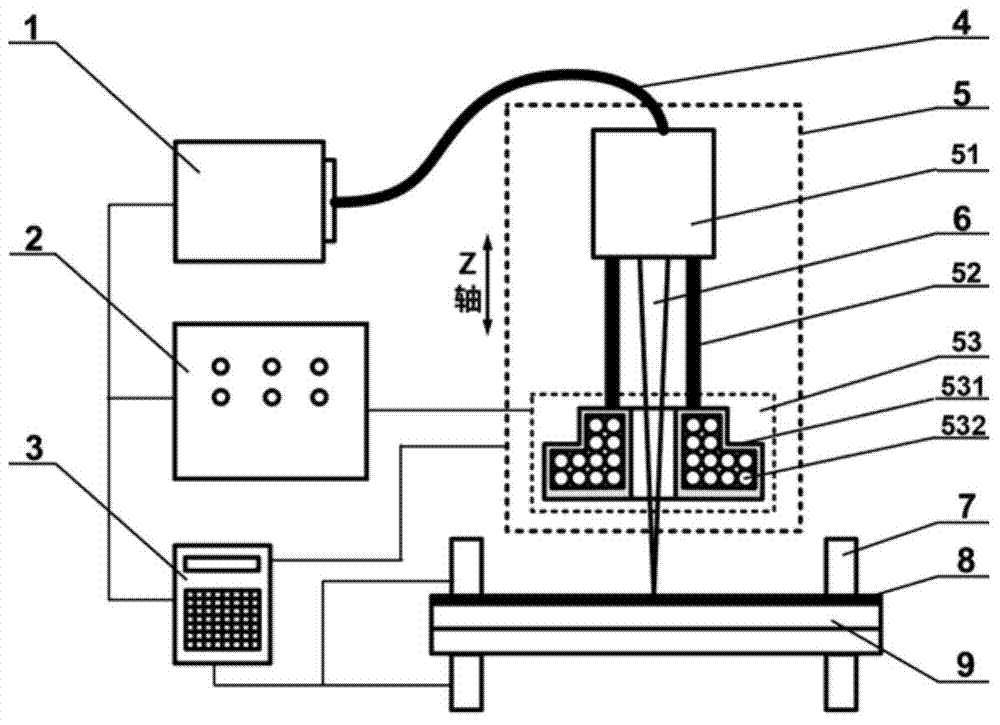

Pulsed high magnetic field auxiliary laser welding method and device

A technology for assisting laser and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems affecting the assembly accuracy of components and the overall performance of the structure, difficulty in welding thermal deformation control, and poor results. The effect of joint quality control and structural deformation, improving joint fatigue strength, and enhancing processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

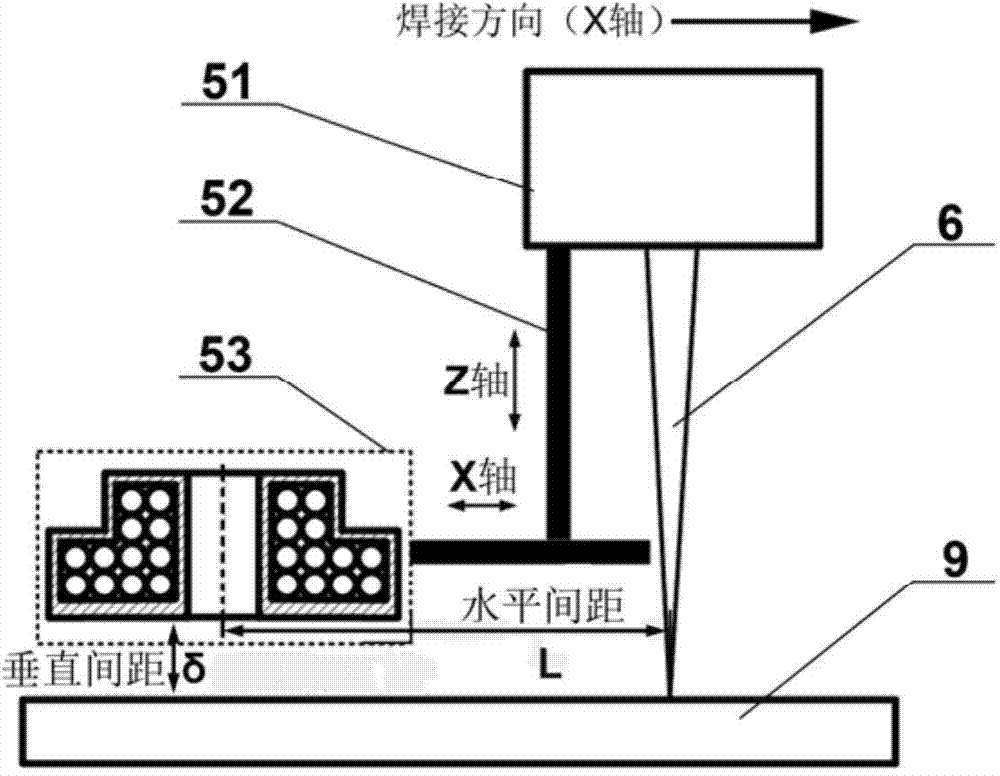

Method used

Image

Examples

Embodiment 1

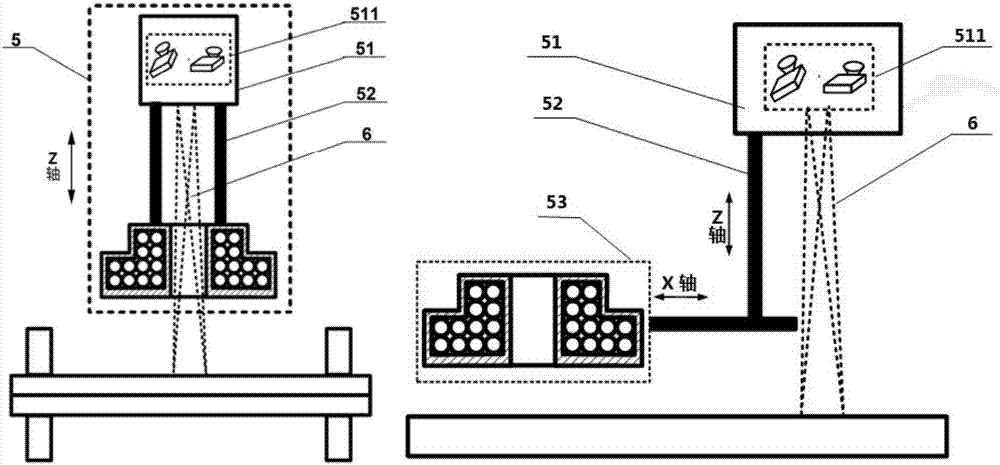

[0079] In this example, the laser spot welding process is implemented first, and then a pulsed strong magnetic field is applied to the spot welding seam area within a specific delay time just after the laser spot welding process is completed.

[0080] In this example, the welding workpiece is a 2219 aluminum alloy cylindrical member with a plate thickness of 3mm. The welding requirements are upper and lower lap spot welding (the thickness of the welding point after lap is 6mm). Figure 11 The pulsed strong magnetic field assisted laser spot welding equipment for the cylindrical structure shown here uses a 6000W fiber laser and a galvanometer scanning and focusing method. The laser focal length is 400mm. . In order to improve the quality of the weld, a 0.1mm thick rare earth film is preset on the surface of the workpiece.

[0081] The process parameters of laser spot welding are: laser power 4500W, laser spot diameter 1.5mm, single spot welding time 0.2s, laser beam swing alon...

Embodiment 2

[0084] The welding workpiece in this example is an MB8 magnesium alloy flat plate member with a plate thickness of 2.5mm, a length of 2m and a width of 1m. The welding requirements are upper and lower lap spot welding (the thickness of the welding point after lap is 5mm). Figure 12 The pulsed strong magnetic field assisted laser spot welding equipment for the flat plate structure shown is selected by the fiber laser and galvanometer scanning and focusing mode, the laser focal length is 300mm, the shape of the welding spot of the welding seam is a solid circle, and the cross-sectional feature is the non-penetration form.

[0085] The process parameters of the laser spot welding process are: laser power 2500W, laser spot diameter 0.5mm, single spot welding time 3s, laser beam swing along the radial direction 5mm. The process parameters of the pulsed magnetic field applied after laser spot welding are as follows: the specific delay time after spot welding is 60s, the distance bet...

Embodiment 3

[0088] In this example, the welding workpiece is a TC4 titanium alloy flat plate structure with a plate thickness of 5mm. The welding requirement is butt spot welding. The DISK solid-state laser and galvanometer scanning focusing method are selected, and the laser focal length is 250mm. The shape of the welding point of the weld is a solid circle, and the cross-sectional feature is a full penetration form.

[0089]The process parameters of the laser spot welding process are: laser power 3500W, laser spot diameter 0.8mm, single spot welding time 1s, laser beam swing along the radial direction 2mm. The process parameters of the pulsed strong magnetic field applied after laser spot welding are: a specific delay time after spot welding is 300s, the distance between the electromagnetic conversion device and the workpiece surface is 5mm, the induction intensity of the pulsed magnetic field is 20T, and the magnetic field pulse width is 30μs.

[0090] After the welding is completed, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com