Patents

Literature

44results about How to "To achieve the processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

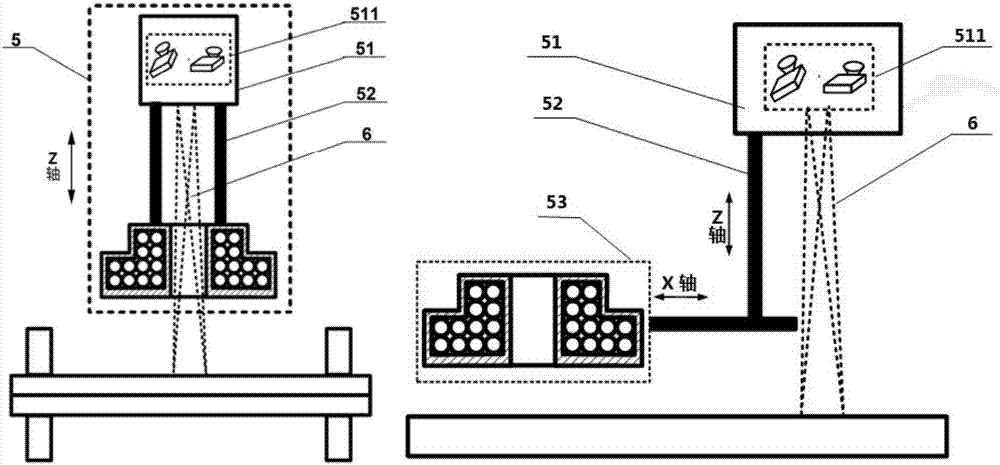

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

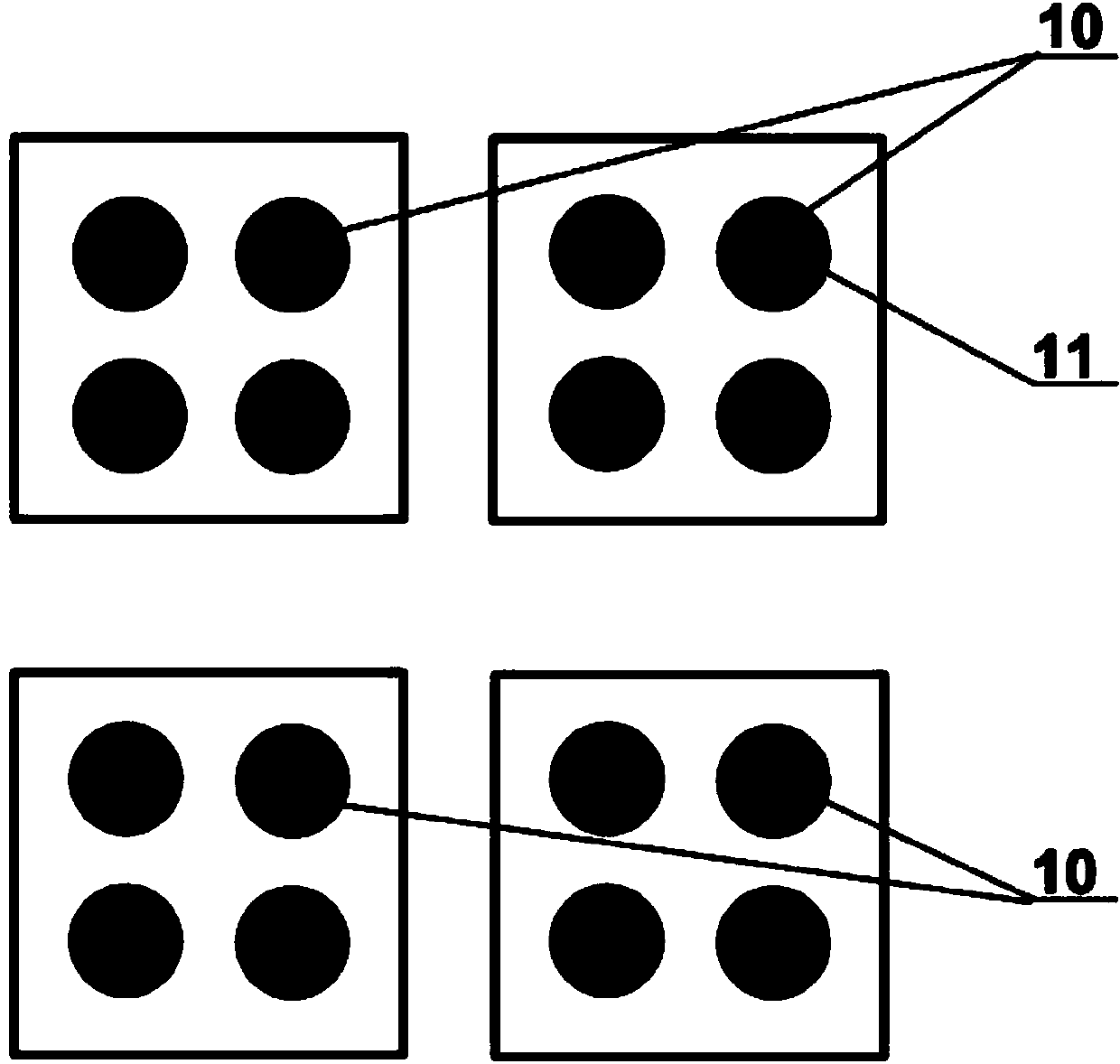

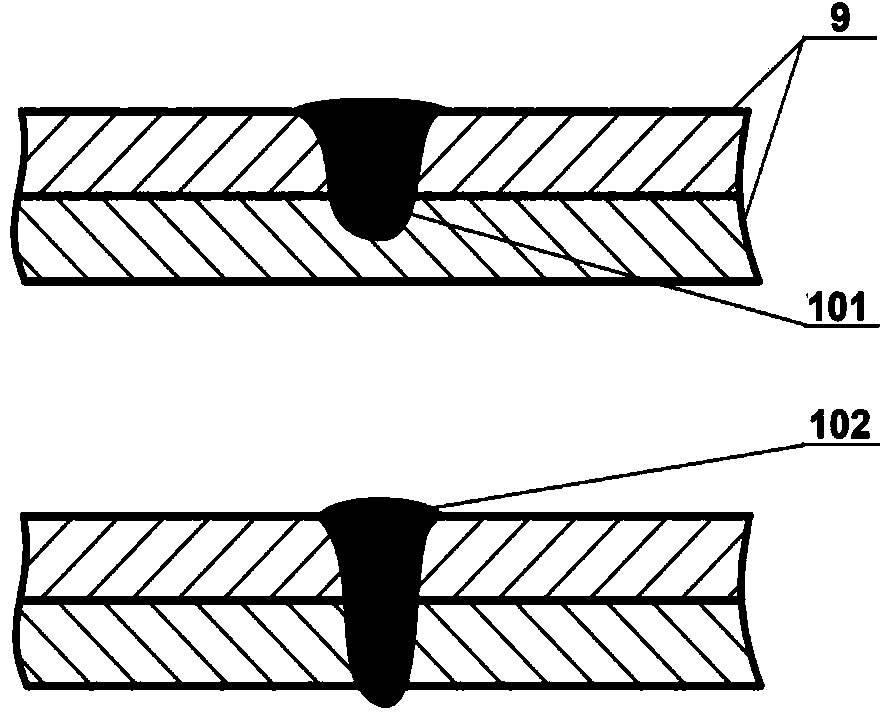

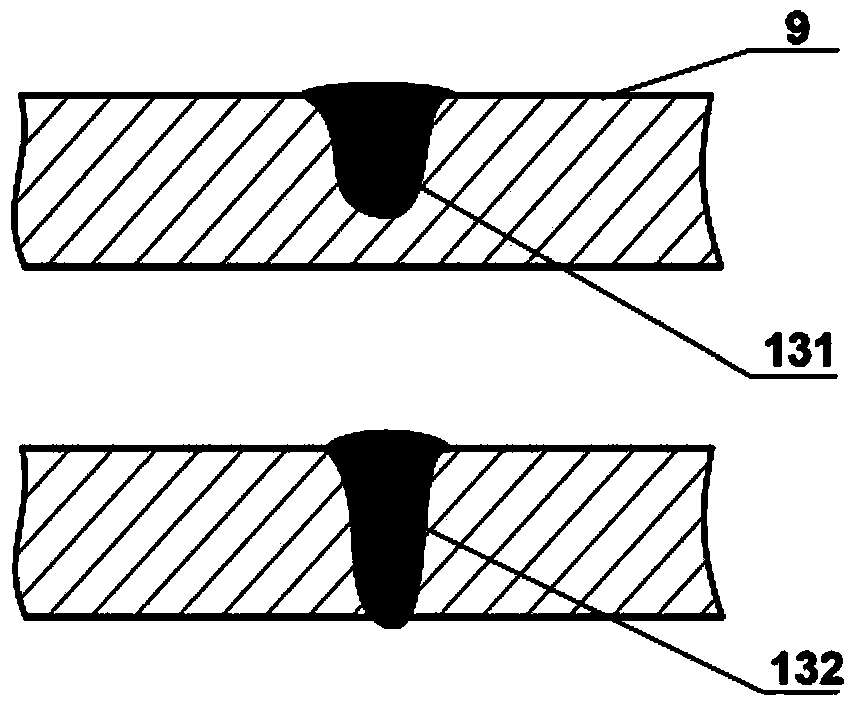

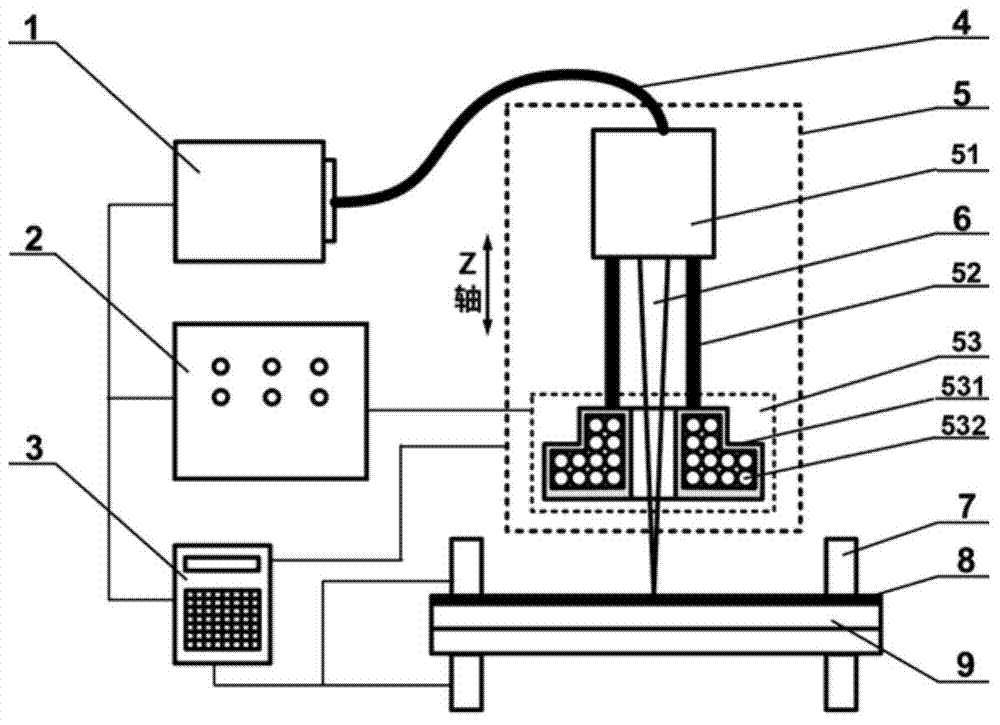

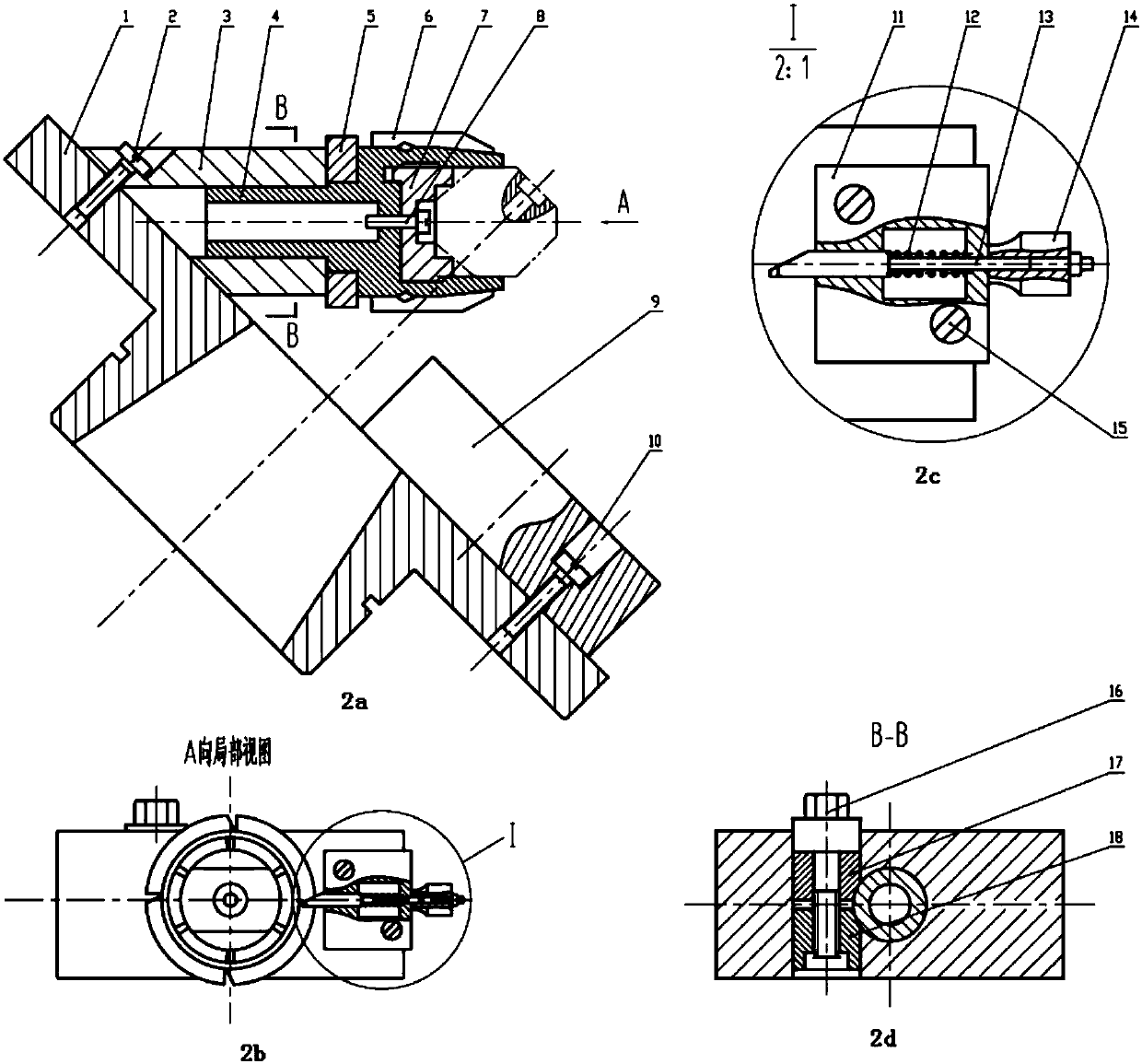

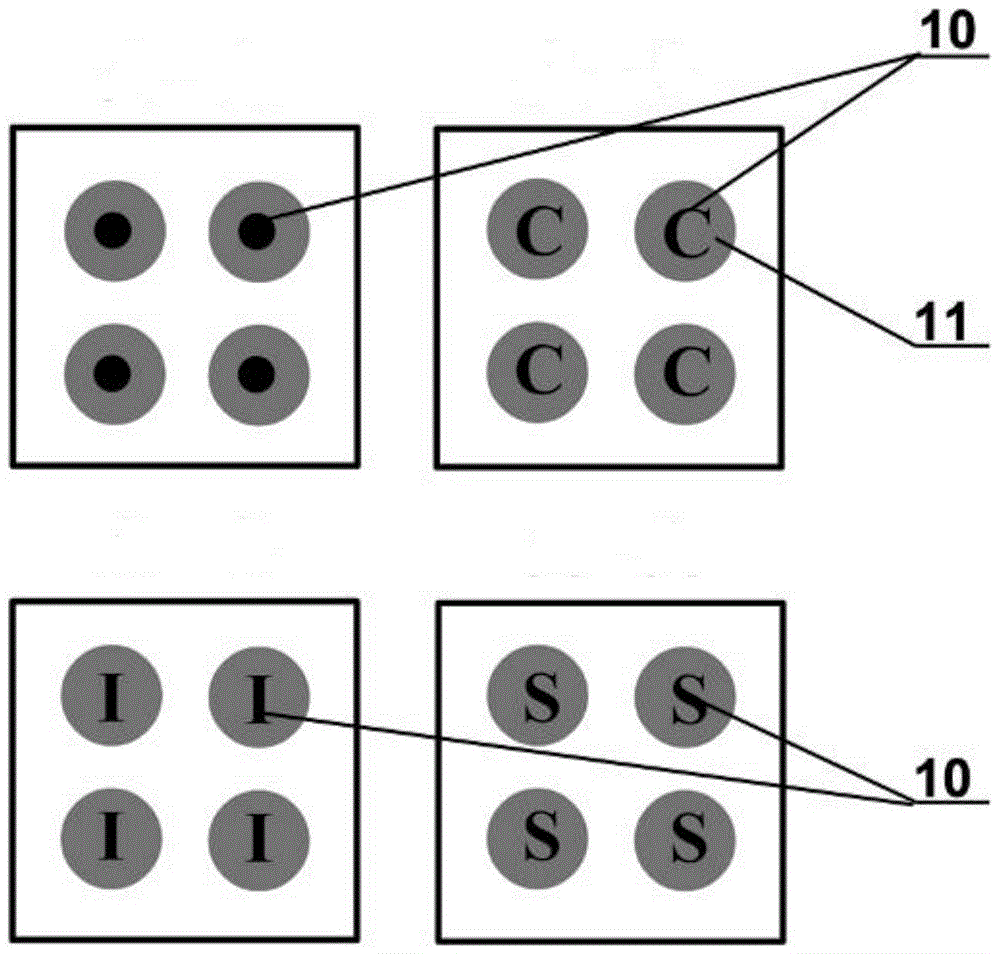

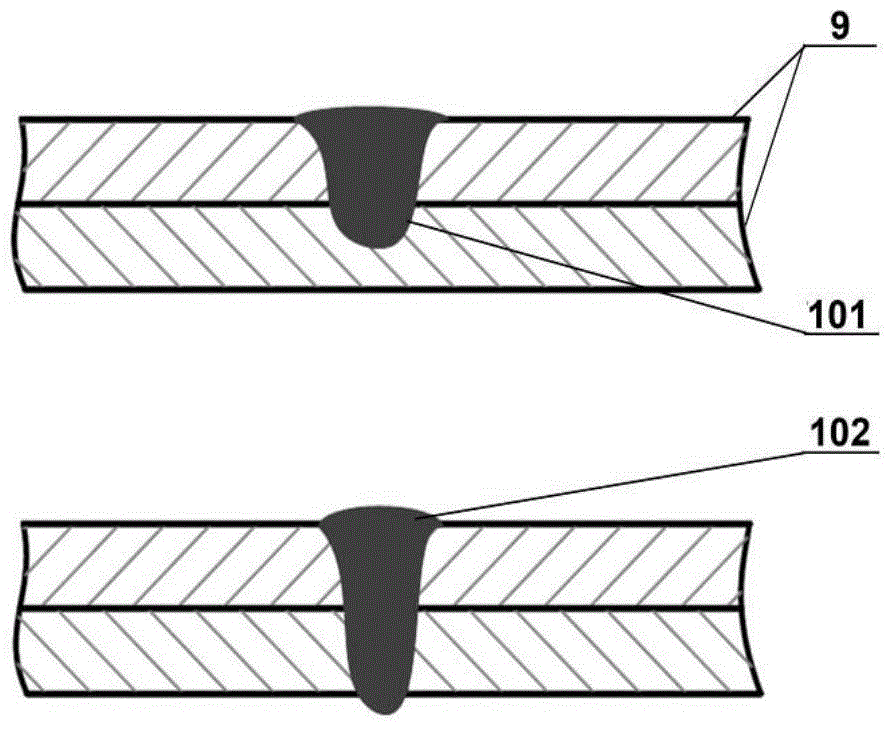

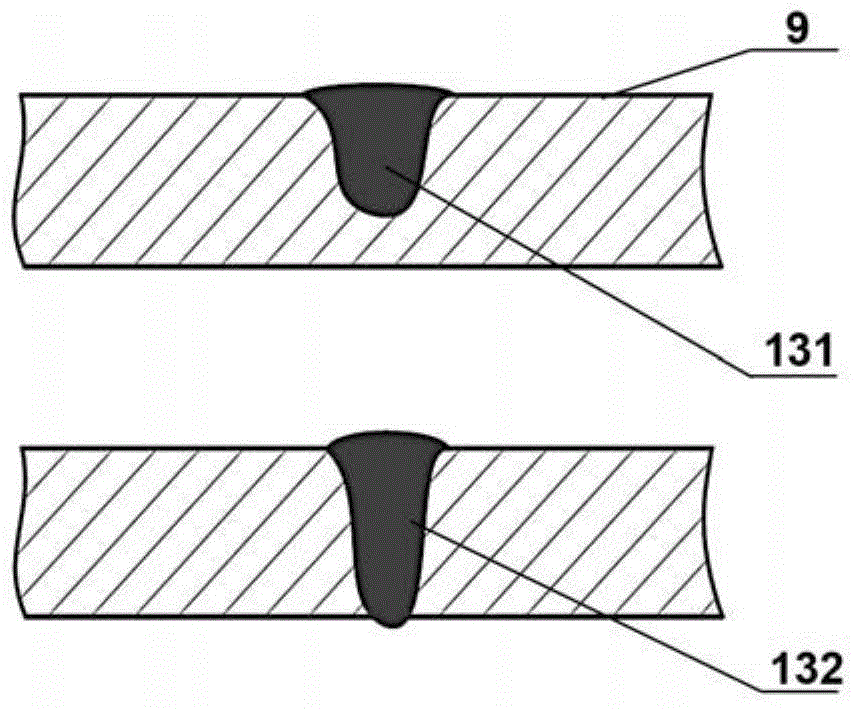

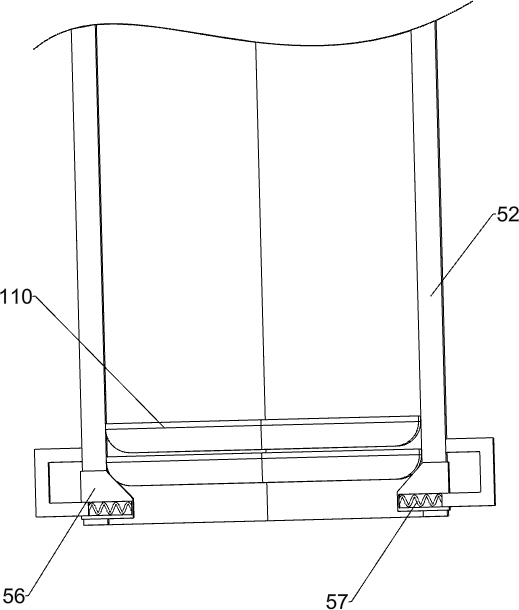

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

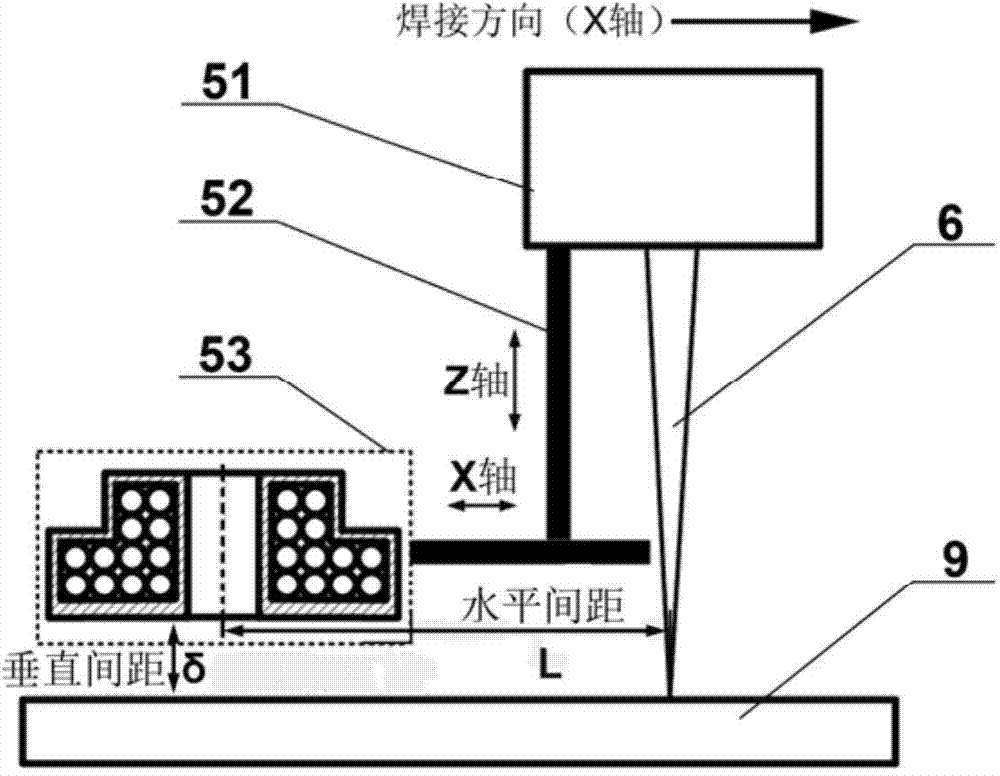

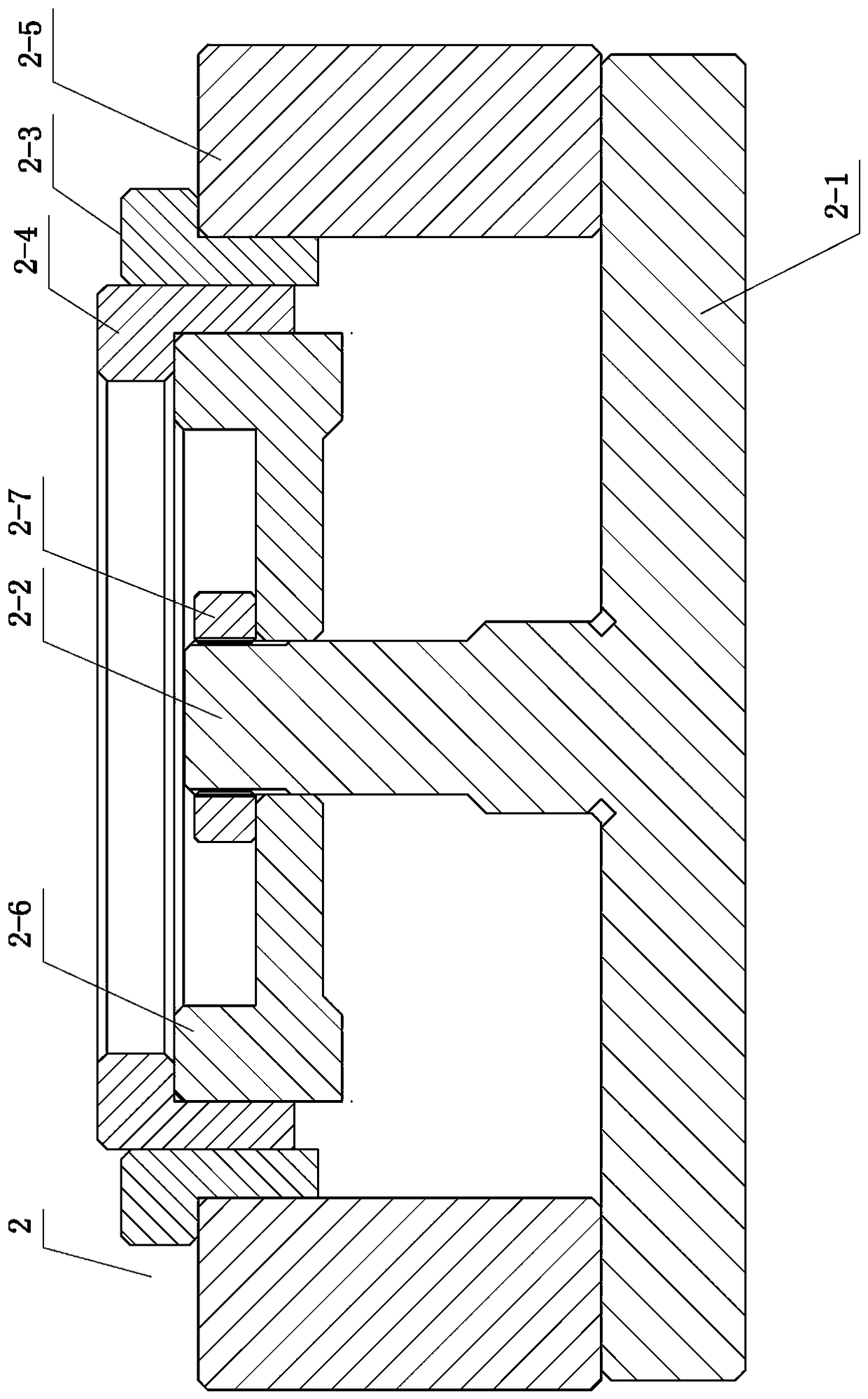

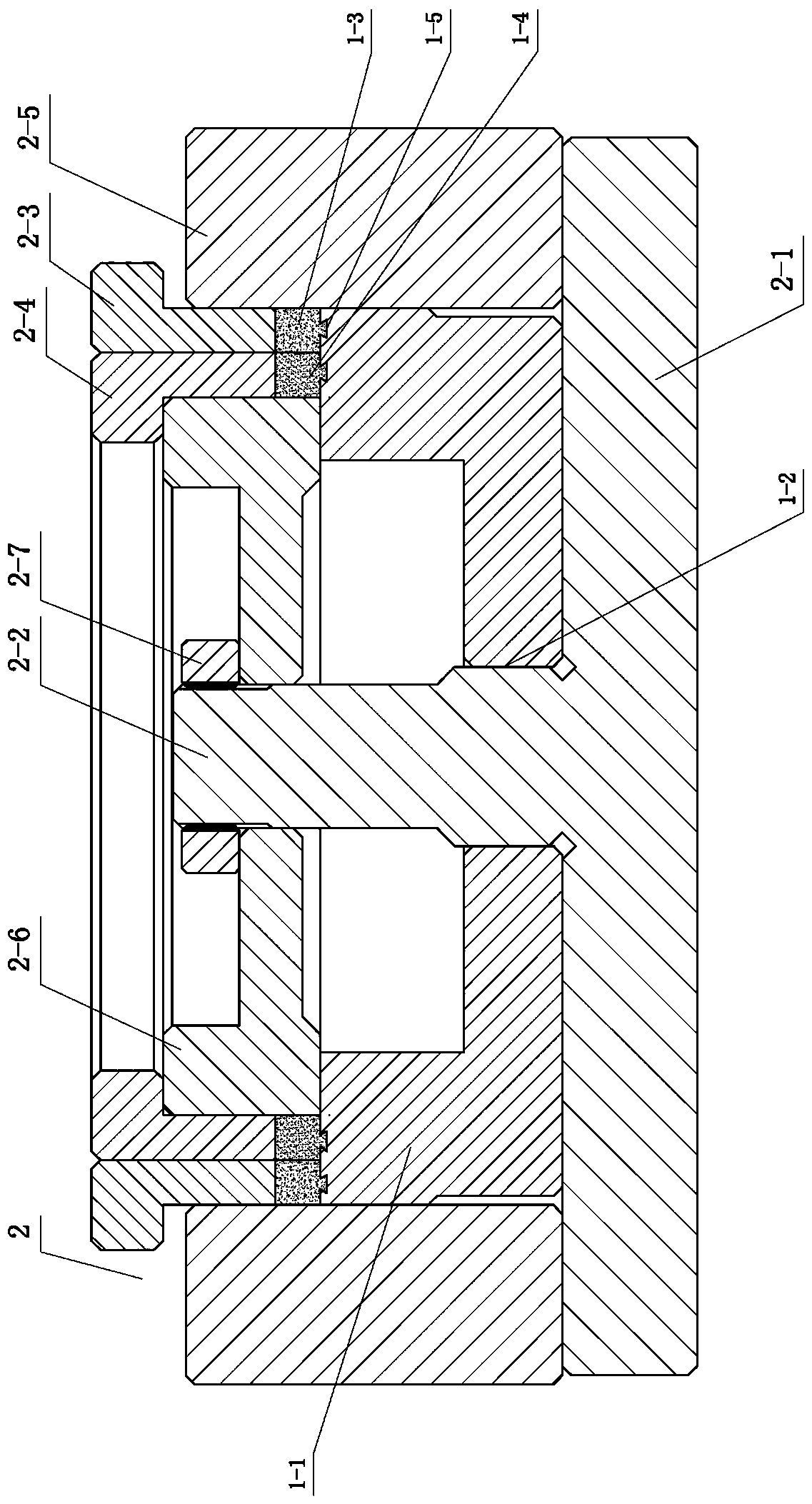

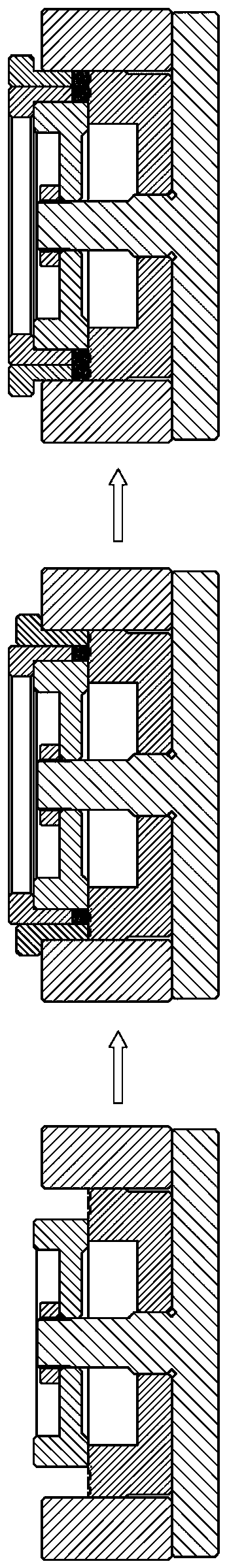

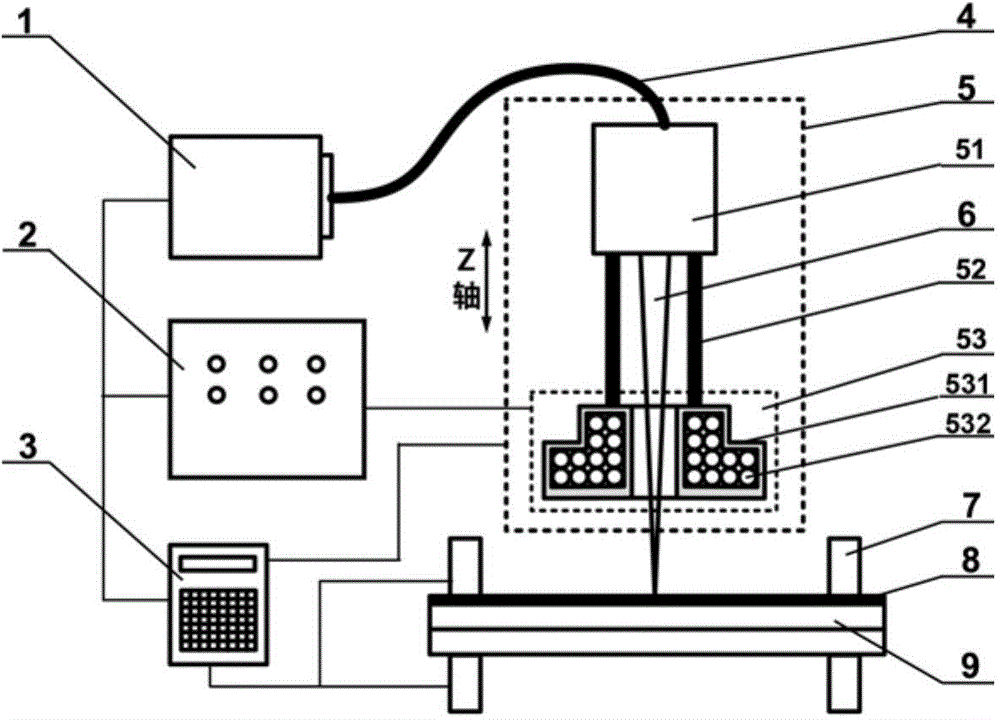

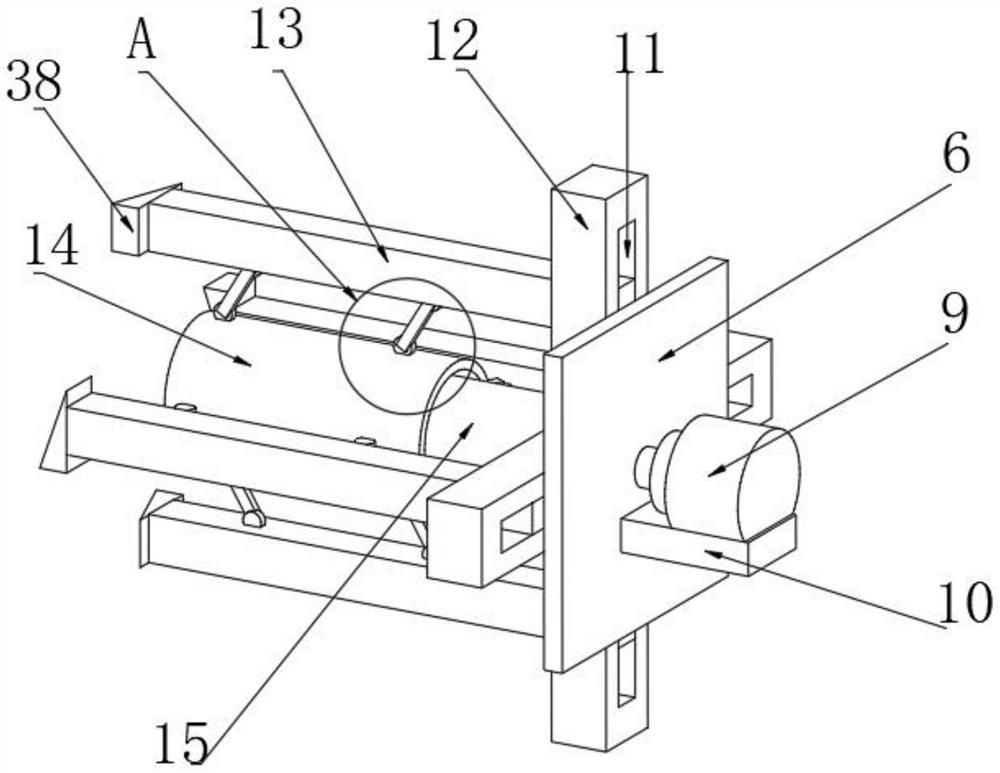

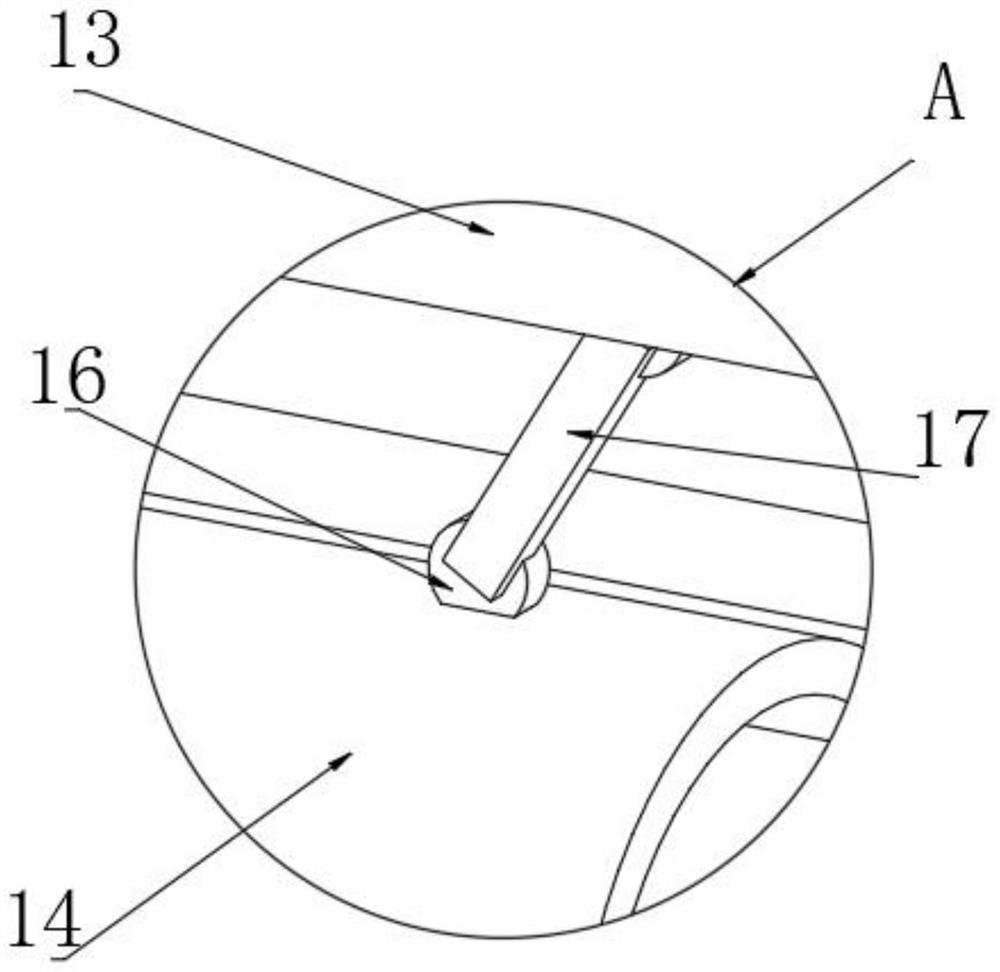

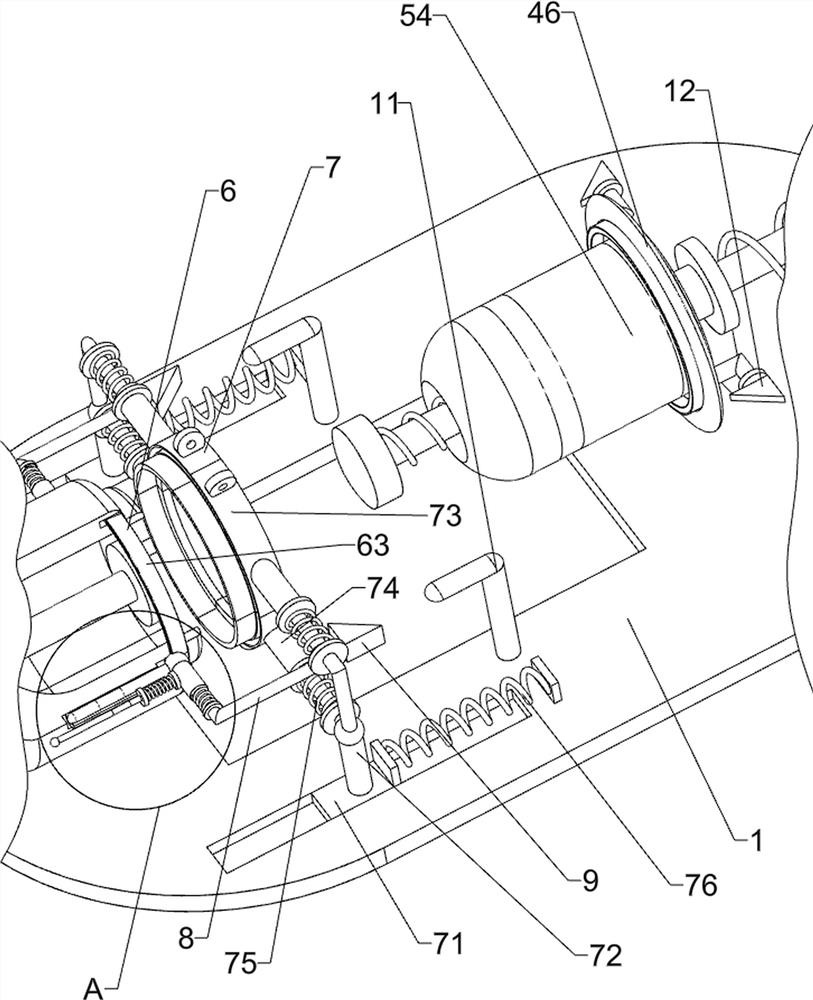

Pulsed high magnetic field auxiliary laser welding method and device

ActiveCN103769746AImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

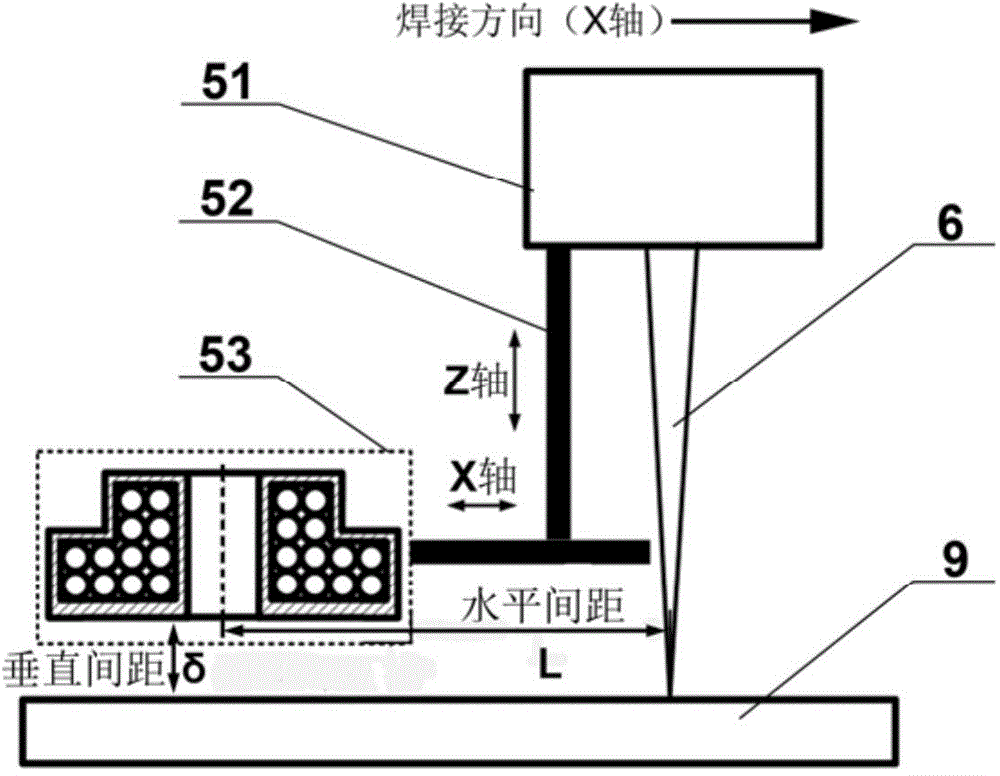

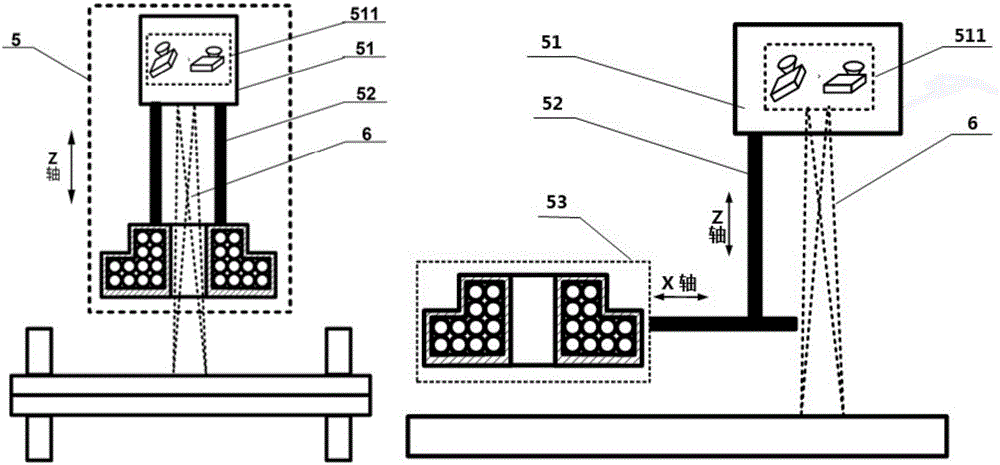

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

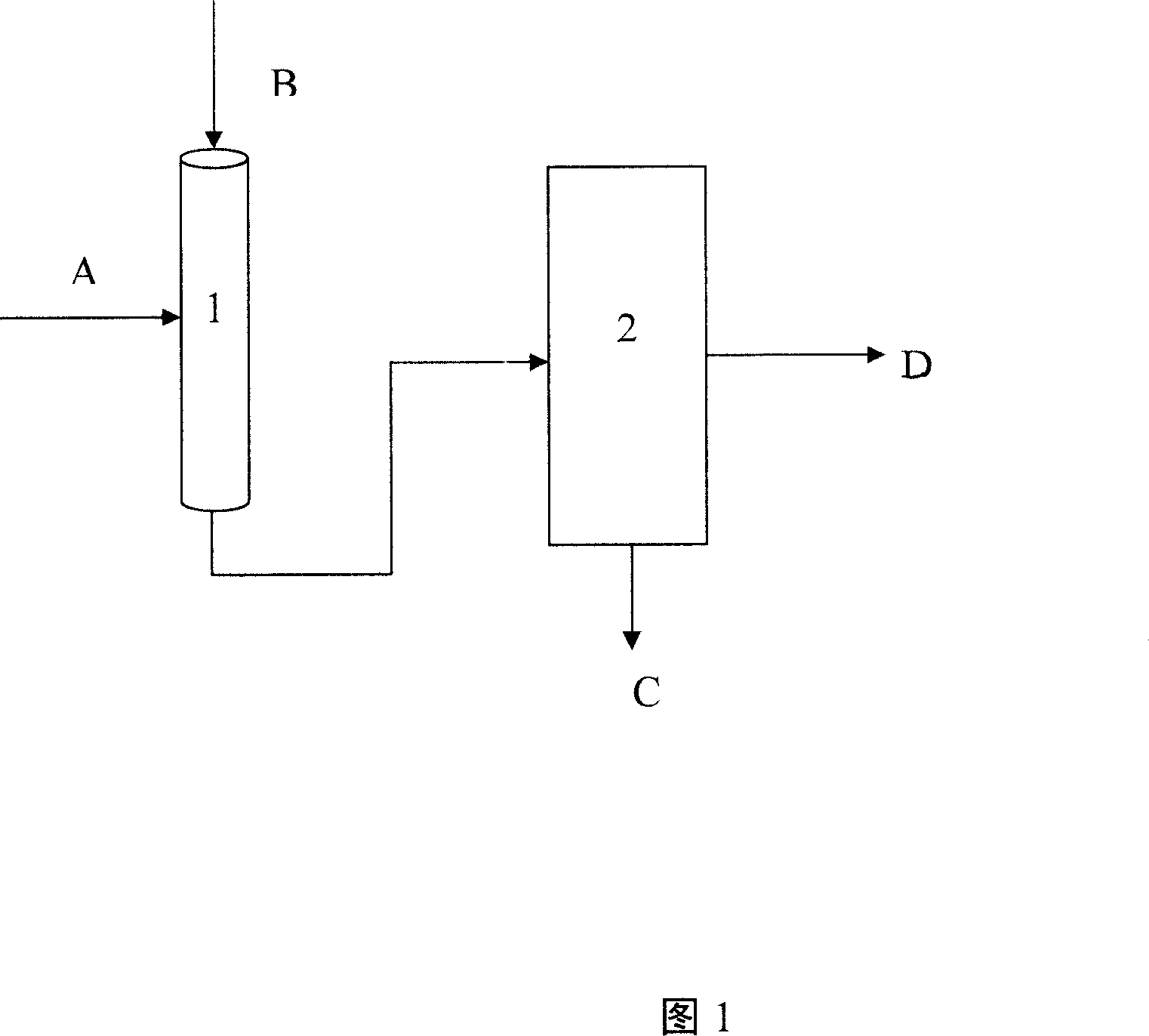

Preprocessing method for coking wax oil used as hydrocracking raw material

ActiveCN101144031ATo achieve the processing effectReduce the temperatureRefining with acid-containing liquidsHydrocarbon oil crackingPhosphorous acidPretreatment method

The invention relates to a pretreatment method for hydrocracking raw material to improve the processing property of coker gas oil to be equivalent with straight-run refining wax oil through remove polar impurities, such as coke powder, colloid, heterocyclic benzenoid, and basic nitrogen compound, from coker gas oil, which includes the following steps: the pretreatment agent and the coker gas oil are mixed under 20-120 DEG C according to 0.1-10 percent by weight proportion; the pretreatment agent includes 49-89 percent of active components, such as hydrochloric acid, nitric acid, perchloric acid, sulfuric acid, phosphorous acid or phosphorous anhydride; 10-50 percent of cosolvents, such as ferric chloride, glycerol, ethylene glycol or DMF; and 0.1-10 percent one or more of polyacrylamide, polyaluminium chloride, polymeric aluminum ferric chloride, sodium meta-aluminate, sodium sulfate, sulfuric acidaluminum, aluminum potassium sulfate, and sodium silicate; the mixed materials are gravity settled in a settling tank, the sedimentation temperature is 60-150 DEG C, and the time is 30-120min, refined coker gas oil can be directly blended into hydrocracking device to decrease the initial temperature of hydrocracking prerefining section by more than 10 DEG C or improve the device processing capacity by more than 30 percent.

Owner:PETROCHINA CO LTD +1

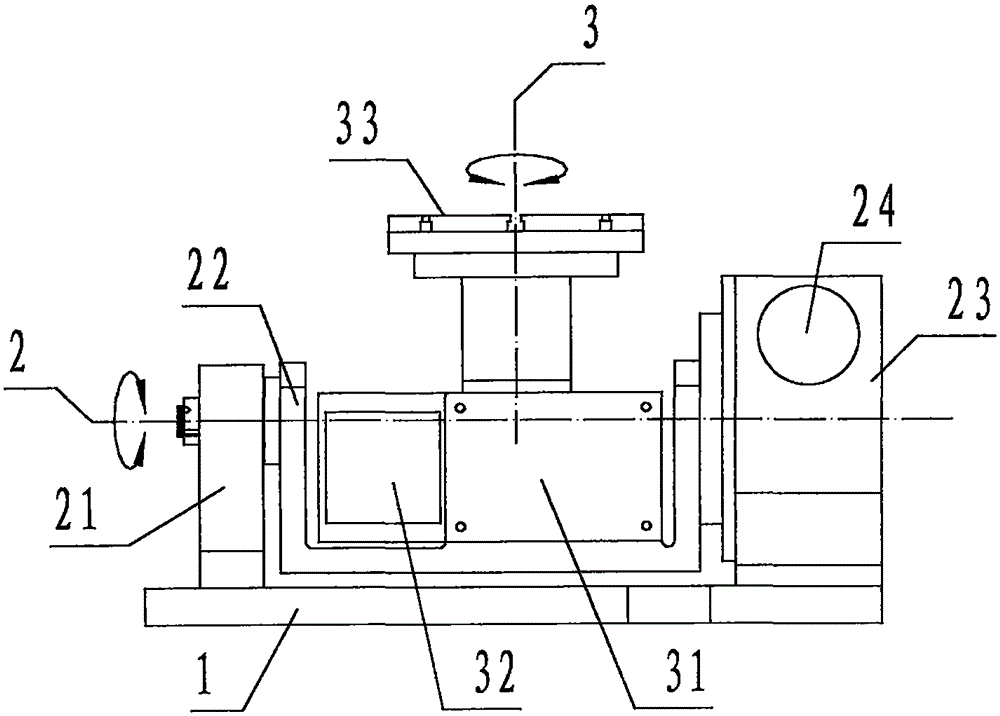

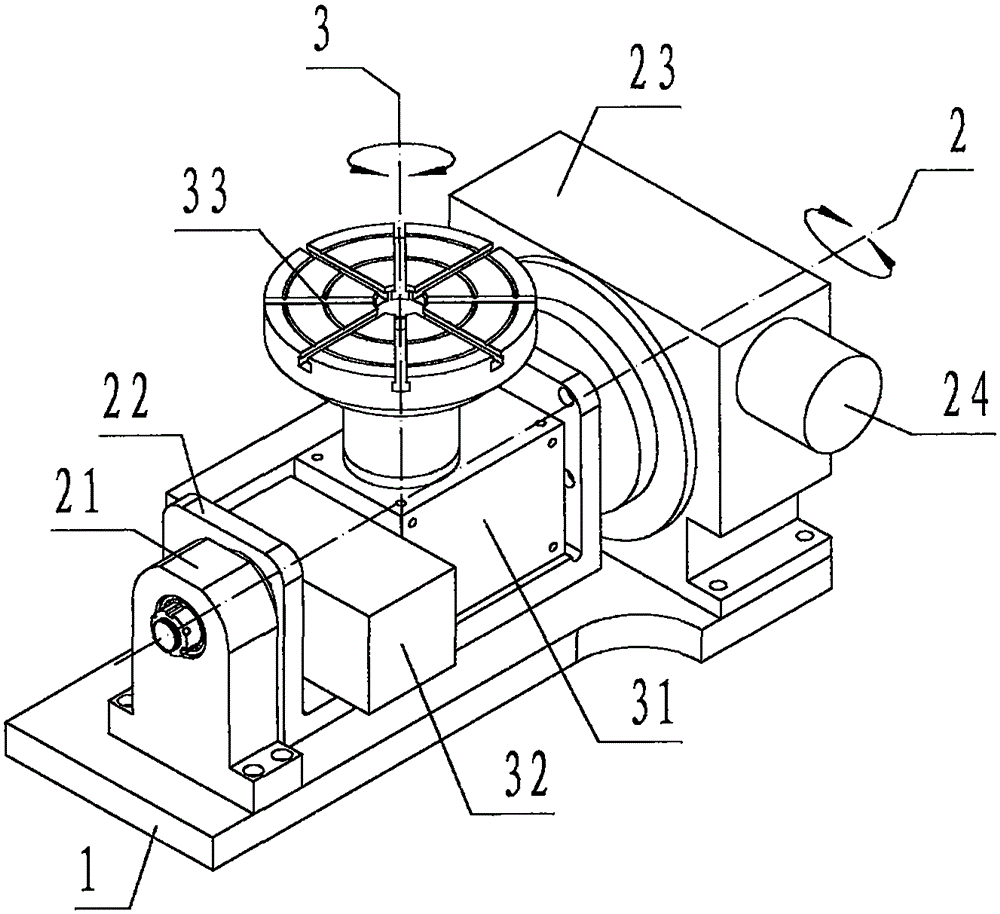

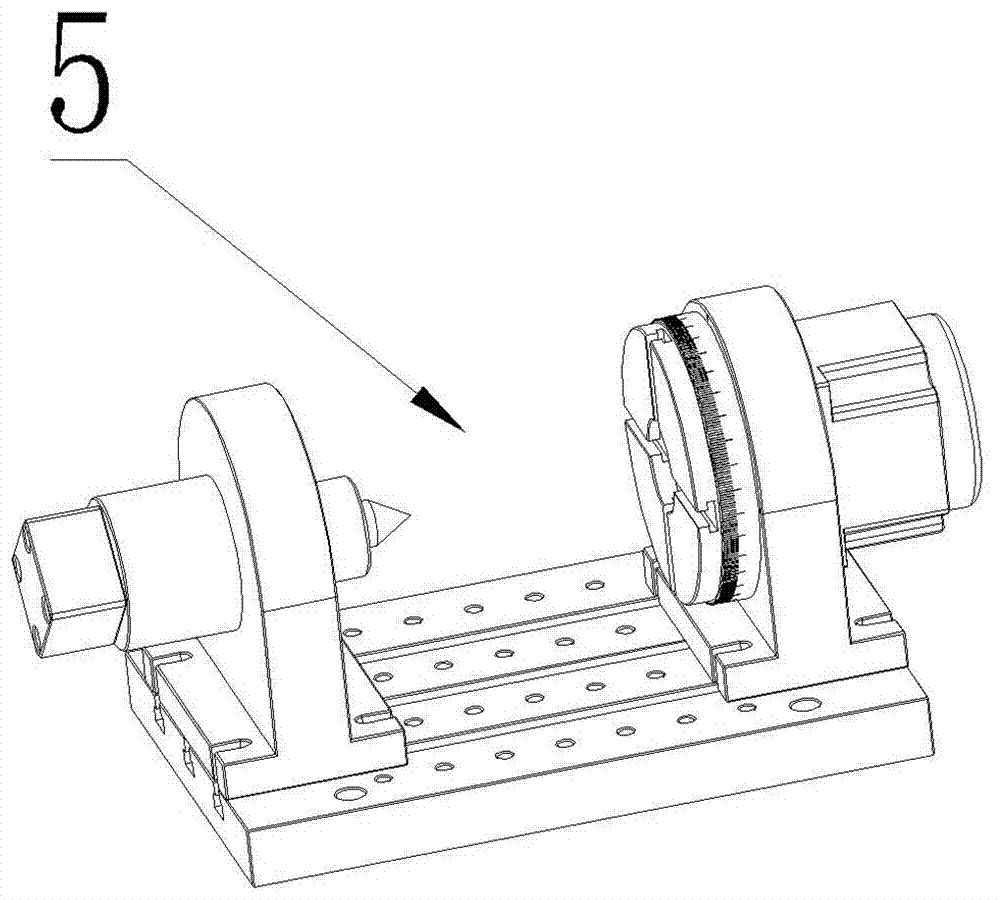

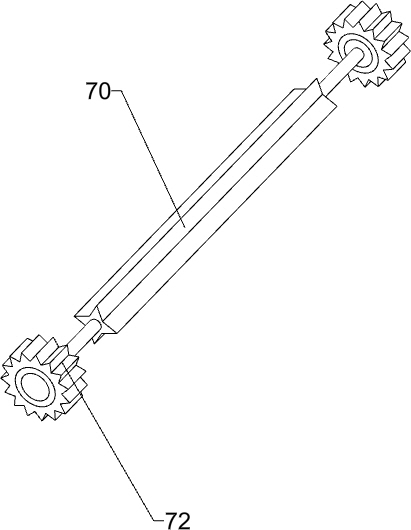

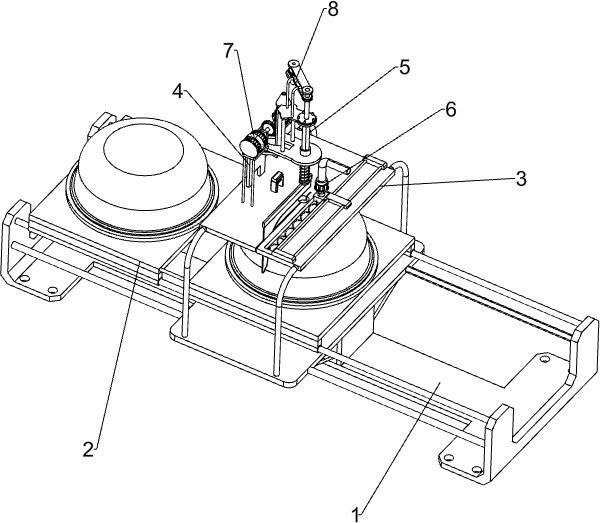

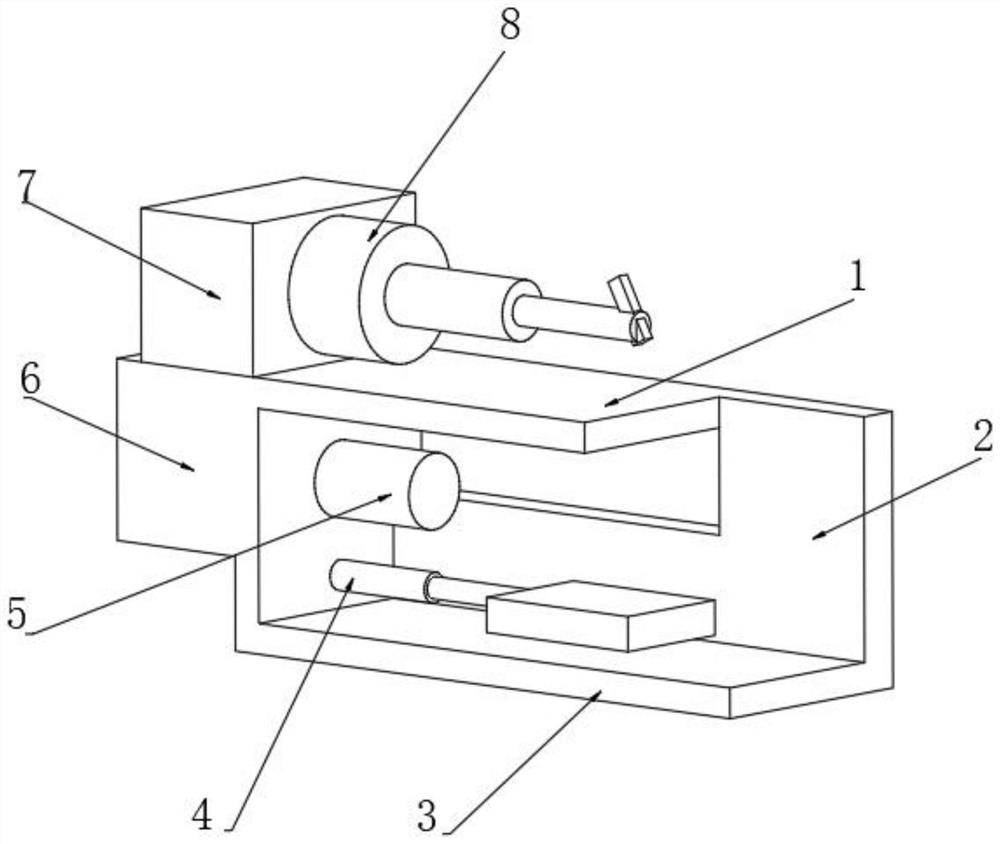

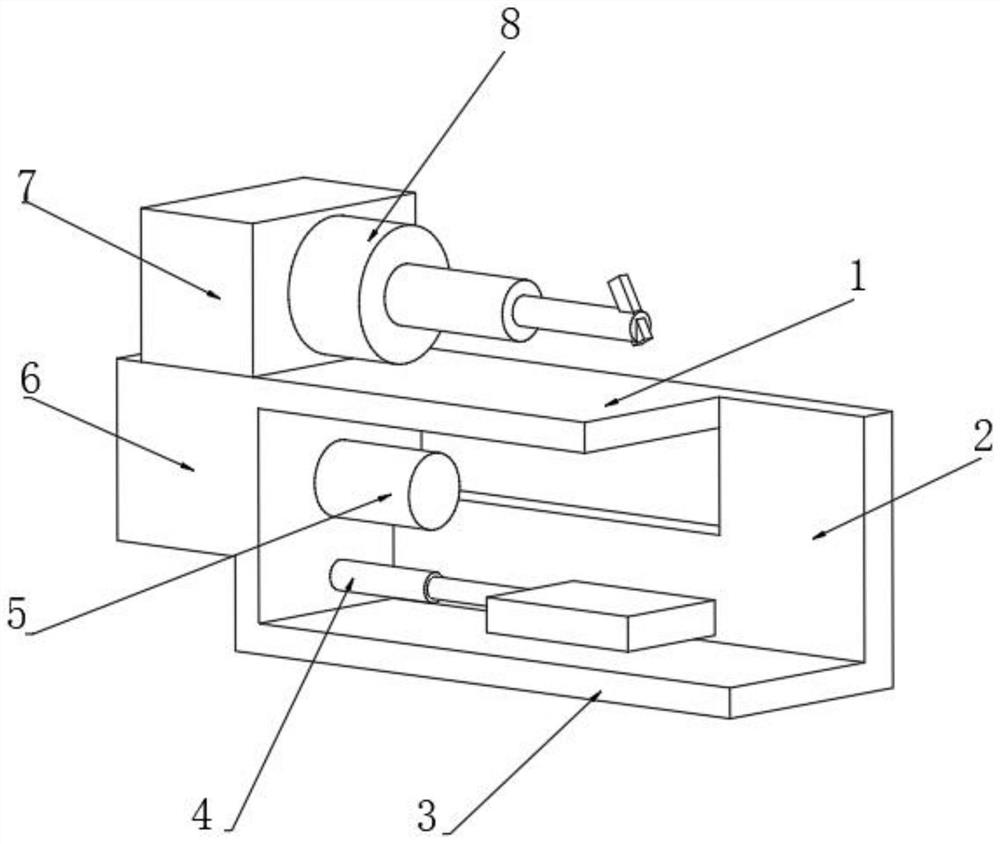

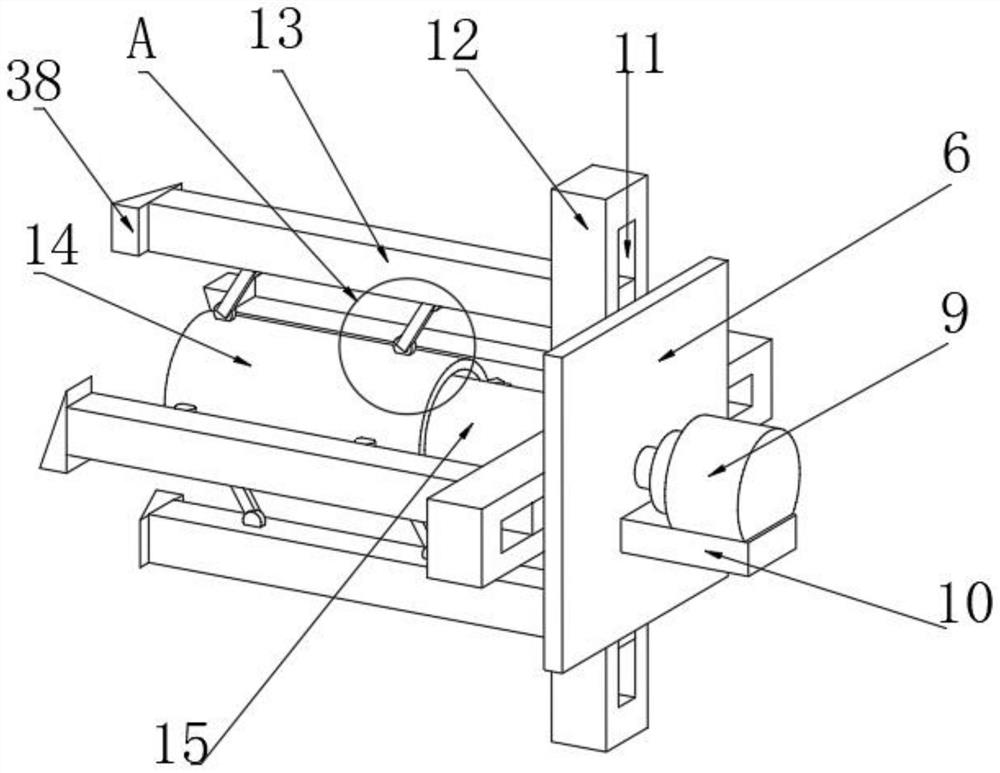

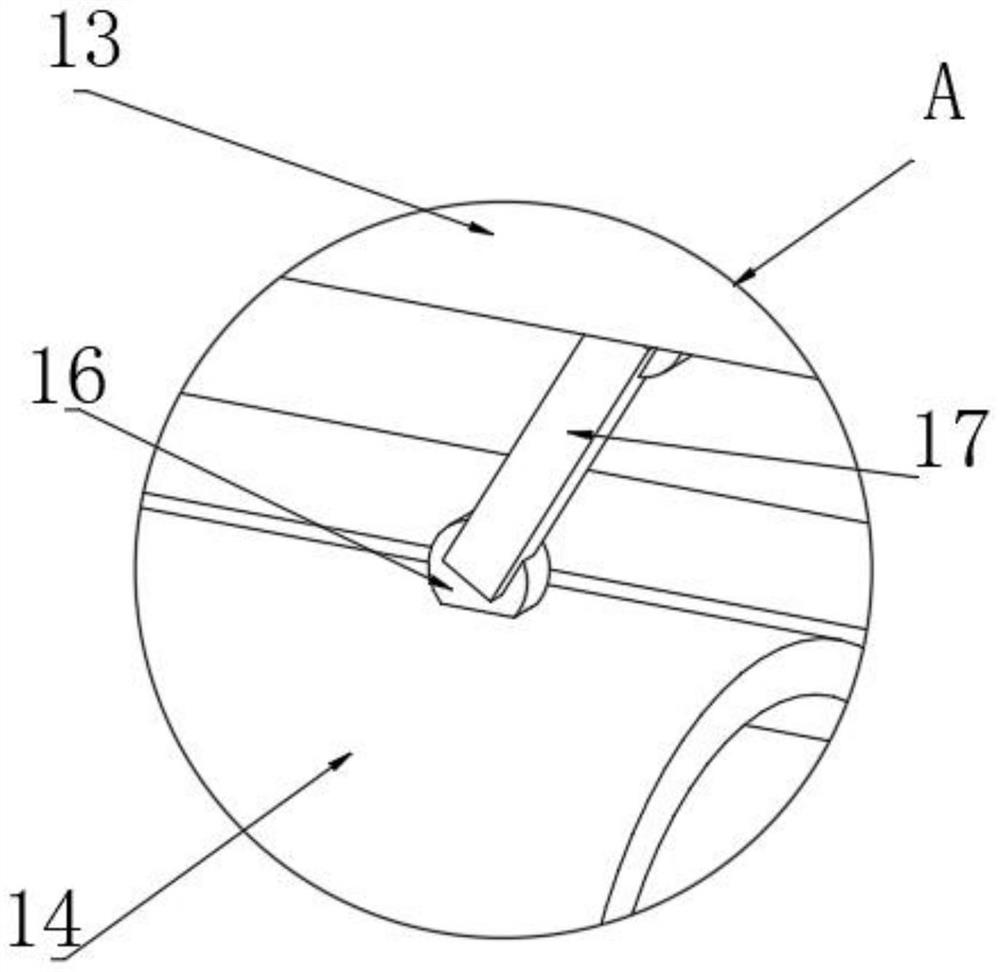

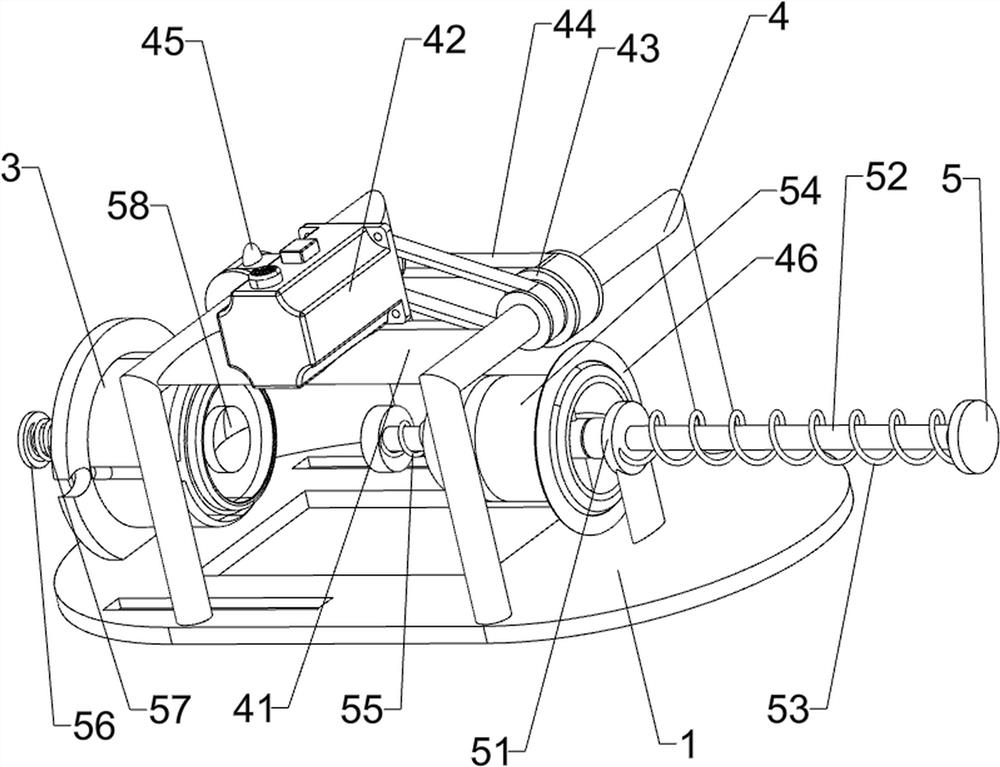

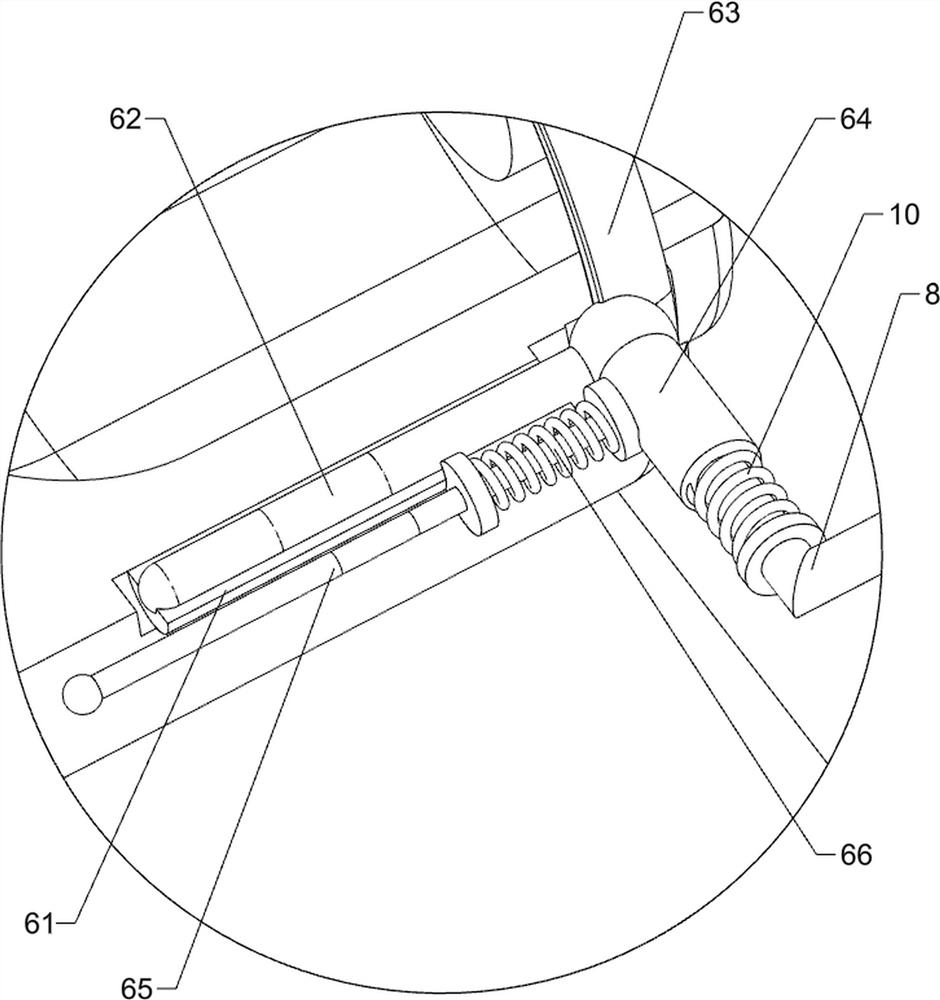

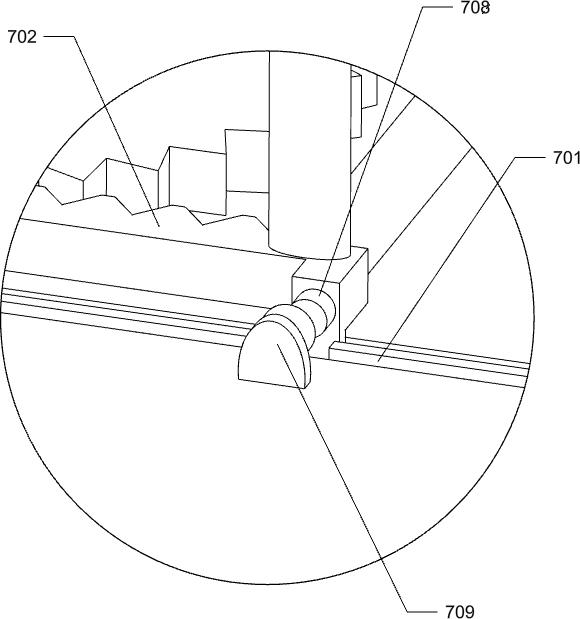

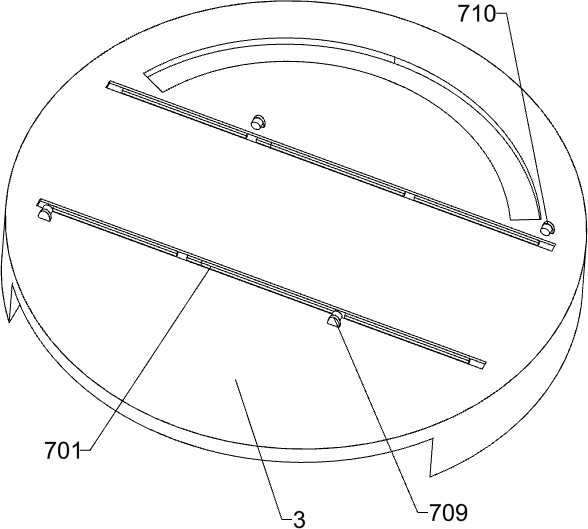

Two-shaft numerical control device used for machining shoe molds

InactiveCN105033671AImprove efficiencyLabor savingMilling machinesFeeding apparatusRotary stageNumerical control

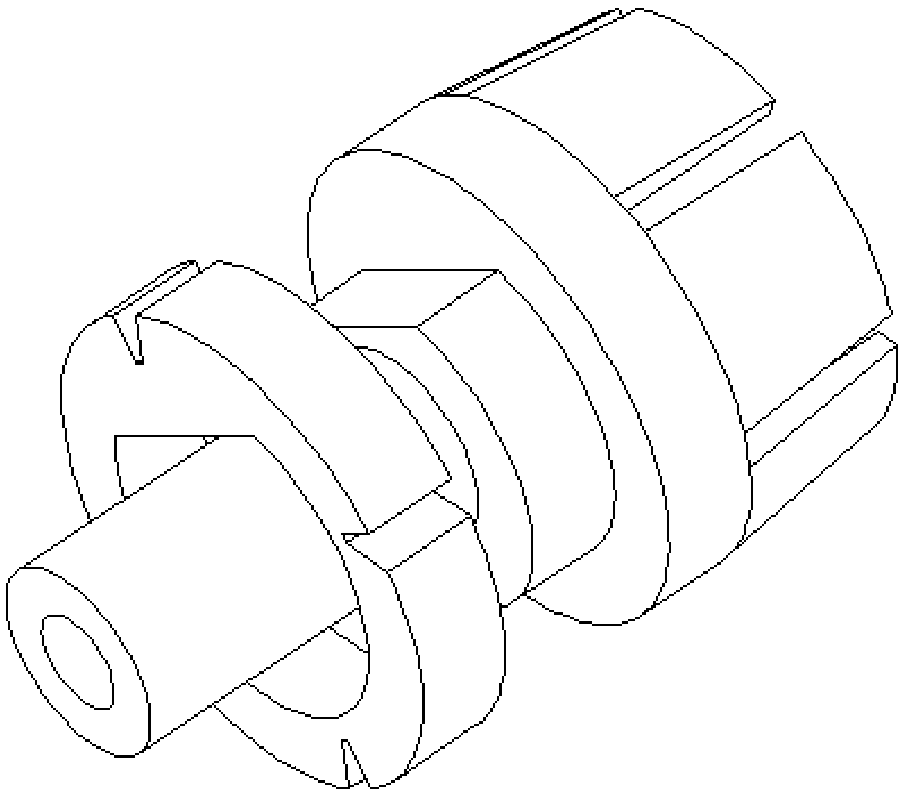

The invention discloses a two-shaft numerical control device used for processing shoe molds. The device comprises a base (1), a horizontal shaft (2) and a vertical shaft (3). The horizontal shaft is composed of a support, a rotating base, a speed reducer P and a servo motor P. The vertical shaft is composed of a speed reducer Z, a servo motor Z and a rotating table. The support and the speed reducer P are fixed to the upper surface of the base. The rotating base is rotationally connected between the support and the speed reducer P. The speed reducer Z and the servo motor Z are located on the rotating base. The output end of the speed reducer Z faces upwards. The rotating table is connected with the output end of the speed reducer Z. During application, the servo motor P drives the rotating base to rotate around the horizontal axis through the speed reducer P. The servo motor Z drives the rotating table to rotate around the vertical shaft through the speed reducer Z. The rotating table bears shoe mold blanks and is matched with a cutting tool of a numerical control carving and milling machine tool for processing. Through the technical scheme, the overall shoe mold carving and milling process can be completed through one time of clamping, and the purposes of improving efficiency, precision and quality and reducing cost are achieved during processing of the shoe molds.

Owner:宁波市凯博数控机械有限公司

Processing method for section bar roll bending

The invention relates to a processing method for section bar roll bending. Forming devices required by the processing method include a stretch bender and a packing block. The forming method comprises the following steps that firstly, the packing block of which the shape is consistent with that of an inner cavity is manufactured according to the shape of the inner cavity of a workpiece to be processed, the packing block is fixed on one end of a screw rod, and the other end of the screw rod is fixed on a right arm of the stretch bender; secondly, the packing block is packed into the inner cavity of the workpiece and is put in the arcing position of the workpiece, and the workpiece is fixed below a top block; finally, a rotating shaft is rotated anticlockwise, so that a left arm of the stretch bender is rotated anticlockwise to drive the workpiece to perform roll bending deformation on a roll bending die, so that the workpiece to be processed is bent and formed, and the packing block is in the bending position all the time. Compared with the prior art, the processing method has the following characteristics that workpieces with different cavities can be processed, the workpieces can be uniformly stressed, and the processed workpieces have high precision in respects of section incision, workpiece depression, twisting, wrinkling and the like.

Owner:SHANDONG NOLLVETEC LIGHTWEIGHT EQUIP CO LTD

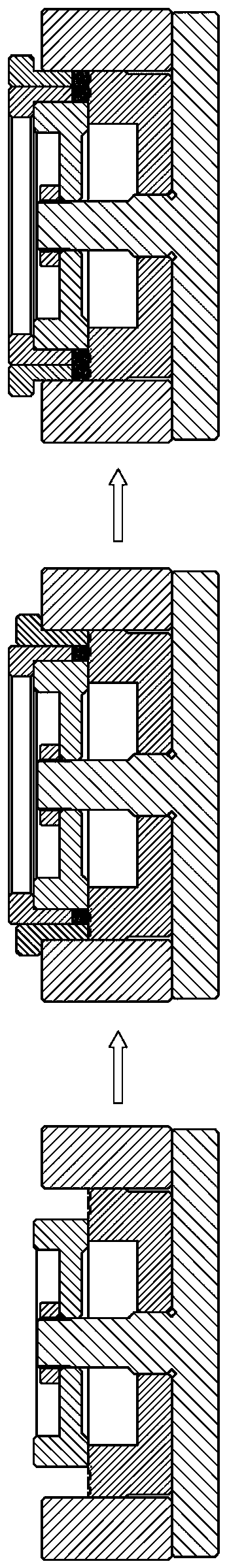

Diamond resin wheel and mold and method for machining resin wheel

ActiveCN108714860AConsistent structureHigh structural densityBonded abrasive wheelsGrinding devicesRough surfaceGrinding wheel

The invention relates to a diamond resin wheel and a mold and a method for machining the resin wheel. The resin wheel comprises a base body and abrasive material layers, wherein the abrasive layers are at least two abrasive layers which are fixed on the surface or the outer circle of a base body through extrusion and hot pressing, and each abrasive layer is formed by mixing and pressing differentcoarse and thin diamond particles and a binding agent; and the bonding position of the abrasive material layers and the base body are adopted with a dovetail-type structure, and the bonding faces arefurther processed into rough surfaces; the mold comprises a positioning base, a mold frame and a center mold, wherein the inner wall of the mold frame and the bottom face of the center mold form a placement area of the diamond resin wheel base body, a gap for installing a pressure head is arranged between the inner wall of the mold frame and the outer wall of the center mold, and the center mold is assembled with an assembling rod in a fixed mode through a fastening nut to be limited; the method for machining the resin wheel comprises the following steps that 1) the resin wheel base body is prepared; 2) the base body is fixed; 3) the abrasive material layers are pressed in advance; 4) hot-pressing forming is carried out; and 5) shaping and manufacturing are carried out. According to the method, a specially designed mold and a machining mode are adopted, so that the resin wheel with multiple utilization can be produced, and the grinding efficiency is improved.

Owner:湖南鑫星凌金刚石工具有限公司

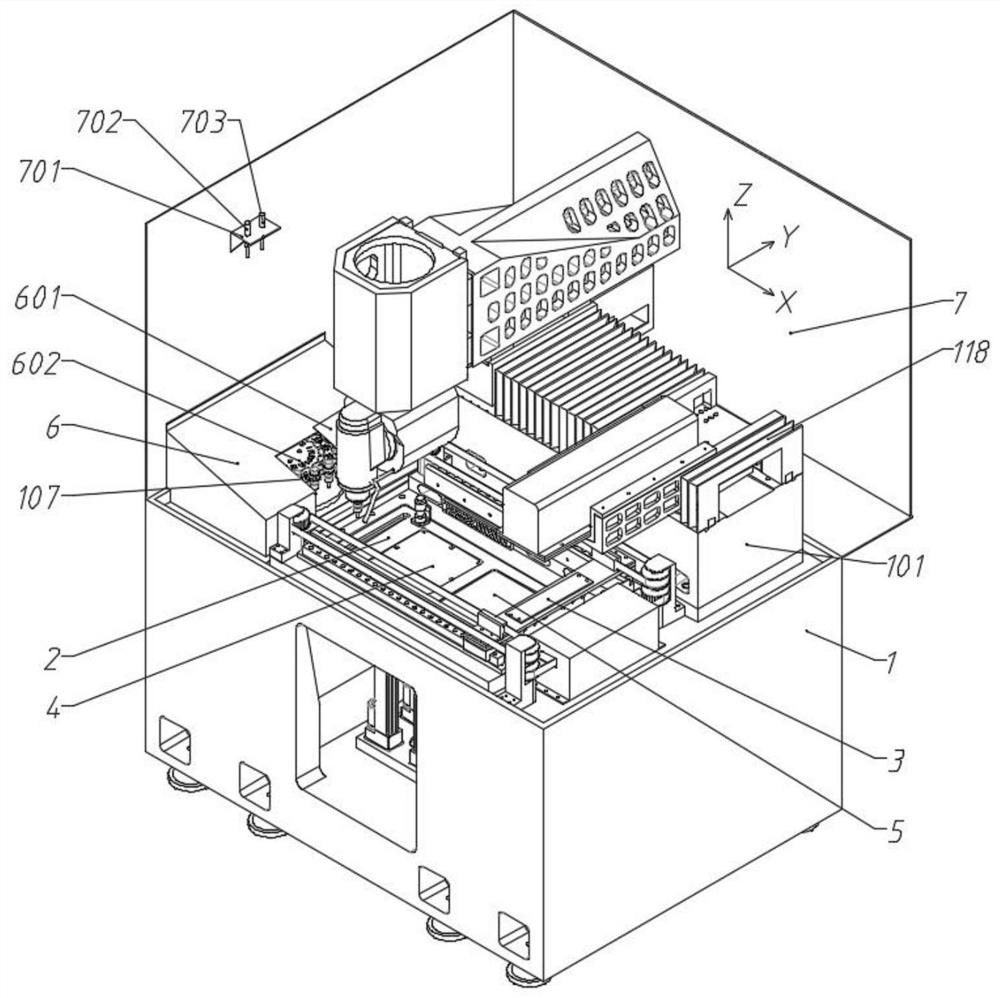

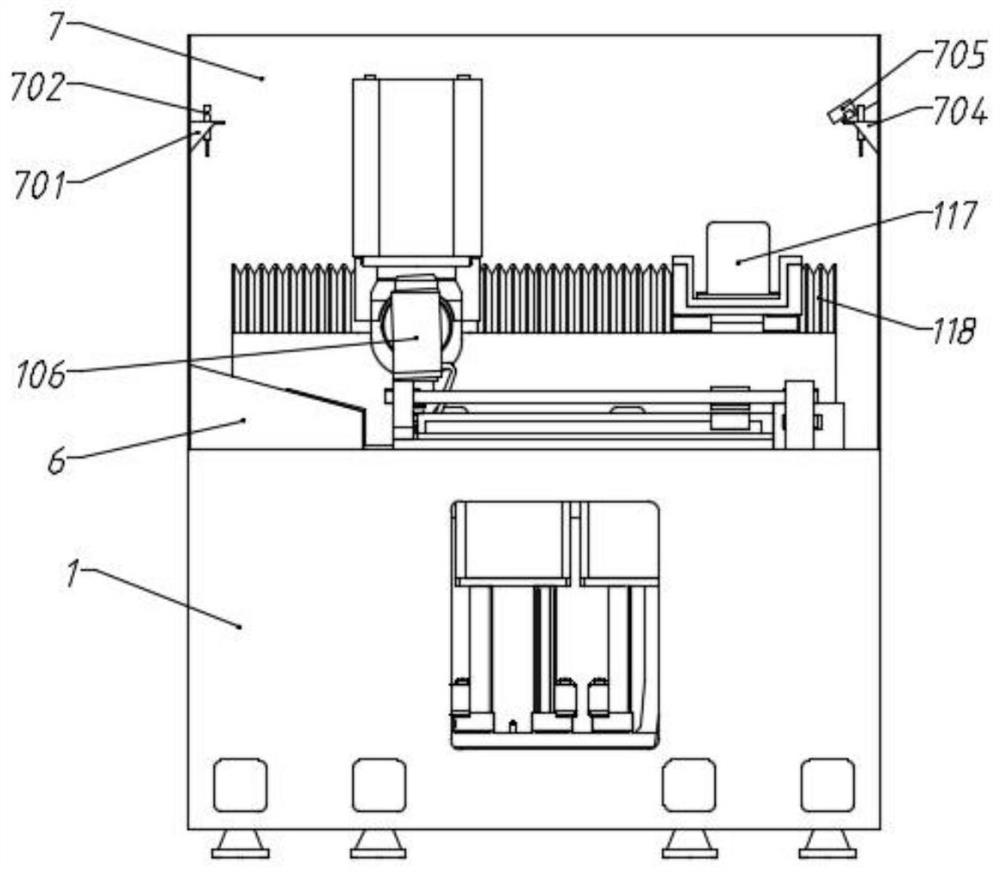

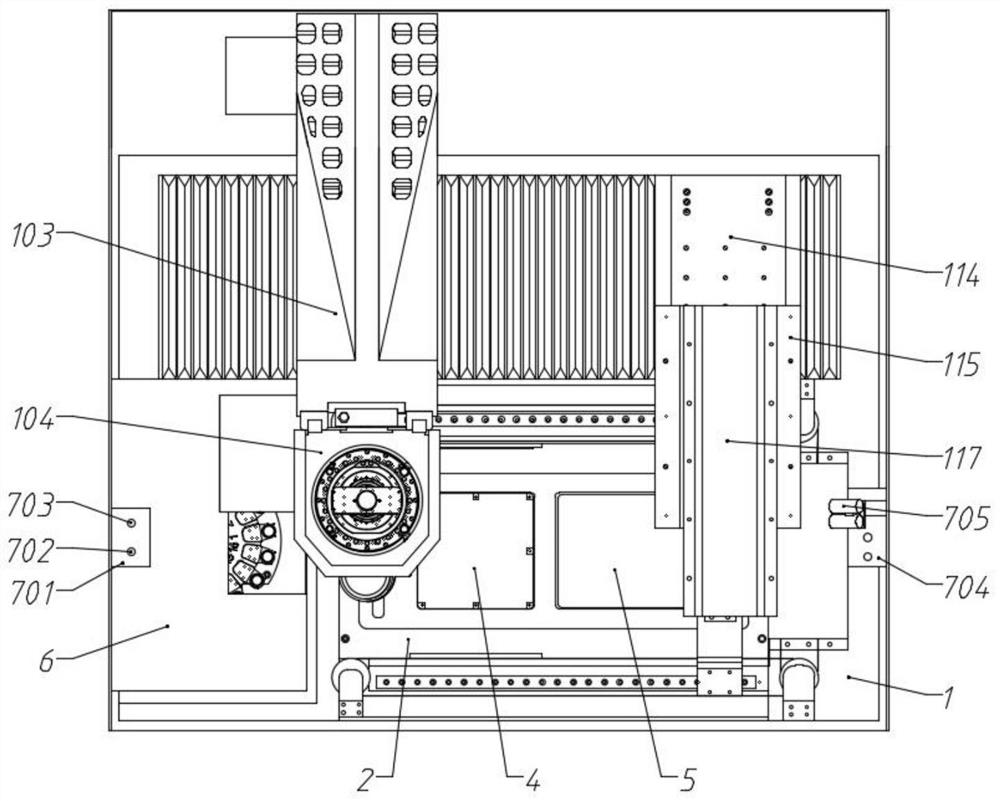

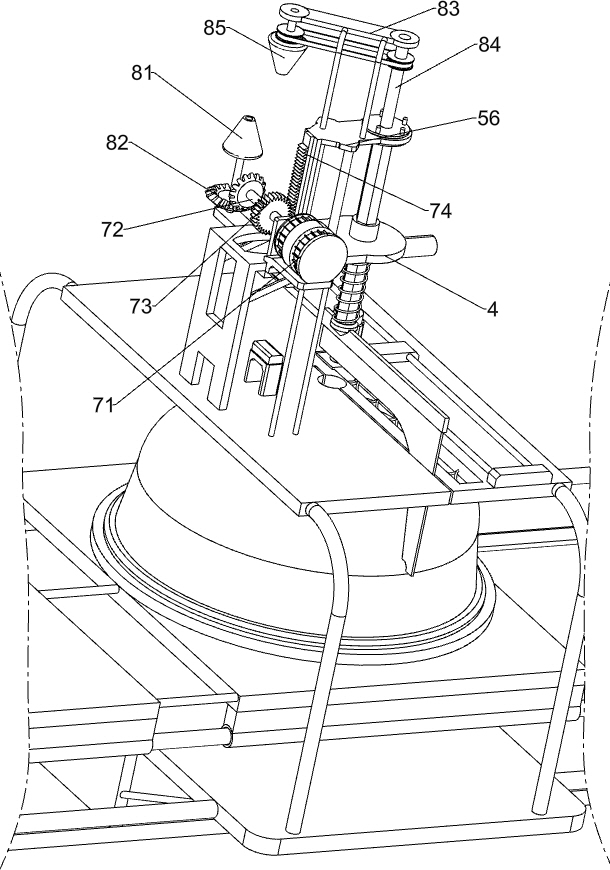

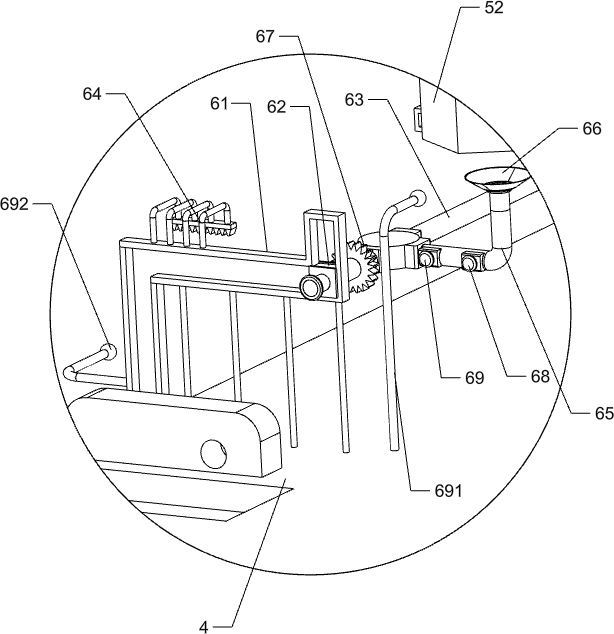

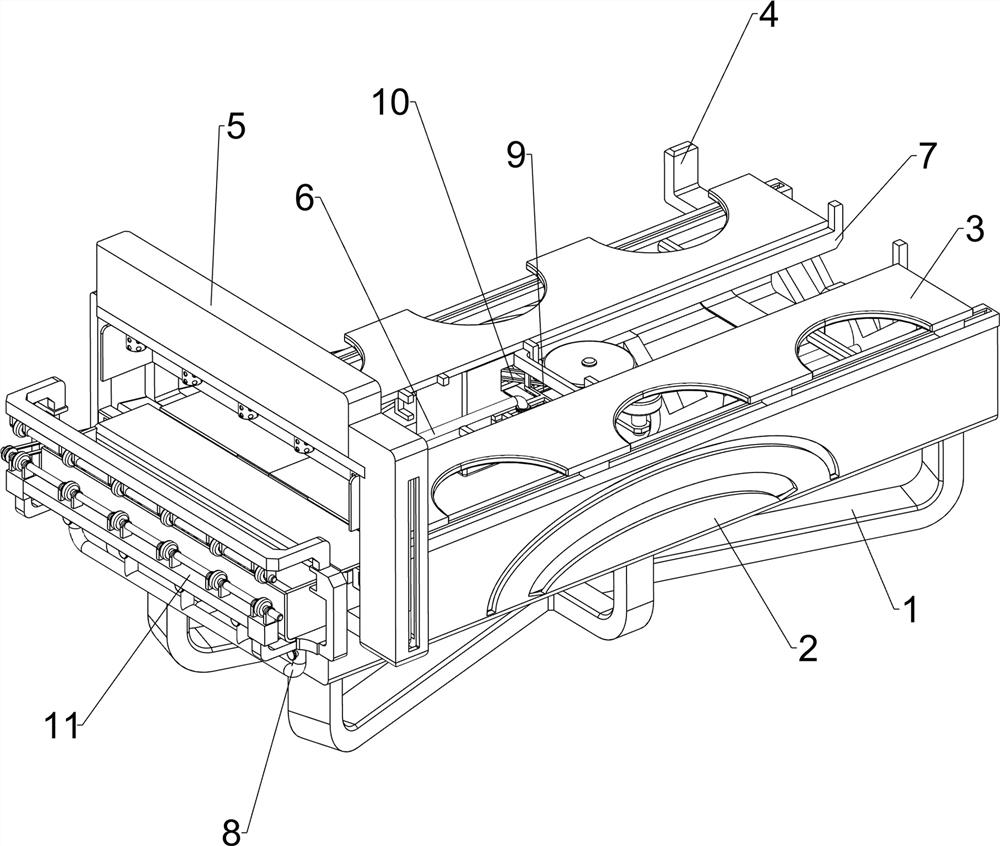

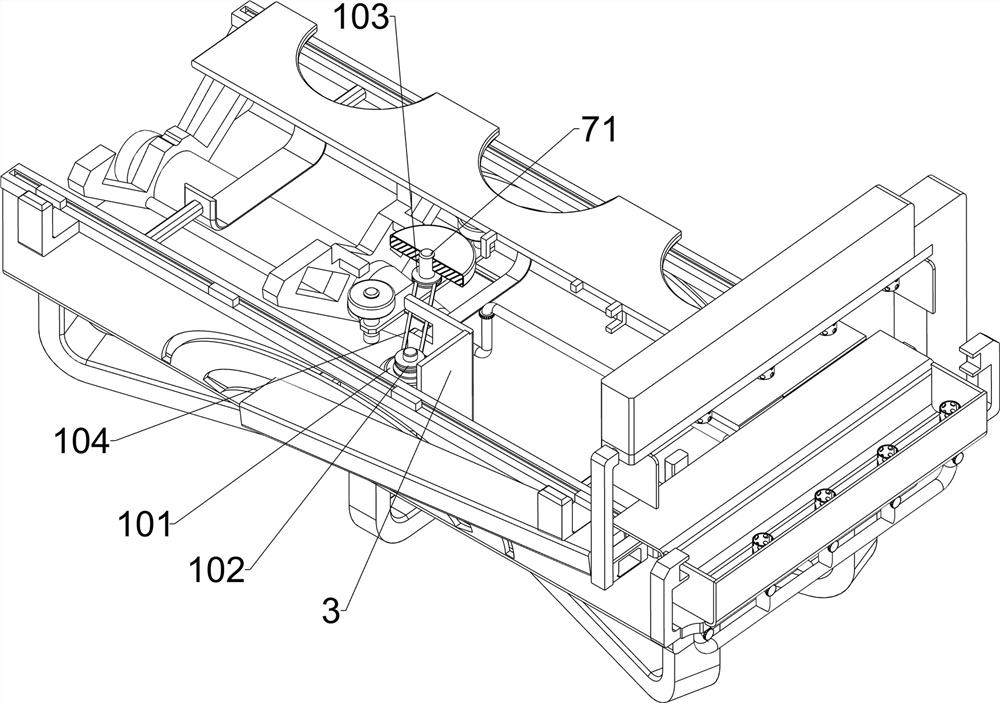

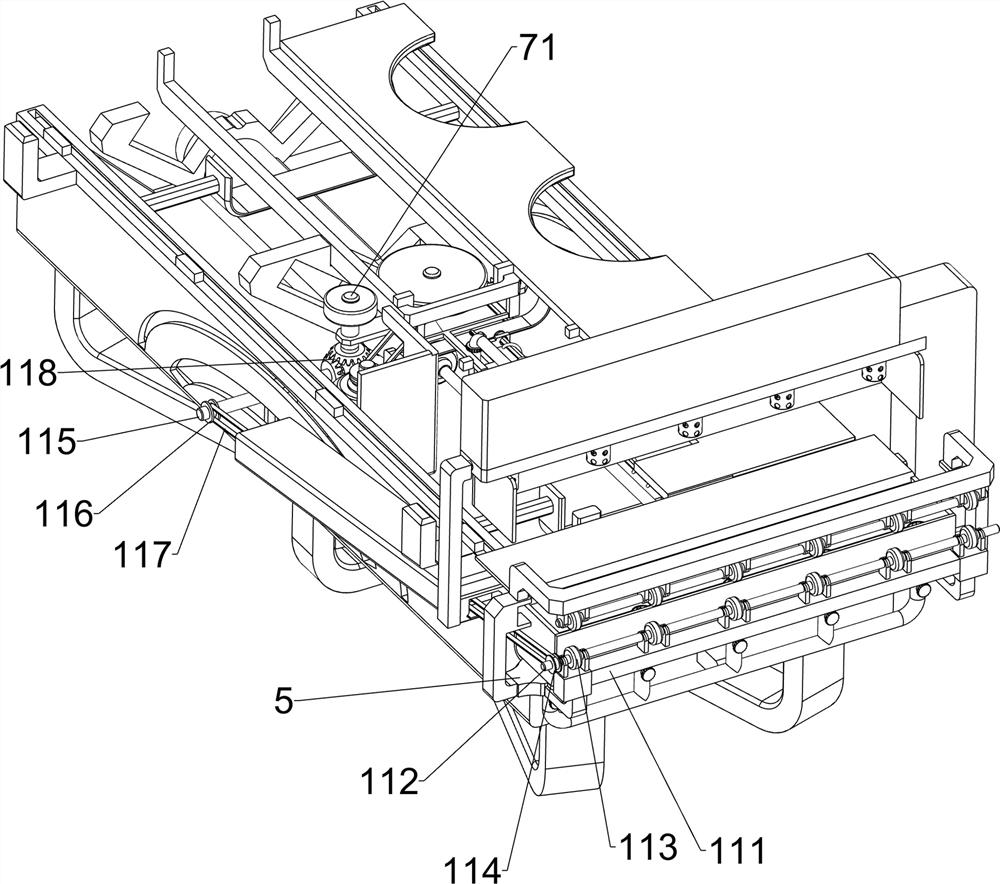

Powder bed five-axis additive and subtractive composite manufacturing device

ActiveCN113369895AReduce difficultyImprove printing accuracyAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedGalvanometer

A powder bed five-axis additive and subtractive composite manufacturing device comprises a machine tool, a subtractive device and an SLM additive device. The subtractive device and the SLM additive device are arranged on the machine tool, and the subtractive device and the SLM additive device are arranged in a protective cover. The subtractive device conducts subtractive machining through a five-axis swing head connected to a machine tool ram. The SLM additive device adopts a powder supply mode of downward powder feeding and comprises an additive base plate and a powder laying scraper, the additive base plate is divided into a powder laying base plate area and a powder bin powder supply area, and a posture-adjustable powder laying base plate of the powder laying base plate area and a powder bin push plate of the powder bin powder supply area both have Z-direction movement freedom degrees and move in opposite directions in the working process. The powder laying scraper moves back and forth between the posture-adjustable powder laying base plate and the powder layer surface of the powder bin push plate, and powder laying work is achieved. A movable laser galvanometer is further arranged on the machine tool ram to carry out the additive process. According to the Powder bed five-axis additive and subtractive composite manufacturing device, less-support or support-free printing of parts with complex structures is achieved, and the precision of internal and external structures of the parts is improved; and the laser spot size is reduced, and the powder bed additive manufacturing precision is improved.

Owner:XI AN JIAOTONG UNIV

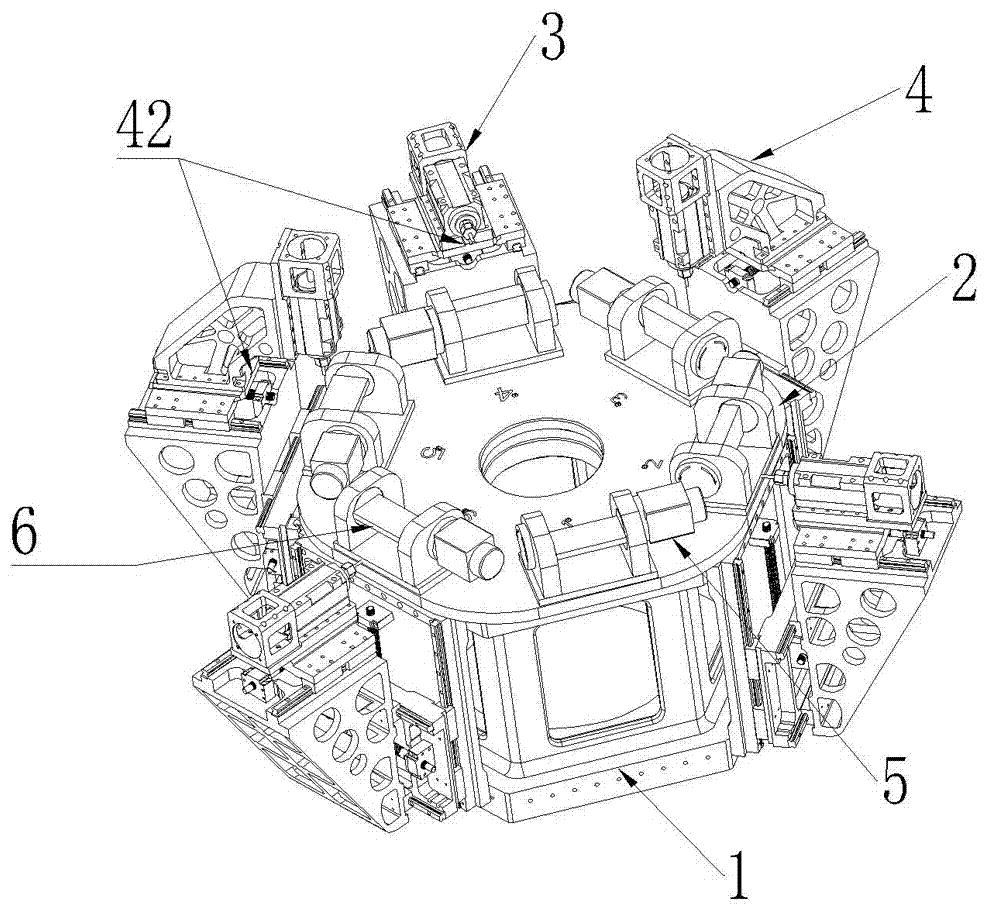

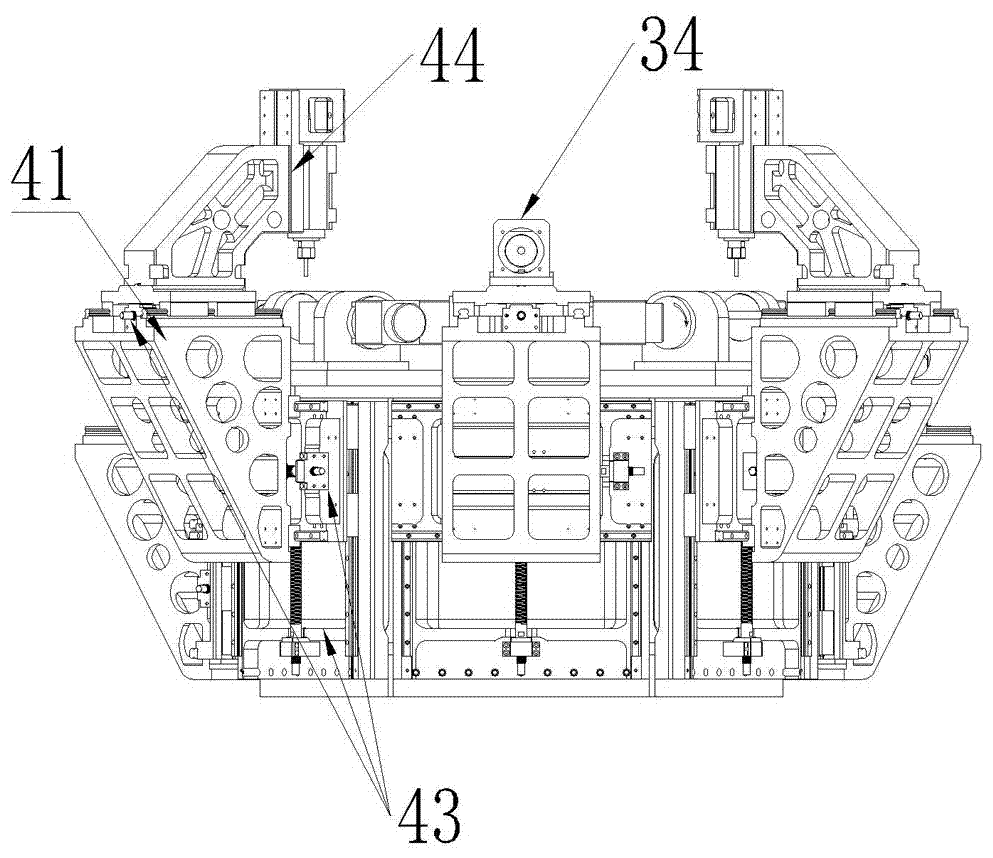

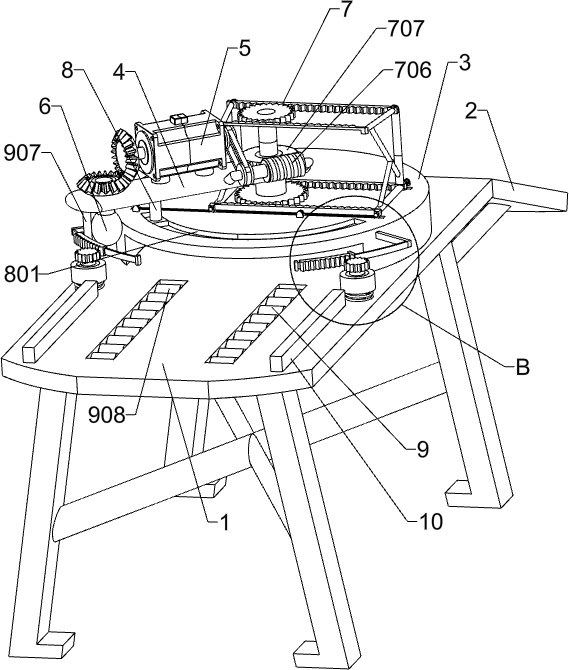

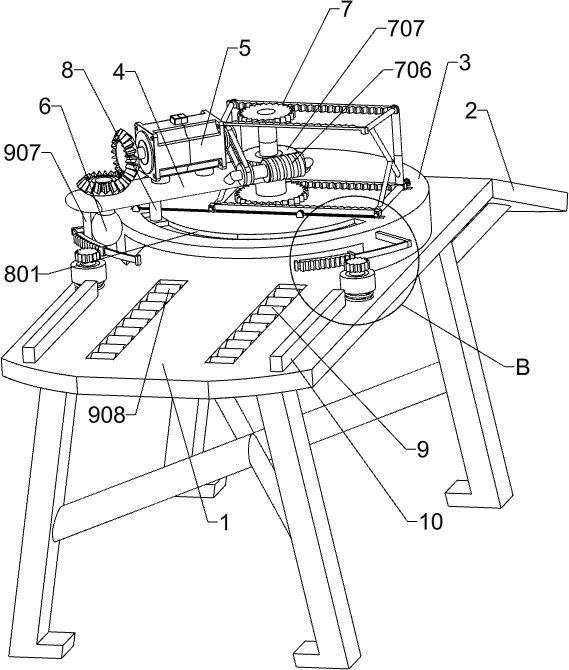

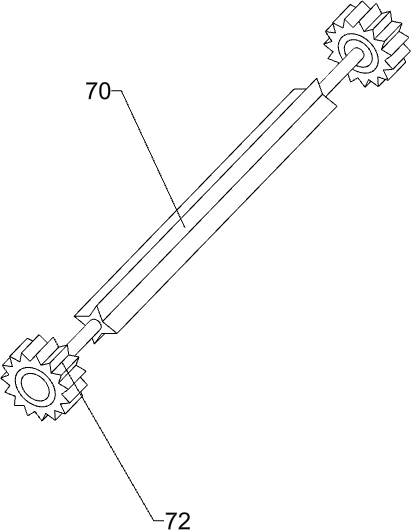

Multistation multiaxis numerical control machining device combining vertical type and horizontal type

PendingCN106863017ATo achieve the processing effectImprove processing efficiencyMetal working apparatusNumerical controlLocking mechanism

The invention relates to a multistation multiaxis numerical control machining device combining the vertical type and the horizontal type. The device comprises a machine tool body. A rotating shaft is arranged in the middle of the machine tool body. A rotating workbench is fixedly combined with the top end of the rotating shaft. A hydraulic locking mechanism is arranged between the machine tool body and the rotating workbench. Horizontal type machining mechanisms and vertical type machining mechanisms are uniformly distributed at the outer edge of the machine tool body, wherein the horizontal type machining mechanisms and the vertical type machining mechanisms are used for machining workpieces. Workpiece rotating and clamping mechanisms are arranged below the horizontal type machining mechanisms and the vertical type machining mechanisms. According to the multistation multiaxis numerical control machining device, the structure principle and the operation mode of the rotating workbench which is of the entirely circumferential distribution type are adopted, so that workpiece transferring time within unit time is shortened, and the cutting amount within unit time is greatly increased; the workpiece rotating and clamping mechanisms enable multiangle machining and multiaxis linkage machining to be possible, and the application scope is enlarged; and expansion design is adopted for a main shaft of the device so that the machining effect that multiple types of tools are obtained on a single station can be achieved.

Owner:银金星

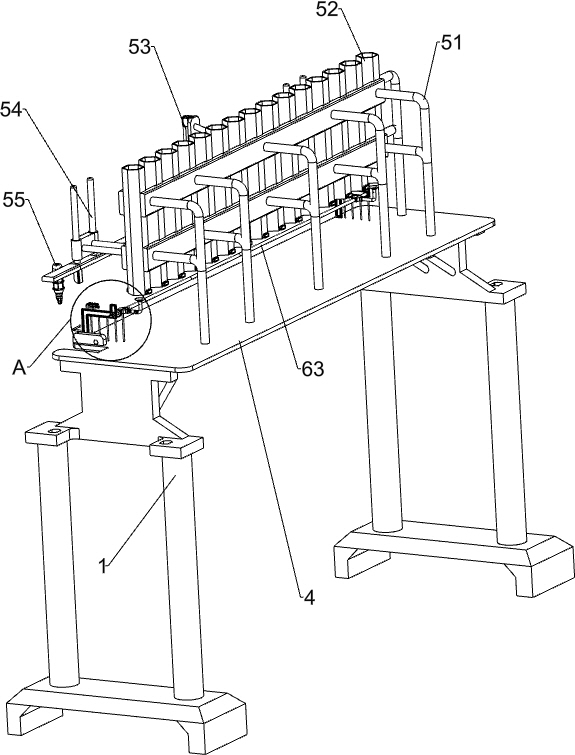

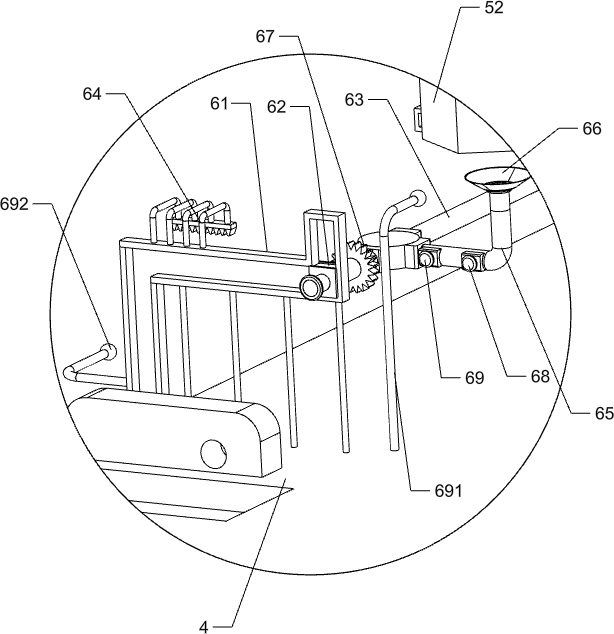

Cement dung leaking plate processing equipment for livestock breeding

ActiveCN111775299ATo achieve the processing effectSave human effortFeeding arrangmentsAuxillary shaping apparatusAgricultural engineeringAgricultural science

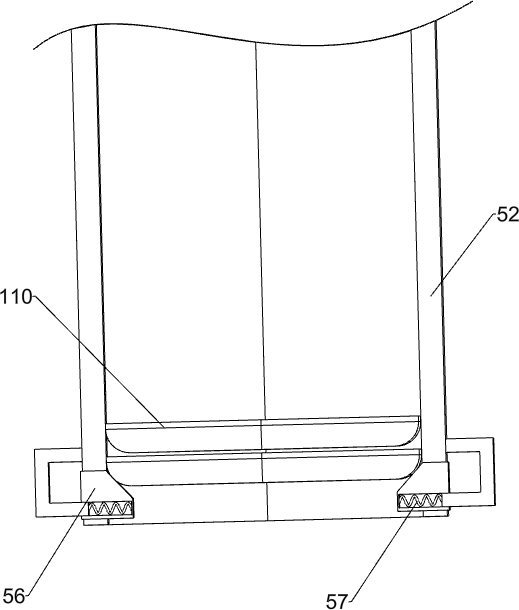

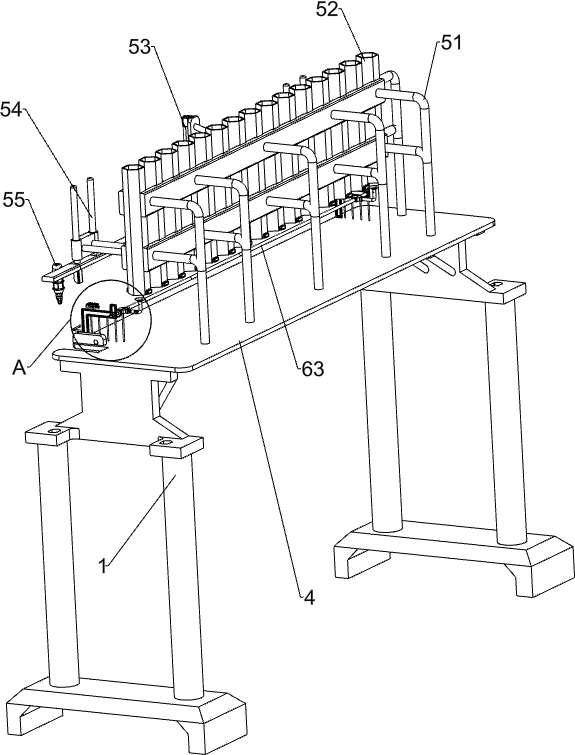

The invention relates to processing equipment, in particular to cement dung leaking plate processing equipment for livestock breeding. The cement dung leaking plate processing equipment for livestockbreeding can improve the working efficiency and save manpower. To solve the technical problems, the cement dung leaking plate processing equipment for livestock breeding comprises a mounting plate, two guide rods, a hopper, a plurality of limiting plates, a one-way device and a driving device, wherein the bottom of the mounting plate is connected with a supporting rod; the two guide rods are connected to the two sides of the top of the mounting plate correspondingly, and sliding sleeves are slidably connected to the guide rods; the hopper is connected between the sliding sleeves on the two sides; the multiple limiting plates are connected to the top of the mounting plate; the one-way device is arranged between the guide rods and the hopper; and the driving device is arranged between the guide rods and the hopper. According to the cement dung leaking plate processing equipment for livestock breeding, the one-way device and the hopper are matched to operate to assist in processing of a dung leaking plate, and thus the effect of processing the dung leaking plate is achieved.

Owner:广州派安环保科技有限公司

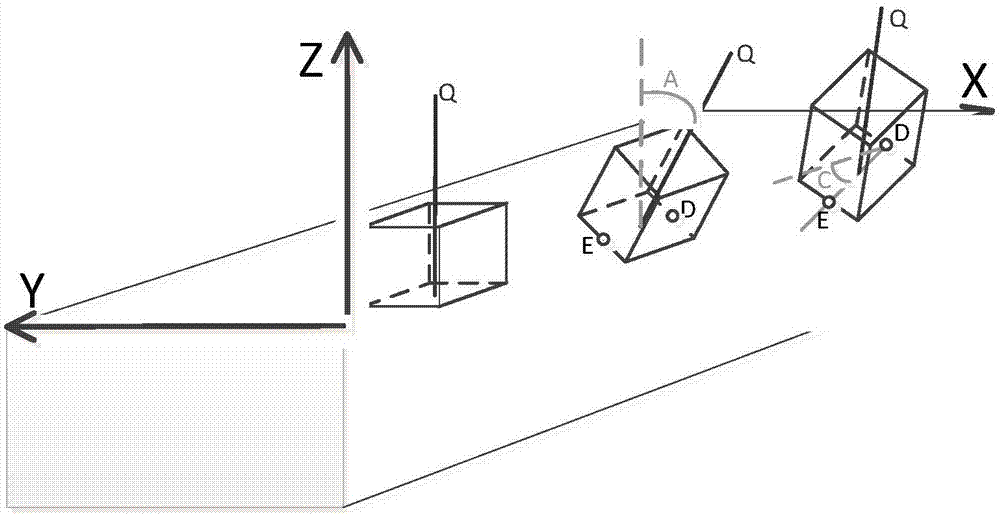

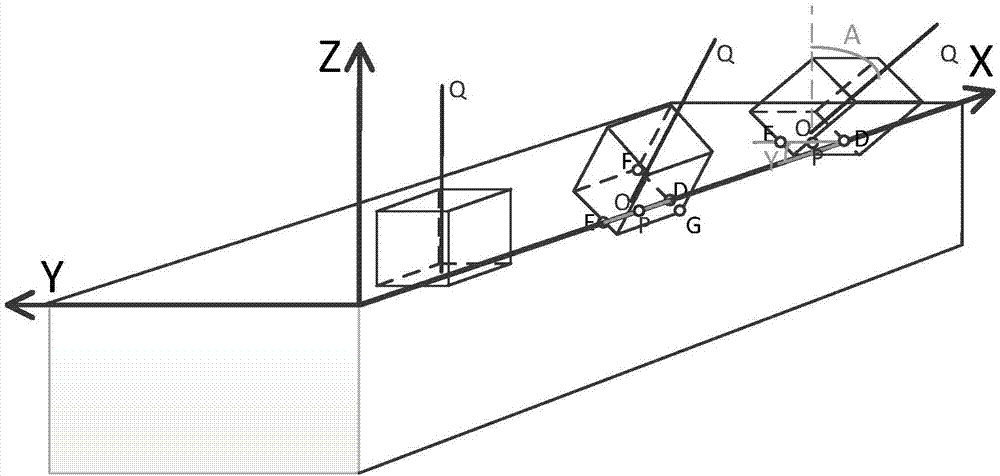

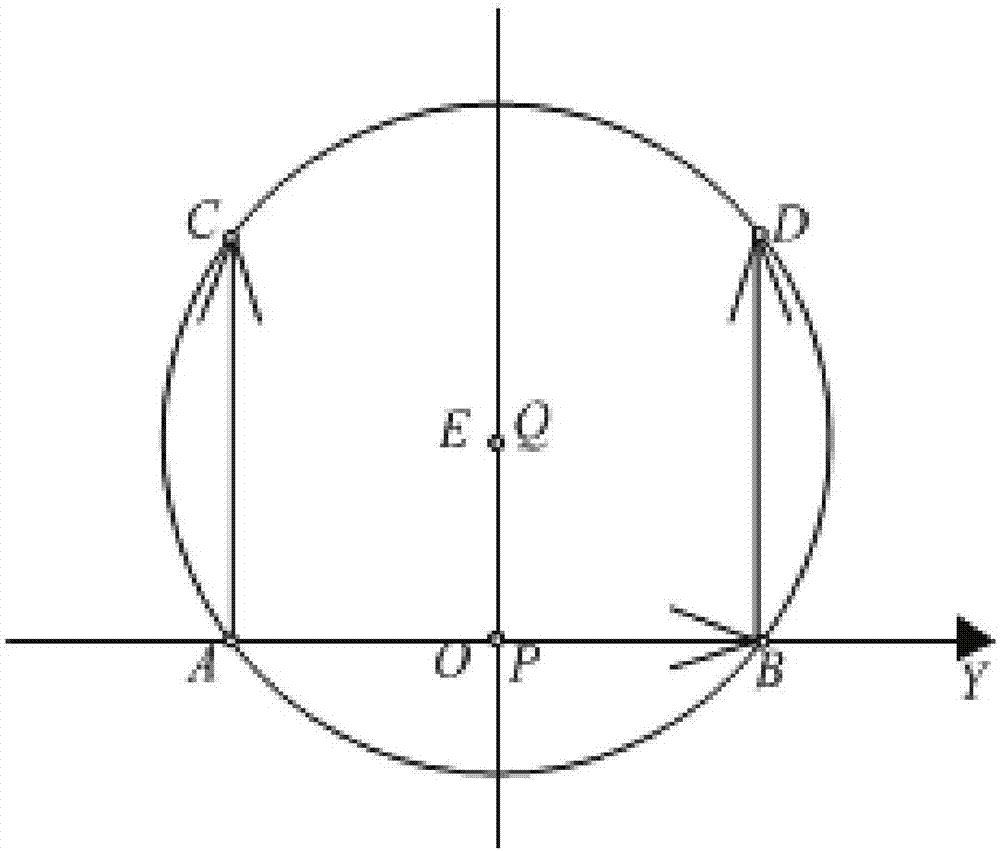

Workpiece bevel edge machining control method capable of effectively avoiding interference in numerically controlled machining system

ActiveCN107505916ATo achieve the processing effectSave memoryProgramme controlComputer controlMachine controlEngineering

The invention relates to a workpiece bevel edge machining control method capable of effectively avoiding interference in a numerically controlled machining system. The control method is characterized in that the system reversely derives a rotation angle of a rotating shaft controlling the rotation of a cutter according to an included angle between a machining surface of the machining cutter and a machining workpiece, the included angle is an angle which not only enables the machining cutter to achieve machining requirements for the machining workpiece but also enables the parts, except for a machining point, of the cutter to be away from the machining workpiece, and then the rotating shaft controlling the rotation of the cutter is rotated according to the calculated rotation angle of the rotating shaft controlling the rotation of the cutter so as to enable the machining surface of the cutter to achieve the expected rotation angle. The control method adopting the structure provided by the invention can directly set a given cutter lifting angle and avoid interference directly through cutter lifting, so that a lot of redundant interference judgment and interference avoidance at not required to be added in codes, the machining efficiency is improved, the cutter lifting angle range is not restricted, and the machining range is enabled to be expanded. In addition, the workpiece bevel edge machining control method can be implemented by applying the existing equipment and has good popularization performance.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

A pulsed strong magnetic field assisted laser welding method and equipment

ActiveCN103769746BImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

A kind of diamond resin grinding wheel and mold and method for processing the grinding wheel

ActiveCN108714860BAchieve inhibitionEasy to operateBonded abrasive wheelsGrinding devicesRough surfaceGrinding wheel

The invention relates to a diamond resin wheel and a mold and a method for machining the resin wheel. The resin wheel comprises a base body and abrasive material layers, wherein the abrasive layers are at least two abrasive layers which are fixed on the surface or the outer circle of a base body through extrusion and hot pressing, and each abrasive layer is formed by mixing and pressing differentcoarse and thin diamond particles and a binding agent; and the bonding position of the abrasive material layers and the base body are adopted with a dovetail-type structure, and the bonding faces arefurther processed into rough surfaces; the mold comprises a positioning base, a mold frame and a center mold, wherein the inner wall of the mold frame and the bottom face of the center mold form a placement area of the diamond resin wheel base body, a gap for installing a pressure head is arranged between the inner wall of the mold frame and the outer wall of the center mold, and the center mold is assembled with an assembling rod in a fixed mode through a fastening nut to be limited; the method for machining the resin wheel comprises the following steps that 1) the resin wheel base body is prepared; 2) the base body is fixed; 3) the abrasive material layers are pressed in advance; 4) hot-pressing forming is carried out; and 5) shaping and manufacturing are carried out. According to the method, a specially designed mold and a machining mode are adopted, so that the resin wheel with multiple utilization can be produced, and the grinding efficiency is improved.

Owner:湖南鑫星凌金刚石工具有限公司

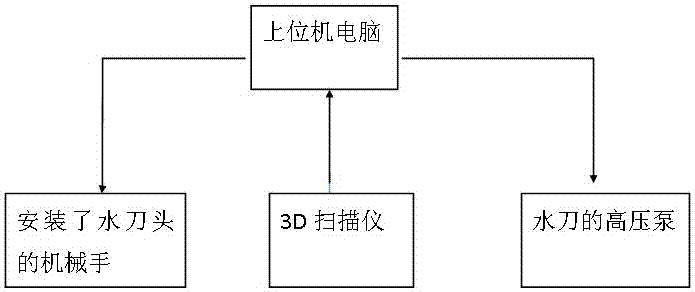

Engraving method of closed-loop control over water milling cutter by applying 3D digital model

InactiveCN107244173ASave manpower and materialsGood securityModel makingEngravingPollutantManipulator

The invention discloses an engraving method of closed-loop control over a water milling cutter by applying a 3D digital model. Firstly, the 3D digital model of a product is established by adopting CAD (Computer Aided Design) software in an upper computer, then a water cutter is controlled to realize the function of a milling cutter so as to engrave and process to-be-processed materials, the processing schedule and effect are detected by applying a 3D scanner, and the speed and moving direction of the water cutter are controlled according to data feedback detected by the 3D scanner. According to the engraving method, a 3D digital modeling technique, a 3D scanning technique, a cutting technique of the water cutter and a control technique of a manipulator are organically integrated and are applied to engraving and processing metal and nonmetal. The engraving method has the advantages that complex special-shaped workpieces and molds can be accurately, quickly and directly manufactured, a large quantity of manpower and materials are saved, the effects of good safety, environmental friendliness and low cost are achieved, and environmental pollutants such as waste water, dust, smoke and the like are not generated.

Owner:章颉

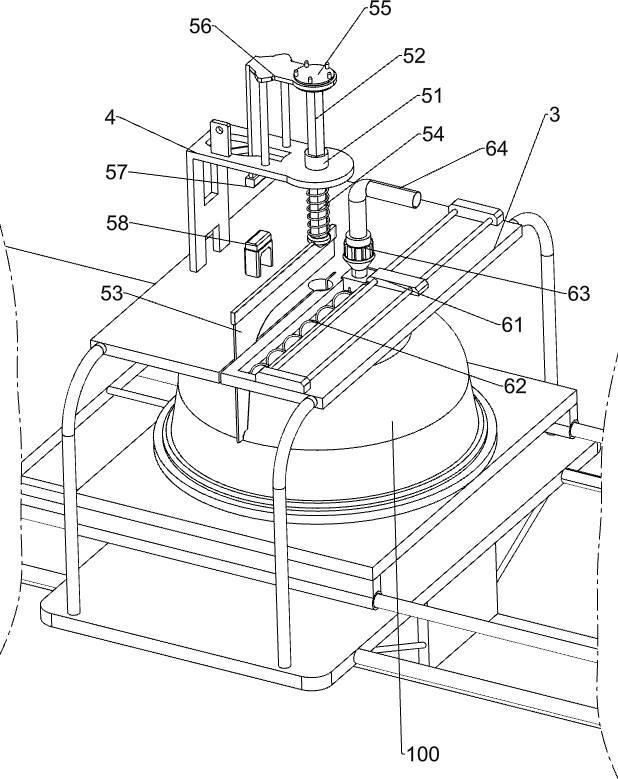

Aluminum pot processing device for kitchen ware processing

ActiveCN111921730ATo achieve the processing effectSave human effortLiquid spraying apparatusGraphiteMechanical engineering

The invention relates to a processing device, and particularly relates to an aluminum pot processing device for kitchen ware processing. The aluminum pot processing device for kitchen ware processingis easy to operate, capable of saving manpower and capable of evenly scraping graphite powder liquid on the outer surface of an aluminum pot. The aluminum pot processing device for kitchen ware processing comprises an installation base, an installation plate, a lifting assembly and a discharging assembly, wherein a containing plate is connected to the installation base in a sliding mode; the installation plate is connected to the middle of the installation base; an installation frame is connected to one side of the installation plate; the lifting assembly is arranged between the installation frame and the installation plate; and the discharging assembly is arranged on the installation plate. According to the aluminum pot processing device for kitchen ware processing, the lifting assembly and the discharging assembly are matched to operate to process the aluminum pot, and therefore the effect of processing the aluminum pot is achieved.

Owner:永康市翁氏科技有限公司

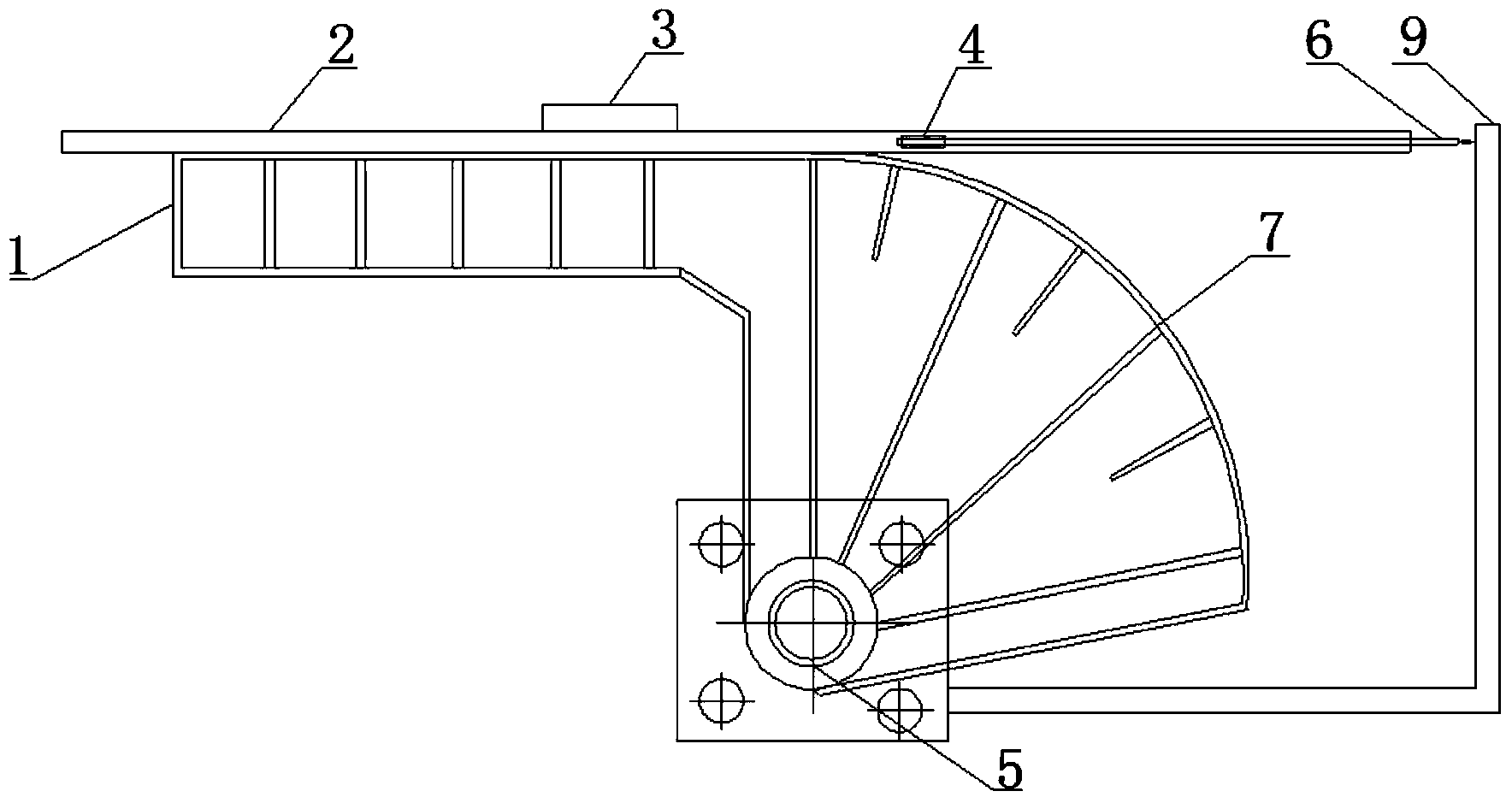

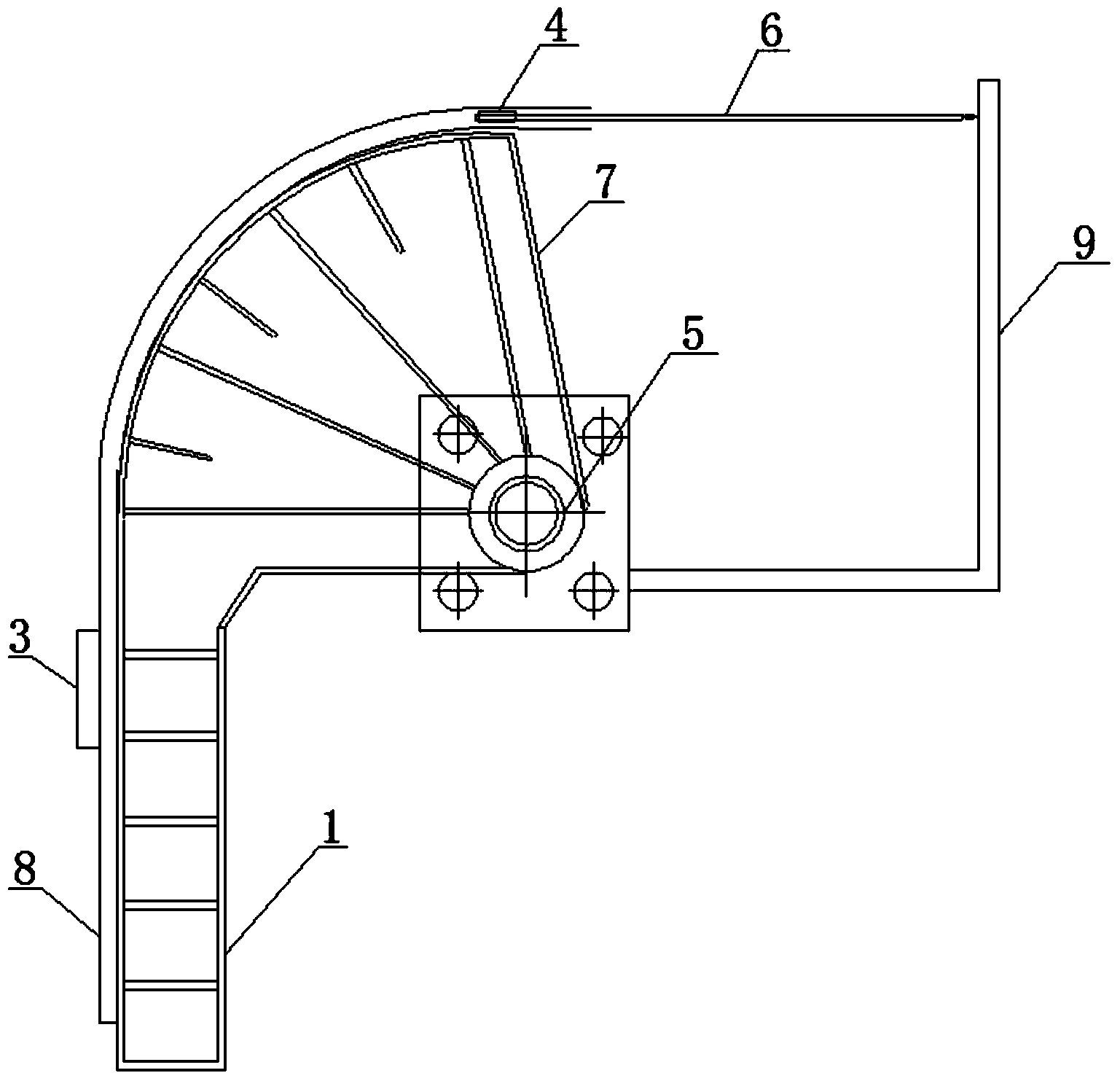

Arc surface cutting equipment for furniture processing and using method thereof

ActiveCN112536881BTo achieve the processing effectMulti-purpose machinesGrinding machinesElectric machineryEngineering

The invention provides a curved surface cutting device for furniture processing and a method for using the same, and relates to the technical field of furniture processing. The curved surface cutting device for furniture processing includes a curved surface processing workbench, and the front end of the No. 1 rotating motor shell is fixed. A drilling device is installed, the lower end of the drilling device is fixedly equipped with an electric telescopic rod, and the electric telescopic rod is fixedly mounted on the front end of the casing of the No. 1 rotating motor. By placing the raw material to be processed on the feeding fixed plate, start the electric telescopic rod, and drill a round hole for the raw material through the drilling device; then start the electric telescopic rod to push the slider connecting plate to slide forward, when the feeding fixed plate reaches When it is on the limit plate, send it to the upper surface of the arc surface processing table; then start the rotating telescopic drive rod to push the processing rod into the round hole drilled before, and adjust the angle of the drive rod to push the arc surface by adjusting the drive rod connection block at the front end of the bushing Process the lower end of the rod to achieve the effect of arc surface processing.

Owner:灵璧县德军家具制造股份有限公司

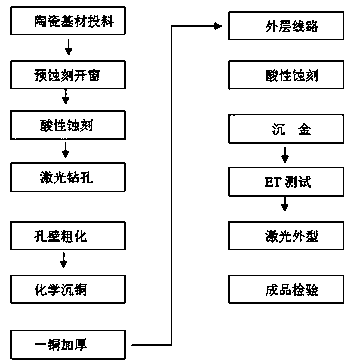

Processing method for surface modification and metallization of hole walls of ceramic circuit board

InactiveCN109688732AStrong adhesionImprove plating efficiencyCircuit susbtrate materialsPrinted element electric connection formationCopper foilSurface modification

The invention provides a processing method for surface modification and metallization of hole walls of a ceramic circuit board. The processing method is characterized in that the double-sided ceramicboard comprises a middle ceramic layer and copper-clad layers arranged on two sides of the ceramic layer. The method comprises the following steps: S1, preparing a ceramic substrate; S2, pre-etching and windowing before laser drilling; S3, metallizing holes and conducting chemical copper deposition after laser drilling. According to the processing method, copper-clad high-temperature sintered ceramic is used as a base material for processing, so that good attachment of the original base copper is ensured; meanwhile, an appropriate copper foil thickness can be selected according to customers' requirements, subsequent electroplating time is shortened, and electroplating efficiency is maximumly improved.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH

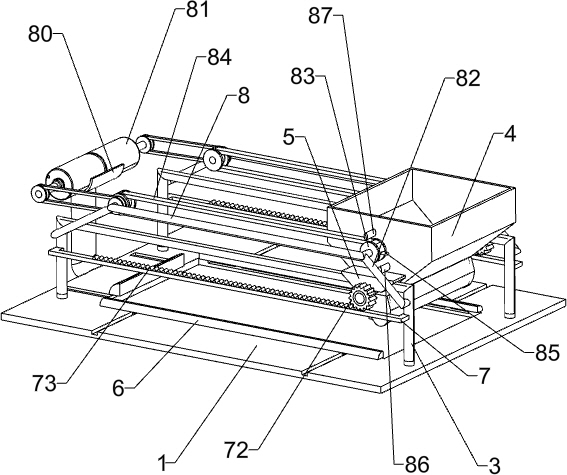

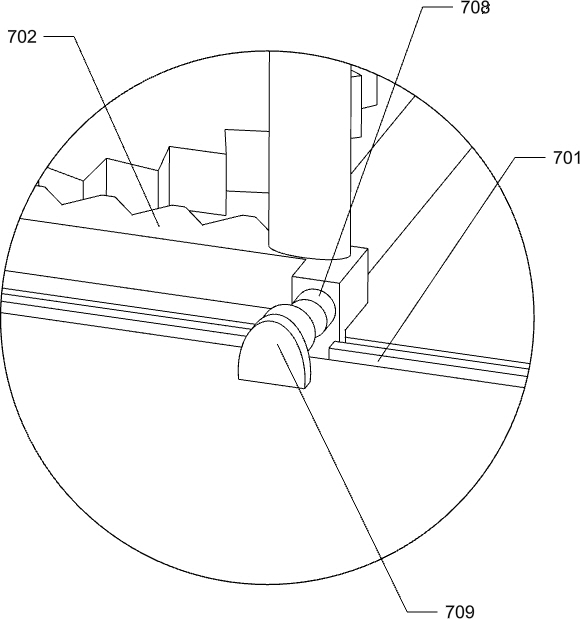

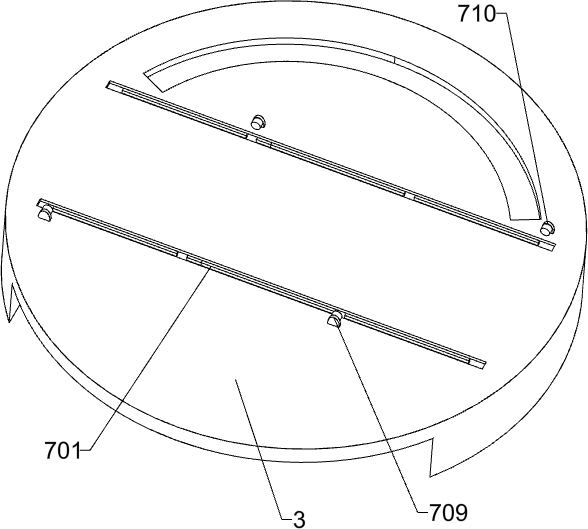

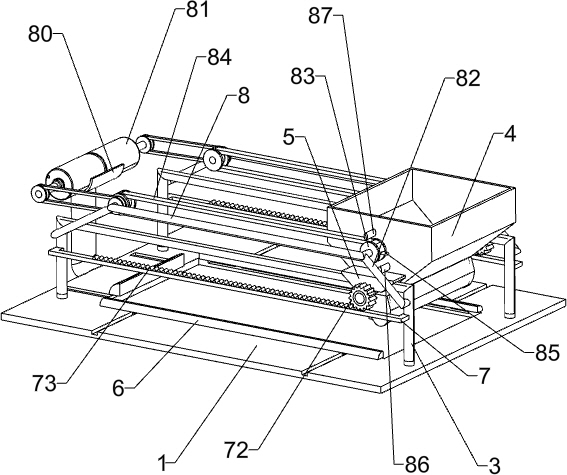

Washboard processing device

ActiveCN111745758ATo achieve the processing effectSave human effortWood mortising machinesWood slotting machinesElectric machineryStructural engineering

The invention relates to a processing device, in particular to a washboard processing device. The washboard processing device can save manpower and improve the working efficiency during operation. Thewashboard processing device comprises a bottom plate, a circular shell, a swing plate, a double-shaft motor, a roller cutter, a reciprocating device and a guiding device, wherein a guide plate is connected with one side of the bottom plate, the circular shell is connected to one side of the top of the bottom plate, the swing plate is rotationally connected to the middle of the top of the circularshell, the double-shaft motor is mounted at the top of the swing plate, the roller cutter is rotationally connected to the tail end of the bottom of the swing plate, the roller cutter is in transmission connection with one output shaft of the double-shaft motor, the reciprocating device is arranged between the circular shell and the swing plate, and the guiding device is arranged between the circular shell and the swing plate. According to the washboard processing device, a washboard is grooved through cooperation of the reciprocating device and the roller cutter, so that the effect of processing the washboard is achieved.

Owner:李林琴

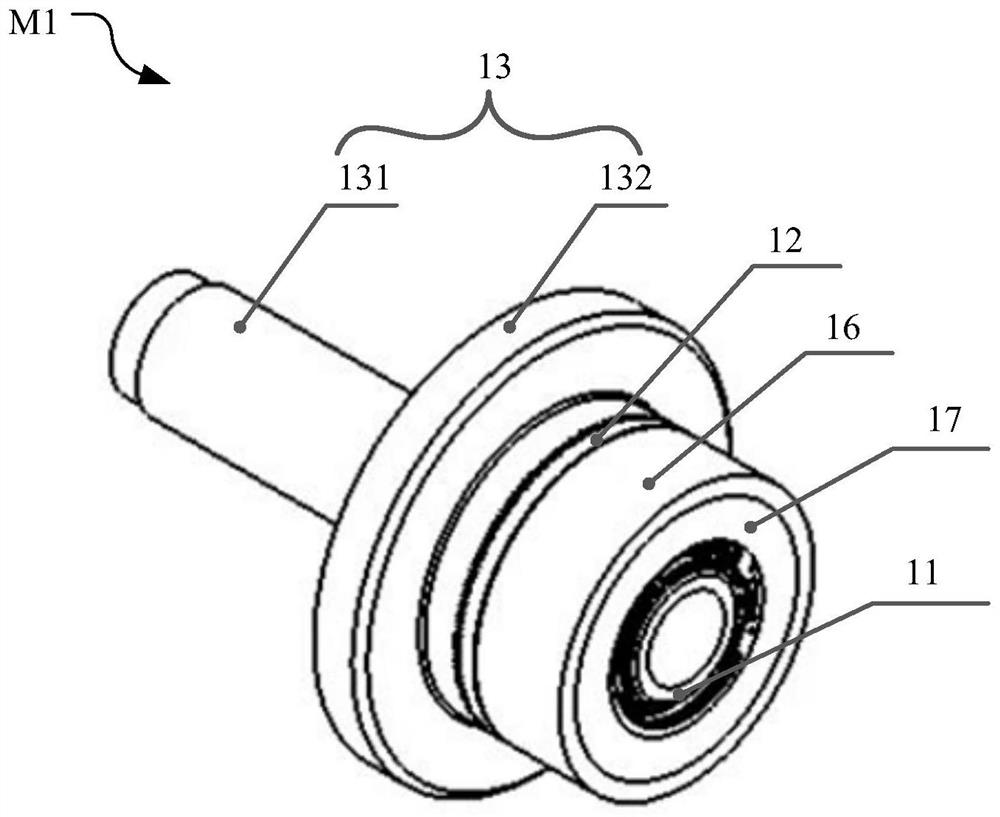

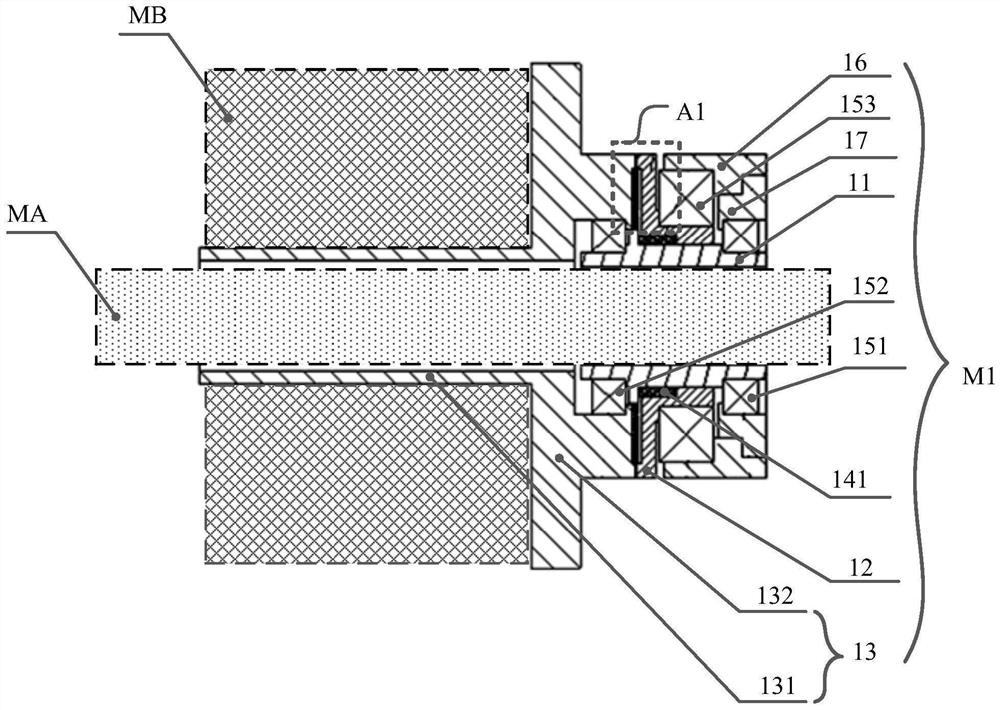

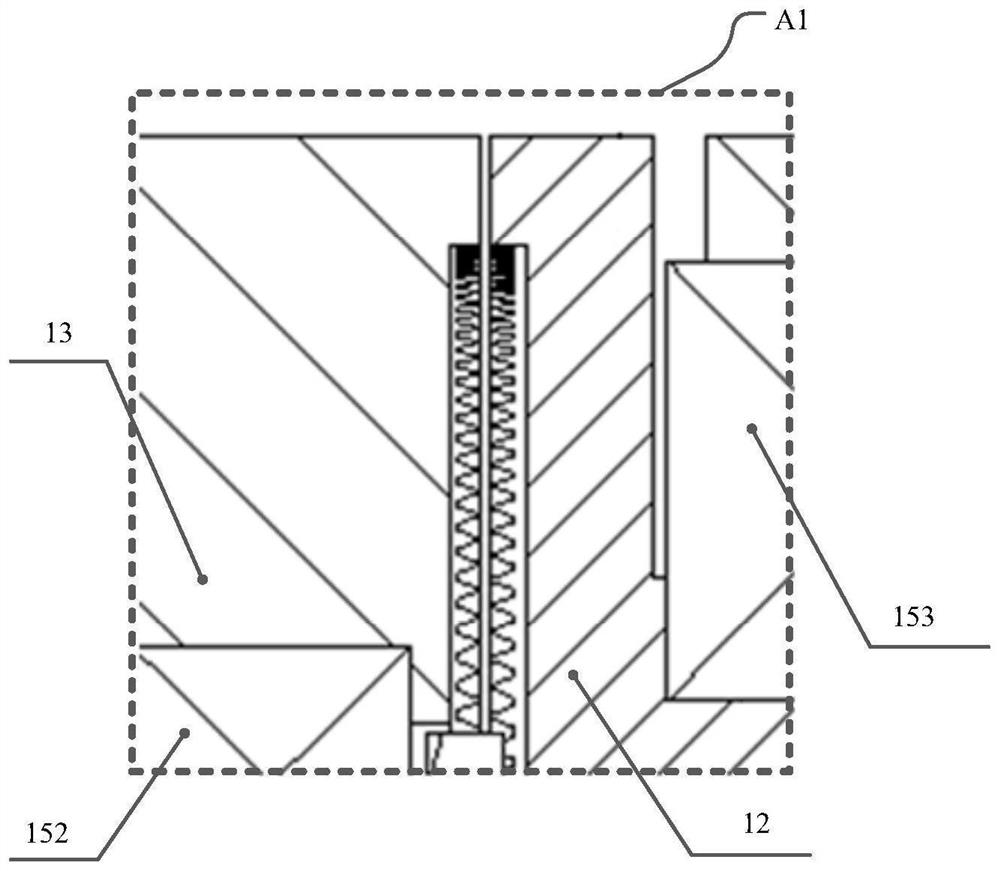

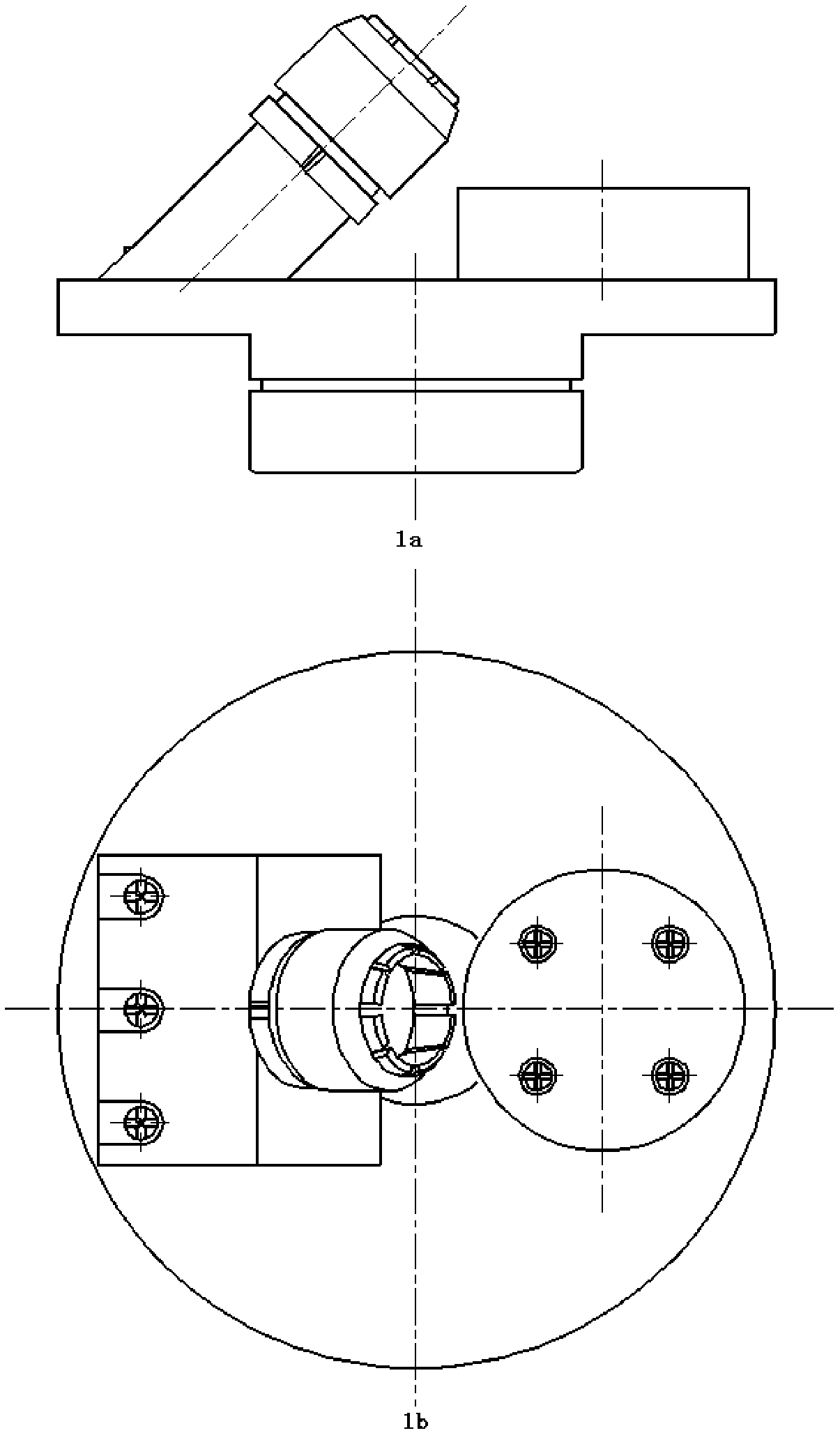

Clutch mechanism and power clutch control device and method

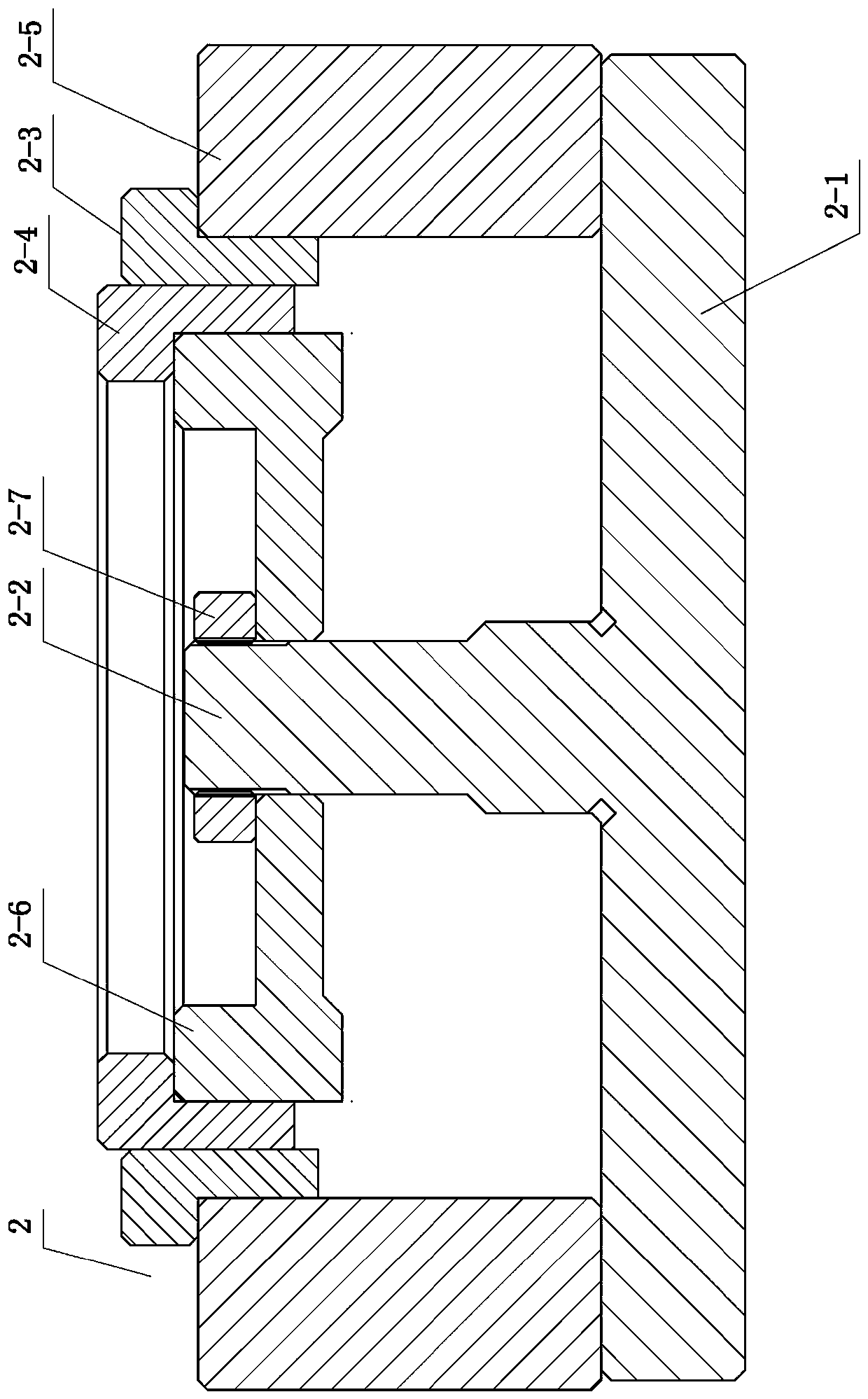

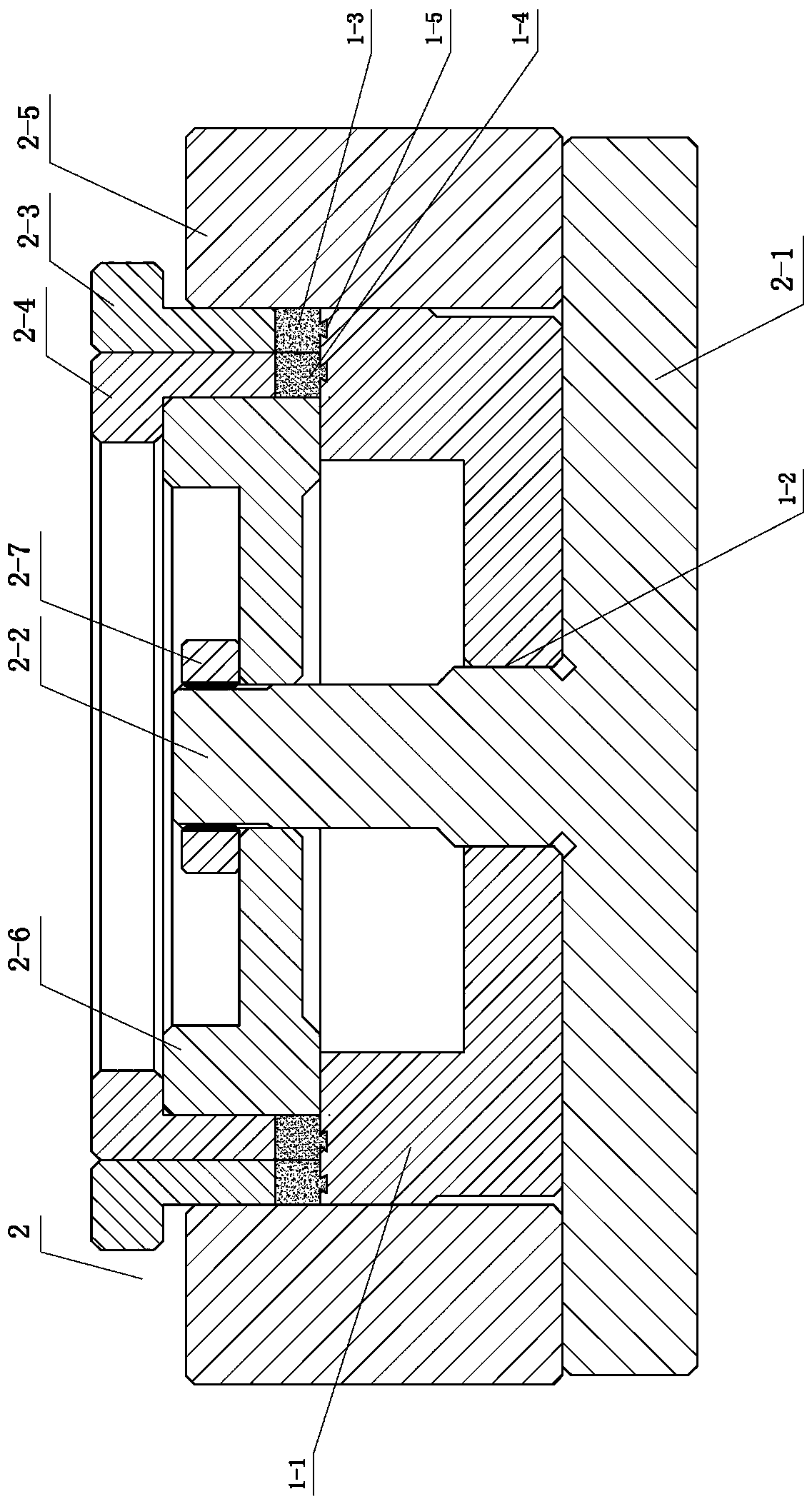

PendingCN114151462AStrong process controllabilityIncrease flexibilityMagnetically actuated clutchesClutch controlControl engineering

The embodiment of the invention provides a clutch mechanism and a power clutch control device and method.The clutch mechanism comprises the clutch mechanism, and the clutch mechanism comprises a supporting component, a first transmission component and a second transmission component; the supporting component is linked with the transmission mechanism; the first transmission part is linked with the supporting part and is connected with or separated from the second transmission part; and the second transmission part is rotatably connected with the supporting part and is suitable for bearing the rotating mechanism and isolating the rotating mechanism from the transmission mechanism. By adopting the scheme of the embodiment of the invention, the energy transmitted to the processing object can be flexibly controlled, and the energy efficiency, the processing quality and the processing yield are improved.

Owner:国焊(上海)智能科技有限公司

Fixture for machining noncoaxial hole of part

ActiveCN107775411AFunction increaseTo achieve the processing effectPrecision positioning equipmentPositioning apparatusMachined surfaceEngineering

The invention discloses a fixture for machining a nonaxial hole of a part. The fixture substantially mainly comprises a flange, a clamping mechanism and a balance block, wherein the clamping mechanismand the balance block are fixedly arranged on the flange through screws, and the fixture can be rapidly arranged on a lathe spindle through the flange; a clamping sleeve can be screwed to squeeze a clamping jaw at the front end of a clamping sleeve shaft to clamp the part to be machined; an index plate and a positioning rod can be matched to rapidly switch the machined surface of the part; the balance block can be used for balancing an eccentric moment of the clamping mechanism during rotation of the fixture to ensure stable rotation of the whole fixture as well as the machining accuracy of an inner hole in the part. According to the fixture, the aims of machining the nonaxial hole of the part on an ordinary lathe and ensuring higher machining accuracy are fulfilled.

Owner:杭州航天电子技术有限公司

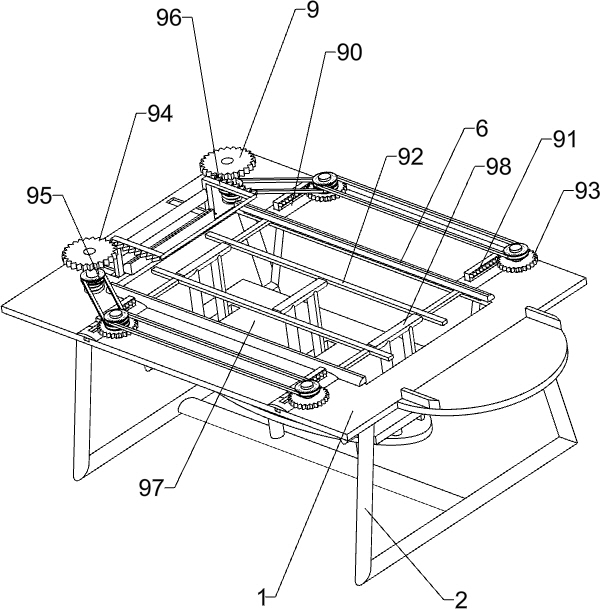

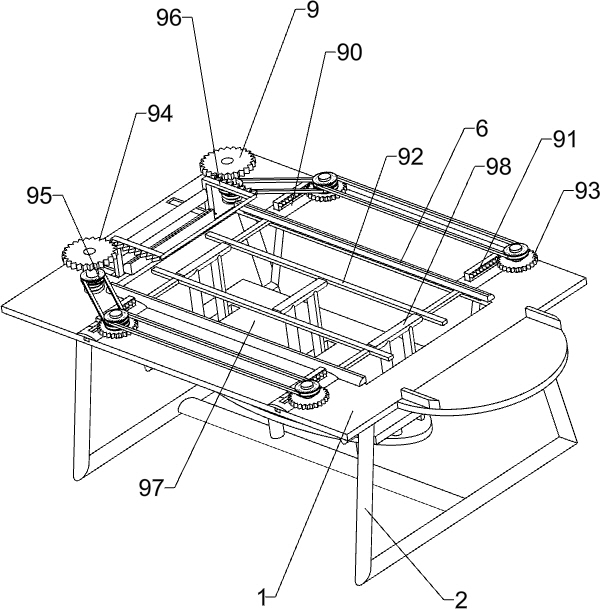

A magnetic therapy mattress processing device for medical conditioning

ActiveCN111828447BTo achieve the processing effectSave human effortLiquid surface applicatorsMaterial gluingSlide plateBiomedical engineering

The invention relates to a processing device, in particular to a processing device for a magnetic therapy mattress for medical conditioning. The technical problem to be solved by the present invention is how to design a magnetic therapy mattress processing device for medical conditioning that is simple to operate, can save manpower, and improve work efficiency. The invention provides such a processing device for magnetic therapy mattresses for medical conditioning, which includes: legs, the top of which is slidably connected to a slide plate; a plurality of limiting slats are arranged, and the plurality of limiting slats are all connected It is distributed on the top of the slide plate in a rectangular shape; the mounting plate is connected to the middle of the outrigger; the blanking component is set on the mounting plate; the bonding component is set on the blanking component. In the present invention, the magnetic therapy block is added on the magnetic therapy pad through the cooperative operation of the blanking component and the bonding component, so as to achieve the effect of processing the magnetic therapy mattress.

Owner:佛山市都禾家具有限公司

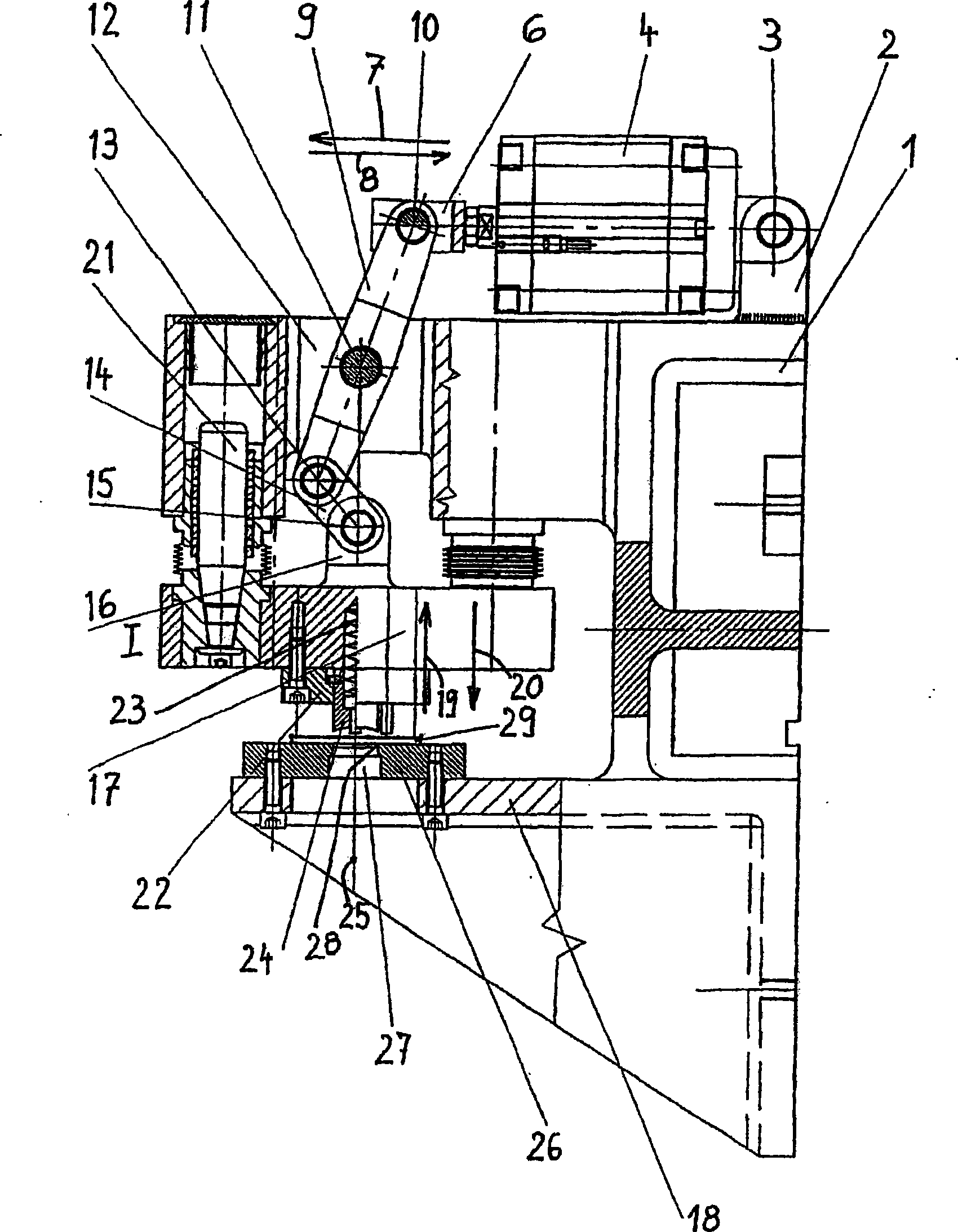

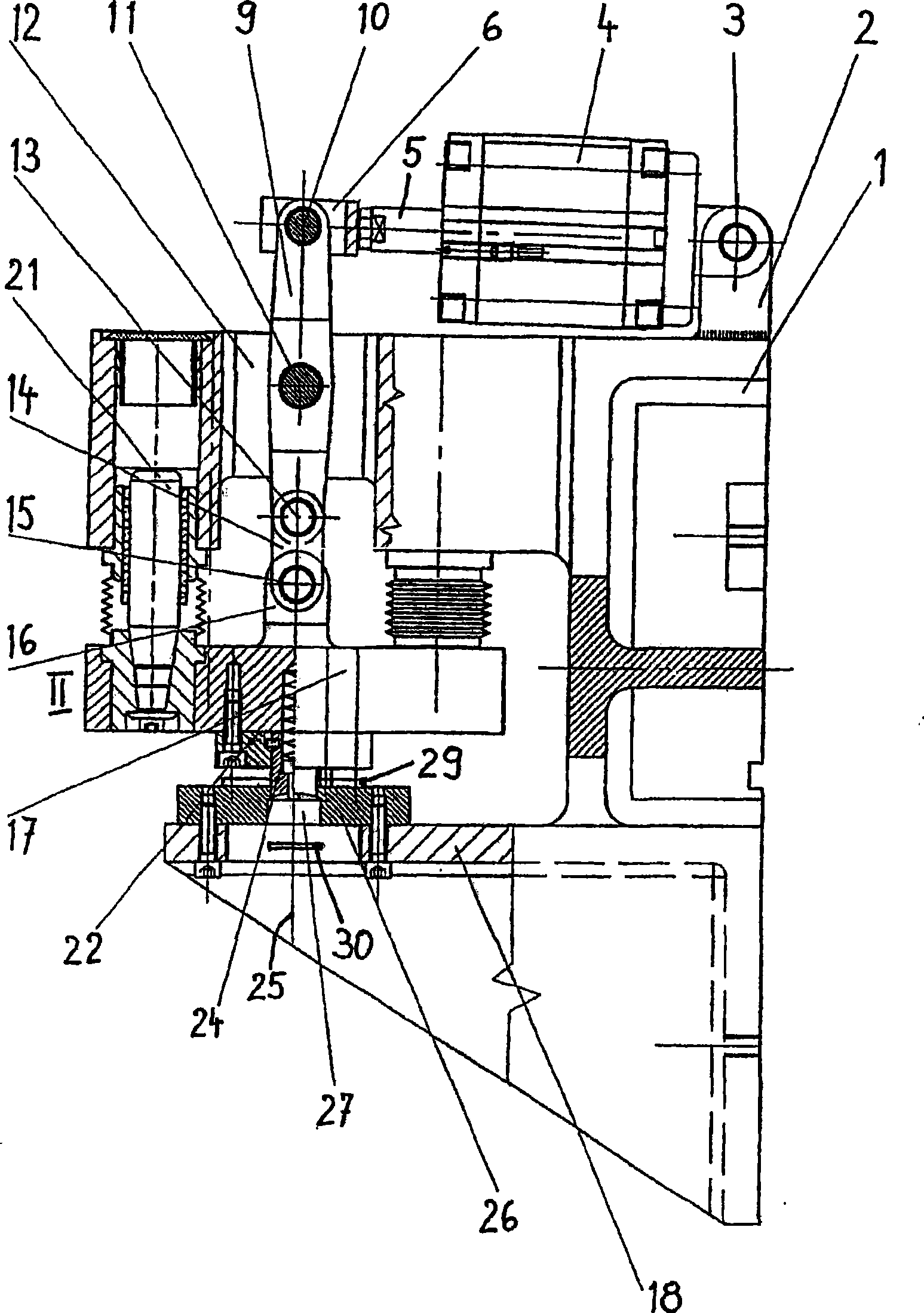

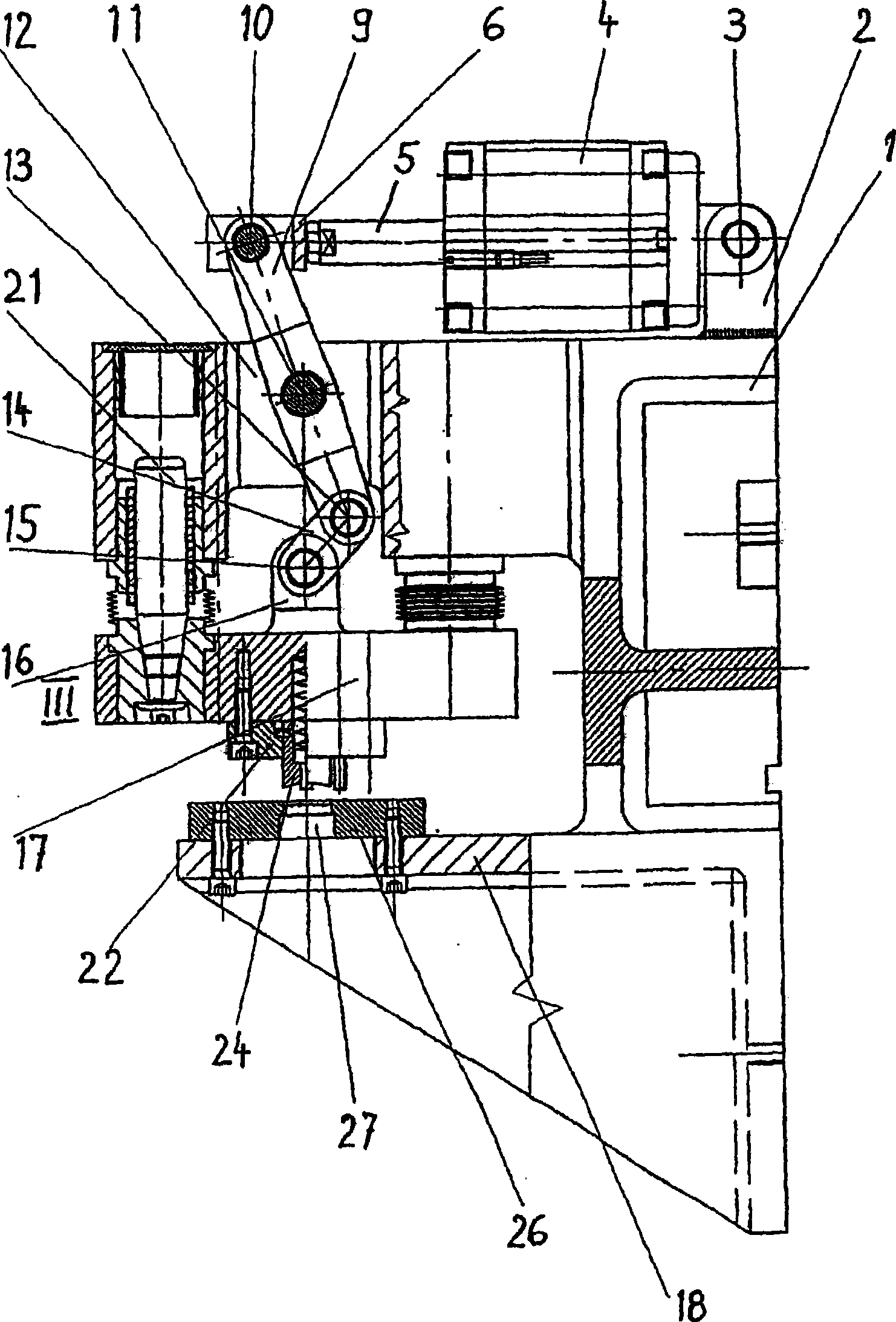

Device for punching, stamping and/or shaping flat elements

InactiveCN100519161CShort air travel timeShort processing stepsPress ramMetal working apparatusPressure buildupTool holder

The present invention provides a kind of equipment that is used for stamping, embossing and / or forming flat part, and it comprises a support plate and a tool seat plate, is connected between driver and tool seat plate a long rotating lever, can make The tool seat plate is moved from the dead center position where the tool punch does not engage the support plate to a position just before the machining position without building up pressure, and then continues to move the tool seat plate a short distance to reach Processing position, during which a high pressure is generated between the tool seat plate and the metal strip, and then the further drive of the driver causes the tool seat plate to move in the opposite direction to the stop position, during which no pressure is established, and the long turning lever One end of it is connected to one end of a short turning lever through a elbow lever pivot shaft, and the other end of the short turning lever is connected to the tool seat plate through a bending lever mounting part, and at the other end of the long turning lever, the driver Mounted so that the drive is axially outward of the pivot axis.

Owner:TETRA LAVAL HLDG & FINANCE SA

Cambered surface cutting equipment for furniture processing and using method of cambered surface cutting equipment

ActiveCN112536881ATo achieve the processing effectMulti-purpose machinesGrinding machinesEngineeringMechanical engineering

The invention provides cambered surface cutting equipment for furniture processing and a using method of the cambered surface cutting equipment, and relates to the technical field of furniture processing. The cambered surface cutting equipment for furniture processing comprises a cambered surface processing workbench, a drilling device is fixedly installed at the front end of a first rotating motor shell, an electric telescopic rod is fixedly installed at the lower end of the drilling device, and the electric telescopic rod is fixedly mounted at the front end of the first rotating motor shell.Raw materials needing to be processed are placed on a feeding fixing plate, the electric telescopic rod is started, and a round hole is drilled in each raw material through the drilling device; thenthe electric telescopic rod is started to push a sliding block connecting plate to slide forwards, and when the feeding fixing plate abuts against a limiting plate, the raw materials are conveyed to the upper surface of the cambered surface processing workbench; and then a rotary telescopic driving rod is started to push a processing rod to enter the drilled round holes, an angle driving rod is pushed by a driving rod connecting block at the front end of an adjusting shaft sleeve to push the lower end of a cambered surface processing rod, and therefore the cambered surface processing effect isachieved.

Owner:灵璧县德军家具制造股份有限公司

Silver sheet processing device for manufacturing porcelain-coated silver wine glass

ActiveCN112122934ATo achieve the processing effectTo achieve the effect of reprocessingOther manufacturing equipments/toolsGlass productionMolding machineMaterials science

The invention relates to a processing device, in particular to a silver sheet processing device for manufacturing a porcelain-coated silver wine glass. The invention provides a silver sheet processingdevice for manufacturing a porcelain-coated silver wine glass, which is easy to operate, can improve the working efficiency and saves manpower. The silver sheet processing device for manufacturing the porcelain-coated silver wine glass comprises a bottom plate, a concave barrel, a driving device and a forming mechanism, wherein the bottom of the bottom plate is connected with a support plate; theconcave barrel is connected to one side of the top of the bottom plate; the driving mechanism is arranged on the bottom plate; the forming mechanism is arranged between the bottom plate and the concave barrel; and the driving mechanism is in transmission connection with the forming mechanism. According to the silver sheet processing device, the concave barrel, the driving mechanism and the forming mechanism are matched to process a silver sheet into the shape of the wine glass, so that the effect of processing the silver sheet is achieved.

Owner:林健福

A washboard processing device

ActiveCN111745758BTo achieve the processing effectSave human effortWood mortising machinesWood slotting machinesElectric machineryPhysics

The invention relates to a processing device, in particular to a washboard processing device. The technical problem to be solved by the present invention is how to design a washboard processing device which can save manpower during operation and improve work efficiency. The invention provides such a washboard processing device, comprising: a bottom plate, one side of which is connected with a guide plate; a circular shell, which is connected to one side of the top of the bottom plate; a swing plate, which is rotatably connected to the circular shell The middle of the top; the double-shaft motor, which is installed on the top of the swing plate; the roller knife, which is rotatably connected to the bottom end of the swing plate, and the roller knife is connected with one of the output shafts of the double-shaft motor; the reciprocating device is arranged in the circular shell between the body and the pendulum plate; the guiding device is arranged between the circular shell and the pendulum plate. In the invention, the reciprocating device and the roller cutter cooperate to slot the washboard, so as to achieve the effect of processing the washboard.

Owner:李林琴

A kind of cement leaking manure board processing equipment for animal husbandry

ActiveCN111775299BTo achieve the processing effectSave human effortFeeding arrangmentsAuxillary shaping apparatusAnimal scienceCrop livestock

The invention relates to a processing device, in particular to a processing device for a cement leaking manure board for animal husbandry. The technical problem to be solved by the present invention is to provide a cement dung slab processing equipment for animal husbandry that can improve work efficiency and save manpower. In order to solve the above-mentioned technical problems, the present invention provides such a cement leaking manure board processing equipment for animal husbandry, including: a mounting plate, the bottom of which is connected with a support rod; Connected to both sides of the top of the mounting plate, sliding sleeves are connected to the guide rod; the hopper is connected between the sliding sleeves on both sides; the limit plate is set in multiple pieces, and the multiple limit plates are all connected to the mounting plate The top; the one-way device, which is arranged between the guide rod and the hopper; the driving device, which is arranged between the guide rod and the hopper. The invention assists the processing of the leaky manure board through the cooperative operation of the one-way device and the hopper, thereby achieving the effect of processing the manure leaky board.

Owner:广州派安环保科技有限公司

Firing equipment for processing carbon-fired wood

ActiveCN114425809ATo achieve the processing effectImprove work efficiencyWood charring/burningConveyor partsProcess engineeringWood plank

The invention relates to firing equipment, in particular to firing equipment for carbon-fired wood processing. The technical problem to be solved by the invention is how to design the firing equipment for processing the charcoal-fired wood, which can improve the working efficiency and save manpower. In order to solve the technical problem, the firing equipment for processing the carbon-fired wood comprises a base, and the top of the base is connected with a box body; the top of the box body is connected with the bedplate; the check block is connected to the box body; one side of the box body is connected with the bracket; the firing mechanism is arranged between the bracket and the box body; and the pushing mechanism is arranged on the box body. According to the wood board processing device, a wood board is processed through cooperative operation of the firing mechanism, the pushing mechanism and the table plate, so that the effect of processing the wood board is achieved.

Owner:骆思渝

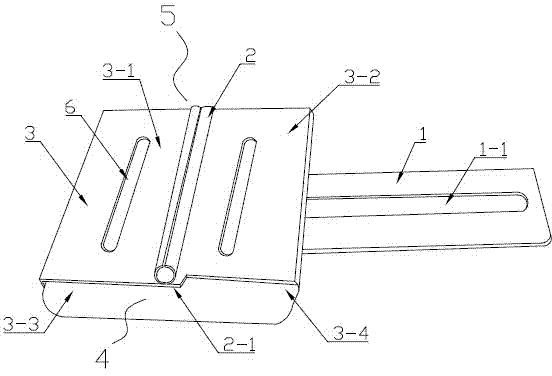

Braid alignment processing hemmer

InactiveCN104120554ATo achieve the processing effectAchieve sewingWork-feeding meansEngineeringBraid

The invention discloses a braid alignment processing hemmer which comprises a fixing plate and a hemming plate. The hemming plate comprises a bottom plate, a left cover plate and a right cover plate. The bottom plate, the left cover plate and the right cover plate define a hemming groove. The left cover plate and the right cover plate are spliced in a welding mode, a trimming plate is welded at the joint of the left cover plate and the right cover plate, and the trimming plate is curved to form a trimming groove. An arc-shaped extending section is arranged at one end of the bottom plate, and a flat opening is formed in the other end of the bottom plate. The trimming groove is formed in the hemming groove and placed in the center line position of the hemming groove. The fixing plate is welded on the bottom plate, and the fixing plate is provided with a fixing groove. By means of the braid alignment processing hemmer, hemming processing of cloth and trimming processing of a braid on the cloth can be conducted at the same time, and the alignment processing effect of the braid on the trimming cloth can be achieved.

Owner:嘉兴莱天华服饰有限公司

A laser electromagnetic pulse hybrid welding method and equipment

ActiveCN103737176BImprove utilization efficiencyGrain refinementLaser beam welding apparatusStructural deformationMetallic materials

Owner:武汉飞能达激光技术有限公司

Machining device of magnetic therapy mattress for medical conditioning

ActiveCN111828447ATo achieve the processing effectSave human effortLiquid surface applicatorsMaterial gluingPhysicsEngineering

The invention relates to a machining device, in particular to a machining device of a magnetic therapy mattress for medical conditioning. The machining device aims to solve the technical problem of how to design the machining device, which is simple to operate, can save manpower and can improve the working efficiency, of the magnetic therapy mattress for medical conditioning. The machining deviceof the magnetic therapy mattress for medical conditioning comprises supporting legs, limiting battens, a mounting plate, a discharging assembly and a bonding assembly, wherein the tops of the supporting legs are connected with a sliding plate in a sliding mode, the multiple limiting battens are arranged, are all connected to the top of the sliding plate and distributed in a rectangular shape, themounting plate is connected to the middle parts of the supporting legs, the discharging assembly is arranged on the mounting plate, and the bonding assembly is arranged on the discharging assembly. According to the machining device, through cooperative operation of the discharging assembly and the bonding assembly, magnetic therapy blocks are added to the magnetic therapy mattress, so that the effect of machining the magnetic therapy mattress is achieved.

Owner:佛山市都禾家具有限公司

Method for manufacturing cast iron

The invention discloses a method for manufacturing cast iron, which comprises the following step of: inputting a filling material to the periphery of an electrode in a medium-frequency electric furnace, wherein the filling material comprises an iron source mixture and a carbon-containing reducer, and the iron source comprises scrap iron or steel; and the method is characterized in that four elements of Ni, Cr, Mo and Cu are also added in an iron casting process. The alloy is as follows by weight percent: 0.5 to 1 percent of Ni, 0.01 to 0.15 percent of Cr, 0.15 to 0.6 percent of Mo and 0.35 to 0.6 percent of Cu. The invention solves the problem of poorer quality of the cast iron in the prior art and provides the manufacturing method for manufacturing the cast iron with better abrasion resistance, heat resistance, corrosion resistance, low-temperature resistance and non-magnetic performance.

Owner:苏州凯贸铸造工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com