Processing method for surface modification and metallization of hole walls of ceramic circuit board

A technology for ceramic circuit boards and surface modification, which is applied in circuit substrate materials, printed circuits, and printed circuit manufacturing. problems, to achieve the effect of reducing the subsequent plating time, improving the plating efficiency, and meeting the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

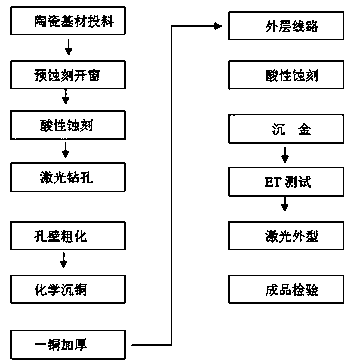

Image

Examples

Embodiment 1

[0058] A processing method for surface modification and metallization of a hole wall of a ceramic circuit board, characterized in that the double-sided ceramic board includes an intermediate ceramic layer and copper clad layers arranged on both sides of the ceramic layer; comprising the following steps:

[0059] S1. Ceramic substrate preparation;

[0060] S2. Pre-etched windows before laser drilling;

[0061] S3. Hole metallization, electroless copper deposition after laser drilling;

[0062] The step S2 includes the following specific steps:

[0063] S21. File design, design the window file at the metallized hole;

[0064] S22. Partially open the window, first paste the dry film on the whole board, then expose it with the window file, and expose the copper surface after development;

[0065] S23. Partial etching, etching away the copper surface of the window to expose the ceramic substrate;

[0066] S24. Electroplating is thickened, the whole board is electroplated, and the...

Embodiment 2

[0075] A processing method for surface modification and metallization of a hole wall of a ceramic circuit board, characterized in that it comprises the following steps:

[0076] A. Ceramic substrate preparation;

[0077] B. Production of engineering documents, in addition to designing conventional drilling, circuit, test and shape documents, add pre-etching window opening documents, the pre-etching window opening documents are pre-etched on the metallized hole parts of the ceramic plate before laser drilling The copper surface is designed with a window as large as the hole;

[0078] C. Pre-etched windows;

[0079] D. Laser drilling, according to the MI drilling file, using laser processing to drill through holes;

[0080] E. Coarsening of the hole wall;

[0081] F. Hole metallization: metallize the hole wall according to the traditional electroless copper deposition method;

[0082] G. Copper electroplating: Electroplate the thickness of hole copper and surface copper to ...

Embodiment 3

[0095] A processing method for surface modification and metallization of a hole wall of a ceramic circuit board, characterized in that it comprises the following steps:

[0096] A. Ceramic substrate preparation;

[0097] B. Production of engineering documents, in addition to designing conventional drilling, circuit, test and shape documents, add pre-etching window opening documents, the pre-etching window opening documents are pre-etched on the metallized hole parts of the ceramic plate before laser drilling The copper surface is designed with a window as large as the hole;

[0098] C. Pre-etched windows;

[0099] D. Laser drilling, according to the MI drilling file, using laser processing to drill through holes;

[0100] E. Coarsening of the hole wall;

[0101] F. Hole metallization: metallize the hole wall according to the traditional electroless copper deposition method;

[0102] G. Copper electroplating: Electroplate the thickness of hole copper and surface copper to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com