Multistation multiaxis numerical control machining device combining vertical type and horizontal type

A processing device and multi-station technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of waste of resources and time, large processing limitations, long processing time, etc., to save space and occupy an area , improved workpiece transit time, high transmission efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

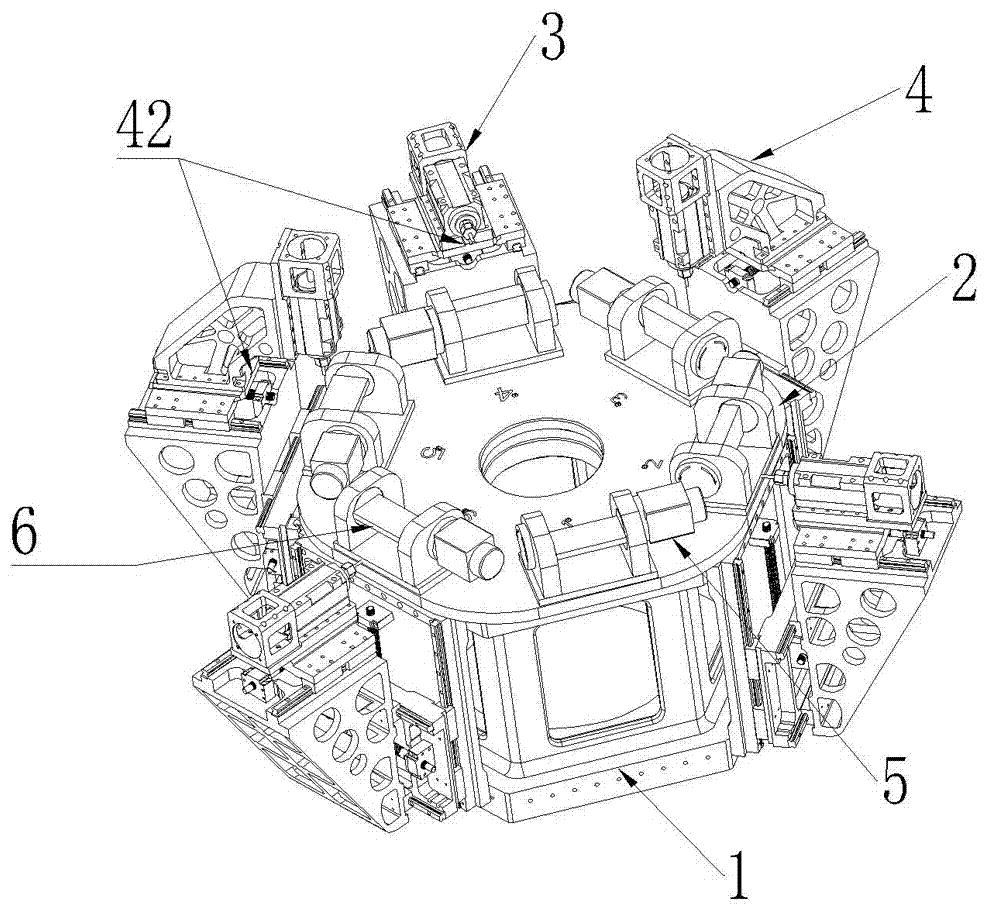

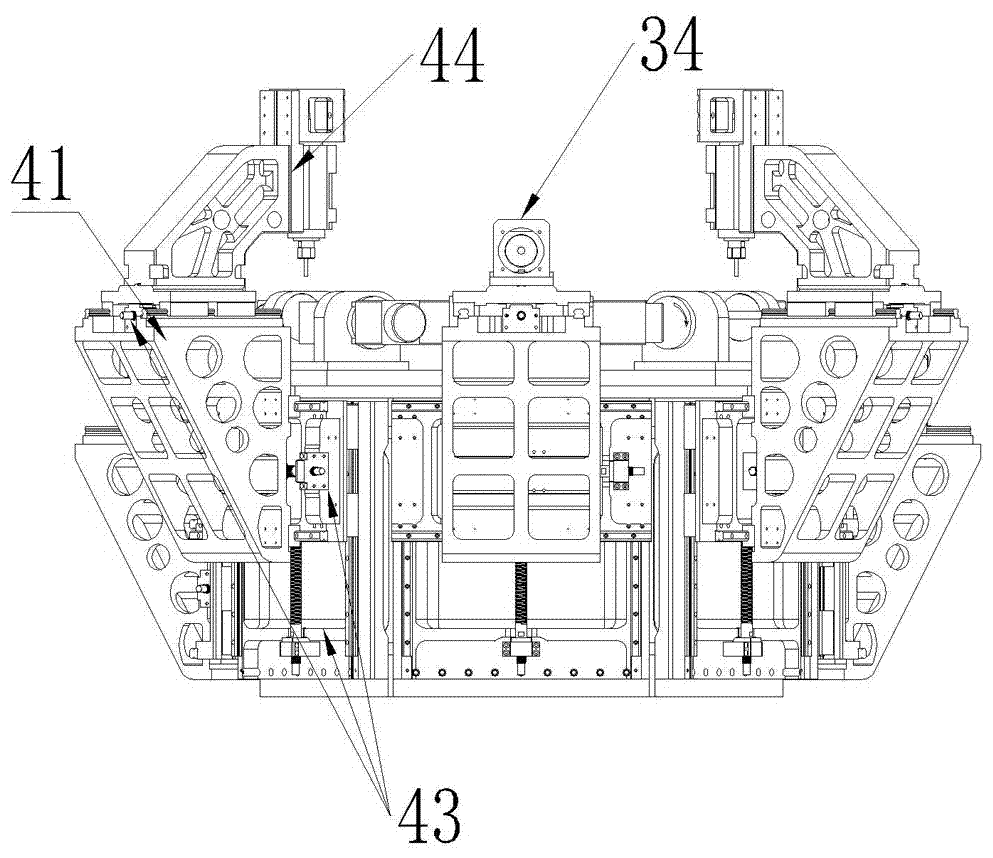

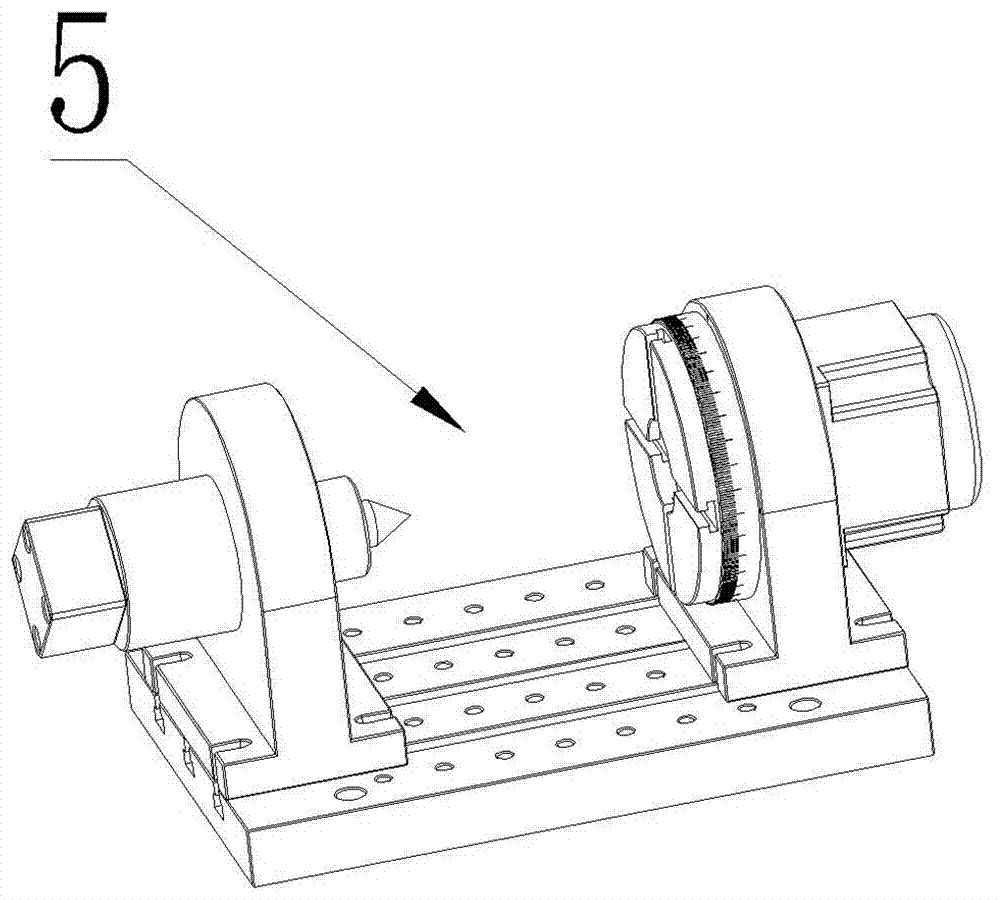

[0021] see Figure 1-5 As shown, the present invention relates to a vertical-horizontal composite multi-station multi-axis CNC machining device, including a machine body 1, a rotating shaft is provided in the middle of the machine body 1, and a rotary table 2 is fixed on the top of the rotating shaft. , the machine body 1 and the rotary table 2 are provided with a hydraulic locking mechanism, and the outer edge of the machine body 1 is staggered and evenly distributed with horizontal processing mechanisms 3 and vertical processing mechanisms for processing workpieces corresponding to the processing procedures. Mechanism 4, the rotary table 2 is evenly distributed with the workpiece rotary clamping mechanism 5 for fixing the workpiece to be processed, and the workpiece rotary clamping mechanism 5 is arranged under the horizontal processing mechanism 3 and the vertical processing mechanism 4. The workpiece rotating and clamping mechanism 5 is driven by a numerical control motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com