Firing equipment for processing carbon-fired wood

A technology of charcoal burning wood and equipment, which is applied in charcoal burning/combustion, transportation and packaging, conveyor objects, etc., can solve the problems of cumbersome operation process and low work efficiency, and achieve simple operation, improve work efficiency, and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

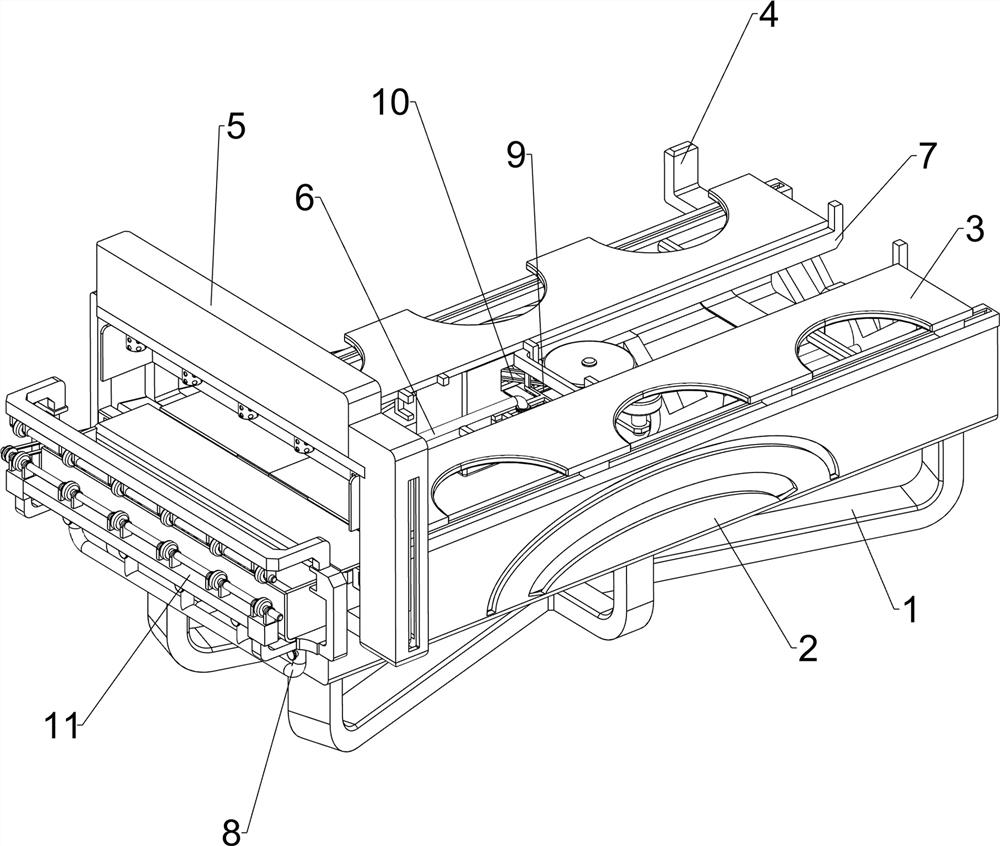

[0028] A kind of burning equipment for carbon burning wood processing, such as Figure 1-2 As shown, it includes a base 1, a box 2, a bedplate 3, a block 4, a bracket 5, a firing mechanism 6 and a pushing mechanism 7. The top of the base 1 is connected to the box 2, the bedplate 3 is connected to the top of the box 2, the block 4 is connected to the back side of the box 2, the bracket 5 is connected to the left side of the box 2, the firing mechanism 6 is arranged between the bracket 5 and the box 2, and the pushing mechanism 7 is arranged on the box 2.

[0029] The firing mechanism 6 includes an oxygen tank 61, a first oxygen pipe 62, a first switch 63 and a first oxygen welding gun 64. The tank body 2 is equipped with the oxygen tank 61, which is connected with the first oxygen pipe 62. The first oxygen pipe 62 is connected with a plurality of first oxygen welding guns 64 at even intervals, and the first oxygen welding guns 64 are connected with the bracket 5. The first switches ...

Embodiment 2

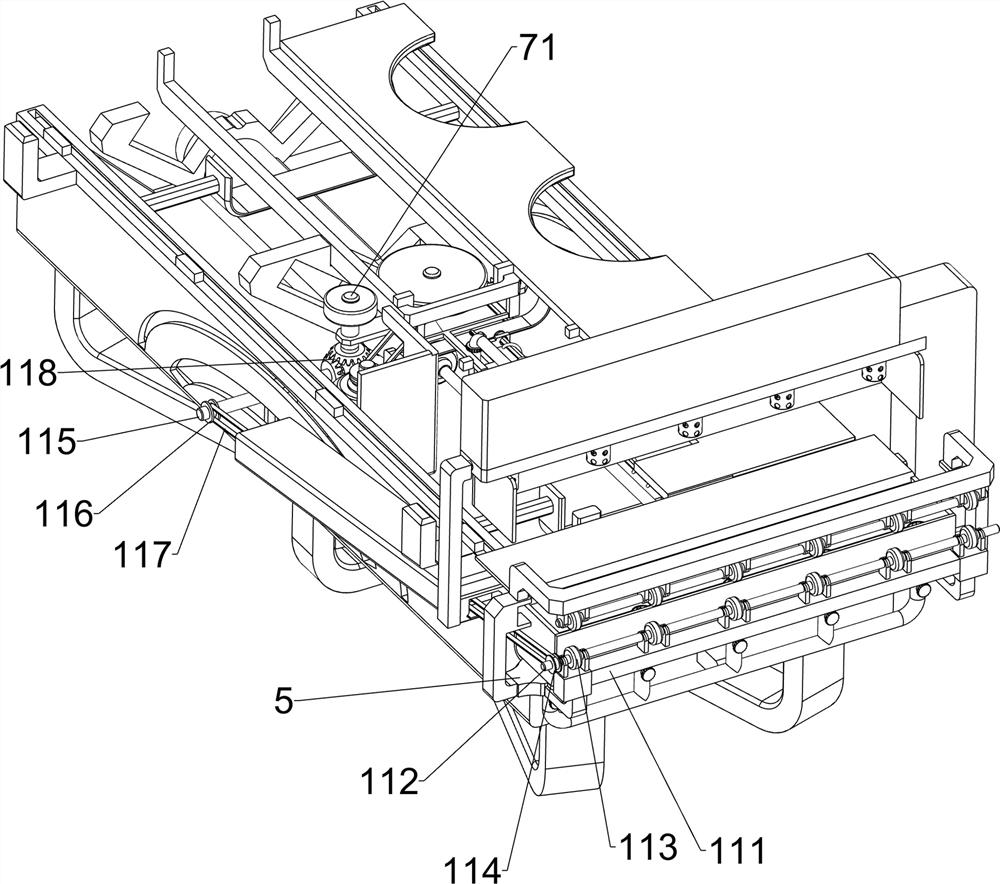

[0034] On the basis of Example 1, for example Figure 3 As shown, it also includes an afterburning assembly 8. The afterburning assembly 8 includes a second oxygen pipe 81, a second switch 82 and a second oxygen welding gun 83. The first oxygen pipe 62 is connected with the second oxygen pipe 81, and a plurality of second oxygen welding guns 83 are connected to the second oxygen pipe 81 at even intervals. The second oxygen welding guns 83 are connected to the bracket 5, and the second switch 82 is arranged at the joint between the second oxygen welding gun 83 and the second oxygen pipe 81.

[0035] When processing, the second switch 82 can be turned on, and the second oxygen welding gun 83 fires fire and cooperates with the first oxygen welding gun 64 to process both sides of the wood board, so that both sides of the wood board can be processed at the same time, and manual turnover of the wood board for secondary processing is not required, which effectively saves manpower.

[0036...

Embodiment 3

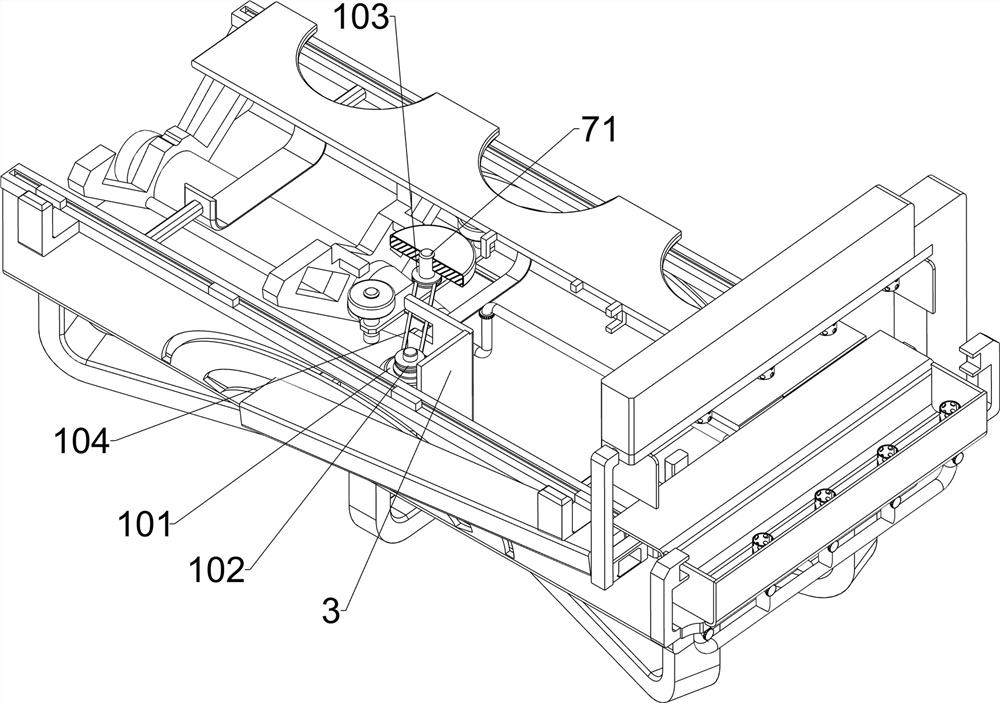

[0039] On the basis of Example 2, for example Figure 4 As shown, it also includes a driving mechanism 10. The driving mechanism 10 includes a motor 101, a first pulley 102, a second pulley 103, and a short belt 104. The motor 101 is mounted on the bedplate 3, the output shaft of the motor 101 is connected with the first pulley 102, the first shaft 71 is connected with the second pulley 103, and the short belt 104 is wound between the second pulley 103 and the first pulley 102.

[0040] When it is necessary to push the push plate 75 to move, the motor 101 can be started to drive the first pulley 102 to rotate, the first pulley 102 drives the second pulley 103 to rotate through the short belt 104, the second pulley 103 drives the first shaft 71 to rotate, the first shaft 71 drives the big wheel 72 to rotate, the big wheel 72 drives the push plate 75 to move forward, and the small wheel 74 can assist the push plate 75 to move, thus pushing the push plate 75.

[0041] such as Figure 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com