Device for punching, stamping and/or shaping flat elements

A technology of parts and equipment, applied in the field of equipment for stamping, imprinting and/or forming flat parts, can solve the problem of difficulty in maintaining the precise position coordinates of a hole, difficulty in maintaining the diameter or shape of the hole wall, and inability to meet the requirements of stamping. Accuracy and other issues, to achieve the effect of short working cycle time, short processing steps, avoiding impact and rush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

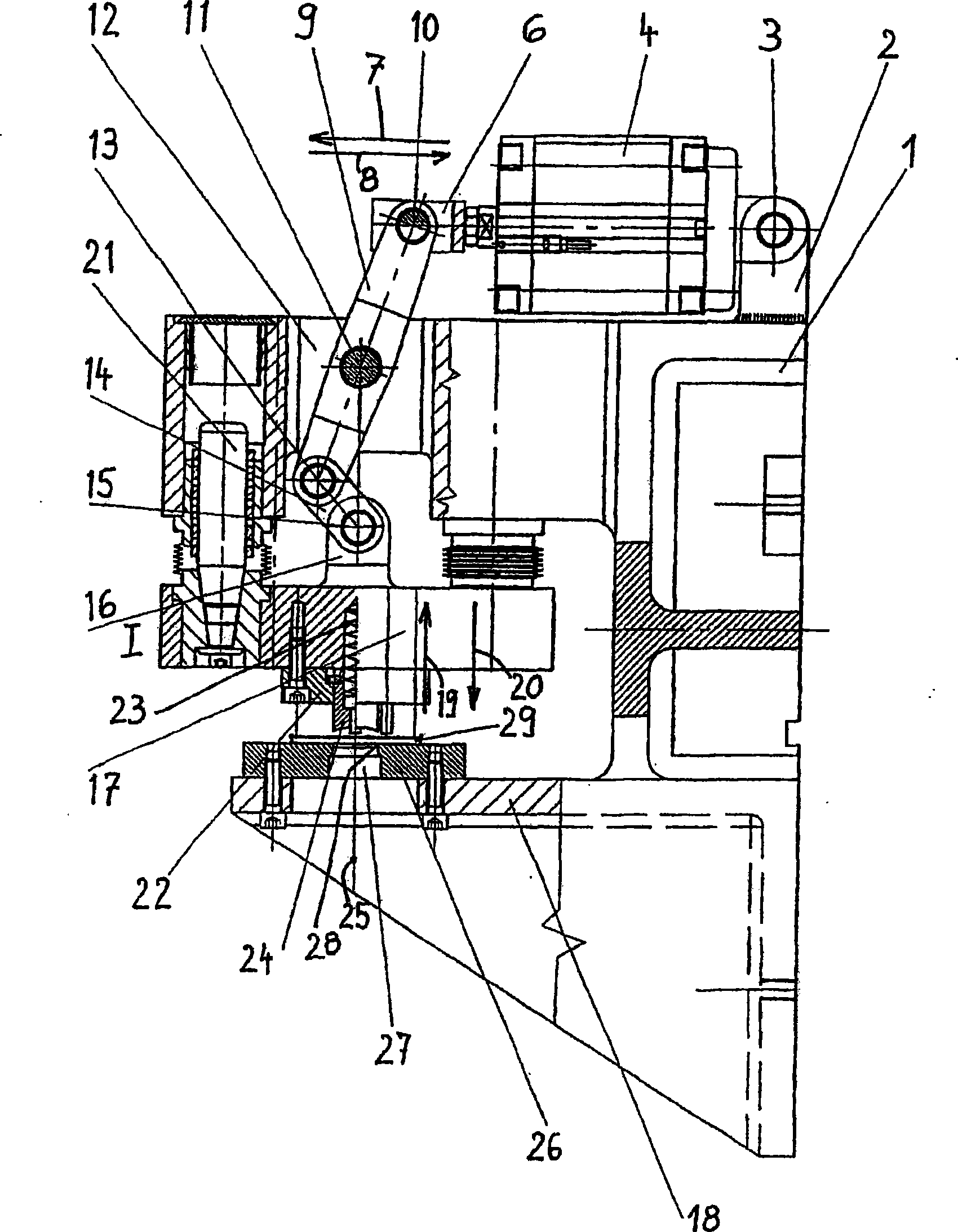

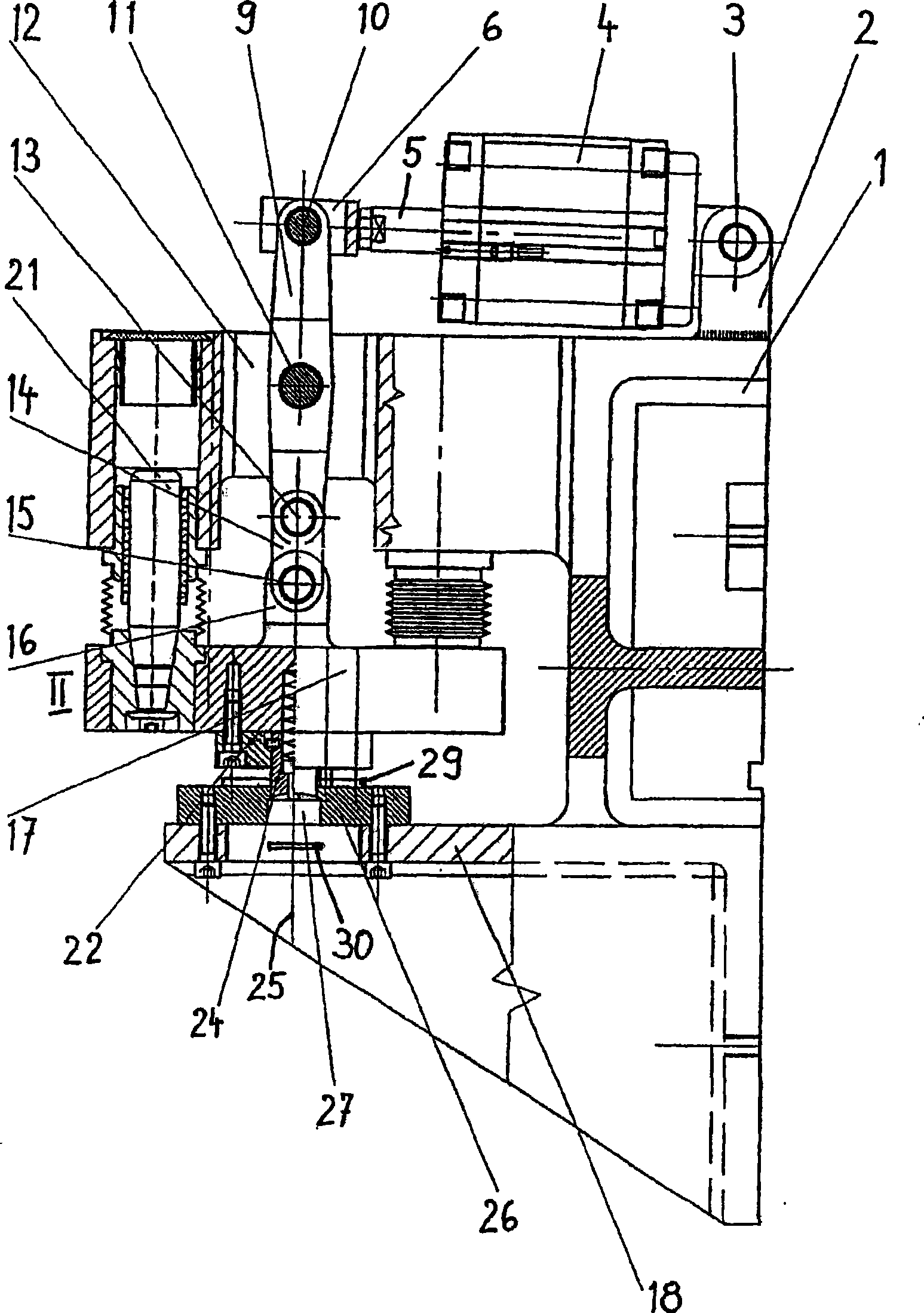

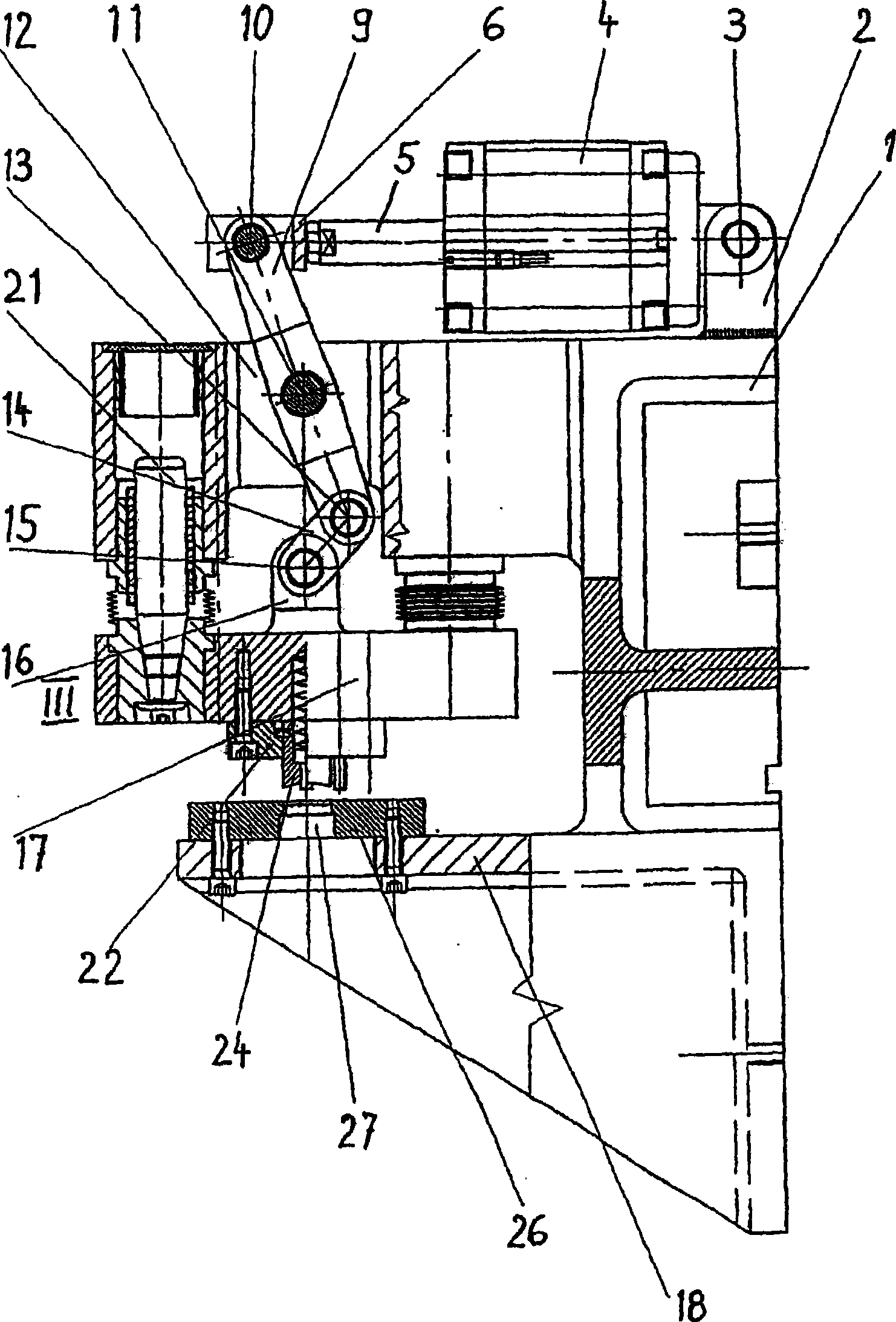

[0036] For a better understanding of the present invention, the various embodiments of the equipment of the present invention represented in the accompanying drawings will be described below with the punching action as a working step. In this case, a metal strip guided in linear translation on a support plate is chosen for illustration, this strip being the so-called flat part. But this does not mean that the invention is limited to the machining of this type of flat parts.

[0037] The apparatus of the first embodiment of the invention is used for punching metal strips fed horizontally into the apparatus, such as figure 1 -3 shown. A support 2 for a cylinder pivot mount 3 is fastened to the machine frame body 1 of the punching machine. Here, the pneumatic cylinder 4 selected as the driver is installed on the frame body 1 through the cylinder pivot mount 3, and the piston rod 5 is installed so as to move linearly in the pneumatic cylinder 4, and the piston rod 5 serves as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com