Two-shaft numerical control device used for machining shoe molds

A numerical control device and shoe mold technology, which is applied to feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to automatically change the surface of the shoe mold, low efficiency and high cost, and avoid multiple clamping and alignment. , reduce costs and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

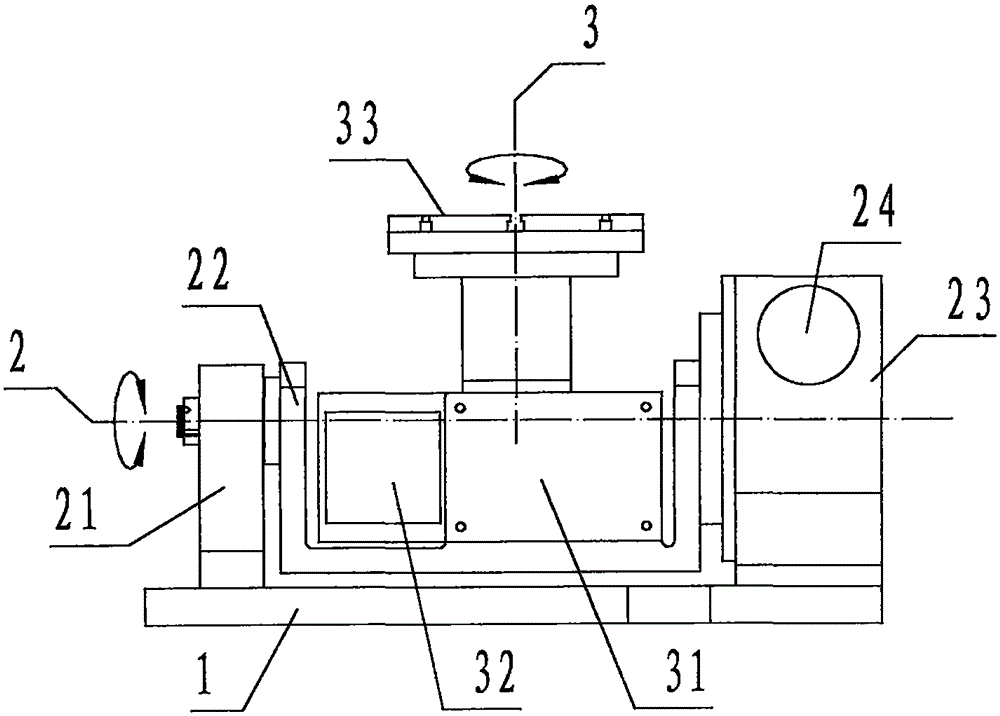

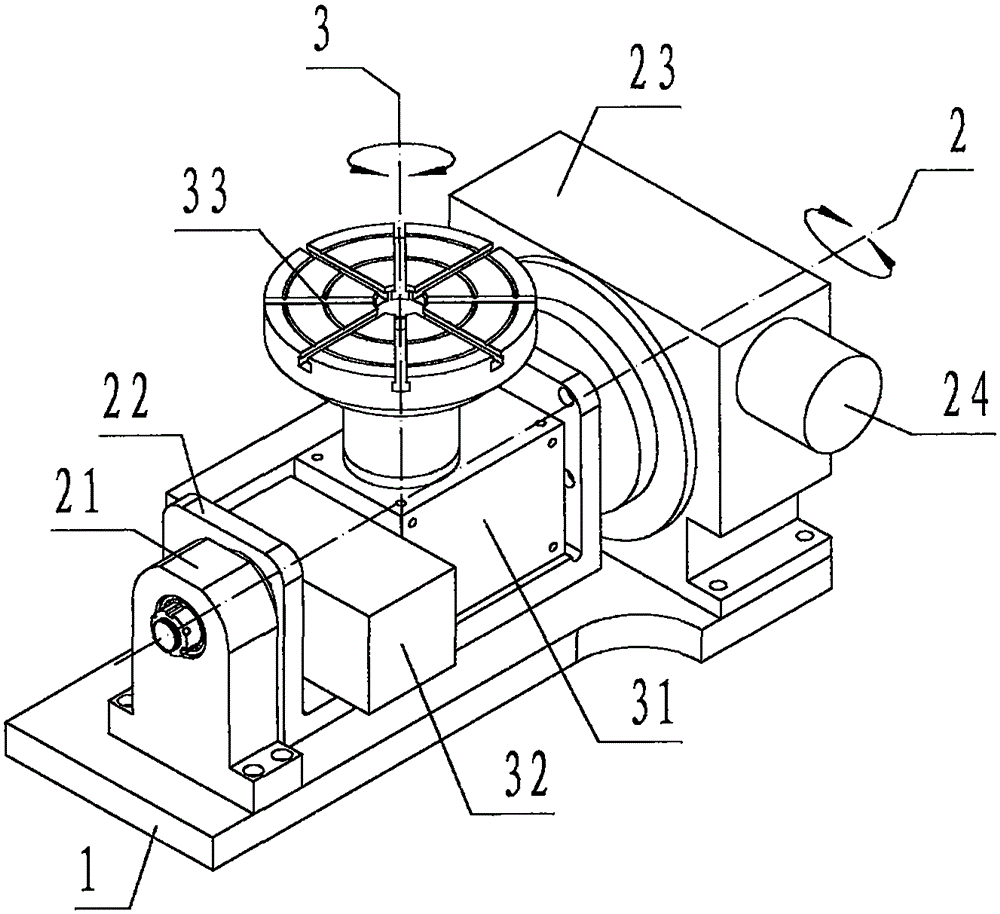

[0018] refer to Figure 1 ~ Figure 2 , a two-axis numerical control device for processing shoe molds of the present invention includes a base 1, a horizontal axis 2, and a vertical axis 3, wherein: the base 1 is a flat steel member;

[0019] The horizontal shaft 2 is a device that can rotate around an imaginary axis in the horizontal direction consisting of a bracket 21, a rotating seat 22, a P reducer 23, and a P servo motor 24, wherein the bracket 21 is an inverted T-shaped steel block The upper center of the bracket 21 is provided with a circular through hole in the left and right direction called the bracket hole, and the rolling bearing in the bracket hole is called the bracket bearing; Components, the upper center of the left side of the left side of the rotating seat 22 is provided with a cylindrical flange protruding to the left and is called the seat rotating shaft, and the upper center of the rotating seat 22 right side of the groove wall is provided with the seat ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com