Powder bed five-axis additive and subtractive composite manufacturing device

A technology of adding and subtracting materials and powder bed, which is applied in the field of additive manufacturing, can solve the problems of limited processing range of subtractive materials, affecting SLM printing quality, and large laser spot size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be explained in detail below in conjunction with the accompanying drawings and embodiments.

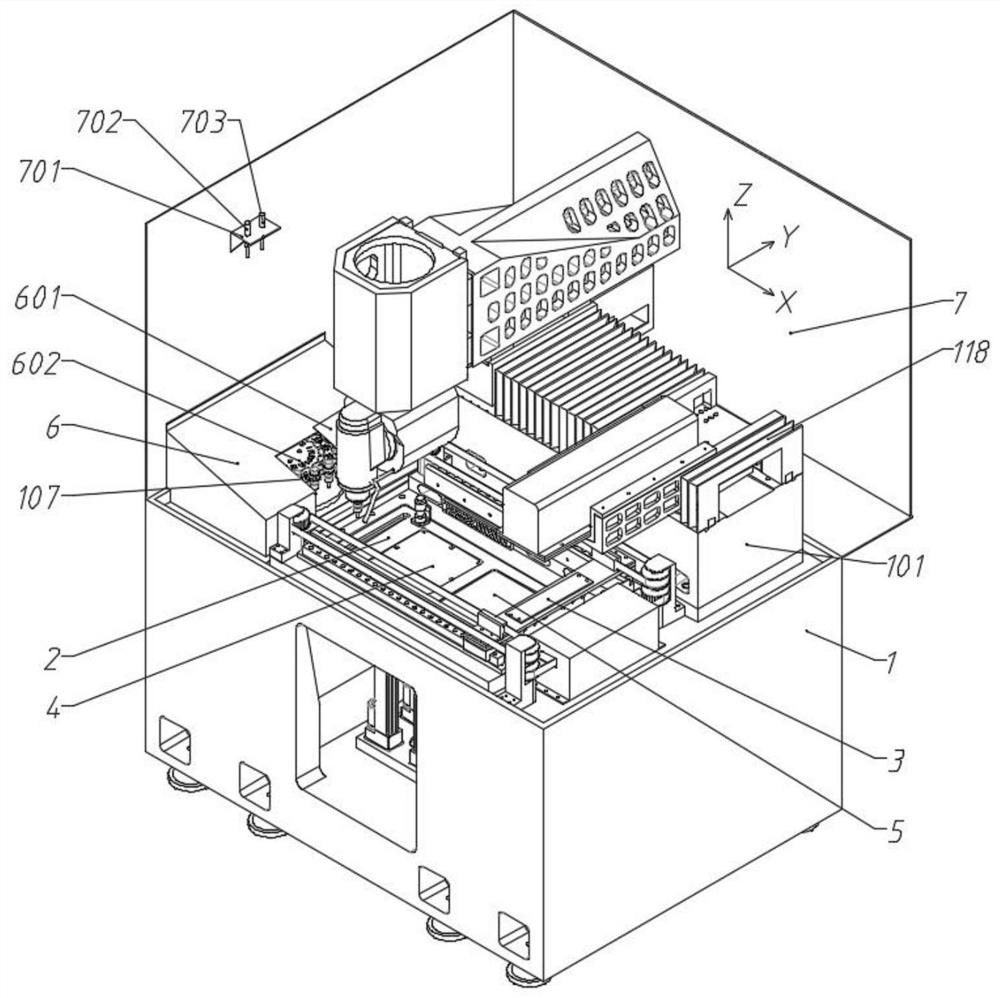

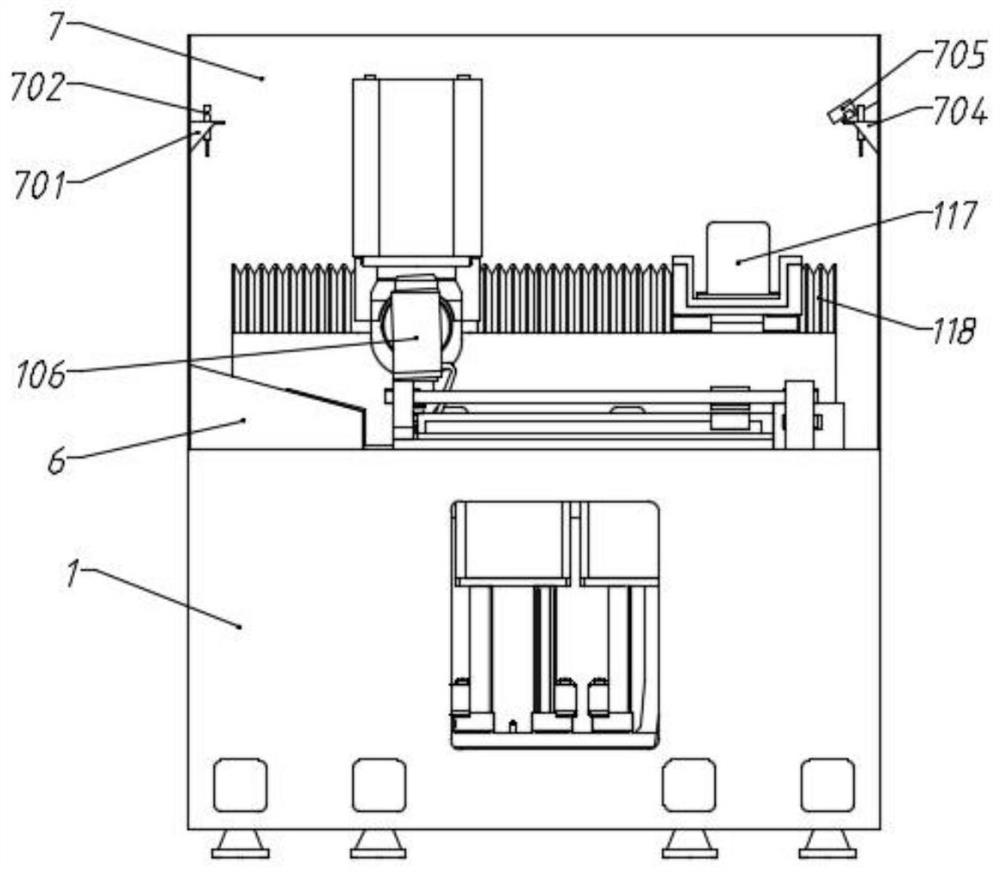

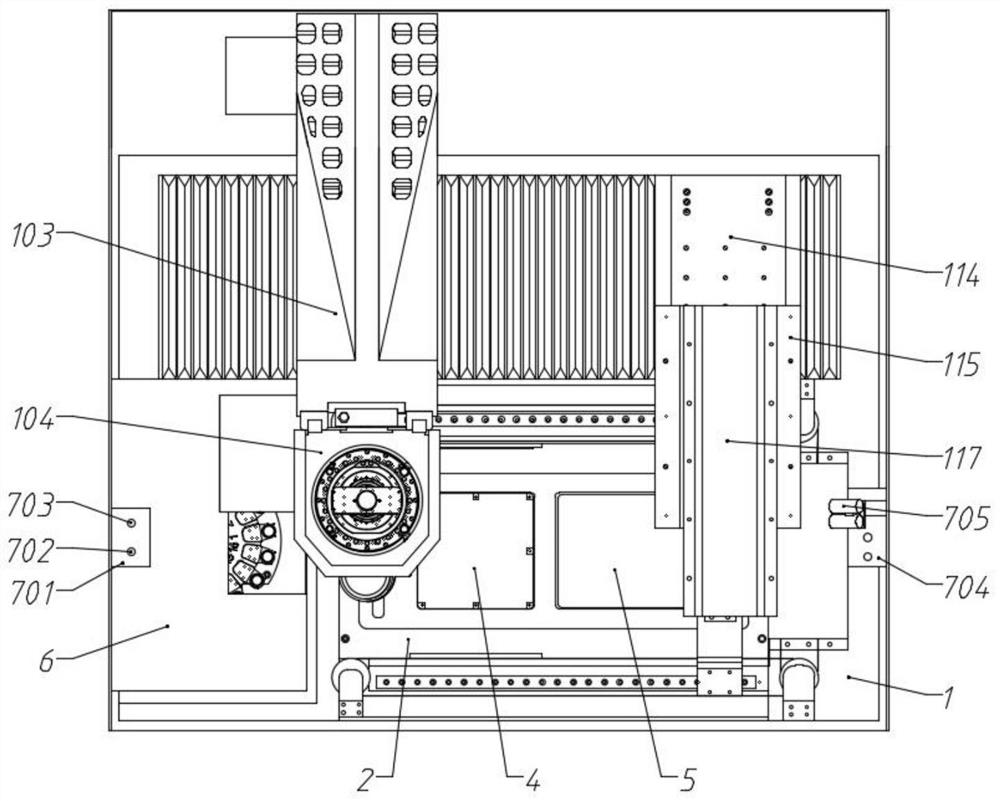

[0042] refer to figure 1 , figure 2 , image 3 with Figure 4 , one A powder bed five-axis additive and subtractive compound manufacturing equipment, including a machine tool 1 and a material subtractive device and an SLM additive device arranged on it, the material subtractive device and the SLM additive device are arranged in the protective cover 7, and the X, Y, and Z directions direction of movement as figure 1 shown;

[0043] The material reduction device performs material reduction processing through a five-axis oscillating head connected to the machine tool ram 101 with degrees of freedom of movement in the X, Y, and Z directions and A and C axes. The tool 107 of the five-axis oscillating head is Replace on the rotary tool rest 602 in the tool magazine 6 on the left side of the material device, and the tool magazine door 601 of the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com