Engraving method of closed-loop control over water milling cutter by applying 3D digital model

A digital model, closed-loop control technology, applied in engraving, processing models, decorative arts, etc., can solve the problems of many processes, inability to directly print workpieces, high cost, and achieve the effect of good safety, saving manpower and materials, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: making stone carving portrait

[0024] An engraving method using a 3D digital model for closed-loop control of a water milling cutter, the specific steps are as follows:

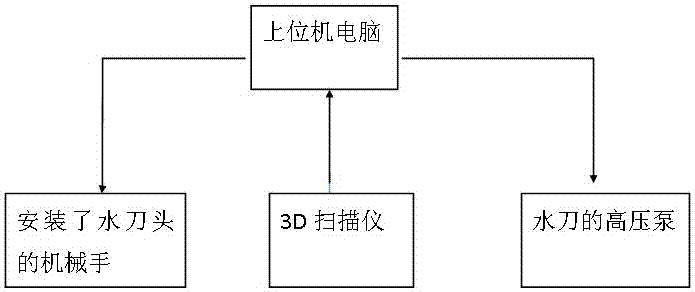

[0025] A. First, carry out 3D scanning of the human entity, and establish a 3D digital model of the human entity in the host computer to determine the stone to be processed;

[0026] B. Position and fasten the stone to be processed on the base within the processing range of the manipulator. The 3D scanner performs 3D scanning of the stone to be processed under the control of the host computer, and saves the 3D data of the stone to be processed to the host. In the computer database, the host computer compares the 3D data of the stone to be processed with the 3D digital model of the human entity to ensure that the stone is sufficient, and then locks it;

[0027] C. Determine the processing plan of the cutting tool according to the nature of the stone and the shape of the 3D digital model;...

Embodiment 2

[0035] Embodiment 2: making steel mold

[0036] An engraving method using a 3D digital model for closed-loop control of a water milling cutter, the specific steps are as follows:

[0037] A. First establish a 3D digital model of the mold in the host computer to determine the steel to be processed;

[0038] B. Position and fasten the stone to be processed on the base within the processing range of the manipulator. The 3D scanner performs 3D scanning of the steel to be processed under the control of the host computer, and saves the 3D data of the steel to be processed to the host. In the computer database, the host computer compares the 3D data of the steel to be processed with the 3D digital model of the mold, and adjusts the 3D digital model of the mold to the 3D digital model of the material to be processed to ensure that the steel is sufficient use, then lock;

[0039] C. Determine the machining plan of the cutting tool according to the properties of the steel and the shap...

Embodiment 3

[0047] Example 3: Making a Wooden Model

[0048] An engraving method using a 3D digital model for closed-loop control of a water milling cutter, the specific steps are as follows:

[0049] A. First establish a 3D digital model of the wooden model in the host computer to determine the wood to be processed;

[0050] B. Position and fasten the stone to be processed on the base within the processing range of the manipulator. The 3D scanner performs 3D scanning of the wood to be processed under the control of the host computer, and saves the 3D data of the wood to be processed to the host. In the computer database, the host computer compares the 3D data of the steel to be processed with the 3D digital model of the wooden model, and adjusts the 3D digital model of the wooden model to the 3D digital model of the material to be processed to ensure enough wood, then locked;

[0051] C. Determine the processing plan of the cutting tool according to the nature of the wood and the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com