A dense filling equipment for high-voltage fuse filler

A high-voltage fuse and filling equipment technology, which is applied in the manufacture of fuses, etc., can solve problems such as high labor intensity, dust pollution, and low efficiency, and achieve the effects of improving filling quality, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

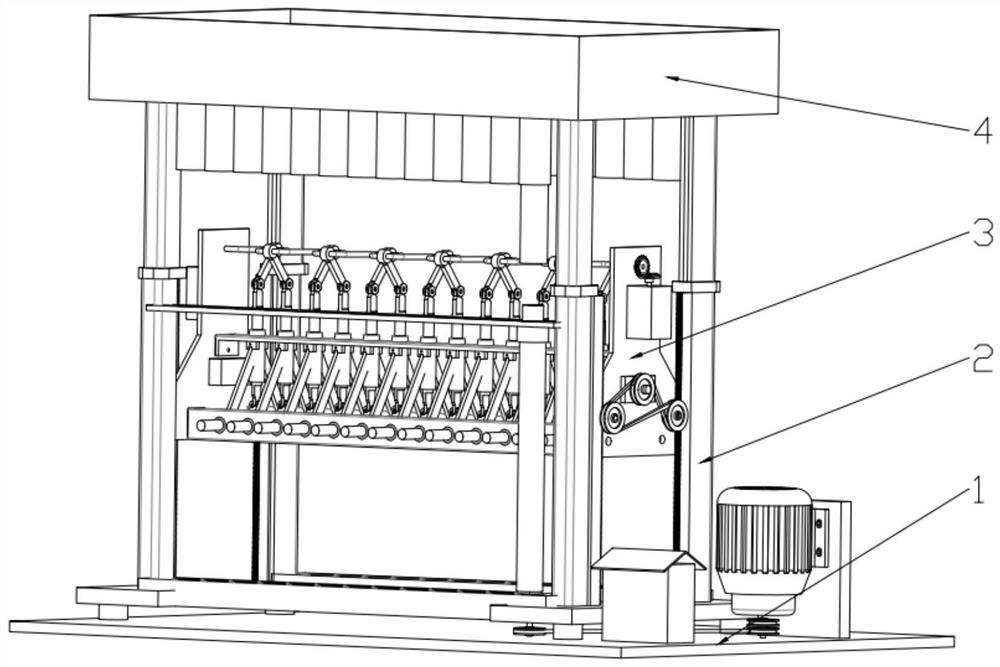

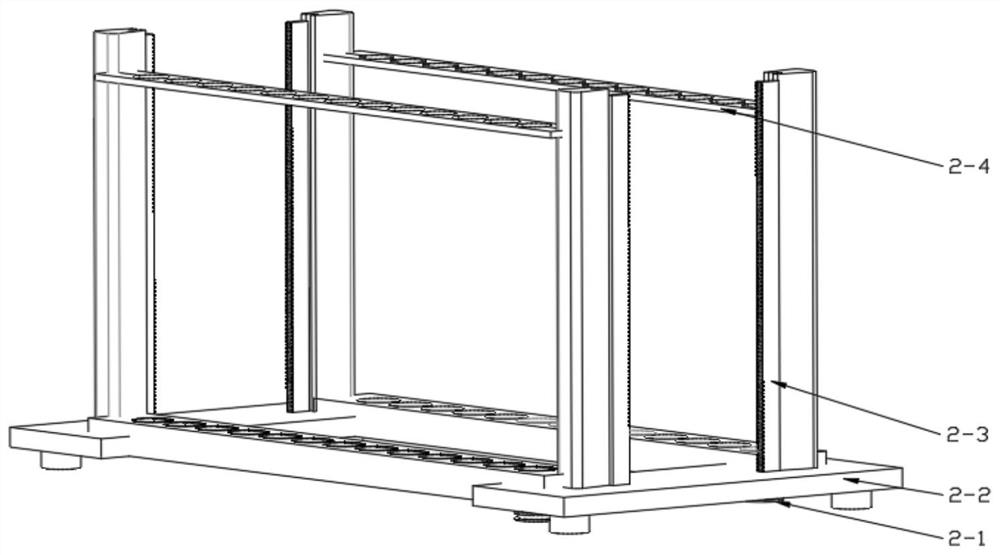

[0052] A dense filling equipment for high voltage fuse filler, such as figure 1 As shown, it includes a bottom plate 1, a tube body rotation mechanism arranged on the bottom plate 1, a tube body restraint mechanism 2 for keeping the tube body upright, a feeding mechanism 4 for conveying fillers into the tube body, and is movable up and down. The lifting mechanism on the column of the frame 2-2 of the pipe restraint mechanism 2, and the impact vibration mechanism installed on the lifting mechanism, the impact vibration mechanism is used to impact the side wall of the pipe body, and the dense filling of the high-voltage fuse filler It is suitable for dense filling of high-voltage fuse fillers, and also suitable for scenes where the internal materials of other tubular objects need to be vibrated and dense.

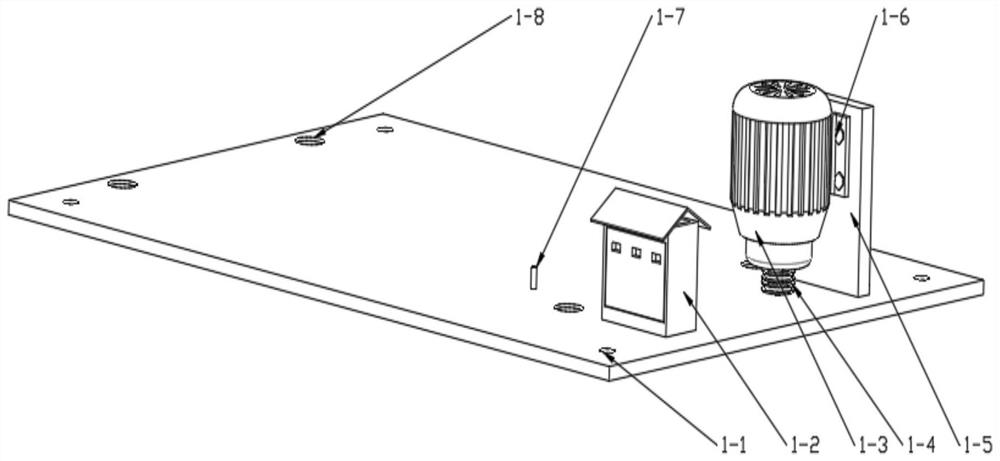

[0053] Such as figure 2 As shown, the bottom plate 1 provides a mounting mechanism for installing the pipe body rotation mechanism. The pipe body rotation mechanism include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com