Cement dung leaking plate processing equipment for livestock breeding

A technology for processing equipment and dung slabs, which is applied in the field of cement slat board processing equipment for animal husbandry, can solve the problems of low work efficiency and manpower consumption, and achieve the effects of improving work efficiency, simple operation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

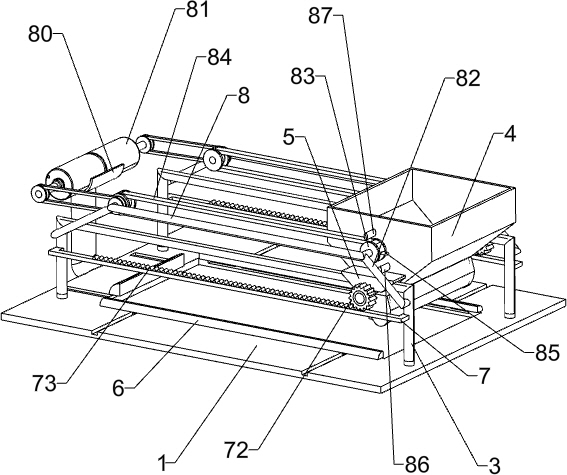

[0025] A kind of cement leaking manure board processing equipment for animal husbandry, such as Figure 1-3 As shown, it includes a mounting plate 1, a support rod 2, a guide rod 3, a hopper 4, a sliding sleeve 5 and a limit plate 6. The rod 3 and the guide rod 3 are slidingly connected with a sliding sleeve 5, and a hopper 4 is connected between the sliding sleeves 5 on both sides, and the left, right and rear sides of the top of the mounting plate 1 are connected with a limit plate 6, and a one-way device is also included. 7 and a driving device 8, a one-way device 7 and a driving device 8 are arranged between the guide rod 3 and the hopper 4.

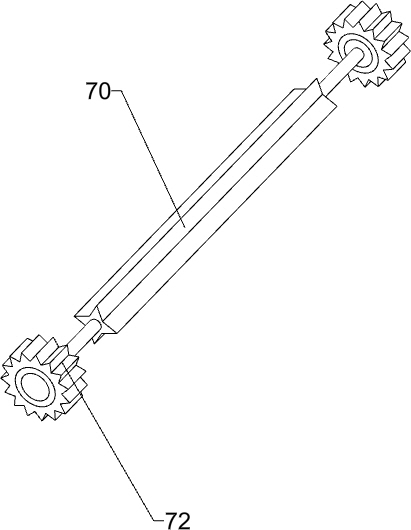

[0026] The one-way device 7 includes a pulling roller 70, a one-way gear 72 and a transmission rack 73. The side of the hopper 4 close to the discharge end is connected to the pulling roller 70 in a rotating manner, and the two ends of the pulling roller 70 are connected to a one-way gear. The gear 72 and the middle part of the guid...

Embodiment 2

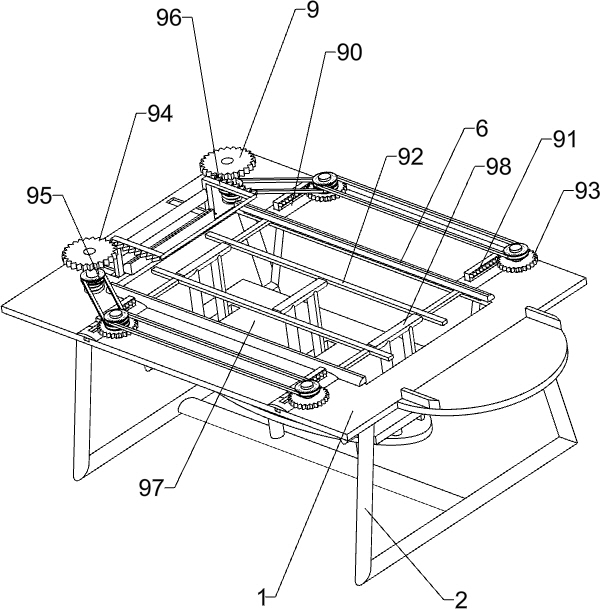

[0030] On the basis of Example 1, such as Figure 4-5 As shown, unloading device 9 is also included, and unloading device 9 includes slide plate 90, connecting rack 91, cross bar 92, first gear 93, second gear 94, torsion spring 95, sliding tooth frame 96, base plate 97 , strut 98, connecting plate 99 and buffer spring 910, the middle part of the mounting plate 1 is an open setting, the left and right sides of the mounting plate 1 are connected with two slide plates 90, the slide plate 90 is slidingly connected with a connection rack 91, and the connection teeth The bar 91 passes through the limiting plate 6 and slides with the limiting plate 6. A cross bar 92 is connected between the two connecting racks 91 on the same side. The cross bar 92 is located at the opening of the mounting plate 1, and the top of the mounting plate 1 Two first gears 93 are rotatably connected to the left and right sides, and the first gear 93 meshes with the connecting rack 91. The two first gears 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com