Aluminum pot processing device for kitchen ware processing

A technology of processing device and aluminum pan, which is applied in spraying device, liquid spraying device and other directions, can solve the problems of labor-consuming, cumbersome operation process, affecting the use effect, etc., and achieve the effect of saving labor and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

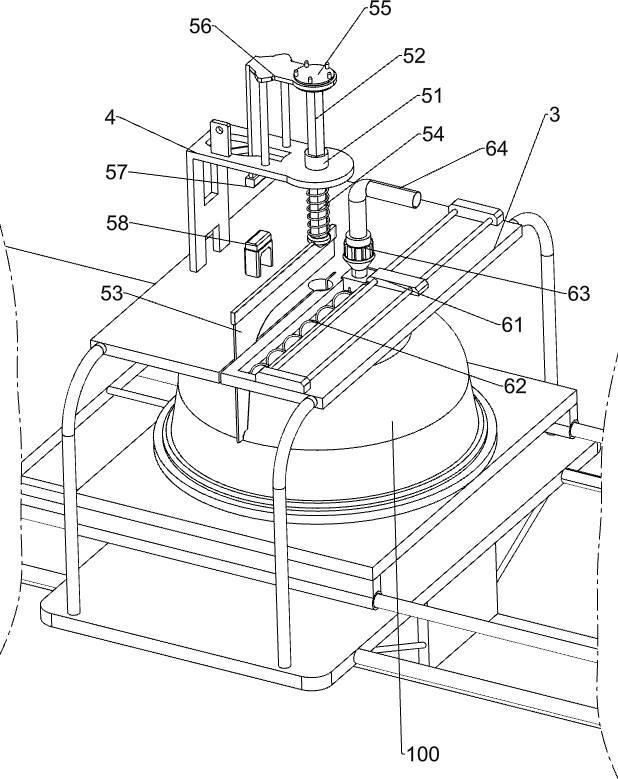

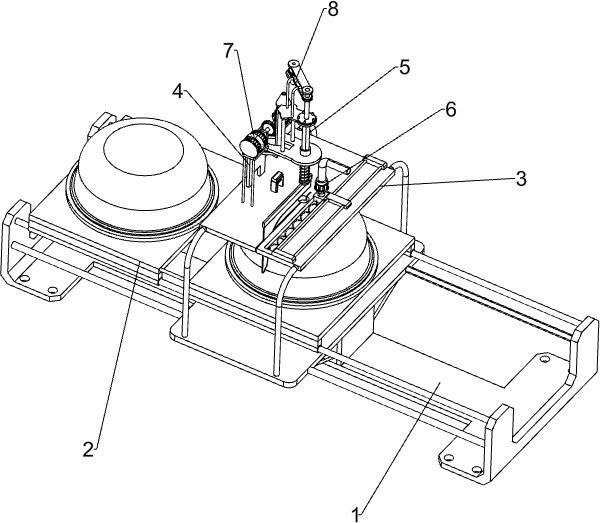

[0023] A kind of aluminum pan processing device for processing kitchen utensils, such as Figure 1-2 As shown, it includes a mounting base 1, a placement plate 2, a mounting plate 3 and a mounting frame 4. The mounting base 1 is slidably connected with a placement plate 2, the middle part of the mounting base 1 is connected with a mounting plate 3, and the left side of the mounting plate 3 is connected with a The mounting frame 4 also includes a lifting assembly 5 and a blanking assembly 6 , the lifting assembly 5 is provided between the mounting frame 4 and the mounting plate 3 , and the blanking assembly 6 is provided on the mounting plate 3 .

[0024] The lifting assembly 5 includes an inner diamond sleeve 51, a rhombus rod 52, a scraper 53, a tension spring 54, a connecting sleeve 55, a sliding frame 56, an iron block 57 and an electromagnet 58, and the mounting frame 4 is rotatably connected with an internal The diamond-shaped sleeve 51 is slidingly connected with a rhomb...

Embodiment 2

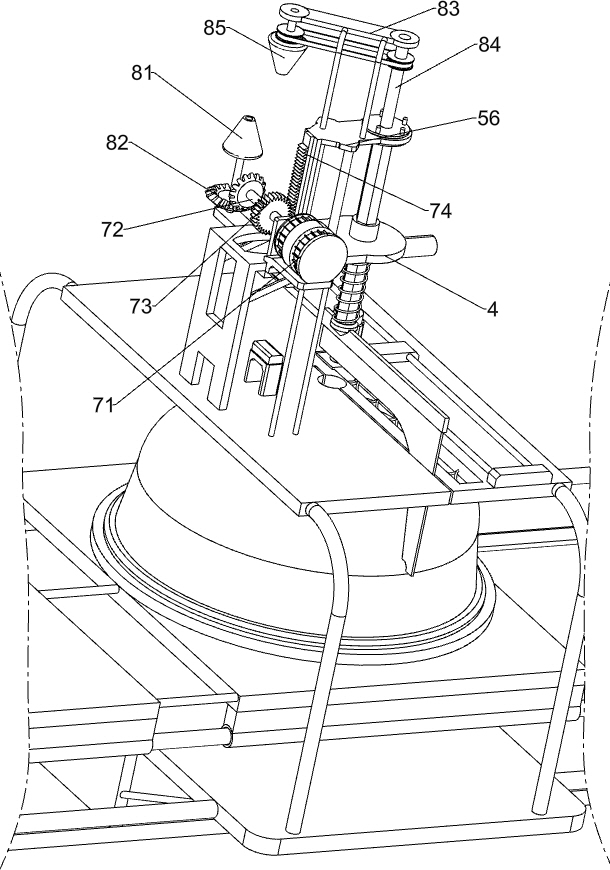

[0028] On the basis of Example 1, such as image 3 As shown, drive assembly 7 is also included. Drive assembly 7 includes servo motor 71, rotating shaft 72, drive gear 73 and drive rack 74. Servo motor 71 is installed on the left side of the top of mounting frame 4. On the output shaft of servo motor 71 A rotating shaft 72 is connected, a driving gear 73 is connected on the rotating shaft 72 , a driving rack 74 is connected on the sliding frame 56 , and the driving gear 73 is meshed with the driving rack 74 .

[0029] When it is necessary to pull the rhombic rod 52 to move downward, the servo motor 71 can be started to drive the rotating shaft 72 to rotate, the rotating shaft 72 rotates to drive the driving gear 73 to rotate, the driving gear 73 rotates and pokes the driving rack 74 to move downward, and the driving rack 74 moves downward The movement drives the sliding frame 56 to move downward, the sliding frame 56 moves downward to drive the connecting sleeve 55 to move dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com