Workpiece bevel edge machining control method capable of effectively avoiding interference in numerically controlled machining system

A technology of avoiding interference and processing system, applied in the field of workpiece bevel machining control that effectively avoids interference, can solve problems such as redundant interference judgment and interference avoidance, inability to directly set the lifting angle, and uncertainty of the lifting angle, so as to save energy. The effect of memory, avoiding interference, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

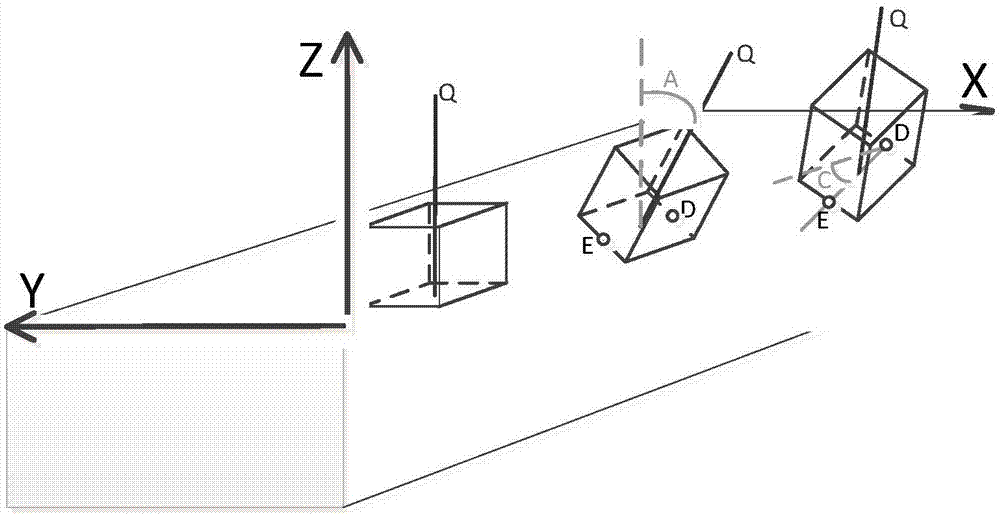

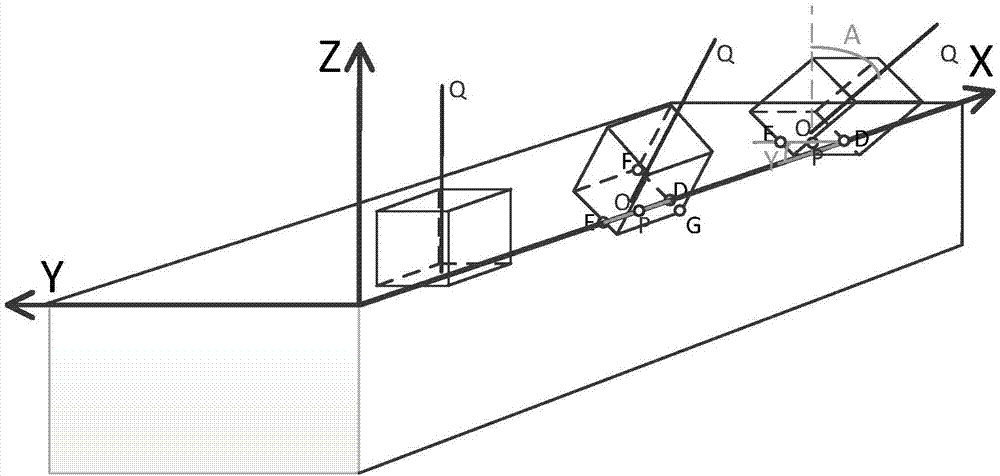

[0030] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

[0031] The workpiece bevel processing control method that effectively avoids interference in the numerical control machining system includes the tool 1 for processing the workpiece and the first control tool rotation axis and the second control tool rotation axis that control the tool lifting angle. Its main features Yes, including the following steps:

[0032] (1) The system calculates the tool lifting angle through the following steps:

[0033] (11) Set the processing point of the workpiece to be processed, the processing surface of the tool under the initial position and the straight line perpendicular to the processing direction as the first rotation axis;

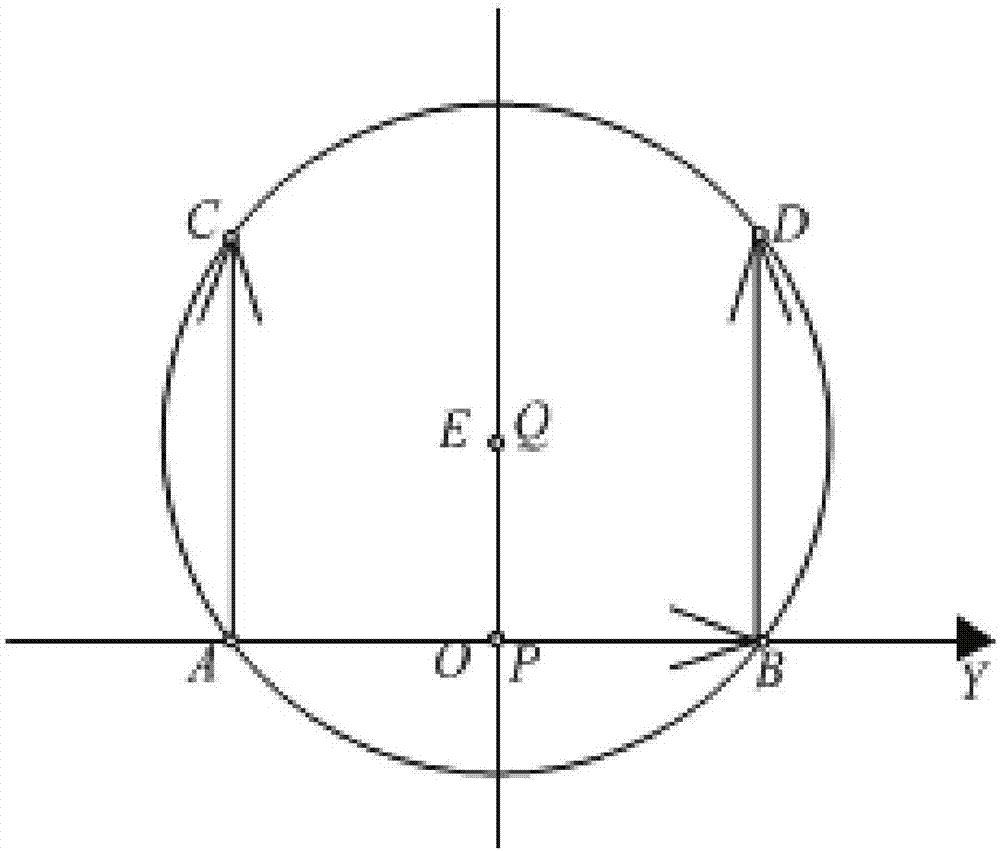

[0034] (12) Establishing a right-handed rectangular coordinate system, the origin of the right-handed rectangular coordinate system is the interse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com