Preprocessing method for coking wax oil used as hydrocracking raw material

A technology for coking wax oil and hydrocracking, which can be used in hydrocarbon oil cracking, petroleum industry, refining with acid-containing liquid, etc., and can solve the problems of poor denitrification selectivity, high operating cost, and low refined oil yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

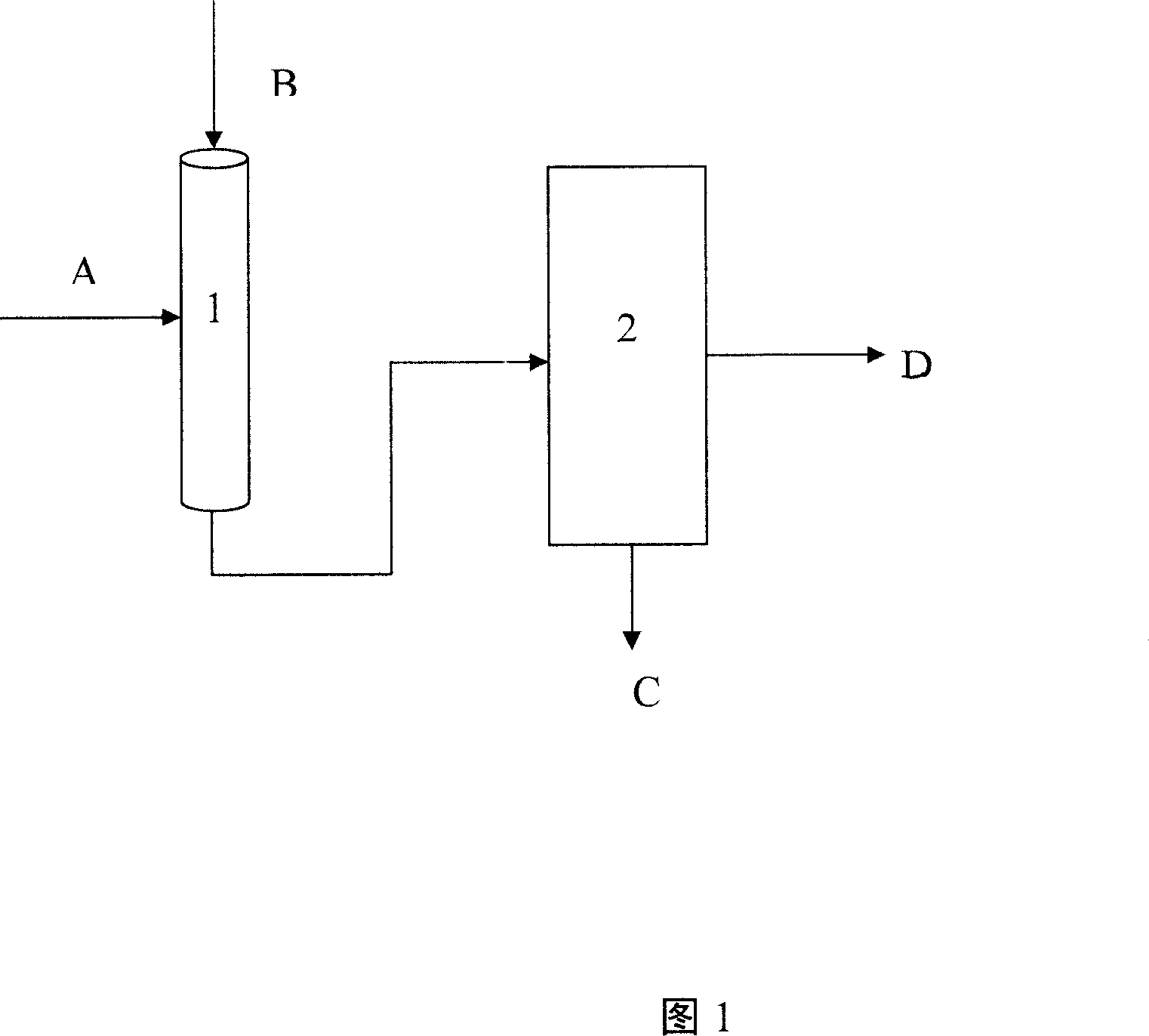

[0021] Daqing coking wax oil (its properties are as shown in Table 1) A from the upstream flow process and adding 2% by 60% nitric acid, 35% glycerol and 5% polyacrylamide synthetic coking wax oil pretreatment agent B first in a static mixer Mixing reaction in 1, mixing enough time and intensity, can also be mixed by mixing tank. The contact temperature is 20-120°C.

[0022] The coker wax oil after the reaction is completed enters the settling tank 2, and the sedimentation adopts natural sedimentation, gravity sedimentation for 120 minutes, and the sedimentation temperature is 60-150° C. to obtain the coker wax oil refined oil D (its properties are shown in Table 1). The macromolecular substances after reaction adsorption settle in the settling tank due to the density difference, and the residue C comes out from the bottom of the settling tank. Due to the poor fluidity of the oil residue, it should be properly insulated at the bottom of the tank or a scraper device should be ...

Embodiment 2

[0028] Liaohe coking wax oil (its properties are as shown in Table 2) is mixed with the pretreatment agent synthesized by 80% phosphorous acid or phosphorous acid anhydride, 16% ethylene glycol and 4% polyaluminum chloride, and the pretreatment agent add-on is 5%, Fully mixed by a static mixer, after settling in a settling tank for 60 minutes, refined coker wax oil (its properties are shown in Table 2) was obtained. The test results of hydrocracking pre-refining show that, compared with untreated coker gas oil, when the total nitrogen content reaches 10 μg·g -1 , the airspeed increases by 35%.

[0029] Table 2 Properties of coker wax oil before and after pretreatment

[0030] analyze data

Embodiment 3

[0032] Daqing coking wax oil (its properties are shown in Table 3) is mixed with a pretreatment agent synthesized by 50% sulfuric acid, 42% DMF and 8% sodium metaaluminate, the addition of the pretreatment agent is 0.5%, and it is fully mixed by a static mixer Afterwards, settling in the settling tank for 30 minutes separated coker wax oil refined oil (its properties are as shown in Table 3). The test results of hydrocracking pre-refining show that, compared with untreated coker gas oil, when the total nitrogen content reaches 10 μg·g -1 , the temperature of the hydrocracking pre-refining section is 10°C lower.

[0033] Table 3 Properties of coker wax oil before and after pretreatment

[0034] analyze data

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com