Cambered surface cutting equipment for furniture processing and using method of cambered surface cutting equipment

A cutting equipment and curved surface technology, which is applied in the field of curved surface cutting equipment for furniture processing, can solve the problems of increasing demand for mass production, poor results, and unsmooth curved surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

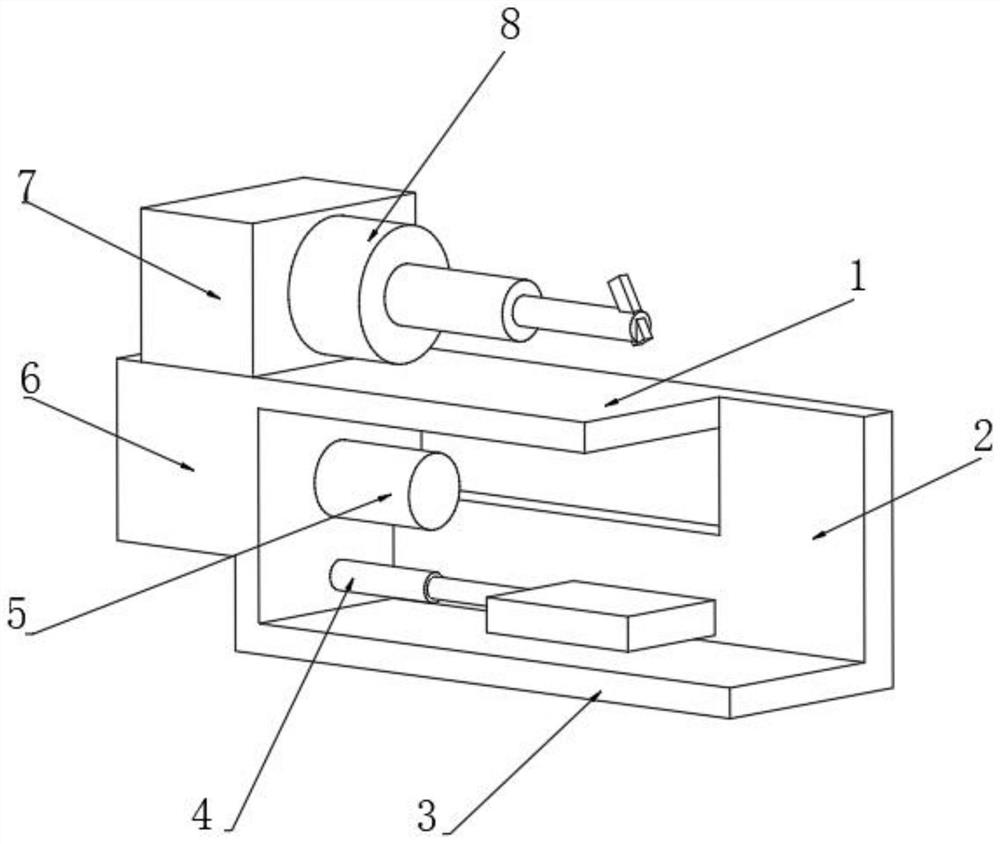

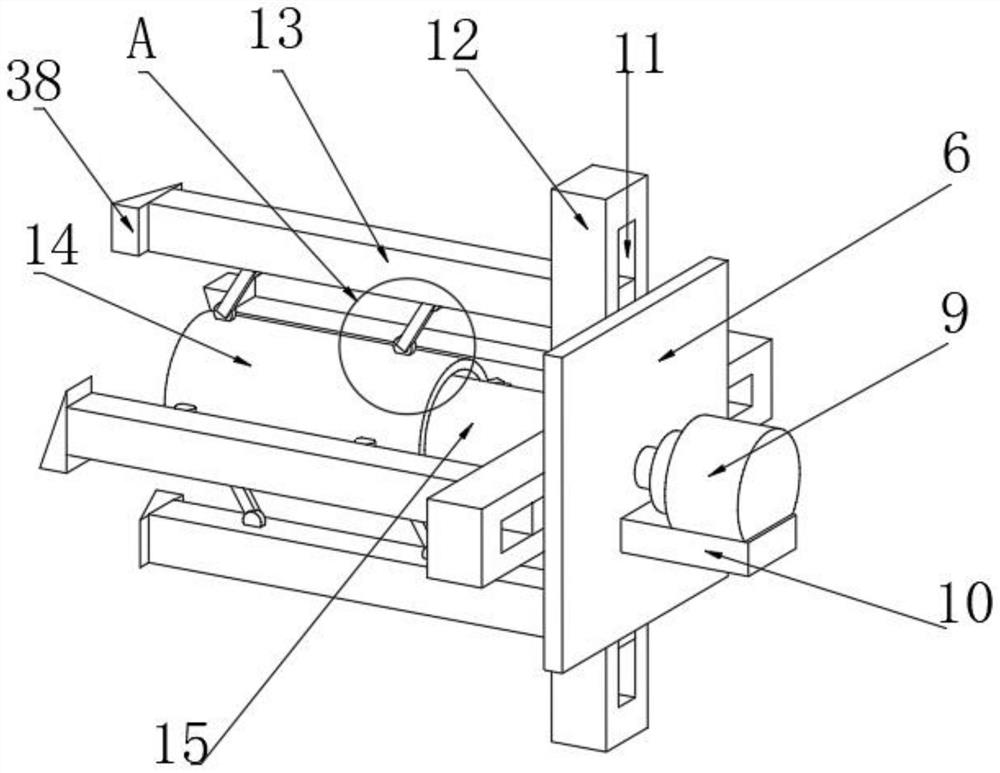

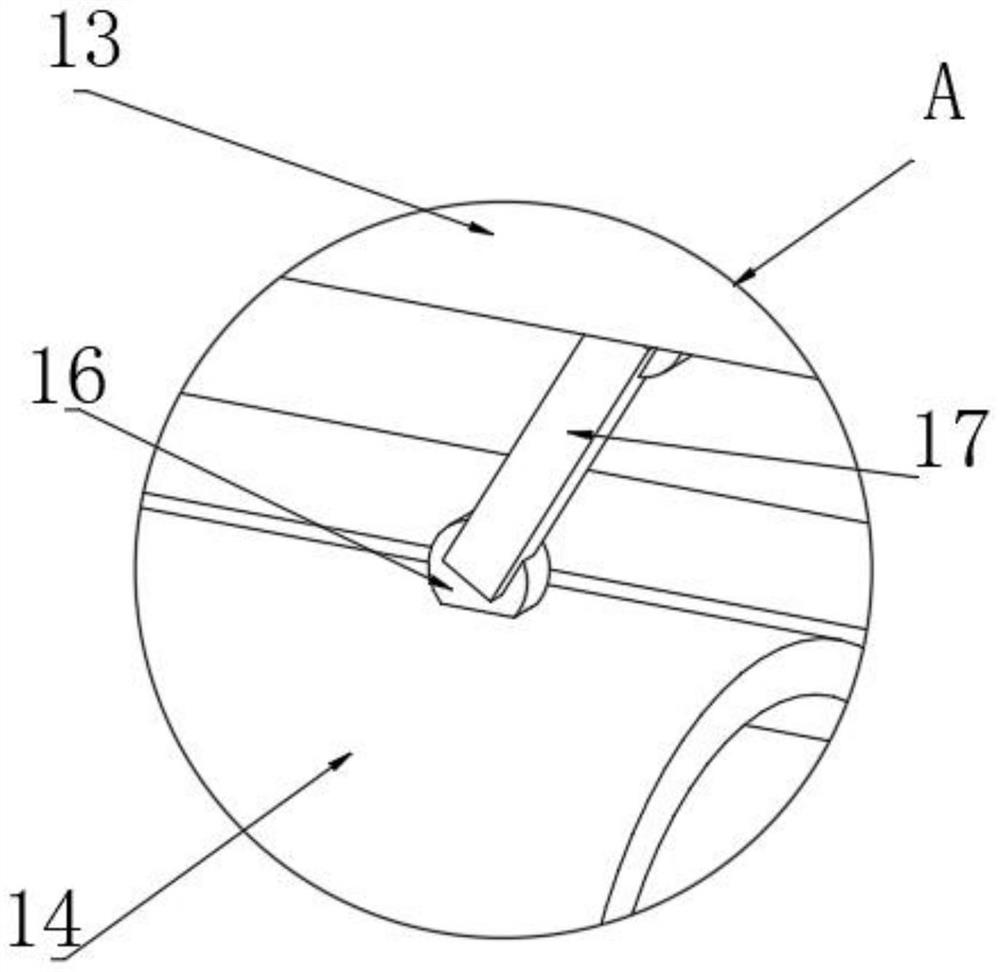

[0030] Such as figure 1 , 2 , 3, 4, and 5, the embodiment of the present invention provides a curved surface cutting device for furniture processing, including a curved surface processing table 1, and the rear end of the upper surface of the curved surface processing table 1 is fixedly installed with a No. 2 rotating motor shell 7. The side of the curved surface processing table 1 is integrally connected with the downwardly extending feeding side plate 2, the rear end of the surface below the curved surface processing table 1 is fixedly installed with the No. 1 rotating motor casing 6, and the front end of the No. 1 rotating motor casing 6 is fixed and installed Drilling device 5 is arranged, and electric telescopic rod 4 is fixedly installed on the lower end of drilling device 5, and electric telescopic rod 4 is fixedly mounted on No. 1 rotary motor housing 6 front ends.

[0031] Through the above technical scheme, first place the raw material to be processed on the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com