Clutch mechanism and power clutch control device and method

A clutch mechanism and control device technology, which is applied in the direction of clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of processing machine tools that cannot flexibly control the transmission of energy, adverse effects on processing objects, and poor processing effects, etc., to achieve improved processing Yield, avoidance of adverse effects, reduction of operational risk and effects of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] As mentioned in the background art, existing processing machine tools cannot flexibly control the energy transmitted to the processing object, resulting in energy loss and poor processing results.

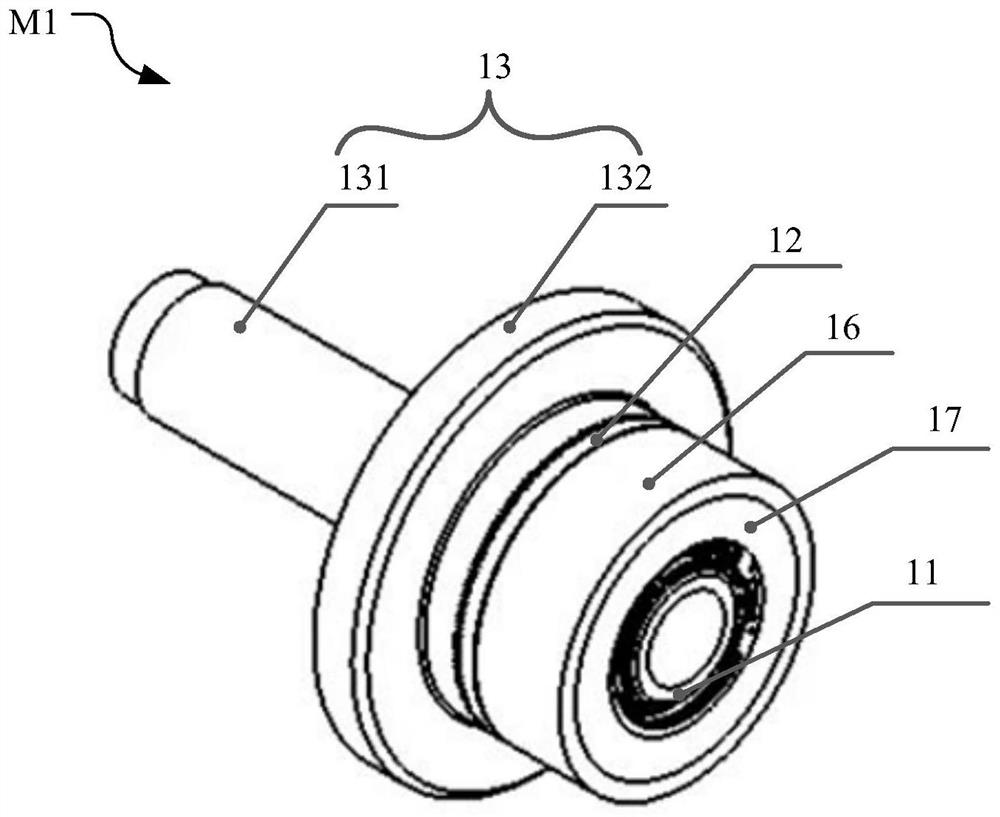

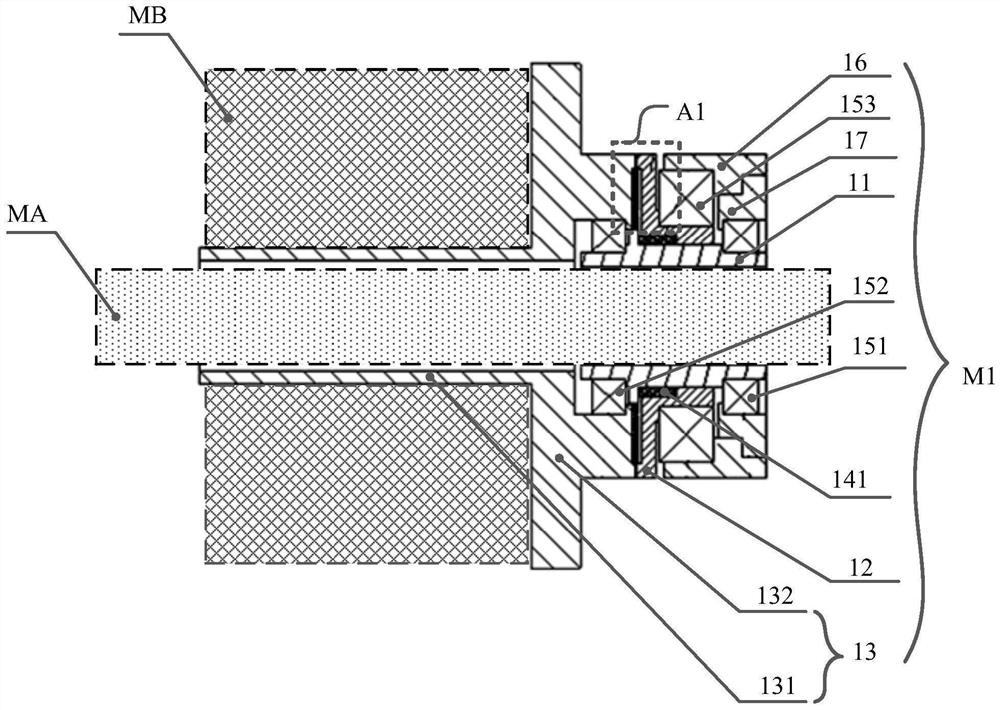

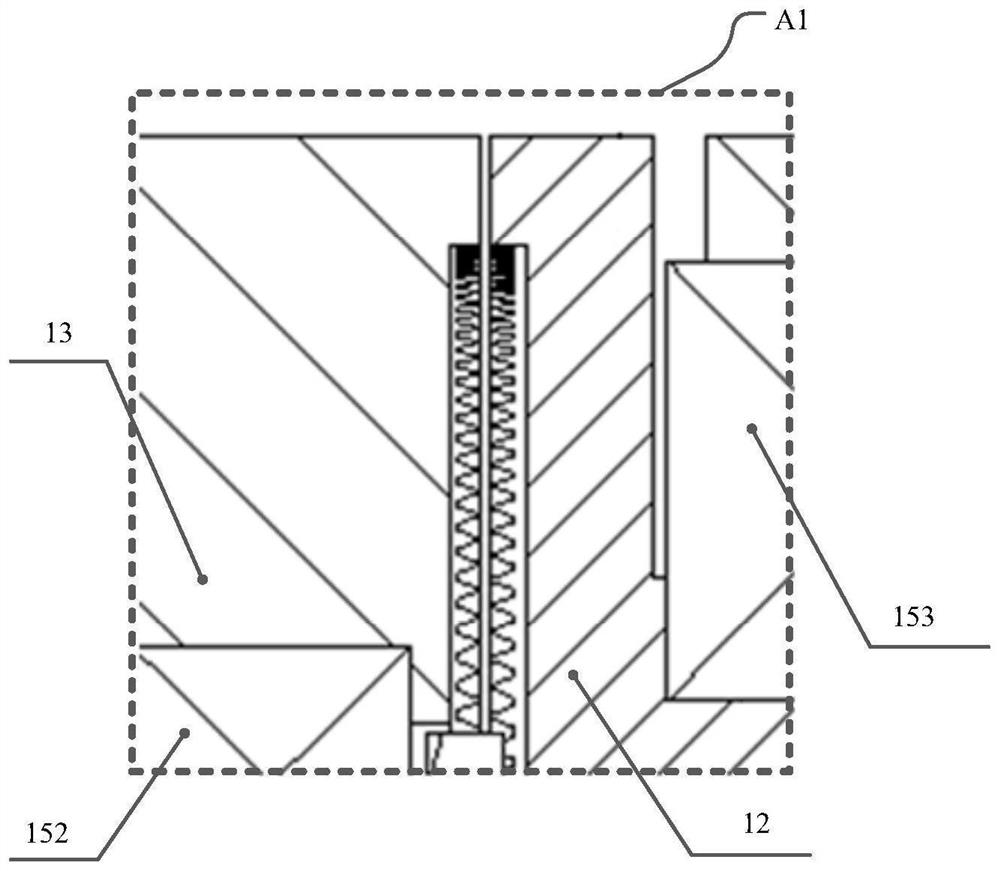

[0042] In order to solve the above problems, the embodiment of this specification provides a clutch mechanism, which is located between the transmission mechanism and the rotation mechanism of the processing machine tool; wherein: the support component can be linked with the transmission mechanism, and the support component can be connected with the support component through the first transmission component. In linkage, the second transmission component can be rotatably connected to the support component, and the carried rotation mechanism can be isolated from the transmission mechanism through the second transmission component.

[0043] On the one hand, by controlling the engagement or separation of the first transmission part and the second transmission part of the clutch m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com