Connecting and sealing device

A sealing device and sealing groove technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as inconvenient operation, inability to meet design requirements, and space exceeding overall expectations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

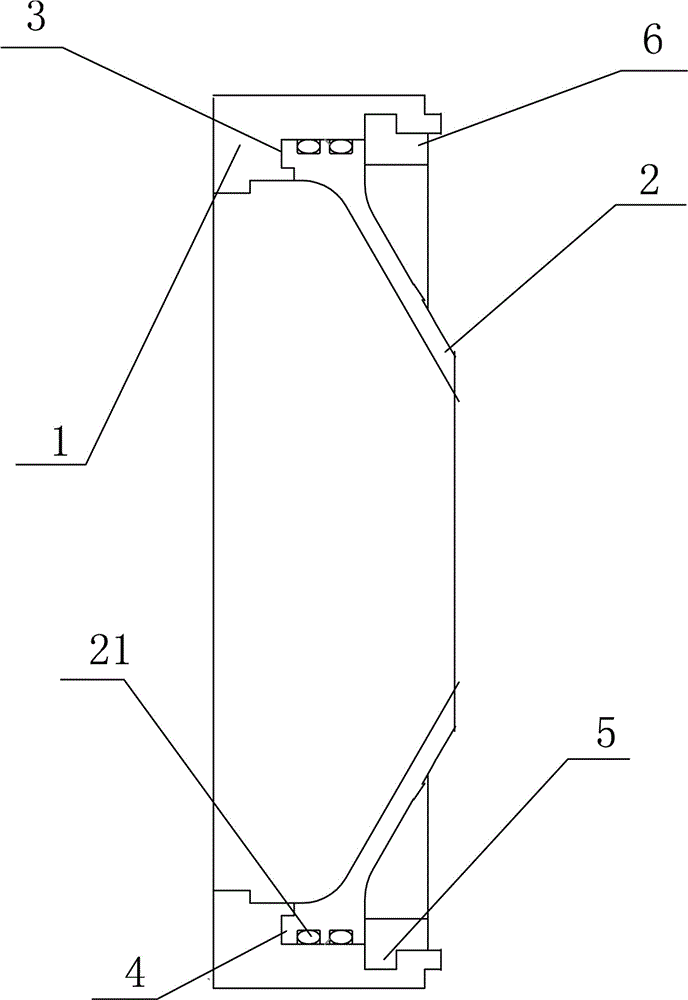

[0021] Such as Figure 1-3 As shown, a connection sealing device includes a housing 1 and a nozzle pipe 2 connected thereto. It is characterized in that: an assembly groove 3 is provided on the inner wall of the housing, and an assembly step 4 matching the assembly groove is provided on the nozzle pipe 2. ; The housing 1 is also provided with a card slot 5, and a snap ring 6 matched with it is installed in the card slot.

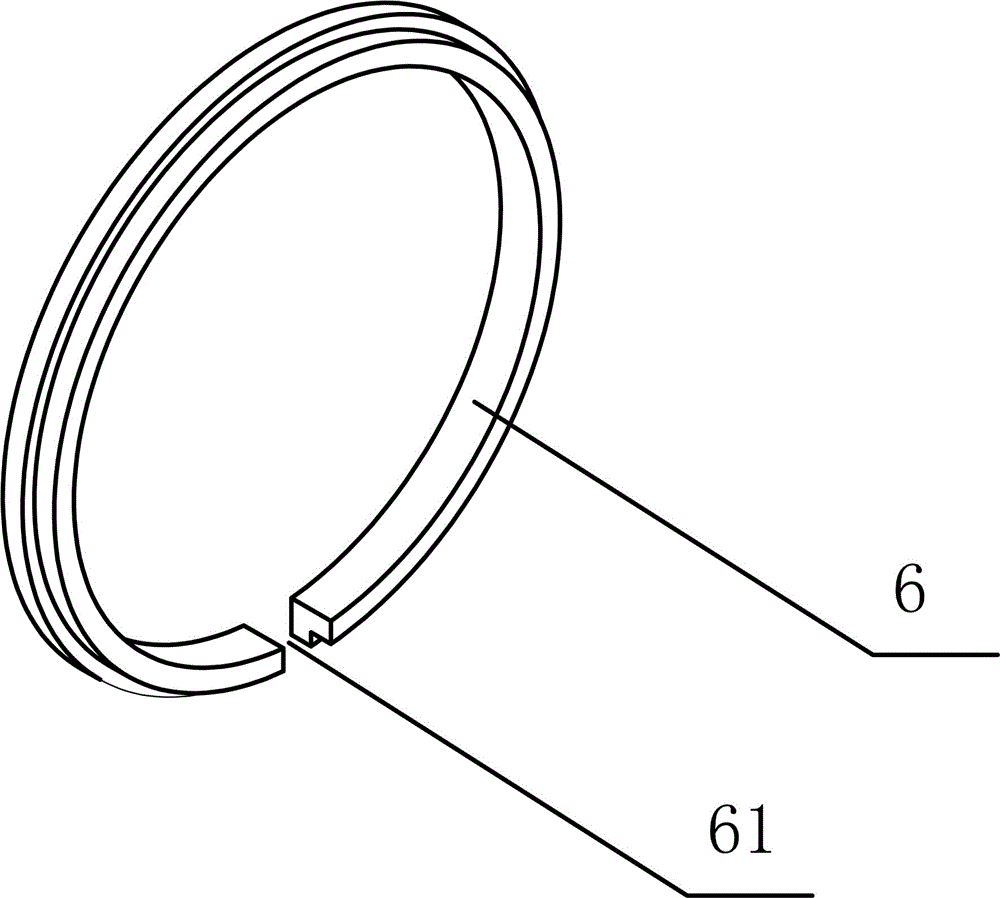

[0022] Further, the cross-section of the snap ring 6 is L-shaped, one end of which is inserted into the slot, and compresses the nozzle through the corner.

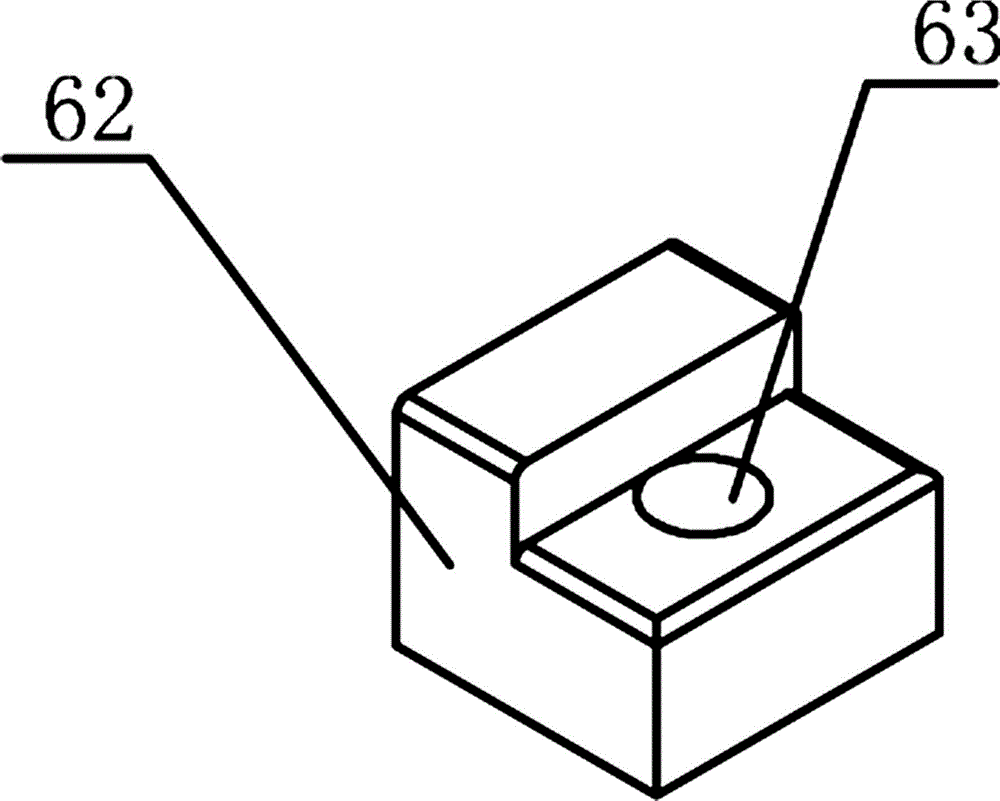

[0023] Further, the snap ring 6 is ring-shaped, and an opening 61 is provided on the ring body of the snap ring, and a compensation block 62 is installed at the opening, and the compensation block 62 mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com