DMT dual-motor hybrid transmission

A technology of transmission and dual motors, which is applied in the direction of power devices, efficient vehicle charging, pneumatic power devices, etc., can solve the problems of high energy consumption, reduce energy consumption, reduce the difficulty of installation process, and reduce the axial layout space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

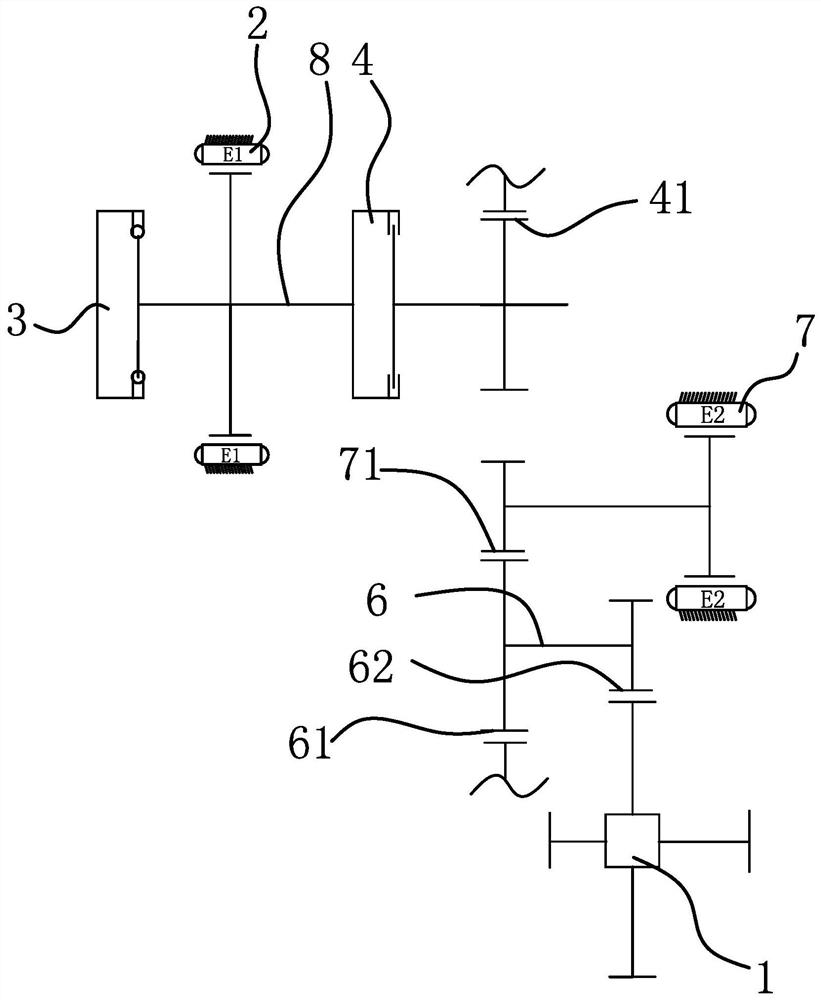

Embodiment 1

[0031] Such as figure 1 A DMT dual motor mixing transmission, including an engine, a flywheel 3, a clutch 4, a power battery, a generator 2, and a drive motor 7, and the output shaft of the engine is connected to the flywheel 3, the flywheel 3 is The clutch 4 is connected to the rigid connection to drive the rigid connection through the input shaft 8. The generator 2 of the transmission is directly connected to the input shaft 8, and directly connects the rotor 2 of the generator 2 to the rotor 2 of the generator 2, and the motor rotor shaft and the input shaft 8 are also omitted. The connection structure of the original generator 2 rotor shaft and the input shaft 8 is designed to reduce the axial arrangement of the transmission, thereby reducing the difficulty of the installation process of the part of the transmission. The generator 2 is electrically powered by the input shaft 8 by the input shaft 8 by the input shaft 8 to perform charging power generation. The engine rotates th...

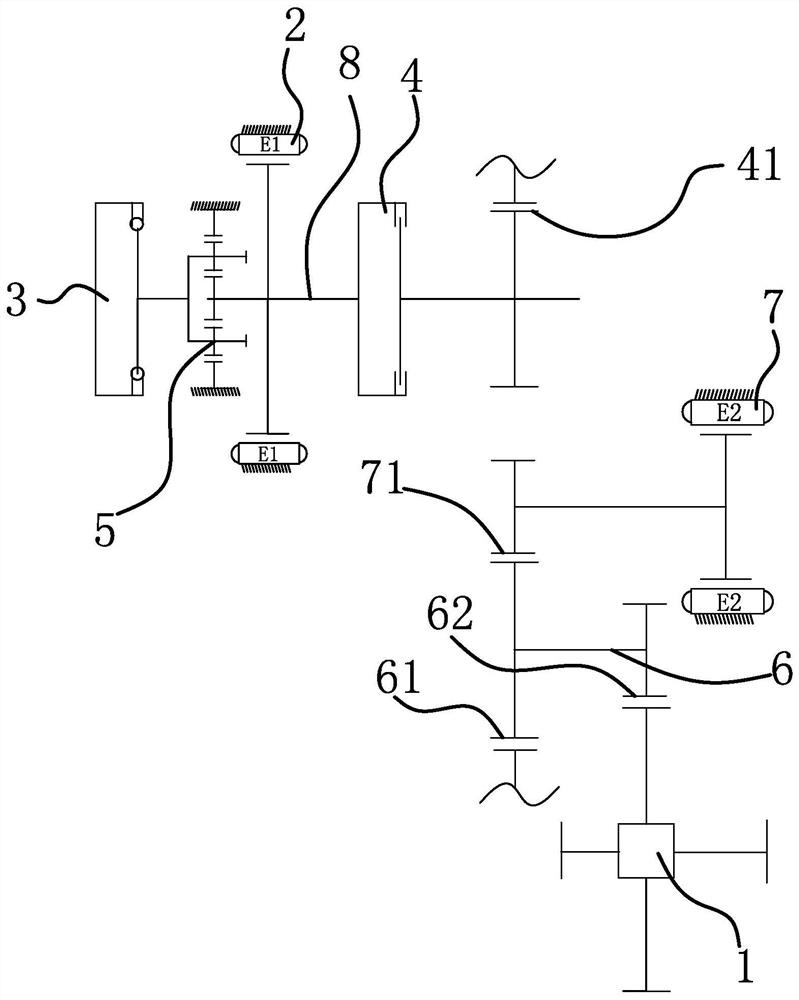

Embodiment 2

[0042] The structure and principles of the present embodiment are substantially the same, and the difference is: figure 2 The mount 3 is fixed to the flywheel 3 in the present embodiment, and the input shaft 8 is rigidly coupled between the planetary discharge render 5 and the clutch 4. The input shaft 8 is also a rotor passed through the generator 2, such that the engine passed the speed of the randor discharge speed, which can be more compatible with the optimum generating speed speed of the generator 2, so that the power generation efficiency is improved, reducing the reduction Decelerator energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com