Method for preparing flexible veneer sheet from modified mineral powder

A flexible veneer and mineral powder technology, applied in the field of building materials, can solve the problems of poor surface abrasion resistance, poor flexibility and poor flexural strength, and achieve high flexural strength, improved cohesion, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

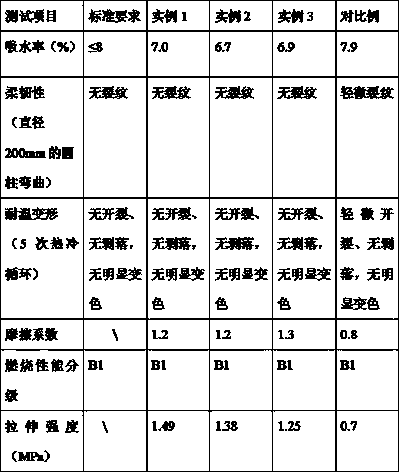

Examples

example 1

[0027] In terms of parts by weight, 80 parts of colored sand, 5 parts of calcite, 8 parts of orthoclase, 15 parts of quartz stone and 5 parts of barite were respectively selected, mixed and added to a jaw crusher for crushing, and passed through a 80-mesh sieve to obtain ore powder; put the ore powder into the muffle furnace, calcined at 700°C for 10 minutes, spray modifier on the surface of the calcined ore powder, the spraying amount is 6% of the mass of the calcined ore powder, spray and mix at the same time, after stirring Wet material is obtained; the wet material is placed in an aging bin, aged at room temperature for 30 hours, and the aged material is milled, dried and crushed after milling to obtain modified mineral powder; in parts by weight, 80 1 part of modified mineral powder, 15 parts of ethylene-vinyl acetate copolymer latex powder, 12 parts of styrene-acrylic polymer emulsion, 30 parts of water, 1 part of calcium lignosulfonate, stir and mix to obtain slurry; pou...

example 2

[0030] In terms of parts by weight, 90 parts of colored sand, 7 parts of calcite, 10 parts of orthoclase, 20 parts of quartz stone and 7 parts of barite were respectively selected, mixed and crushed in a jaw crusher, and passed through a 100-mesh sieve to obtain ore powder; put the ore powder into the muffle furnace, calcined at 750 °C for 13 minutes, spray modifier on the surface of the calcined ore powder, the spraying amount is 8% of the mass of the calcined ore powder, spray and mix at the same time, after stirring Wet material is obtained; the wet material is placed in an aging bin, aged at room temperature for 35 hours, the aged material is milled, dried and pulverized after milling, to obtain modified mineral powder; in parts by weight, 90 1 part of modified mineral powder, 16 parts of ethylene-vinyl acetate copolymer latex powder, 13 parts of polyacrylate emulsion, 40 parts of water, 2 parts of sodium lignosulfonate, stir and mix to obtain a slurry; pour the slurry into...

example 3

[0033] In terms of parts by weight, respectively select 100 parts of colored sand, 10 parts of calcite, 12 parts of orthoclase, 25 parts of quartz stone and 10 parts of barite, mix them and add them to a jaw crusher for crushing, pass through a 120-mesh sieve to obtain ore powder; put the ore powder into the muffle furnace, calcined at 800°C for 15 minutes, spray modifier on the surface of the calcined ore powder, the spraying amount is 10% of the mass of the calcined ore powder, spray and mix at the same time, after stirring Wet material is obtained; the wet material is placed in an aging bin, aged at room temperature for 40 hours, the aged material is milled, dried and pulverized after milling, to obtain modified mineral powder; in parts by weight, 110 Parts of modified mineral powder, 18 parts of ethylene-vinyl chloride-vinyl laurate latex powder, 15 parts of silicon-acrylic polymer emulsion, 45 parts of water, 3 parts of magnesium lignosulfonate, stir and mix to obtain slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com