High strength wood plastic composite plate capable of reducing noise

A composite board and wood-plastic board technology, applied in building components, buildings, building structures, etc., can solve the problems of low strength, no cushioning and shock absorption, and low impact resistance, so as to improve structural strength, enhance Connection strength, good noise reduction and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

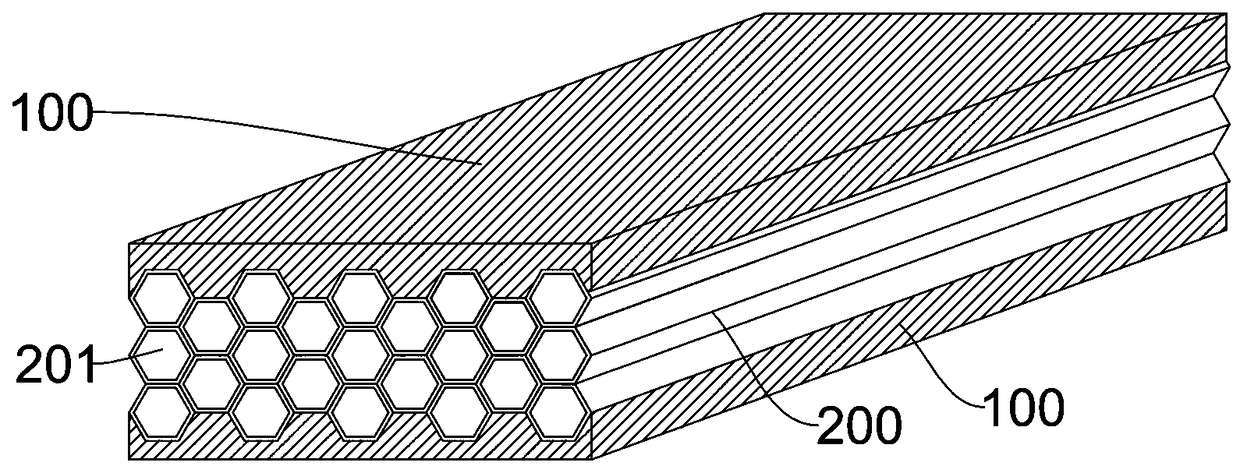

[0024] A noise-reducing high-strength wood-plastic composite board, such as figure 1 As shown: it includes at least two wood-plastic substrates 100 and a board core 200 arranged between the wood-plastic substrates 100, wherein the wood-plastic substrate 100 can be PVC wood-plastic board, PE wood-plastic board or PP wood-plastic board A sort of.

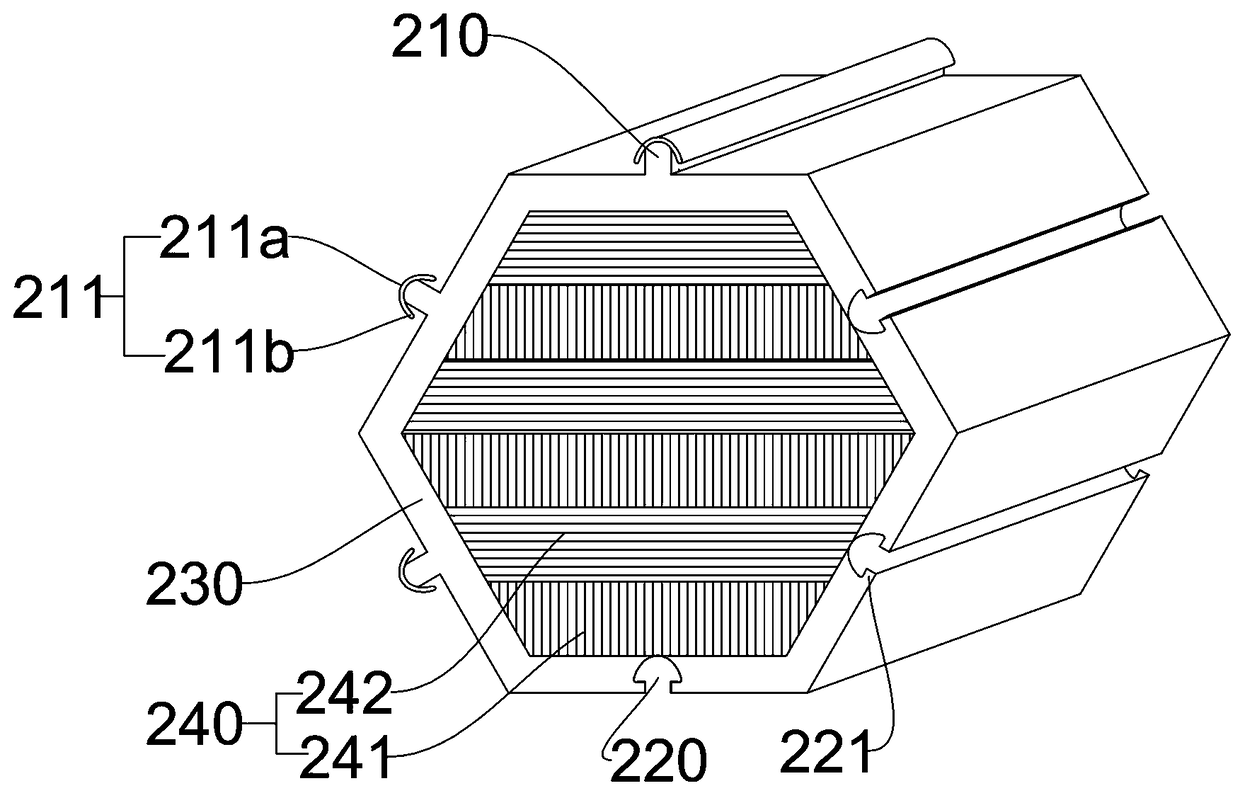

[0025] The core 200 of the present invention is composed of several regular hexagonal structural blocks 201 connected by a concave-convex structure. It is different from the honeycomb structure formed by regular hexagonal structures in the prior art. In general honeycomb structures, the structural blocks are perpendicular to The substrate, that is, is formed by connecting the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com