Material plate used for manufacturing door plate

A technology of material panels and door panels, applied in the field of material panels for manufacturing door panels, can solve the problems of easy damage of connection points, old manufacturing process, low assembly strength, etc., to achieve the effect of avoiding assembly process, simple manufacturing process, and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

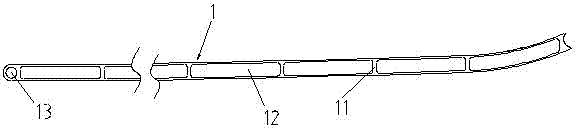

[0034] The difference between this embodiment 2 and embodiment 1 is:

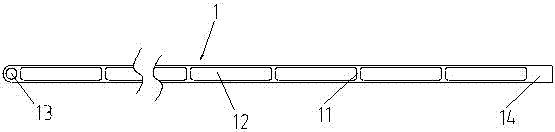

[0035] Such as figure 2 In this embodiment, the first connecting portion 14 having a solid structure is provided on the right side of the first board 1 . In the actual production process, it is more difficult to carry out integral extrusion molding of door panels with a width exceeding 500mm. The larger the width, the double the production cost, and the larger the width of the door panel is for the production of dies, extrusion machines and other equipment. The cost is relatively high, so when it is necessary to manufacture a large door panel, in order to save costs, a solid first connecting part 14 is provided on the right side of the first panel 1, which can be used to butt another first panel 14 or add another panel by friction stir welding. Wide panels are widened; then cut to custom door panel widths as required.

Embodiment 3

[0037] The difference between this embodiment 3 and embodiment 2 is:

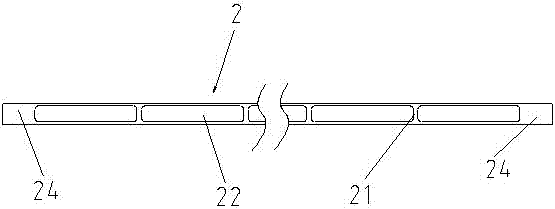

[0038] Such as Figure 2-Figure 4 As shown, the material plate not only includes the first plate 1 in Embodiment 2, but also includes an integrally extruded widened plate 2; The second cavity and the second supporting rib part 21 which is located in the second cavity and runs through the front and rear ends of the widening plate 2; the second supporting rib part 21 is connected to the upper and lower sides of the second cavity On the inner side wall, several second supporting ribs 21 are arranged in parallel and at intervals to divide the second cavity into several second through holes 22 spaced left and right; the left and right sides of the widening plate are provided with The second connection part 24 of solid structure. Because one side of the first plate 1 is provided with a hinge hole, if the first plate 1 is widened to another first plate 1, it is necessary to cut the plate on the side with the hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com