Polyurethane composite floor and manufacturing process thereof

A composite floor, polyurethane technology, applied in elastic floors, buildings, building structures, etc., can solve problems such as reducing the service life of wood-plastic floors, reducing the use effect of wood-plastic floors, and failing to meet long-term use needs, and achieves high utilization. , The appearance is natural and beautiful, the effect of good wood feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

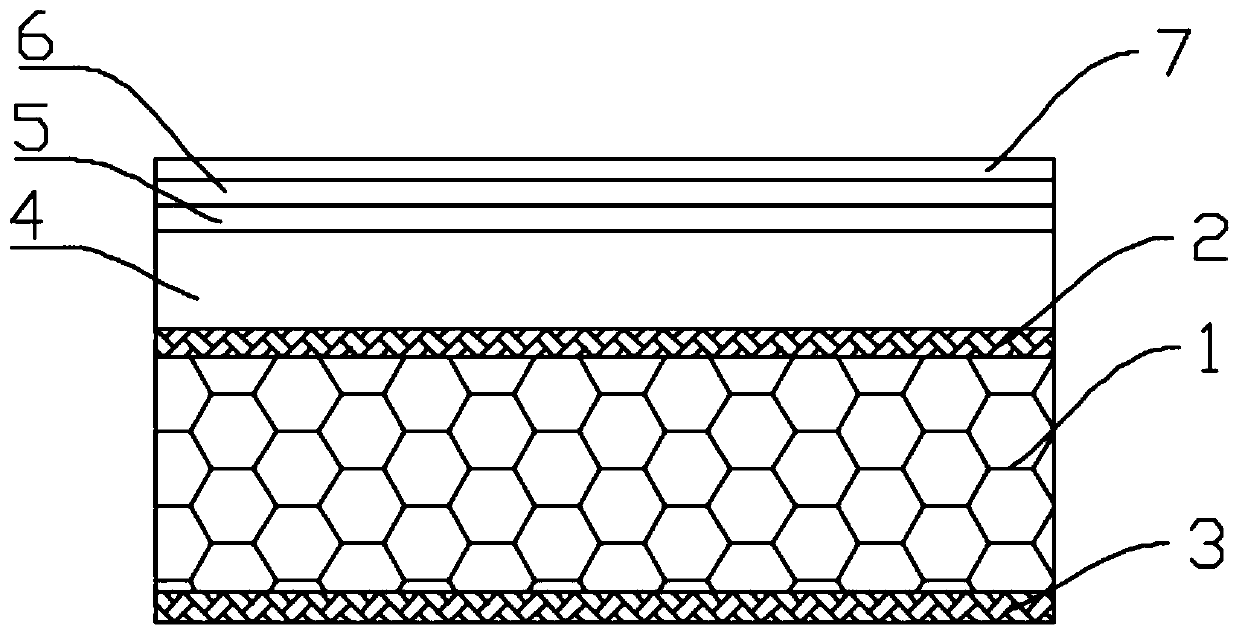

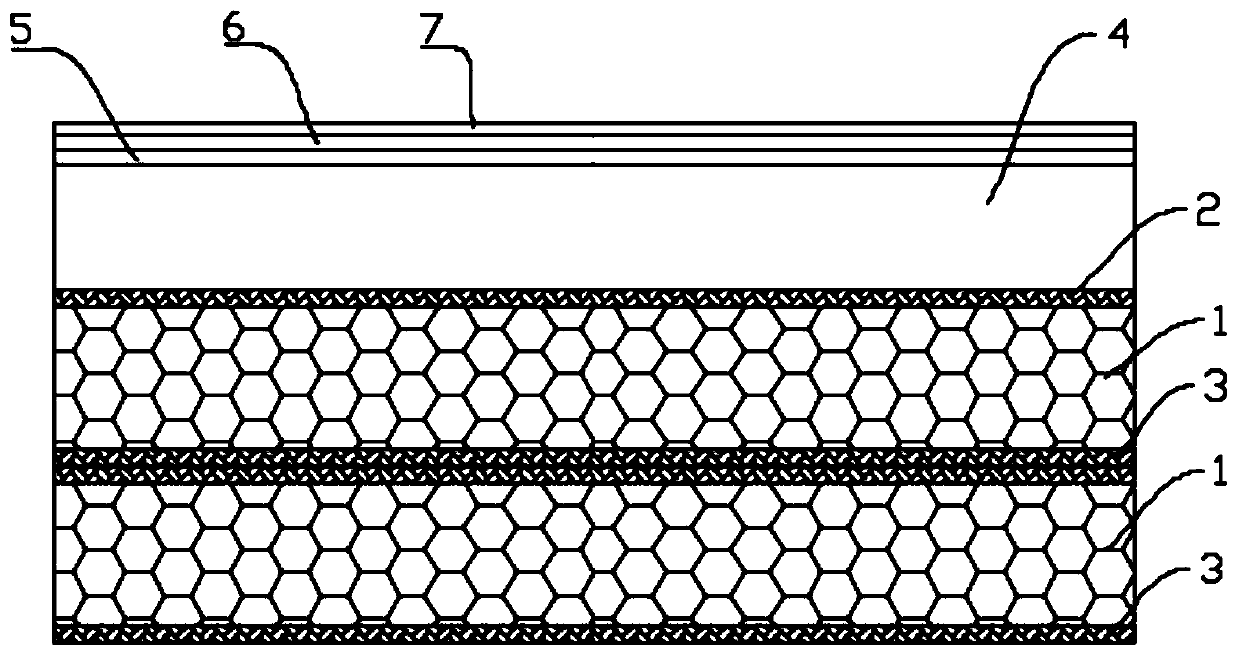

[0056] Such as figure 1 As shown, this embodiment provides a polyurethane composite floor, including a foam layer and a decorative layer arranged on the foam layer, the foam layer includes an intermediate core material 1, and the upper and lower parts of the intermediate core material 1 are respectively provided with continuous braided fibers layer, the continuous braided fiber layer on the upper part of the middle core material 1 is the upper continuous braided fiber layer 2, the continuous braided fiber layer on the lower part of the middle core material 1 is the lower continuous braided fiber layer 3, and the middle core material 1 is provided with several filling Voids, several filled voids are filled with polyurethane rigid foam.

[0057] Since this board is cured and shaped after foaming reaction, it has the effect of sound insulation and heat insulation. In addition, the continuous braided fiber layer provides horizontal and transverse bending force support for the boar...

Embodiment 2

[0064] This embodiment is optimized on the basis of the above-mentioned embodiment 1.

[0065] The rigid polyurethane foam is composed of the following components in parts by weight: 50 parts of polyether polyol, 50 parts of isocyanate, 20 parts of filler, 5 parts of coupling agent, 12 parts of flame retardant and 5 parts of auxiliary agent. The auxiliary agent is at least one of dispersant, film-forming auxiliary agent, thickener, defoamer, active agent, penetrating agent, toner and suspending agent. In this embodiment, the dispersant is selected, and the filler is sand, cement , quartz powder, heavy calcium powder, talcum powder, fly ash, mineral powder and silica fume at least one, select mineral powder in the present embodiment.

Embodiment 3

[0067] This embodiment is optimized on the basis of the above-mentioned embodiment 2.

[0068] The rigid polyurethane foam is composed of the following components in parts by weight: 40 parts of polyether polyol, 40 parts of isocyanate, 10 parts of filler, 3 parts of coupling agent, 8 parts of flame retardant and 3 parts of auxiliary agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com