Wood-grain-like HDPE co-extrusion foam board and preparation method thereof

A technology of foam board and imitation wood grain, applied in the field of foam materials, can solve the problems of single surface color of foam material, uneven traction and tensile force, influence of natural direction of imitation wood grain, etc., and achieves low cost and good quality. Economical value, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

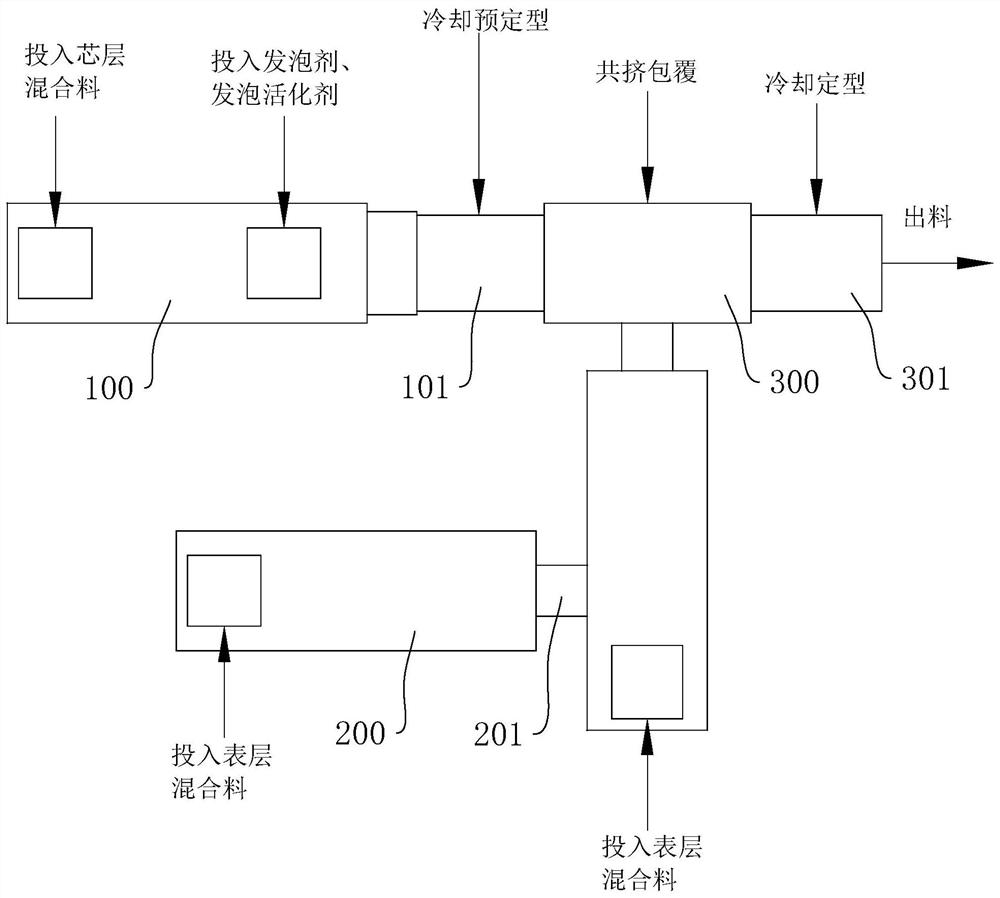

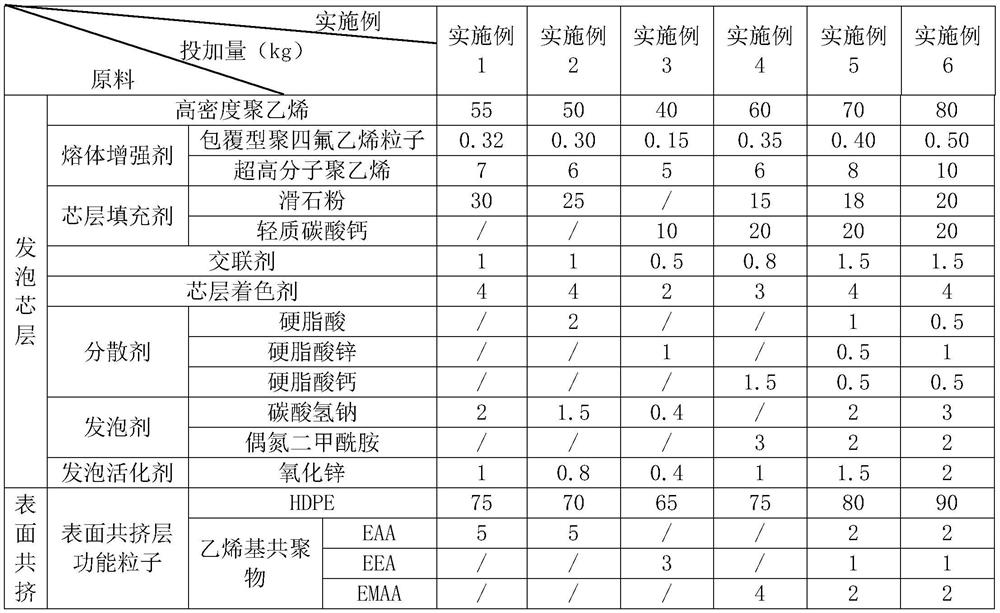

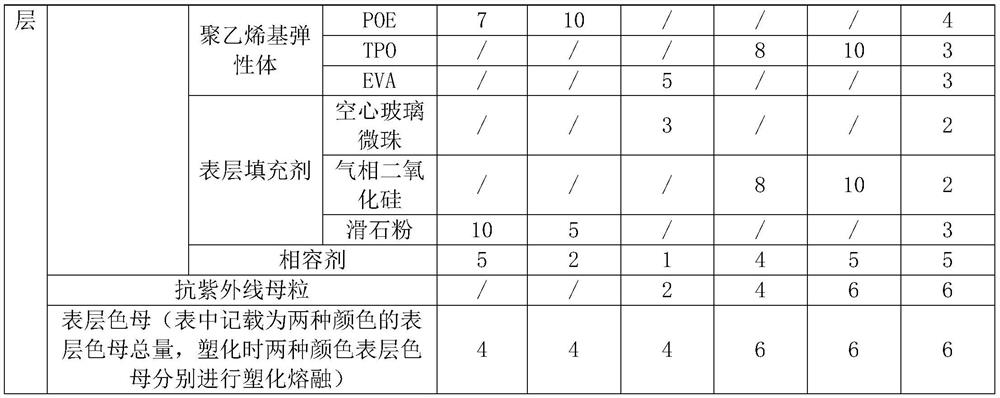

[0050] A kind of imitation wood grain HDPE co-extruded foam board, its raw materials and dosage are shown in Table 1, refer to figure 1 , its preparation method comprises the following steps:

[0051] Step 1) material preparation:

[0052] Core layer mixture: mix the high-density polyethylene, melt reinforcing agent, core layer filler, crosslinking agent and core layer coloring agent in the foam layer raw material according to the proportioning in Table 1 to obtain the core layer mixture, spare;

[0053] Surface layer compound: mix HDPE, vinyl copolymer, surface filler, compatibilizer, and polyethylene-based elastomer according to the ratio in Table 1, and then melt and plasticize it at 200°C through a granulator and granulate it to obtain The functional particles of the surface co-extrusion layer with a diameter of 2-3 mm are weighed according to the proportion and divided into two equal parts, and then mixed with the same amount of different color surface layer masterbatch...

Embodiment 2

[0061] A kind of imitation wood grain HDPE co-extruded foam board, its raw materials and dosage are shown in Table 1, refer to figure 1 , its preparation method comprises the following steps:

[0062] Step 1) material preparation:

[0063] Core layer mixture: mix the high-density polyethylene, melt reinforcing agent, core layer filler, crosslinking agent, dispersant and core layer coloring agent in the foam layer raw materials according to the ratio in Table 1 to obtain the core layer mix, spare;

[0064] Surface layer compound: mix HDPE, vinyl copolymer, surface filler, compatibilizer, and polyethylene-based elastomer according to the ratio in Table 1, and then melt and plasticize it at 160°C through a granulator and granulate it to obtain The functional particles of the surface co-extrusion layer with a diameter of 2-3 mm are weighed according to the proportion and divided into two equal parts, and then mixed with the same amount of different color surface layer masterbatc...

Embodiment 3

[0072] A kind of imitation wood grain HDPE co-extruded foam board, its raw materials and dosage are shown in Table 1, refer to figure 1 Its preparation method comprises the following steps:

[0073] Step 1) material preparation:

[0074] Core layer mixture: mix the high-density polyethylene, melt reinforcing agent, core layer filler, crosslinking agent, dispersant and core layer coloring agent in the foam layer raw materials according to the ratio in Table 1 to obtain the core layer mix, spare;

[0075] Surface layer compound: mix HDPE, vinyl copolymer, surface filler, compatibilizer and polyethylene-based elastomer uniformly according to the ratio in Table 1, and then melt and plasticize it at 180°C through a granulator and granulate it to obtain For surface co-extrusion layer functional particles with a diameter of 2-3mm, weigh the surface co-extrusion layer functional particles and anti-ultraviolet masterbatch according to the ratio and divide them into two equal parts, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com