Aluminum-coated glass fiber energy-saving fire-resistant window

A technology of aluminum-clad glass fiber and fire-resistant windows, which is applied in the field of aluminum-clad glass fiber energy-saving fire-resistant windows, can solve the problems of complex manufacturing process, unreachable energy saving, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

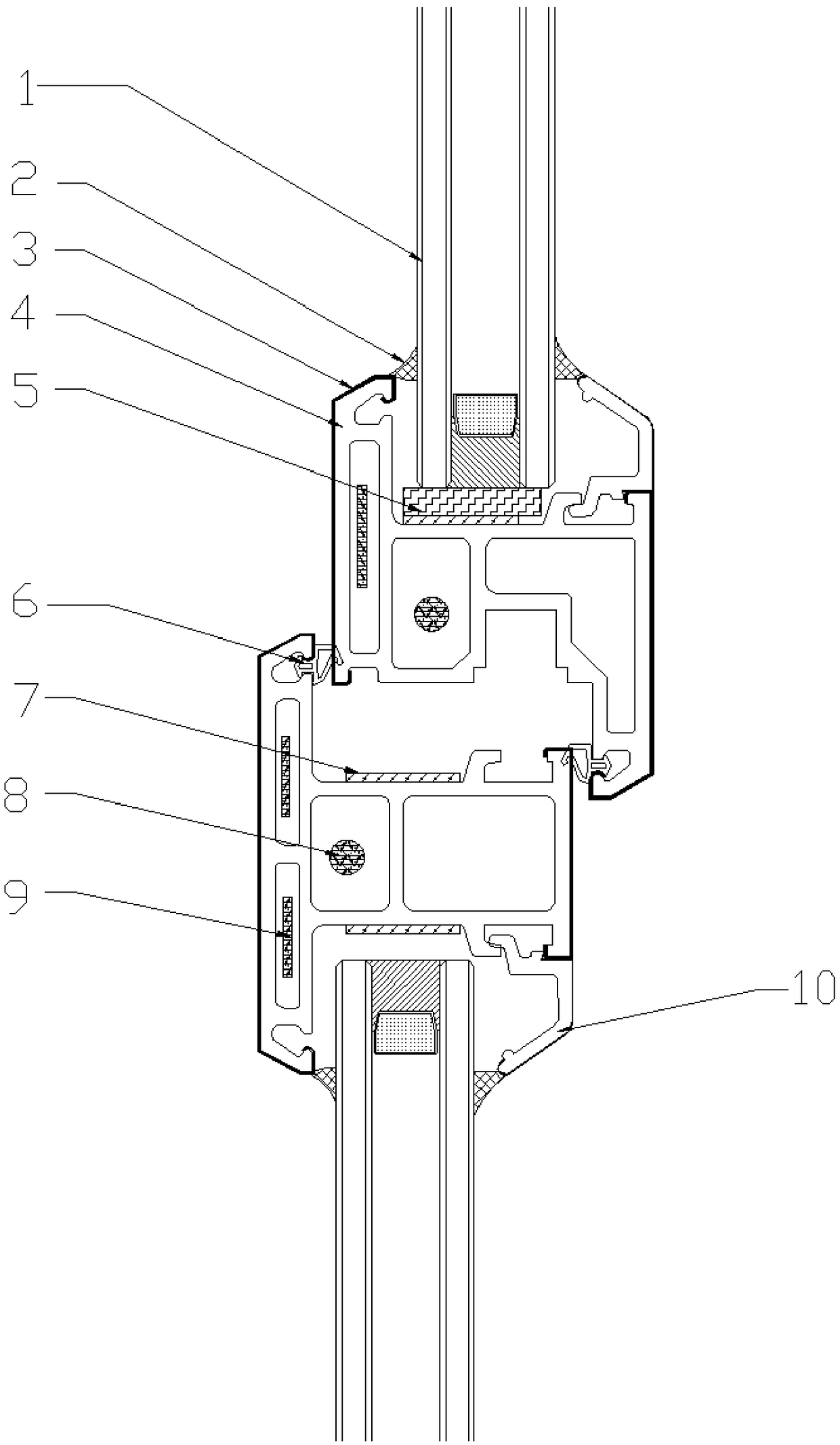

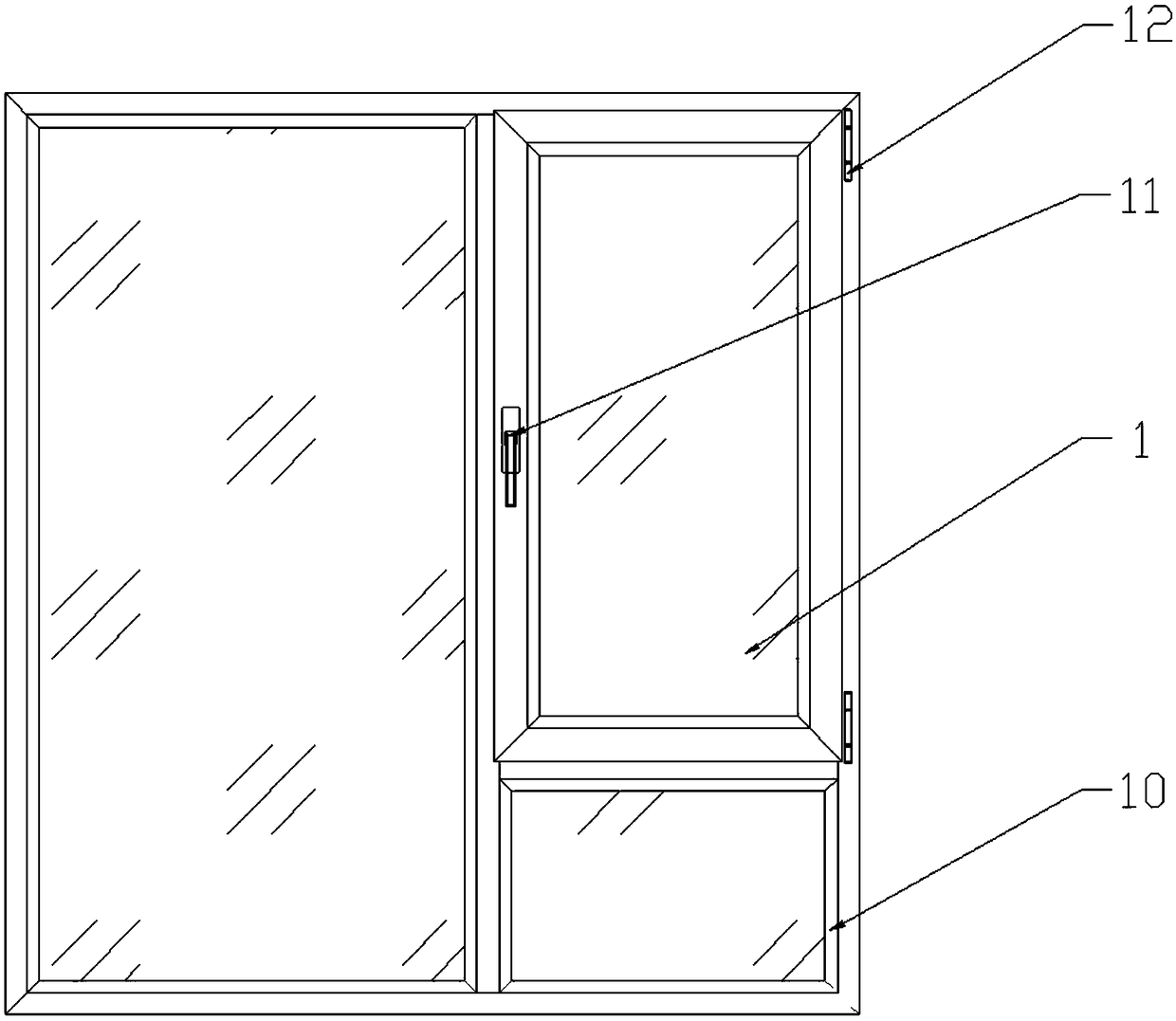

[0014] like figure 1 As shown, an aluminum-clad glass fiber energy-saving fire-resistant window includes fire-resistant insulating glass; the fire-resistant insulating glass 1 is fixedly connected to the upper frame profile and the lower frame profile respectively through the flame retardant sealant 2 for construction, and the upper frame profile is connected with the The lower frame profiles are connected up and down in a staggered manner, the connection ports on the left and right sides of the upper frame profile and the lower frame profile are clamped with flame-retardant sealing strips 6, and the glass fiber profiles 4 on both sides of the upper frame profile and the lower frame profile are decorated. The surface is mechanically covered with a layer of aluminum alloy outer decorative sheet 3 . Among them, the window profile of the aluminum-clad glass fiber energy-saving fire-resistant window of the present invention adopts the self-developed polyurethane to add flame retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com