Fiber cavity door plate

A cavity and door panel technology, applied in the direction of the door leaf, etc., can solve the problems of non-moisture proof, variable shape, door panel bite damage, etc., and achieve the effect of advanced production technology, not easy to change shape, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

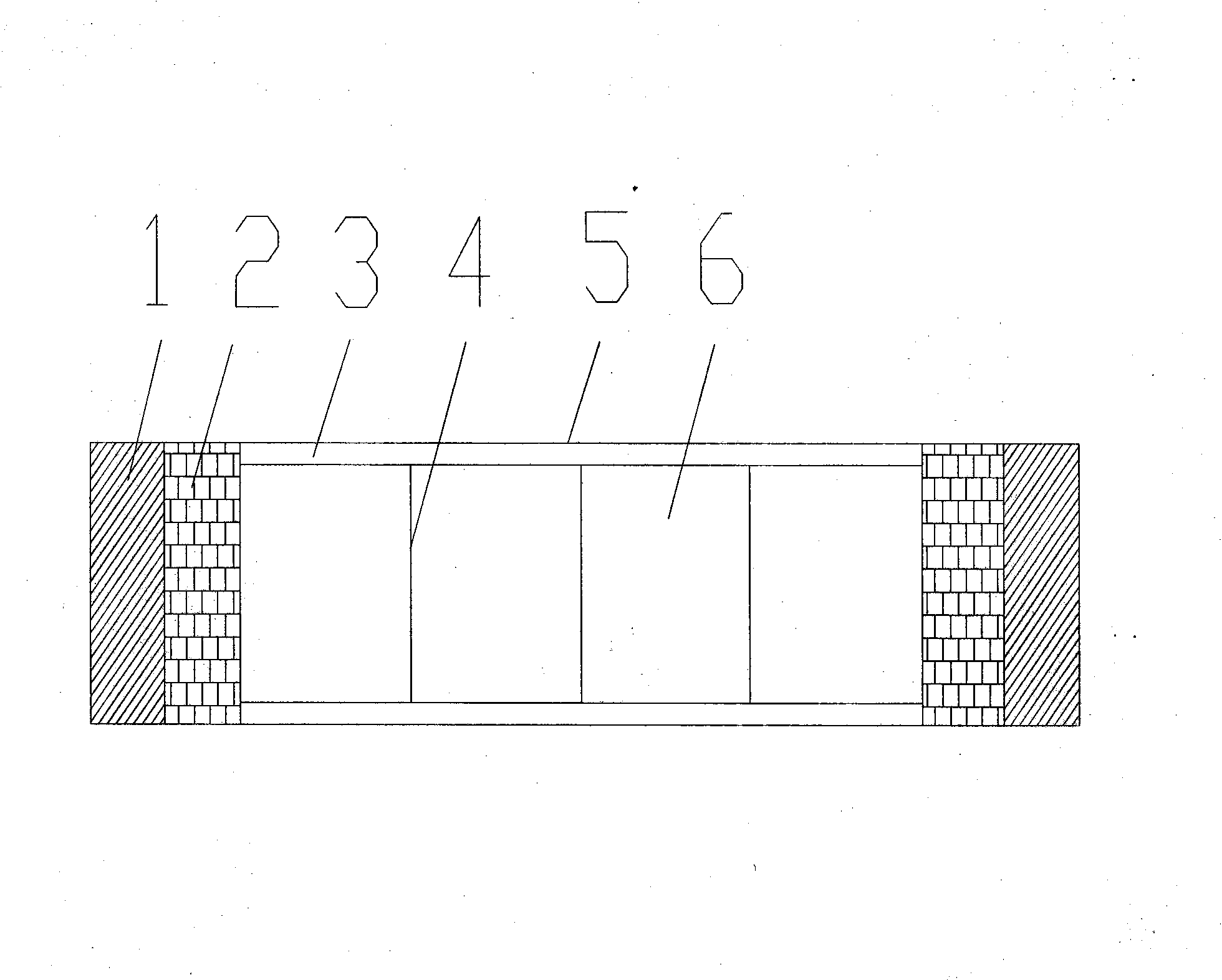

[0009] Such as figure 1 As shown, the present invention is a fiber cavity door panel. A cavity door panel is composed of two wooden boards 5 and a wooden frame 2 on both sides of the wood board 5. A horizontal and vertical stiffener 4 is arranged at regular intervals in the middle of the cavity door panel. A mold 6 is placed between the reinforcing ribs 4, and both sides of the reinforcing ribs 4 and the mold 6 are covered with a fiber layer 3. The outer surface of the fiber layer 3 is attached to the wood board 5, and the cavity door panel is sealed with wood strips 1 around it. The spacing between adjacent ribs 4 is 25 mm. The invention has advanced production technology, beautiful appearance, sound insulation and heat insulation, strong and durable, low price, and not easy to change.

[0010] The embodiments of the present invention are described in detail above with reference to the accompanying drawings, but the present invention is not limited to the above-mentioned embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com