Cement block recovery processing equipment for highway construction

A technology for recycling and processing cement blocks, which is applied in grain processing, cement production, and the use of liquid separating agents, etc. It can solve the problems of poor crushing effect, polluted working environment, time-consuming and labor-intensive crushing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

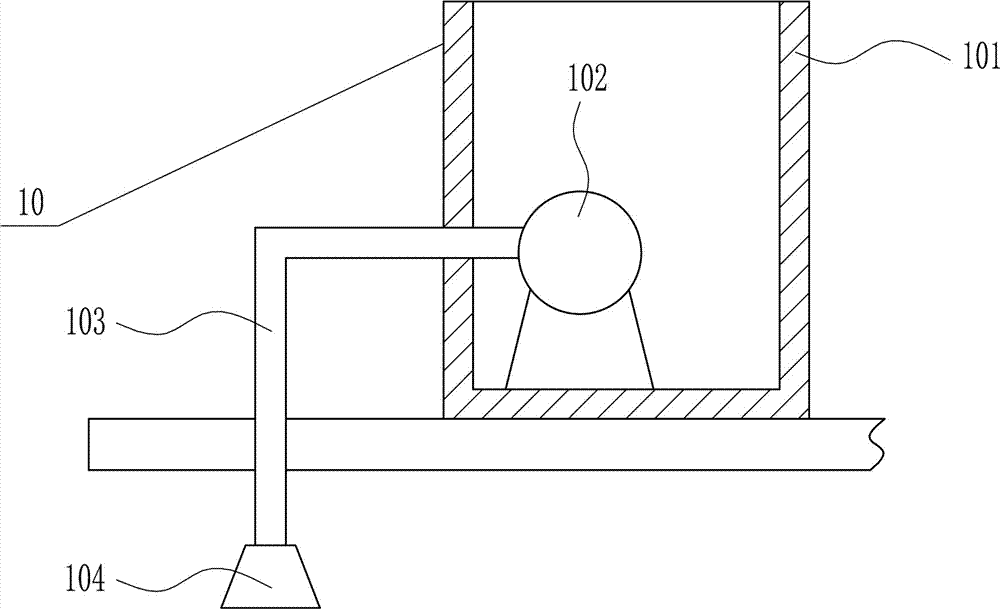

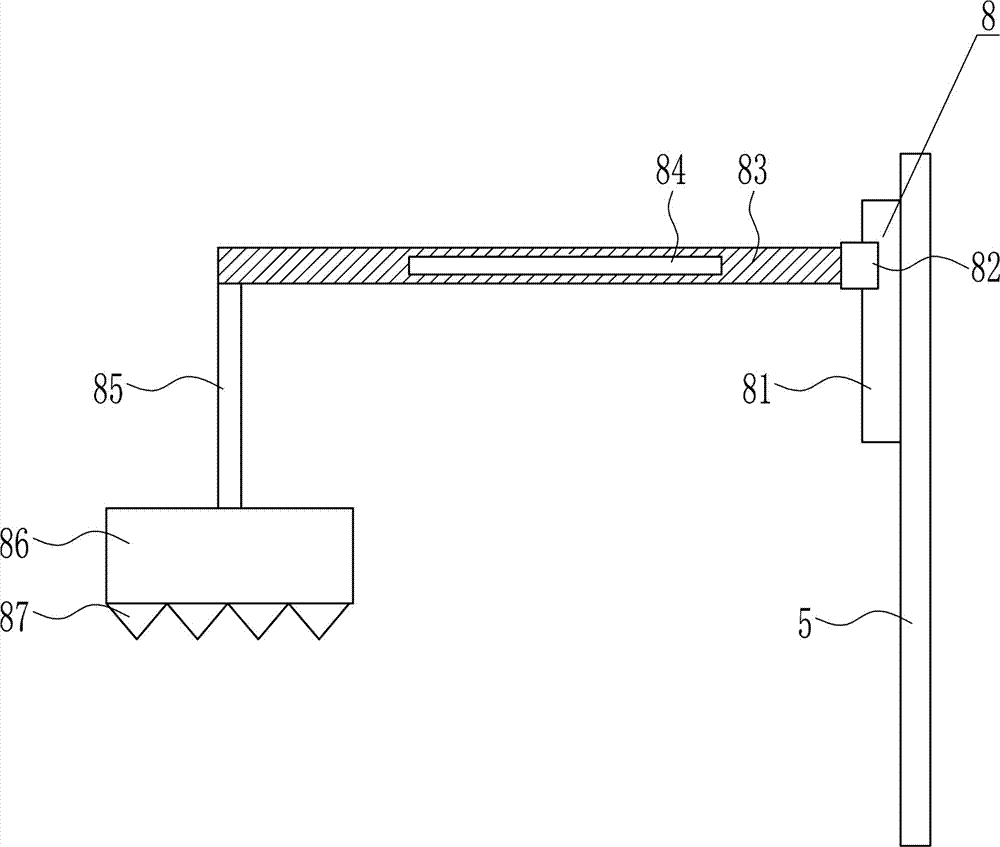

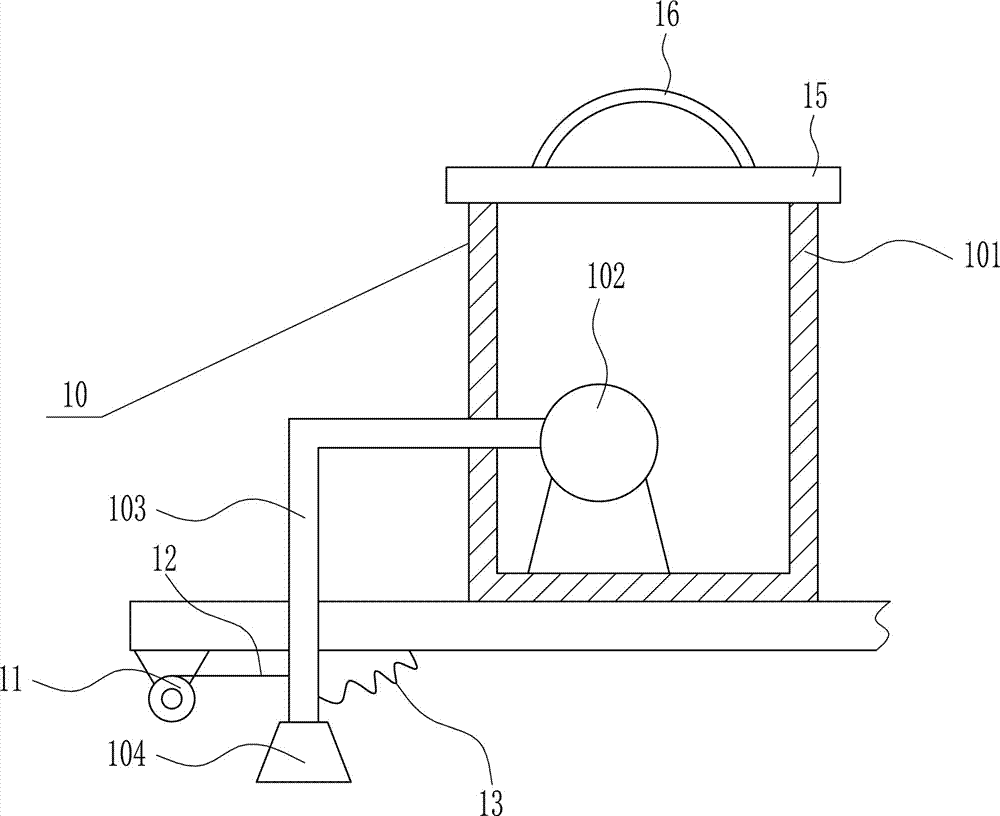

[0037] A kind of cement block recovery processing equipment for highway construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a crushing frame 4, a bracket 5, a top plate 6, a driving device 7 and a crushing device 8, and the top of the bottom plate 1 is horizontally installed with a bolt connection. A slide rail 2 and a bracket 5 are installed vertically, the first slide rail 2 is positioned at the left side of the bracket 5, the first slide rail 2 is provided with a first slide block 3 slidingly, and the top of the first slide block 3 is connected by bolts The crushing frame 4 is installed in the same way, the top left side of the bracket 5 is horizontally installed with a top plate 6 connected by bolts, the driving device 7 is installed on the right side of the bottom of the top plate 6, and the crushing device 8 is installed on the upper left side of the bracket 5, and the crushing device 8 The crushing parts are ...

Embodiment 2

[0039] A kind of cement block recovery processing equipment for highway construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a crushing frame 4, a bracket 5, a top plate 6, a driving device 7 and a crushing device 8, and the top of the bottom plate 1 is horizontally installed with a bolt connection. A slide rail 2 and a bracket 5 are installed vertically, the first slide rail 2 is positioned at the left side of the bracket 5, the first slide rail 2 is provided with a first slide block 3 slidingly, and the top of the first slide block 3 is connected by bolts The crushing frame 4 is installed in the same way, the top left side of the bracket 5 is horizontally installed with a top plate 6 connected by bolts, the driving device 7 is installed on the right side of the bottom of the top plate 6, and the crushing device 8 is installed on the upper left side of the bracket 5, and the crushing device 8 The crushing parts are ...

Embodiment 3

[0042] A kind of cement block recovery processing equipment for highway construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a first slide rail 2, a first slider 3, a crushing frame 4, a bracket 5, a top plate 6, a driving device 7 and a crushing device 8, and the top of the bottom plate 1 is horizontally installed with a bolt connection. A slide rail 2 and a bracket 5 are installed vertically, the first slide rail 2 is positioned at the left side of the bracket 5, the first slide rail 2 is provided with a first slide block 3 slidingly, and the top of the first slide block 3 is connected by bolts The crushing frame 4 is installed in the same way, the top left side of the bracket 5 is horizontally installed with a top plate 6 connected by bolts, the driving device 7 is installed on the right side of the bottom of the top plate 6, and the crushing device 8 is installed on the upper left side of the bracket 5, and the crushing device 8 The crushing parts are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com