Heater body scaling delaying method and water heater

A technology for heaters and water heaters, applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of affecting the service life of water heaters, wasting manpower and material resources, increasing maintenance costs, etc., and achieves simple and reliable structure and economical Energy, Effects of Disturbance Protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

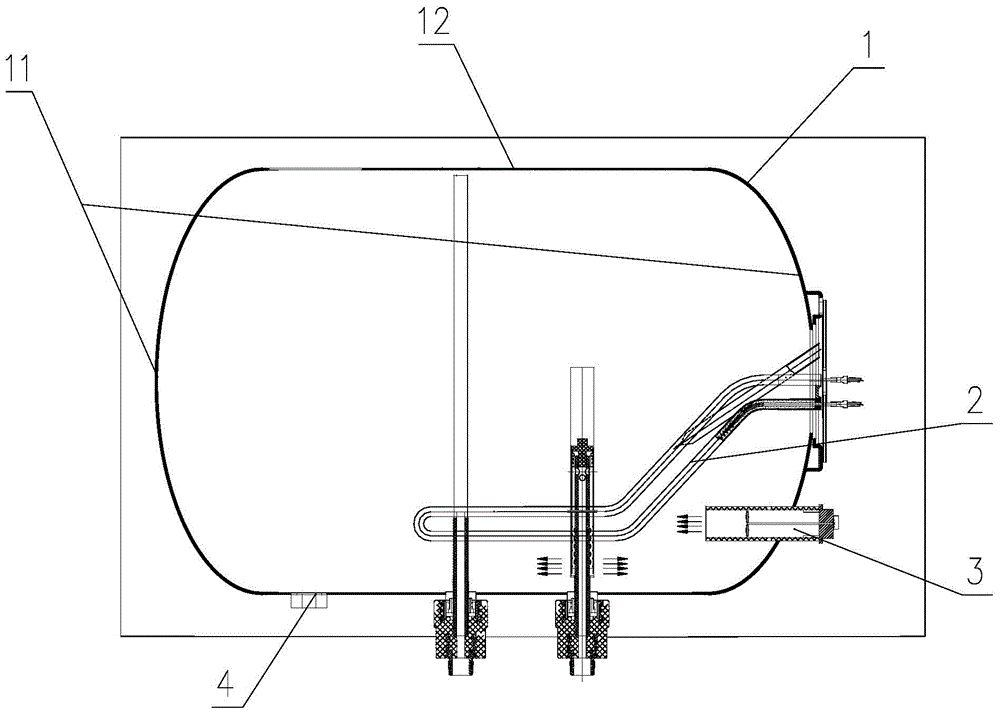

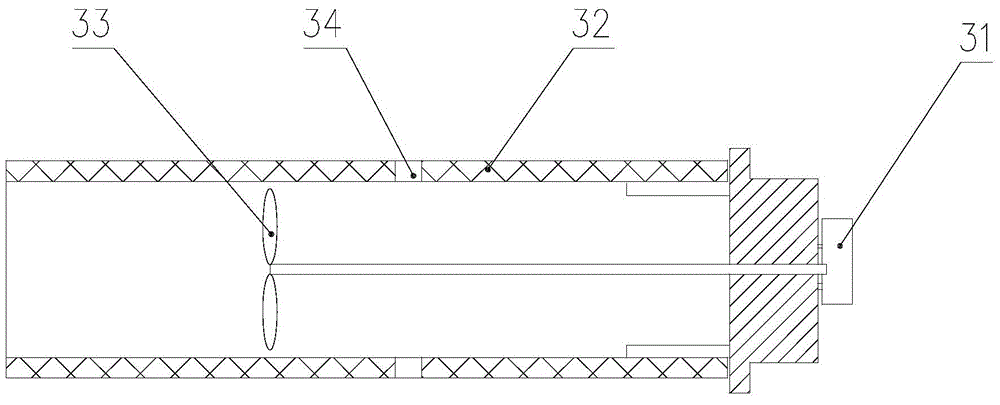

[0041] figure 1 A schematic structural view of the water heater of this embodiment is given. As shown in the figure, the water heater includes a controller, an inner tank 1 and a heater 2 installed in the inner tank 1 through a flange. The inner tank 1 includes a tank body 12 in the middle and sealing heads 11 on the left and right sides, close to the heater 2 The lower part of the fan 3 is provided with a fan 3, and the fan 3 is fixed on the right side head 11 of the liner 1. Such as figure 2 As shown, the fan 3 includes a motor 31, a housing 32 and a fan blade 33 arranged inside the housing 32. The housing 32 is provided with two inflow holes 34, and the water outlet of the housing 32 is connected to the heater 2. Relatively, the water in the water heater can quickly flow into the housing 32 of the fan 3, the controller controls the starting motor 31, the motor 31 drives the fan blade 33 to rotate, and the fan blade 33 disturbs the water flow around it, thereby driving th...

Embodiment 2

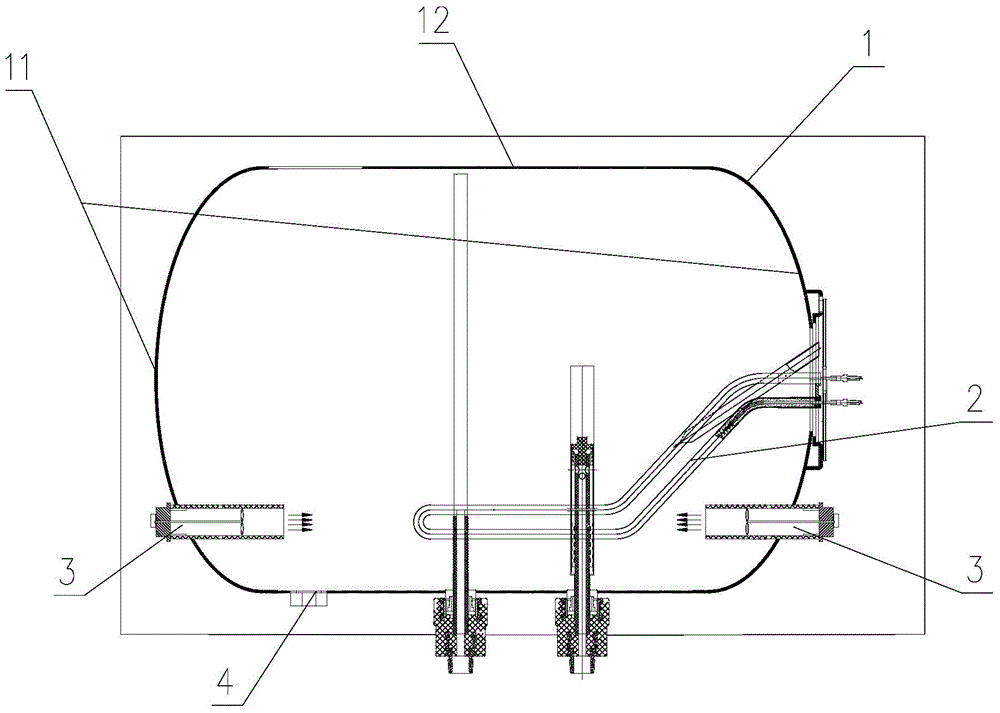

[0045] Such as Figure 5 As shown, the basic structure of this embodiment is the same as the first embodiment, including a controller, an inner tank 1 and a heater 2 installed in the inner tank 1 through a flange, and a fan 3 is arranged near the lower part of the heater 2 . The difference from the first embodiment is that the heater 2 is further provided with a temperature sensor 5 for detecting the temperature of the heater 2 .

[0046] Its working process is similar to the first embodiment, the difference is that the disturbance temperature T is preset in the controller, the heater temperature detected by the temperature sensor is t, and the temperature sensor transmits the detected t value to the controller, when t≥ When T, the controller controls the fan to continue to rotate or alternately performs the spoiler segment and the intermittent segment; when t<T, the controller controls the fan to stop working. The turbulence temperature T can be selected and set according to...

Embodiment 3

[0049] Such as Figure 6As shown, the basic structure of this embodiment is the same as that of the first embodiment, including a controller, an inner tank 1 and a heater 2 installed in the inner tank 1 through a flange. The difference from Embodiment 1 is that a vibrator 6 is provided near the lower part of the heater 2, and the controller controls the vibration of the vibrator 6 to disturb the water flow in the area where the heater 2 is located to drive the scale movement in the water flow , so as to avoid scale deposition on the surface of the heater. Using a vibrator instead of the fan in Embodiment 1 can also achieve the effect of delaying the fouling of the heater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com