Liquid level detection device and liquid level detection method

A liquid level detection and detection device technology, which is applied in the field of metal billet production, can solve the problems of interference of measurement results, influence of measurement results, irregular size changes, etc., and achieve correct control of liquid level height, safe working environment, and stable measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

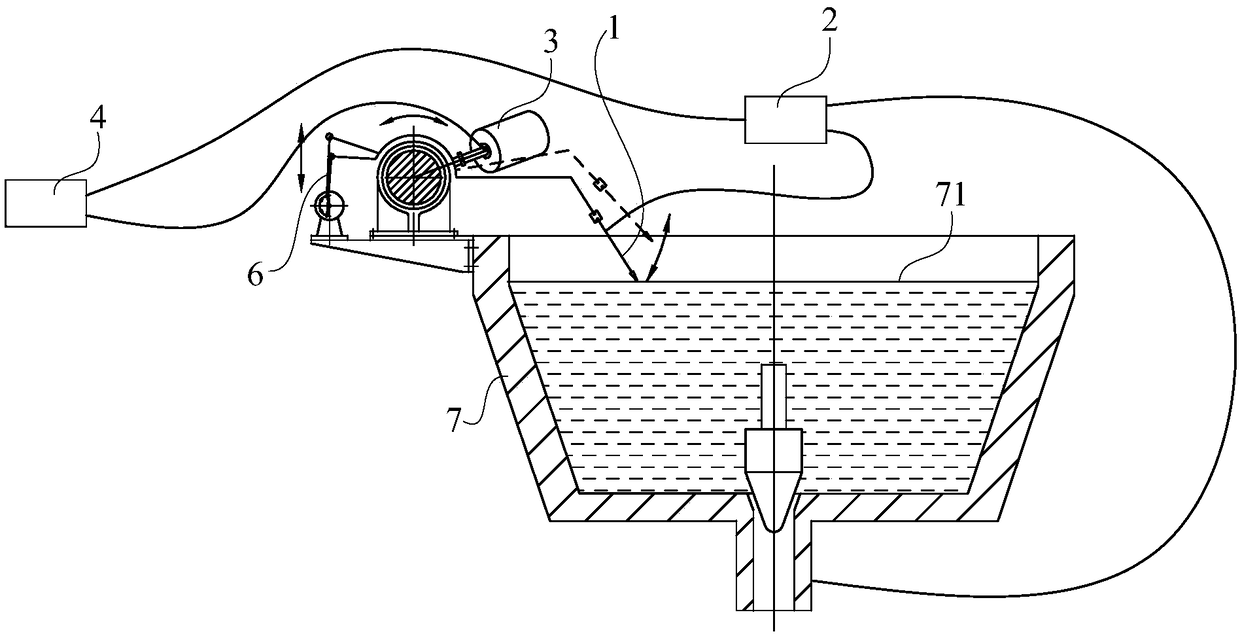

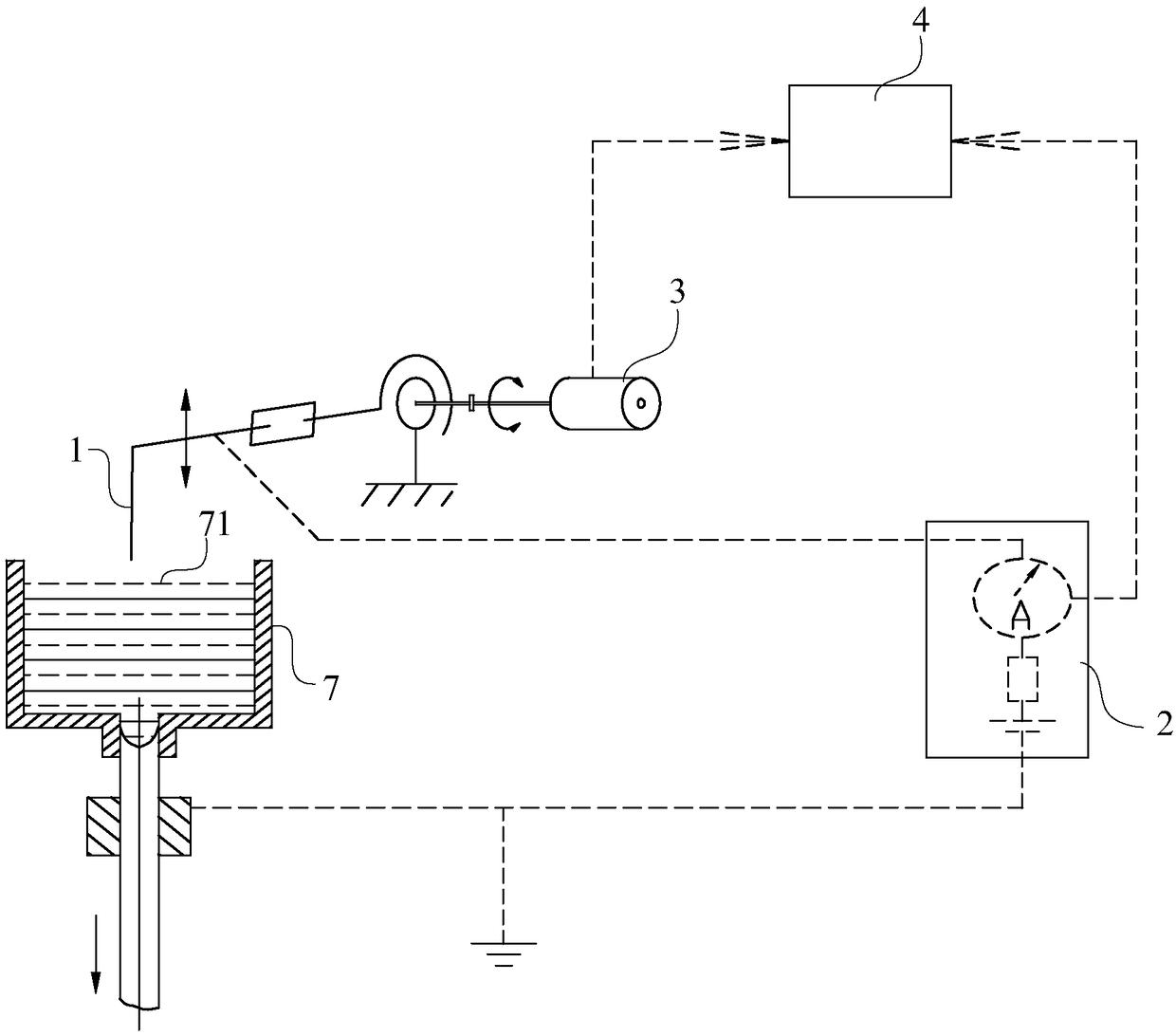

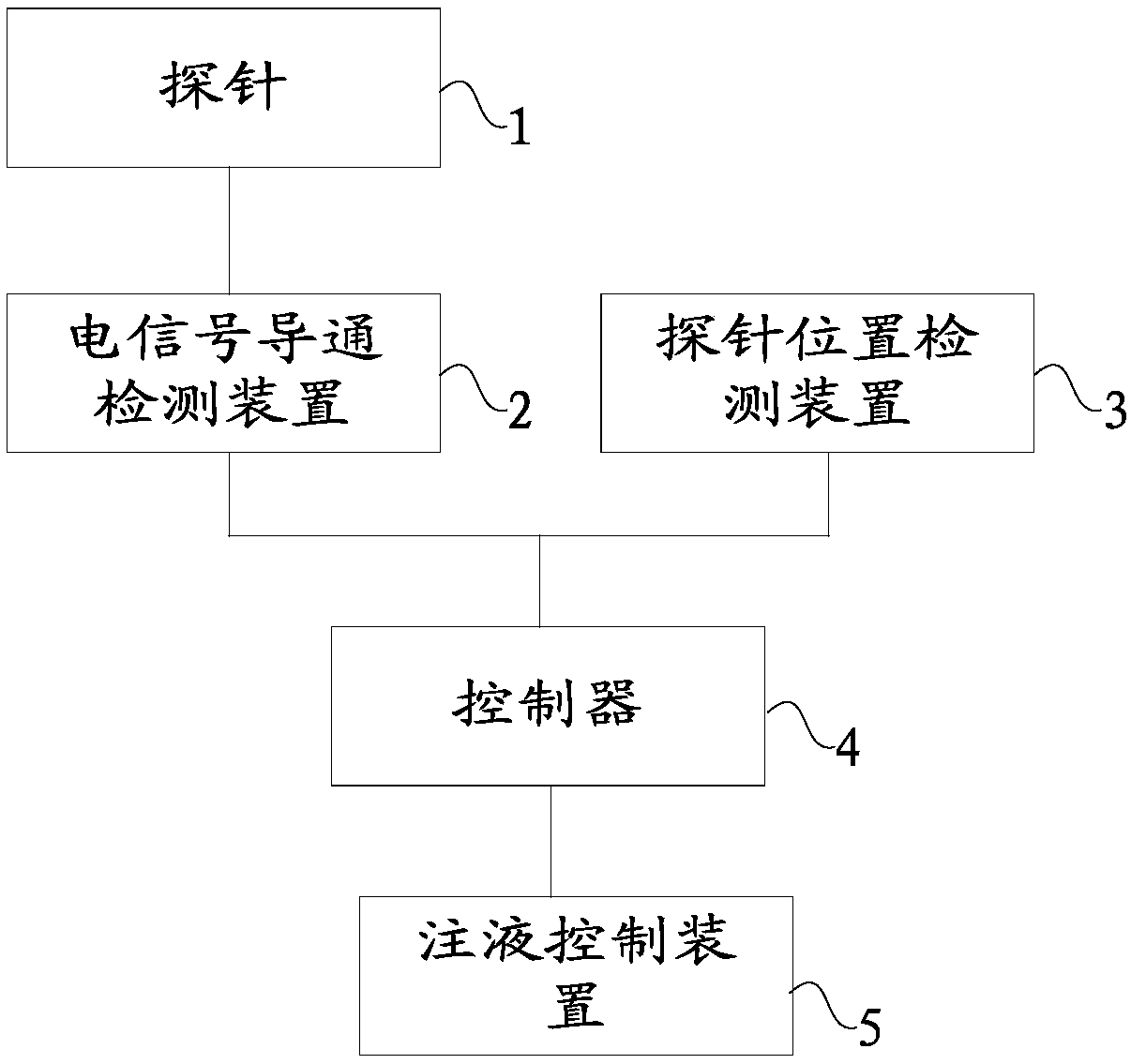

[0055] Please refer to Figure 1 to Figure 3 , this solution provides a liquid level detection device, which is applied to continuous casting equipment 7. The liquid level detection device uses the reciprocating motion of the probe 1 to repeatedly contact and separate from the liquid surface of the metal melt, so as to realize the conduction and disconnection of electrical signals , while recording the displacement of the probe 1 when it is turned on, and the controller 4 processes the displacement when the probe 1 is turned on as the height of the metal liquid level, thereby continuously and accurately measuring the height of the metal liquid level.

[0056] The liquid level detection device includes a probe 1, a probe movement mechanism 6, a probe position detection device 3, an electric signal conduction detection device 2 and a controller 4, the probe movement mechanism 6 is connected to the probe 1, and the electric signal conduction detection The device 2 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com