Terminal, terminal shell, and shell processing method

A processing method and terminal technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of poor film thickness uniformity, affecting product appearance, low yield rate, etc., and achieve low cost and high realization Bright metal effect, the effect of improving the processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

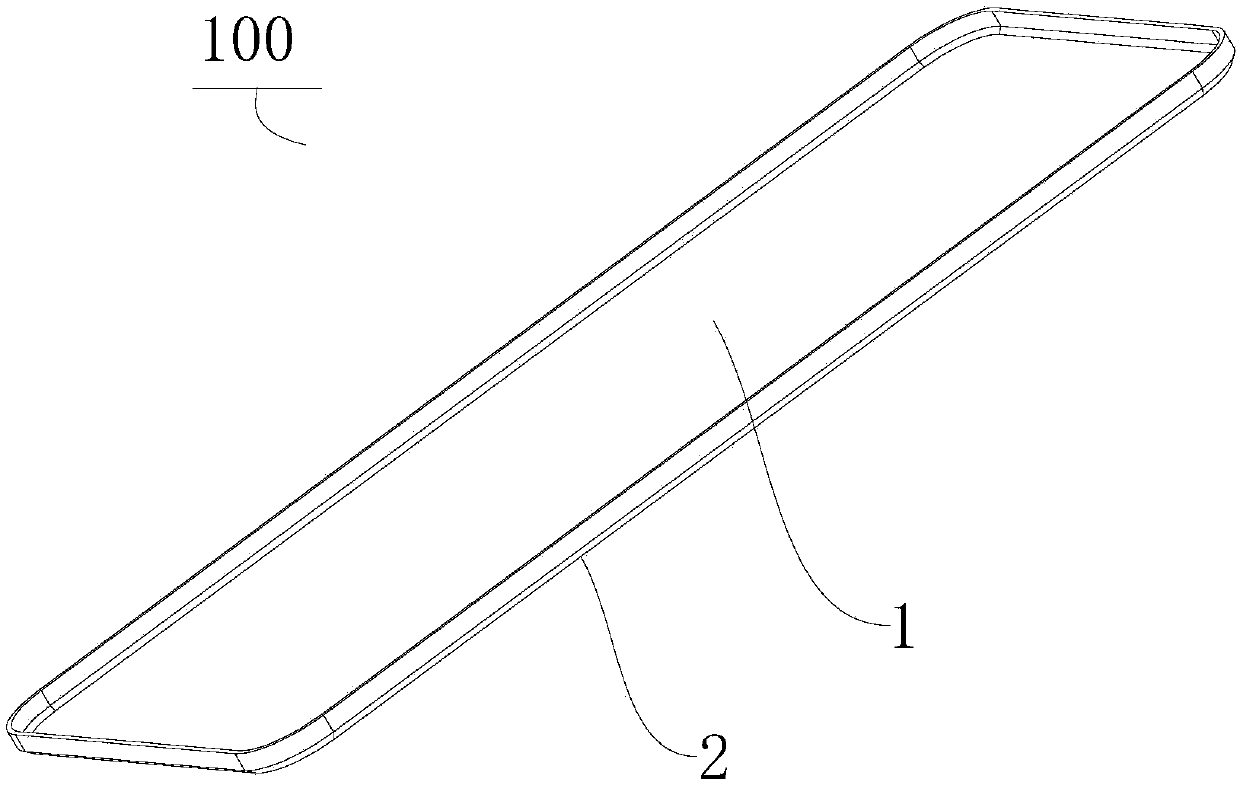

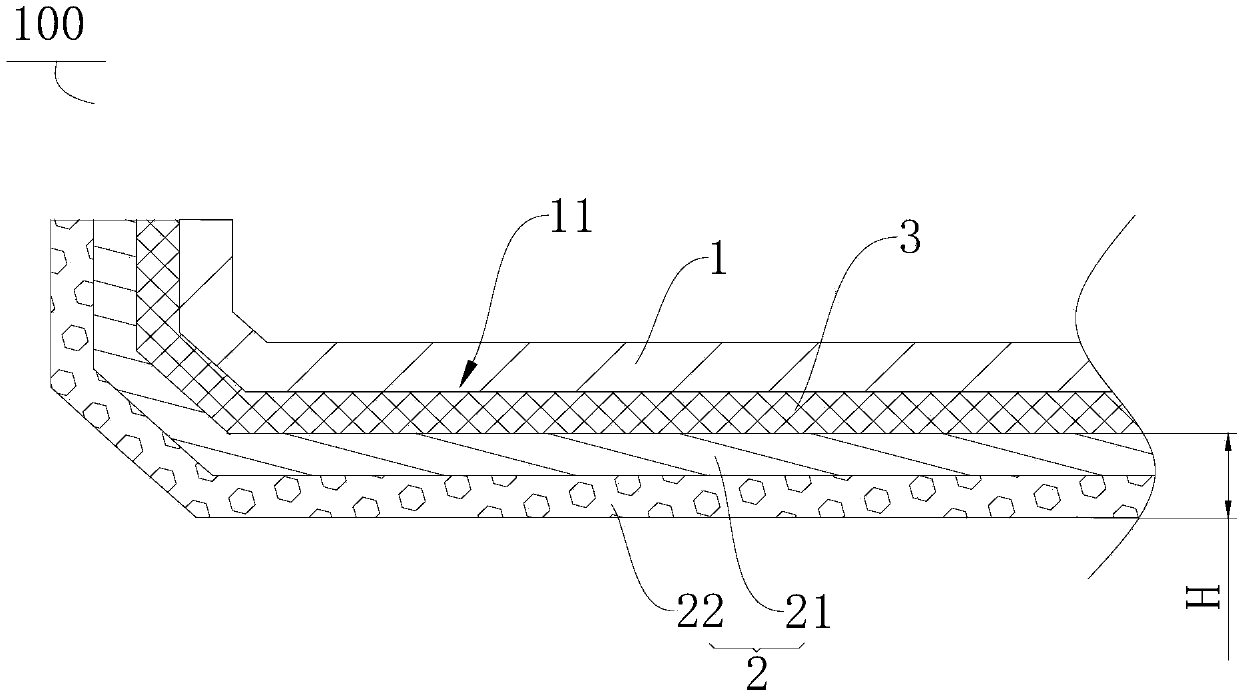

[0093] Such as Figure 1-Figure 2 As shown, the housing 100 of the terminal 1000 according to the embodiment of the present invention includes a metal body 1 and a PVD coating layer 2. Among them, the metal body 1 is an aluminum alloy piece.

[0094] The outer surface of the metal body 1 is a mirror-polished surface 11. A pretreatment layer 3 is provided on the mirror polished surface 11, and the pretreatment layer 3 is a Cr layer. The PVD coating layer 2 includes a functional layer 22 and a transition layer 21. The transition layer 21 is provided on the pretreatment layer 3, and the functional layer 22 is provided on the transition layer 21, wherein the functional layer 22 is a TiC layer with good wear resistance, and the transition layer 21 is a Ti layer.

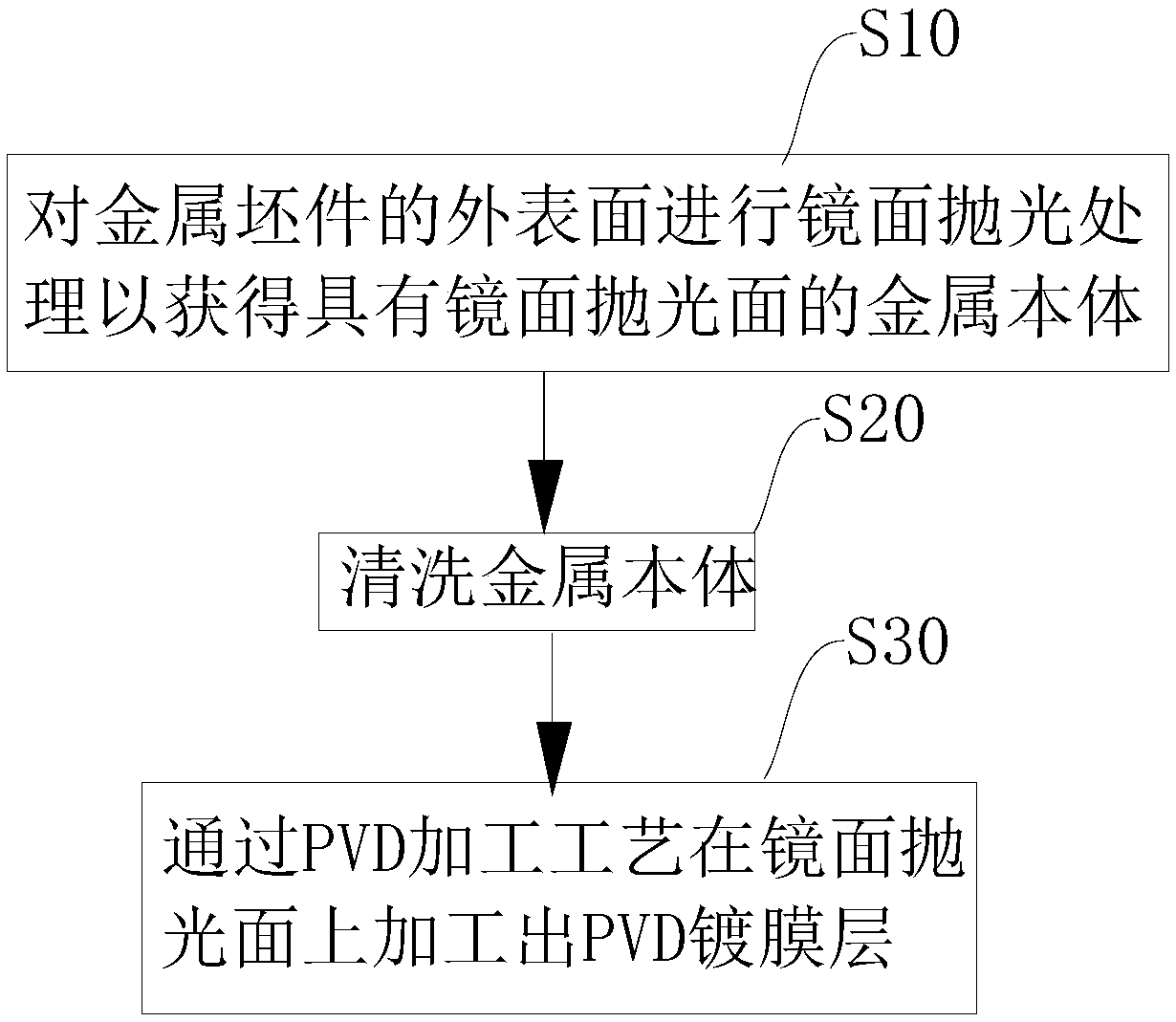

[0095] Such as Figure 7 As shown, the processing method of the housing 100 includes:

[0096] S10: Pressing the metal material to obtain a metal blank with the outer shape of the housing 100, and then mirror polishing the ou...

Embodiment 2

[0104] Such as Figure 1-Figure 2 As shown, the housing 100 of the terminal 1000 according to the embodiment of the present invention includes a metal body 1 and a PVD coating layer 2. Among them, the metal body 1 is an aluminum alloy piece.

[0105] The outer surface of the metal body 1 is a mirror-polished surface 11. A pre-treatment layer 3 is provided on the mirror-polished surface 11, and the pre-treatment layer 3 is a Cu layer. The PVD coating layer 2 includes a functional layer 22 and a transition layer 21. The transition layer 21 is provided on the pretreatment layer 3, and the functional layer 22 is provided on the transition layer 21, wherein the functional layer 22 is a WC layer with good wear resistance, and the transition layer 21 is a W layer.

[0106] Such as Image 6 As shown, the processing method of the housing 100 includes:

[0107] S10: Pressing the metal material to obtain a metal blank with the outer shape of the housing 100, and then mirror-polishing the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com