Anti-static antimicrobial ceramic tile prepared from coal ash and preparation method of anti-static antimicrobial ceramic tile

An anti-static, fly ash technology, applied in the field of ceramic materials, can solve electric tremor accidents; mines, petrochemicals cause fires, explosions, slow motion, and cause dust and bacteria in medicine, affecting equipment and equipment. Human activity safety and other issues to achieve the effect of promoting human health, protecting the living and working environment, and eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with embodiment.

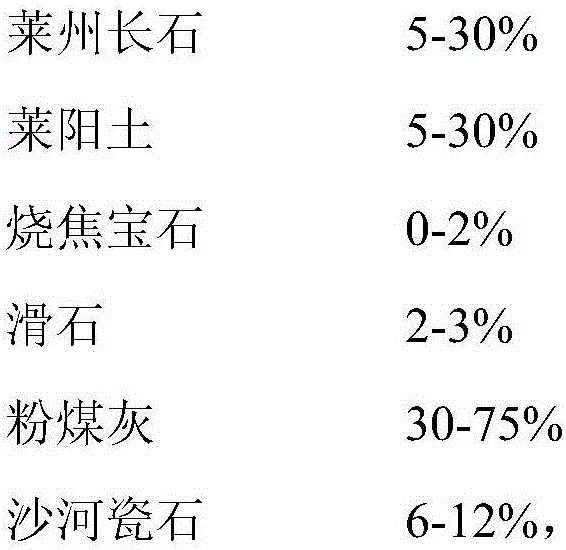

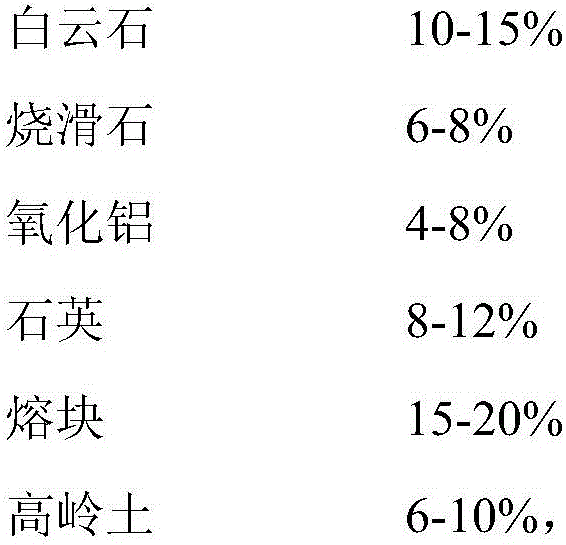

[0041] The chemical weight percentage composition of the raw materials used is shown in Table 1.

[0042] The chemical weight percentage composition of the raw materials used in Table 1

[0043]

[0044]

[0045] The composition of raw materials in Table 1 is less than 100%, and the balance is conventional mineral impurities.

[0046] Other raw materials are industrially purified industrial raw materials.

[0047] The weight percent of the frit is composed of: R 2 O4.1%, CaO4.1%, BaO1.5%, ZnO6.2%, PbO0.50%, Al 2 o 3 8.5%, B 2 o 3 2.7%, SiO 2 67.4%, ZrO 2 0.8%, where R 2 O is Na 2 O and K 2 O sum.

[0048] The composition of raw materials and process parameters of Examples 1-9 are shown in Table 2.

[0049] Table 2 embodiment 1-9 raw material weight percentage composition and process parameter

[0050]

[0051]

[0052] The preparation method is as follows:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com